PR 5350 Instruction sheet

5350

PROFIBUS®PA / FOUNDATION™

Fieldbus Transmitter

No. 5350Q102(0420)

From ser. no. 030640001

Approvals

Configuration Manual

FOUNDATION™Fieldbus

2

CONTENTS

Introduction ......................................................................... 4

This configuration manual......................................................... 4

The Fieldbus Software............................................................ 4

Parameter lists abbreviations...................................................... 4

1.0 The Resource Block, Fieldbus Foundation........................................... 5

1.1 Introduction .................................................................. 5

1.2 Description ................................................................... 5

1.3 RESTART parameter........................................................... 5

1.4 Non-volatile parameters....................................................... 5

1.5 Timeout for remote cascade modes ............................................ 5

1.6 Alert Notification ............................................................. 5

1.7 FEATURES / FEATURE_SEL parameters ......................................... 6

1.8 Fault state for the whole resource ............................................. 6

1.9 Write lock by software ........................................................ 6

1.10 Features being implemented ................................................ 6

1.11 BLOCK_ERR ................................................................. 6

1.12 Supported Modes............................................................ 6

1.13 Resource Block Parameter List, Fieldbus Foundation ............................... 7

2.0 The Transducer Block ............................................................. 9

2.1 The Transducer Block ......................................................... 9

2.2 The data of the Transducer Block Parameter List are grouped as follows: ......... 9

2.3 Default configuration ......................................................... 9

2.4 Your application set up......................................................... 9

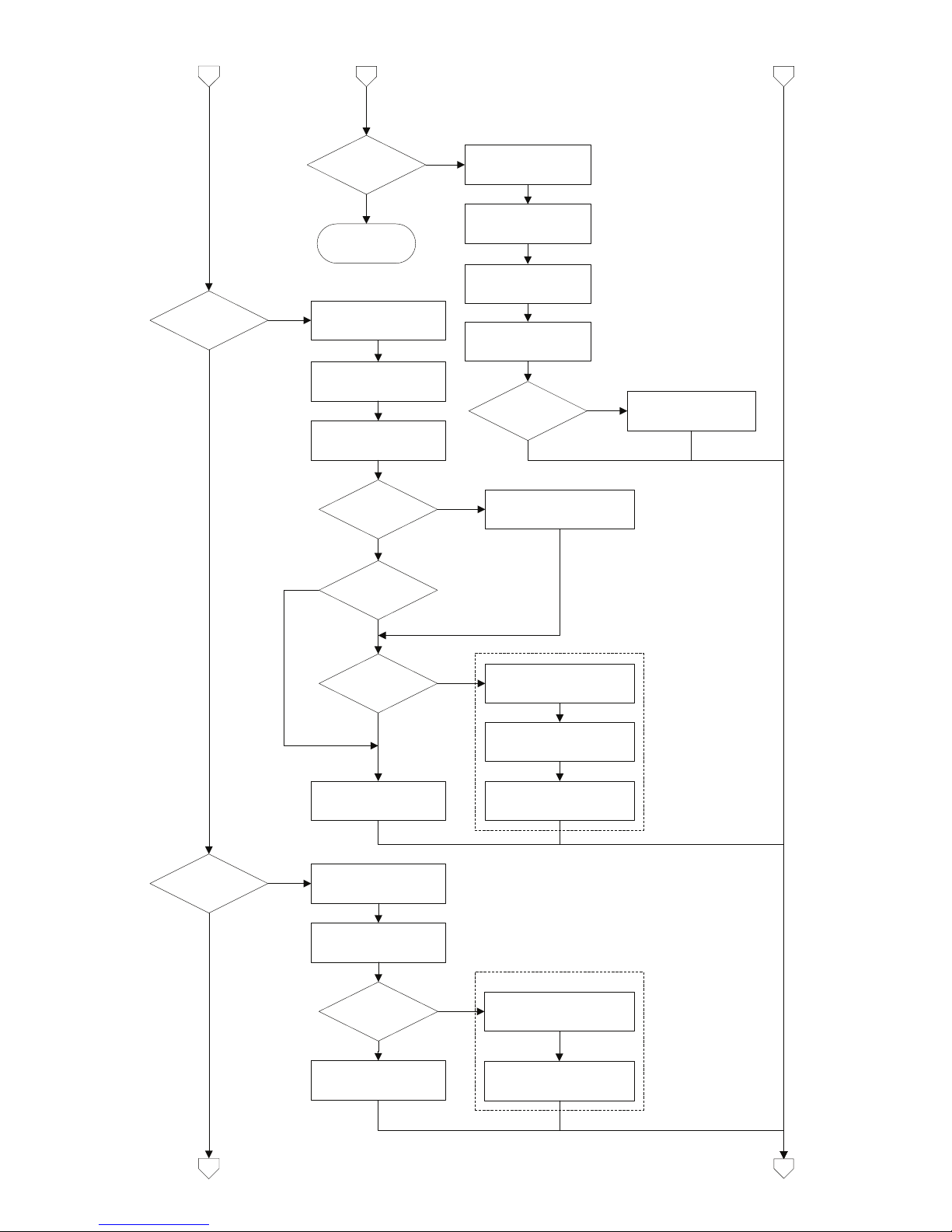

2.5 AI_Transducer Block Configuration Flowchart ....................................... 10

2.6 - Transducer Block Examples Setup ................................................ 13

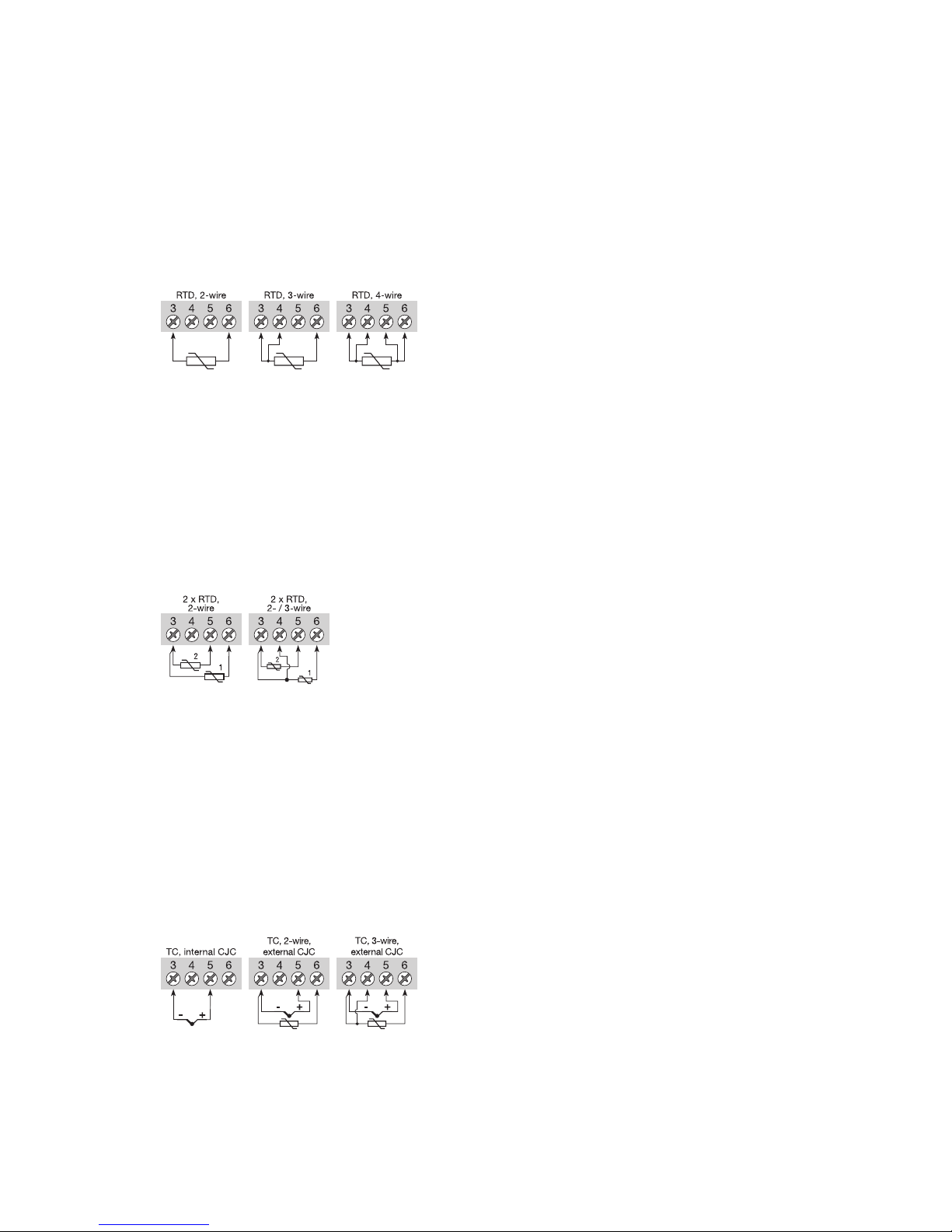

2.6.1 Measurement of RTD with one sensor:........................................ 13

2.6.2 Measurement of RTD with two sensors: ...................................... 13

2.6.3 Measurement of thermocouple with one sensor: .............................. 13

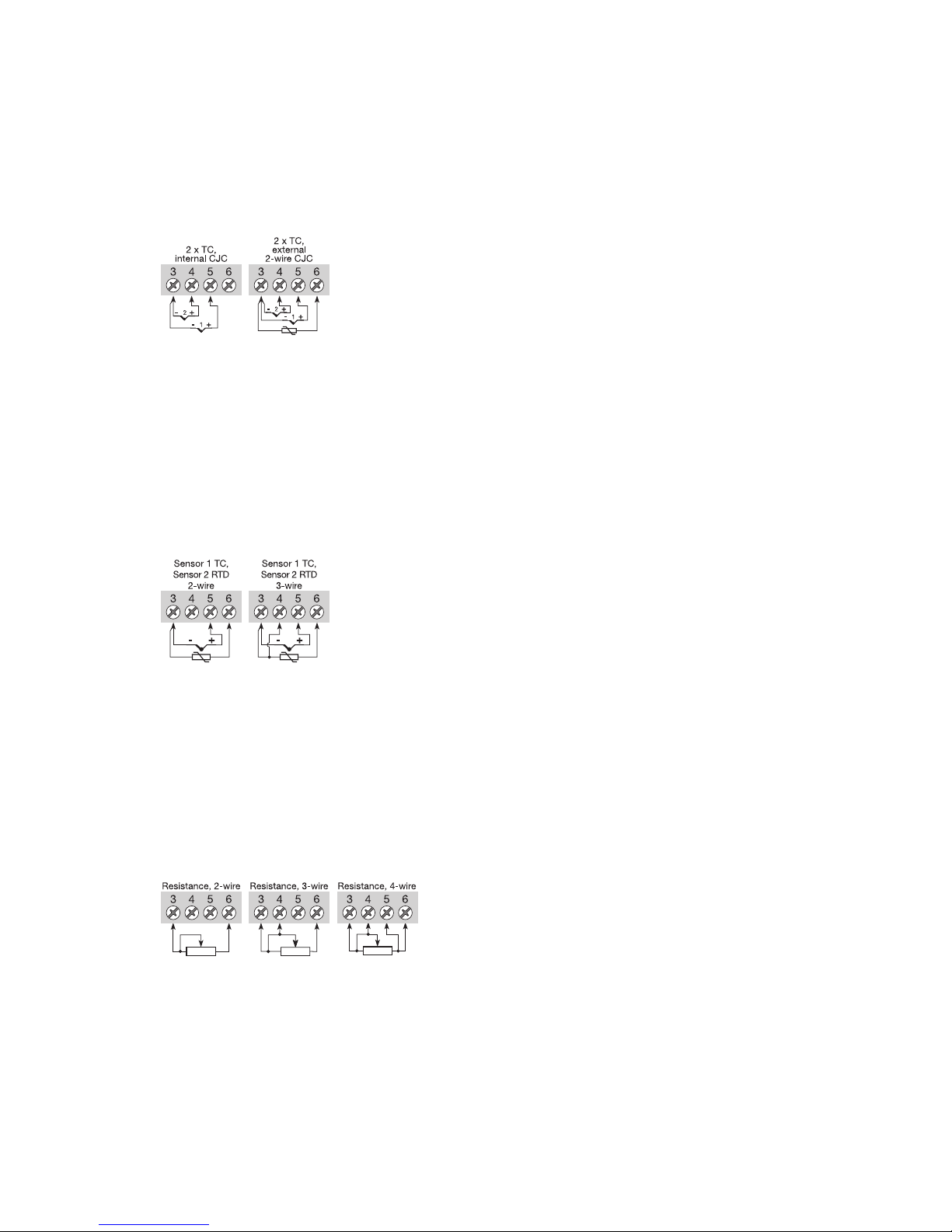

2.6.4 Measurement of thermocouple with two sensors: ............................. 14

2.6.5 Measurement of combined sensors (Sensor 1 = TC and Sensor 2 = RTD): ........ 14

2.6.6 Measurement of resistance (linear) with one sensor: .......................... 14

2.6.7 Measurement of resistance (linear) with two sensors: ......................... 15

2.6.8 Measurement of potentiometer (linear) with one sensor: ...................... 15

2.6.9 Measurement of potentiometer (linear) with two sensors: ..................... 15

2.6.10 Measurement of voltage (linear) with one sensor: ........................... 16

2.6.11 Measurement of voltage (linear) with two sensors: .......................... 16

2.6.12 Measurement of 2 potentiometers (with Linear interpolation linearisation): ... 16

2.6.13 Measurement of TC (with Custom Polynomial Linearisation) on sensor 1 ....... 17

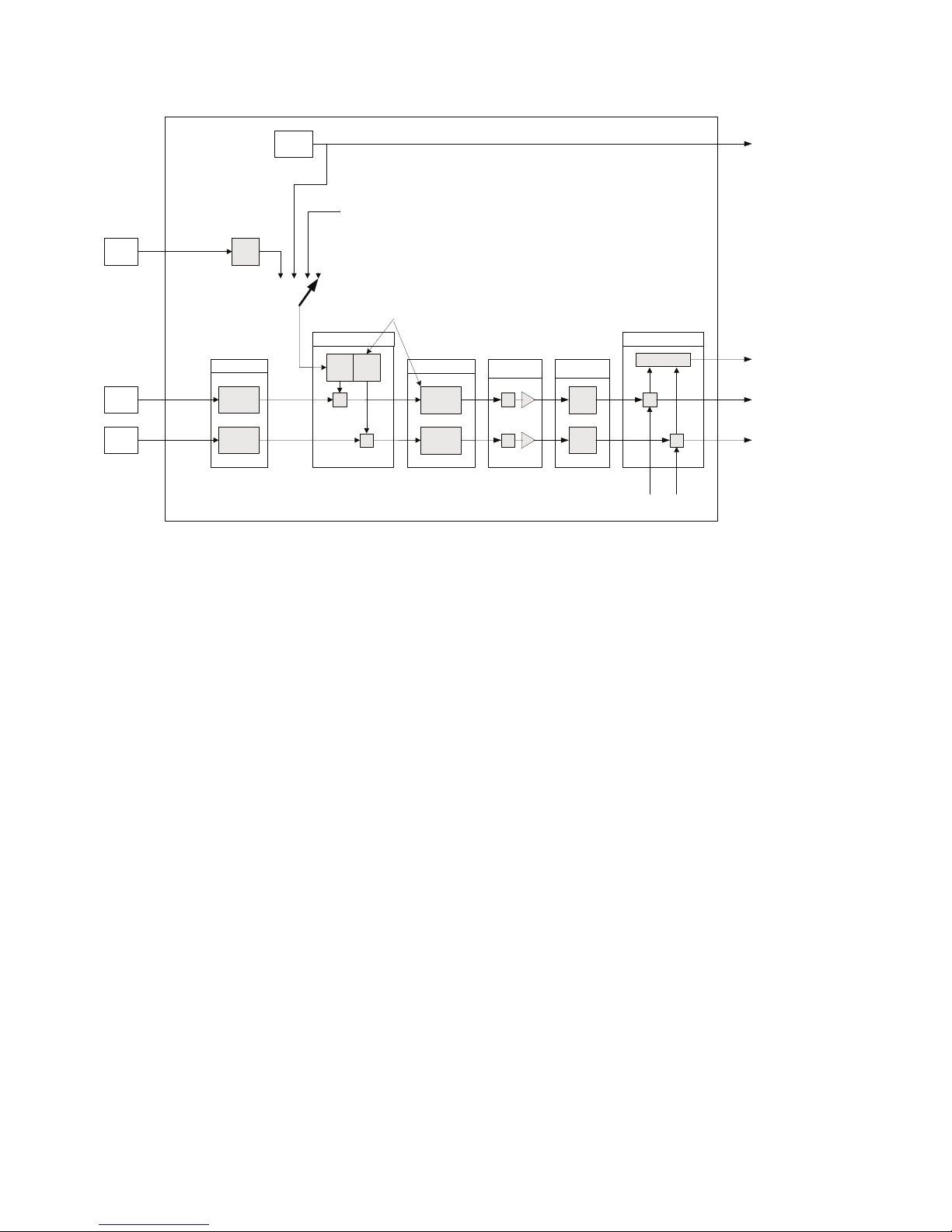

2.7 AI_Transducer and PR_CUST_LIN Block, Schematic .................................. 18

2.8 AI_TRANSDUCER Block Parameter List ............................................. 19

2.8.1 Sensor characterising parameters ............................................ 19

2.8.2 RTD / Resistor specific parameters ........................................... 20

2.8.3 Thermocouple specific parameters ........................................... 20

2.8.4 Output conditioning parameters.............................................. 21

2.8.5 Output parameters.......................................................... 21

2.8.6 Diagnostic parameters ...................................................... 22

2.8.7 Sensor error detection parameters ........................................... 22

2.8.8 Sensor calibration, Description ............................................... 23

2.8.9 Sensor Calibration Parameters ............................................... 23

2.9 PR_CUST_LIN Block Parameter List ................................................ 25

2.9.1 Linear interpolation linearisation, Description ................................. 25

2.9.2 Linear Interpolation Linearisation, Parameter List. ............................ 25

3

2.9.3 Custom polynomial linearisation, Description .................................. 26

2.9.4 Custom Polynomial Linearisation, Parameter List .............................. 27

2.10 PR_CUST_PRIV Block Reserved Parameter List .................................... 27

2.10.1 Description, PR_CUST_PRIV Block........................................... 27

3.0 Analogue Input Blocks ............................................................ 28

3.1 Analogue Input Blocks, Fieldbus Foundation ........................................ 28

3.2 Overview .................................................................... 28

3.3 Analogue Input Block Schematic ............................................... 28

3.4 Description .................................................................. 28

3.5 Supported Modes ............................................................. 29

3.6 To enable the Simulation mode ................................................ 29

3.7 Alarm Types .................................................................. 29

3.8 Mode Handling ............................................................... 29

3.9 Status Handling .............................................................. 29

3.10 Initialisation ................................................................ 29

3.11 Analogue Input Blocks Parameter List, Fieldbus Foundation ........................ 29

4.0 PID Control Block, Fieldbus Foundation ............................................. 31

4.1 Introduction: ................................................................. 31

4.2 Overview .................................................................... 31

4.3 Schematic: ................................................................... 31

4.4 Description ................................................................... 31

4.5 Supported Modes ............................................................. 32

4.6 Alarm Types .................................................................. 32

4.7 Mode Handling ............................................................... 32

4.8 Status Handling .............................................................. 32

4.9 Initialization.................................................................. 32

4.10 PID Control Block Parameter List.................................................. 33

5.0 Link Active Scheduler (LAS) ....................................................... 36

5.1 Introduction: ................................................................. 36

5.2 Overview .................................................................... 36

5.3 Description ................................................................... 36

4

Introduction

This configuration manual

contains the necessary information for configuration of the temperature transmitter PR5350

via a host system with application software for either FoundationTM Fieldbus or Profibus® PA.

The autoswitch function of the modules ensures automatic switch to the connected protocol.

The Fieldbus Software

has been developped by PR electronics A/S according to the specifications of the Fieldbus

Foundation and the PROFIBUS Nutzerorganisation.

The files for FoundationTM Fieldbus are:

xxyy.o - Device Description binary file

xxyy.sym - Device Description symbol file

xxyyzz.c - Capability file

xx, yy and zz refer to the version numbers of the files.

PR electronics fieldbus transmitters are delivered with a CD that contains the files needed to

configure the transmitters from a fieldbus host. These files can also be downloaded from our

homepage www.prelectronics.com.

Please follow the instructions for the application software in question when installing the

files.

Parameter lists abbreviations

In the Store column:

SRC = Static Revision Counter; N = No; D = Dynamic;

Cst = Constant. The parameter doesn’t change in a device

In the RO / R/W column:

RO = Read Only; R /W = Read Write; * = Mixed of RO and R/W; ** = Don’t care

5

1.0 The Resource Block, Fieldbus Foundation

1.1 Introduction

The resource block is used to define a hardware specific characteristics of the function block

applications. It provides PR’s manufacturer’s name, device name, DD and block status and hard-

ware details. It also indicates how much resource (memory and CPU) is available and controls

the overall device.

1.2 Description

This block contains data that is specific to the hardware that is associated with the resource.

All data is modelled within a controlled space, so there are no outside inputs into this block re-

quired.

This parameter “set” is intended to be the minimum required for the Function Block Application

associated with the resource in which it resides. Some parameters that could be in the set, like

calibration data and ambient temperature, are more part of their respective transducer blocks.

The “mode” is used to control major states of the resource. O/S mode stops all function block

execution. The actual mode of the function blocks will be changed to O/S (out of service), but

the target mode will not be changed. Auto mode allows normal operation of the resource. IMan

shows that the resource is initializing or receiving a software download. Parameters MANU-

FAC_ID, DEV_TYPE, DEV_REV, DD_REV, and DD_RESOURCE are required to identify and locate

the DD so that Device Description Hosting Services can select the correct DD for use with

the resource. The parameter HARD_TYPES is a read only bit string that indicates the types of

hardware that are available to this resource. If an I/O block is configured that requires a type

of hardware that is not available, the result will be a block alarm for a configuration error. The

RS_STATE parameter contains the operational state of the Function Block Application for the

resource containing this resource block.

1.3 RESTART parameter

The RESTART parameter allows degrees of initialization of the resource. They are:

1 - Run: it is the passive state of the parameter

2 - Restart resource: it is intended to clear up problems for example the memory management

resource.

3 - Restart with defaults: it is intended to wipe configuration memory, it works like a factory

initialization.

4 - Restart processor: it provides a way to hit the reset button on the processor associated

with the resource This parameter does not appear in a view because it returns to 1 shortly af-

ter being written.

1.4 Non-volatile parameters

All non-volatile parameters are saved in EEPROM and therefore used if the device is restarted.

1.5 Timeout for remote cascade modes

SHED_RCAS and SHED_ROUT set the time limit for loss of communication from a remote de-

vice. These constants are used by all function blocks that support a remote cascade mode. The

eect of a timeout is described in Mode Calculation. Shedding from RCAS/ROUT shall not hap-

pen when SHED_RCAS or SHED_ROUT is set to zero.

1.6 Alert Notification

The MAX_NOTIFY parameter value is the maximum number of alert reports that this resource

can have sent without getting a confirmation, corresponding to the amount of buer space

available for alert messages. A user can set the number lower than that, to control alert flood-

ing, by adjusting the LIM_NOTIFY parameter value. If LIM_NOTIFY is set to zero, then no alerts

are reported. The CONFIRM_TIME parameter is the time for the resource to wait for confirma-

tion of receipt of a report before trying again. If the CONFIRM_TIME = 0 the device shall not

retry.

6

1.7 FEATURES / FEATURE_SEL parameters

The bit strings FEATURES and FEATURE_SEL determine optional behaviour of the resource.

The first defines the available features, and is read only. The second is used to turn on an

available feature by configuration. If a bit is set in FEATURE_SEL that is not set in FEATURES,

the result will be a block alarm for a configuration error. The device supports the following fea-

tures: Reports supported, Fault State supported, Soft Write lock supported.

1.8 Fault state for the whole resource

If the user sets the SET_FSTATE parameter, the FAULT_STATE parameter will indicate active

and it will cause all output function blocks in the resource to go immediately to the condition

chosen by the fault state Type I/O option. It may be cleared by setting the CLR_FSTATE param-

eter. The set and clear parameters do not appear in a view because they are momentary.

1.9 Write lock by software

The WRITE_LOCK parameter, if set, will prevent any external change to the static or non

volatile data base in the Function Block Application of the resource. Block connections and cal-

culation results will proceed normally, but the configuration will be locked. It is set and cleared

by writing to the WRITE_LOCK parameter. Clearing WRITE_LOCK will generate the discrete alert

WRITE_ALM, at the WRITE_PRI priority. Setting WRITE_LOCK will clear the alert, if it exists. Be-

fore setting WRITE_LOCK parameter to Locked, it is necessary to select the “Soft Write lock

supported” option in FEATURE_SEL.

1.10 Features being implemented

The parameter CYCLE_TYPE is a bit string that defines the types of cycles that this resource

can do. CYCLE_SEL allows the configurator to choose one of them. If CYCLE_SEL contains more

than one bit, or the bit set is not set in CYCLE_TYPE, the result will be a block alarm for a con-

figuration error. MIN_CYCLE_T is the manufacturer specified minimum time to execute a cycle.

It puts a lower limit on the scheduling of the resource.

MEMORY_SIZE declares the size of the resource for configuration of function blocks, in kilo-

bytes. The parameter FREE_SPACE shows the percentage of configuration memory that is still

available. FREE_TIME shows the approximate percentage of time that the resource has left for

processing new function blocks, should they be configured.

1.11 BLOCK_ERR

The BLOCK_ERR of the resource block will reflect the following causes:

Device Fault State Set – When FAULT_STATE is active.

Simulate Active – When the Simulate jumper is ON.

Out of Service – When the block is in O/S mode.

1.12 Supported Modes

O/S, IMAN and AUTO

7

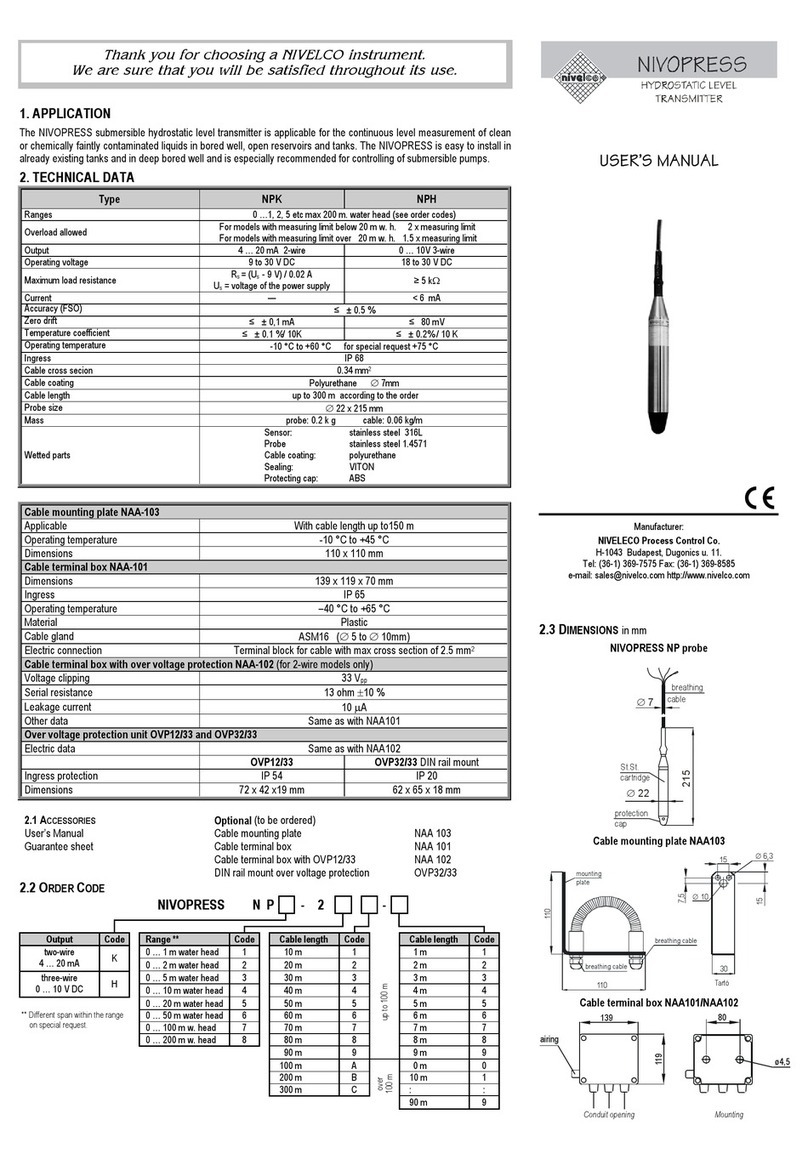

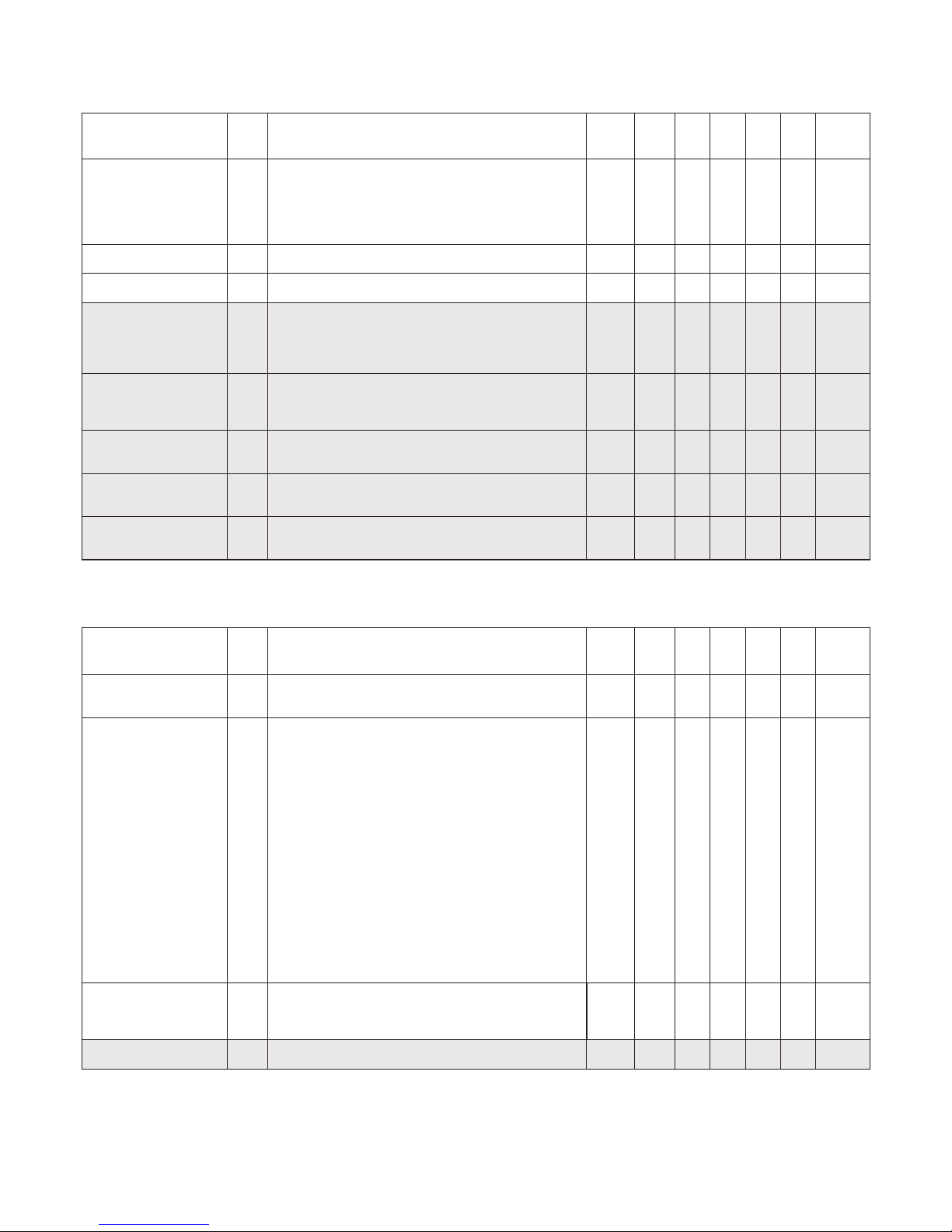

1.13 Resource Block Parameter List, Fieldbus Foundation

Parameter Rel.

Index Description Type Store Size

byte

RO /

R/W Min. Max. Default

ST_REV 1Is incremented each time that there is a change in a static

parameter in the physical block.

Un-

signed

16

SRC 2RO 0

TAG_DESC 2Tag name of the block. This parameter must be unique in the

configuration.

OCTET_

STRING SRC 32 R/W »«

STRATEGY 3This can be used to group a Function Block. It is a user supplied

parameter for identification purpose.

Un-

signed

16

SRC 2 R/W 0

ALERT_KEY 4Alert keys

Un-

signed

8

SRC 1 R/W 0

MODE_BLK 5Block running mode DS-69 Mix 4 * 1,1,

17,16

BLOCK_ERR 6Block errors BIT_

STRING D 2 RO 0

RS_STATE 7State of the function block application state machine

Un-

signed

8

D 1 RO 0

TEST_RW 8Read/write test parameter used only for conformance testing DS-85 D 112 R/W 0..0

DD_RESOURCE 9String identifying the tag of the resource which contains the

Device Description for this resource.

VISIBLE_

STRING SRC 32 RO » »

MANUFAC_ID 10

Enumeration; controlled by FF

Manufacturer identification number - used by an interface

device to locate the DD file for the resource.

Un-

signed

32

SRC 4RO

PR

Electronics

A/S

DEV_TYPE 11 Manufacturer’s model number associated with the resource -

used by interface devices to locate the DD file for the resource.

Un-

signed

16

SRC 2RO 128

DEV_REV 12

Manufacturer revision number associated with the resource

- used by an interface device to locate the DD file for the

resource.

Un-

signed

8

SRC 1RO 2

DD_REV 13 Revision of the DD associated with the resource - used by an

interface device to locate the DD file for the resource.

Un-

signed

8

SRC 1RO 1

GRANT_DENY 14

Access Permissions. Options for controlling access of host com-

puter and local control panels to operating, tuning and alarm

parameters of the block.

DS-70 SRC 2 R/W 0

HARD_TYPES 15 The types of hardware available as channel numbers. BIT_

STRING SRC 2RO 0

RESTART 16

1: Run,

2: Restart resource,

3: Restart with defaults,

4: Restart processor

Allows a manual restart to be initiated. Several degrees of

restart are possible.

Un-

signed

8

D 1 R/W 1

FEATURES 17 Used to show supported resource block options. BIT_

STRING SRC 2RO 0

FEATURE_SEL 18 Used to select resource block options. BIT_

STRING SRC 2RW 0

CYCLE_TYPE 19 Identifies the block execution methods available for this

resource

BIT_

STRING SRC 2RO 0xC000

CYCLE_SEL 20 Used to select the block execution method for this resource. BIT_

STRING SRC 2 ** 0xC000

MIN_CYLCE_T 21 Time duration of the shortest cycle interval of which the

resource is capable.

Un-

signed

32

SRC 4RO 0

MEMORY_SIZE 22 Available configuration memory in the empty resource. To be

checked before attempting a download.

Un-

signed

16

SRC 2RO 0

NV_CYCLE_T 23 Interval between writing copies of NV parameters to non-volatile

memory. Zero means never.

Un-

signed

32

SRC 4RO 0

FREE_SPACE 24 Percent of memory available for further configuration. Zero in a

preconfigured resource.

Floating

Point D 4 RO 0.0

FREE_TIME 25 Percent of the block processing time that is free to process addi-

tional blocks.

Floating

Point D 4 RO 0.0

SHED_RCAS 26 Time duration at which to give up on computer writes to func-

tion block RCas locations.

Un-

signed

32

SRC 4 R/W 640000

SHED_ROUT 27 ms time duration at which to give up on computer writes to

function block ROut locations.

Un-

signed

32

SRC 4 R/W 640000

8

Parameter Rel.

Index Description Type Store Size

byte

RO /

R/W Min. Max. Default

FAULT_STATE 28

Active E D Condition set by loss of communication to an output

block, failure promoted to an output block or a physical contact.

When Fault State condition is set, Then output function blocks

will perform their FSAFE actions.

Un-

signed

8

N 1 RO 1

SET_FSTATE 29 Allows the fault state condition to be manually initiated by

selecting Set.

Un-

signed

8

D 1 R/W 1

CLR_FSTATE 30 Writing a Clear to this parameter will clear the device fault state

if the field condition, if any, has cleared.

Un-

signed

8

D 1 R/W 1

MAX_NOTIFY 31 Maximum number of unconfirmed notify messages possible.

Un-

signed

8

SRC 1RO 8

LIM_NOTIFY 32 Maximum number of unconfirmed alert notify messages allowed.

Un-

signed

8

SRC 1 R/W 8

CONFIRM_TIME 33 Ms The minimum time between retries of alert reports.

Un-

signed

32

SRC 4 R/W 640000

WRITE_LOCK 34 If set, no writes from anywhere are allowed, except to clear

WRITE_LOCK. Block inputs will continue to be updated.

Un-

signed

8

SRC 1 R/W 1

UPDATE_EVT 35 This alert is generated by any change to the static data DS-73 D 14 RO 0,0,0,

0,0,9,0

BLOCK_ALM 36

The block alarm is used for all configuration, hardware, connec-

tion failure or system problems in the block. The cause of the

alert is entered in the sub code field. The first alert to become

active will set the Active status in the Status attribute. As soon

as the Unreported status is cleared by the alert reporting task,

another block alert may be reported without clearing the Active

status, if the sub code

has changed.

DS-72 D 13 R/W

0,0,0,

0,0,0,

8,0,0

ALARM_SUM 37

The current alert status, unacknowledged states, unreported

states, and disabled states of the alarms associated with the

function

block.

DS-74 Mix 8 R/W 0,0,0,0

ACK_OPTION 38

0: Auto ACK Disable

1: Auto ACK Enable

Selection of whether alarms associated with the block will be

automatically acknowledged.

BIT_

STRING SRC 2 R/W 0

WRITE_PRI 39 Priority of the alarm generated by clearing the write lock.

Un-

signed

8

SRC 1 R/W 0

WRITE_ALM 40 This alert is generated if the write lock parameter is cleared. DS-72 D 13 R/W

0,0,0,

0,0,0,

10,0,0

ITK_VER_NR 41

ITK Version Number

This parameter informs which ITK version is the device (for certi-

fied devices only).

Un-

signed

16

SRC 2RO 4

9

2.0 The Transducer Block

2.1 The Transducer Block

contains all of the manufacturer-specific parameters that define how the PR5350 Transmitter

functions. Selections such as setting of input type, engineering units, defining the dual func-

tionality when using the dual input, and so forth, are performed in the Transducer Block.

The transducer block in PR5350 allows the user to select a large number of sophisticated

functions. Therefore, the configuration of the transmitter must be carried out with the great-

est possible care.

2.2 The data of the Transducer Block Parameter List are grouped as follows:

2.8 AI_TRANSDUCER Block

2.8.1 Sensor characterising parameters

2.8.2 RTD / resistor specific parameters

2.8.3 Thermocouple specific parameters

2.8.4 Output conditioning parameters

2.8.5 Output parameters

2.8.6 Diagnostic parameters

2.8.7 Sensor error detection parameters

2.8.9 Sensor calibration parameters

2.9 PR_CUST_LIN Block

2.9.2 Linear Interpolation Linearisation

2.9.4 Custom Polynomial linearisation

2.10 PR_CUST_PRIV Block

2.10.1 PR_CUST_PRIV Block

All product-specific parameters are set o in grey background in the TB Parameter List. In order

to configure these parameters, the files mentioned in the introduction must be available to the

application software.

2.3 Default configuration

PR electronics delivers the transmitters with at default configuration which will suit the cus-

tomer’s demand in many cases. The configuration task has thus been reduced considerably.

The individual default configurations are shown in the TB Parameter List, but in short the de-

fault configuration is as follows:

Pt100 acc. to the standard EN 60 751 (2.8.1 LIN_TYPE, value 102)

°C (2.8.1 PRIMARY_VALUE_UNIT, value 1001)

3-wire connection (2.8.2 SENSOR_CONNECTION, value 1)

Only sensor 1 (2.8.4 SENSOR_MEAS_TYPE, value 220)

No sensor error detection (2.8.7 SENSOR_WIRE_CHECK_1, value 3)

2.4 Your application set up.

In the Transducer block all parameters marked R / W can be adapted to suit any measurement

in temperature, ohm or mV. The way of presenting the file data mentioned in the introduction

varies greatly from one piece of application software to the other. Some programs show drop

down menus in which the parameters must be selected via text lines, while other programs re-

quire the user to type in the numerical value of the parameter selection.

10

2.5 AI_Transducer Block Configuration Flowchart

Configure 5350

Transducer block

Temperature

measurement?

Set

PRIMARY_VALUE_UNIT

to F,R,C or K

RTD?

Thermo-couple?

Set LIN_TYPE to RTD

type (Pt100 etc.)

4-wire?

Set

SENSOR_CONNECTION

to 2-,3- or 4-wire.

Enter wire resistance in

Ohms for both wires to

COMP_WIRE1

2-wire?

Enter wire resistance in

Ohms for both wires to

COMP_WIRE2

YES

Enter setup for sensor 2:

YES

Set LIN_TYPE to TC

type (TC K etc.)

Set RJ_TYPE (internal,

external etc.)

Set LIN_TYPE_2 to RTD

type (Pt100 etc.)

Set

SENSOR_MEAS_TYPE

to single sensor type

Dual sensor?

Enter setup for sensor 2:

Set LIN_TYPE_2 to TC type

(TC K etc.)

Enter RJ temperature to

EXTERNAL_RJ_VALUE

RJ_TYPE

external?

YES

YES

RJ_TYPE

ext. 2.wire?

Enter wire resistance in

Ohms for both wires to

COMP_WIRE_RJ

YES

YES

YES

2c

Set

SENSOR_MEAS_TYPE

to single sensor type

2b

2a

Set SENSOR_MEAS_TYPE

to dual sensor type

Set SENSOR_MEAS_TYPE

to dual sensor type

YES

Dual sensor? YES

11

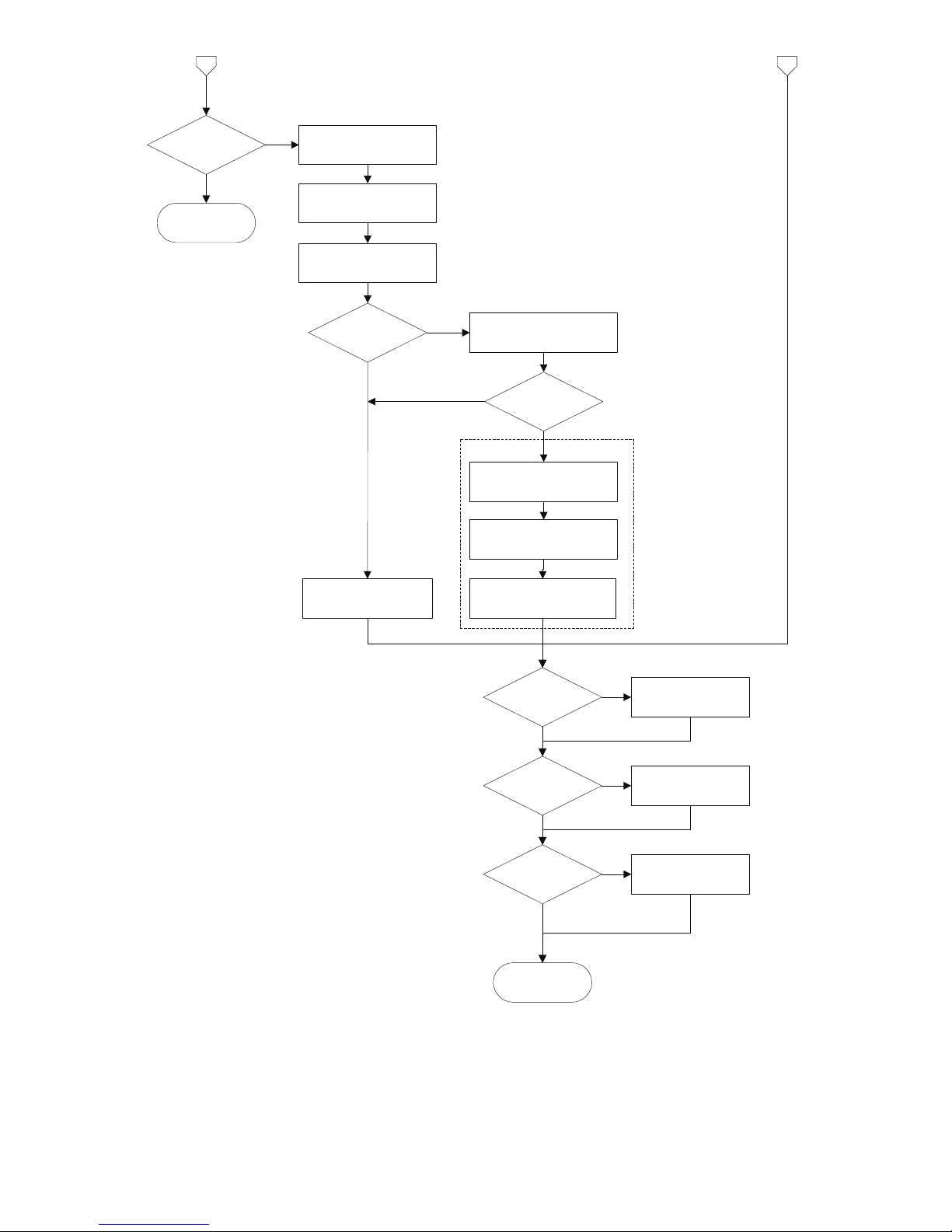

2c

RTD+Thermo-

couple?

2b

Set LIN_TYPE to TC

type (TC K etc.)

Set RJ_TYPE

(internal, external etc.)

Set

SENSOR_MEAS_TYPE

to dual sensor type

Set LIN_TYPE_2 to

RTD type (Pt100 etc.)

Enter RJ temperature to

EXTERNAL_RJ_VALUE

RJ_TYPE

external?

YES

YES

2a

Error! (try again)

Resistance?

Set

PRIMARY_VALUE_UNIT

to Ohm or kOhm

Set

SENSOR_CONNECTION

to 2-,3- or 4-wire.

Dual sensor?

Enter wire resistance in

Ohms for both wires to

COMP_WIRE1

2-wire?

YES

Enter setup for sensor 2:

YES

Set LIN_TYPE_2 to

”no linearisation” or

”linearisation table”

Set

SENSOR_MEAS_TYPE

to single sensor type

Set LIN_TYPE to

”no linearisation” or

”linearisation table”

Set SENSOR_MEAS_TYPE

to dual sensor type

Enter wire resistance in

Ohms for both wires to

COMP_WIRE2

Millivolts?

Set

PRIMARY_VALUE_UNIT

to V,mV or µV

Set LIN_TYPE to

”no linearisation” or

”linearisation table”

Dual sensor?

Set LIN_TYPE_2 to

”no linearisation” or

”linearisation table”

Set

SENSOR_MEAS_TYPE

to single sensor type

Set SENSOR_MEAS_TYPE

to dual sensor type

3b

3a

Enter setup for sensor 2:

YES

YES

YES

4-wire?

YES

12

3b3a

Potentiometer?

Set

PRIMARY_VALUE_UNIT

to ”%”

Set

SENSOR_CONNECTION

to 3- or 4-wire.

Enter wire resistance in

Ohms for 2 wires to

COMP_WIRE1

3-wire?

YES

Enter setup

for sensor 2:

YES

Set LIN_TYPE_2 to

”no linearisation” or

”linearisation table”

Set

SENSOR_MEAS_TYPE

to single sensor type

Set LIN_TYPE to

”no linearisation” or

”linearisation table”

Set SENSOR_MEAS_TYPE

to dual sensor type

Enter wire resistance in

Ohms for 2 wires to

COMP_WIRE2

Error! (try again)

Finished.

Transducer block

is configured!

Enter Custom RTD

polynomial values

Linearisation

table?

Custom RTD?

Enter linearisation

table values

YES

YES

Enter Custom TC

polynomial values

Custom TC? YES

Dual sensor?

YES

13

2.6 - Transducer Block Examples Setup

2.6.1 Measurement of RTD with one sensor:

PRIMARY_VALUE_UNIT .......= K, °C, °F or °R

LIN_TYPE....................= Any RTD

LIN_TYPE_2 .................= N/A (ignored in setup check)

SENSOR_MEAS_TYPE.........= PV = SV_1, SV_2 not available

SENSOR_CONNECTION .......= 2-, 3- or 4-wire

SENSOR_CONNECTION_2 .....= N/A (ignored in setup check)

RJ_TYPE .....................= N/A (ignored in setup check)

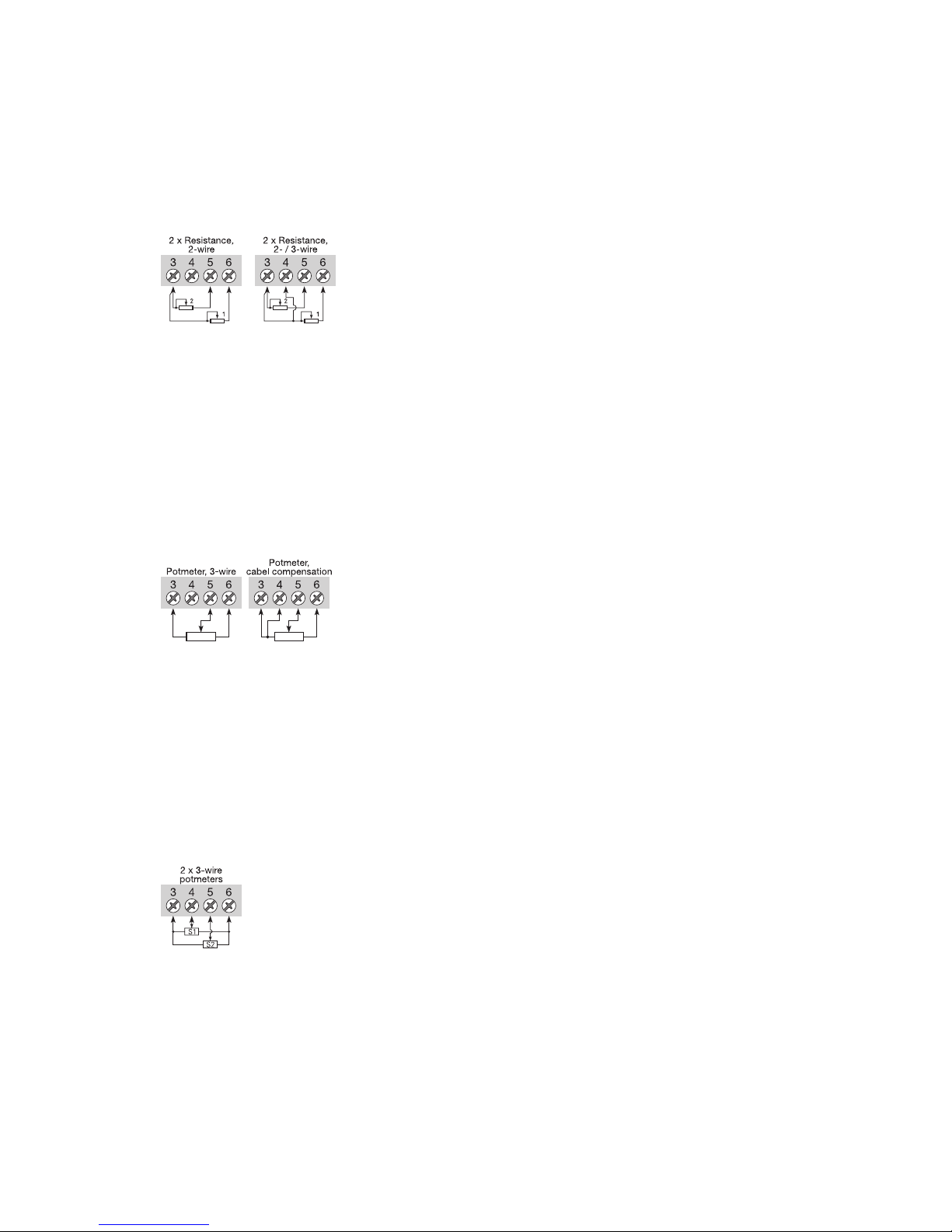

Connections:

2.6.2 Measurement of RTD with two sensors:

PRIMARY_VALUE_UNIT .......= K, °C, °F or °R

LIN_TYPE....................= Any RTD

LIN_TYPE_2 .................= Any RTD

SENSOR_MEAS_TYPE.........= Anything, but not "PV = SV_1, SV_2 not available"

SENSOR_CONNECTION .......= 2- or 3-wire

SENSOR_CONNECTION_2 .....= Default set to 2-wire

RJ_TYPE .....................= N/A (ignored in setup check)

Connections:

2.6.3 Measurement of thermocouple with one sensor:

PRIMARY_VALUE_UNIT .......= K, °C, °F or °R

LIN_TYPE....................= Any TC

LIN_TYPE_2 .................= N/A (ignored in setup check)

SENSOR_MEAS_TYPE.........= PV = SV_1, SV_2 not available

SENSOR_CONNECTION .......= N/A (ignored in setup check)

SENSOR_CONNECTION_2 .....= N/A (ignored in setup check)

RJ_TYPE .....................= No Reference Junction, Internal, External (constant value),

Sensor 2-wire or Sensor 3-wire

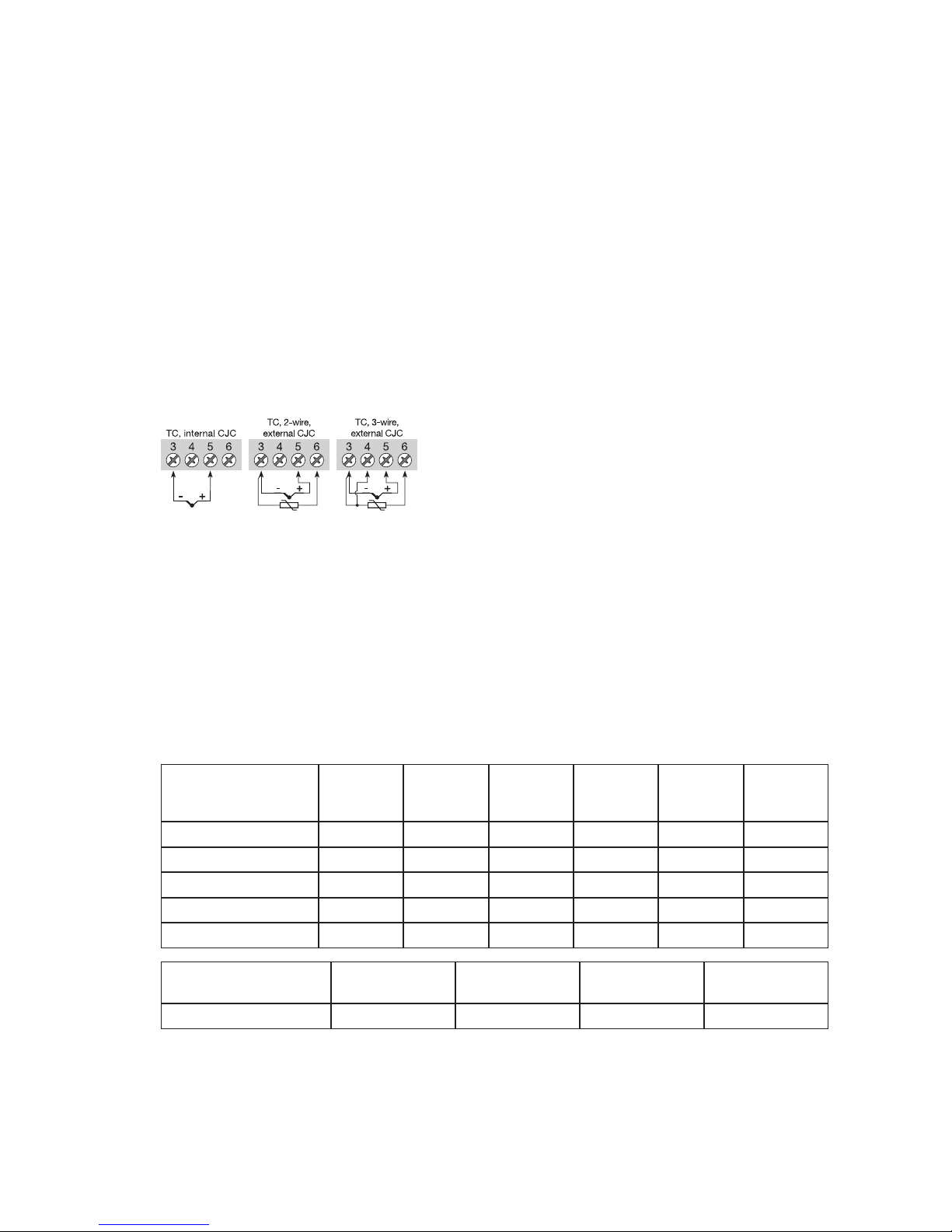

Connections:

Connections with two sensors

can be configured for

2 measurements, dierence,

average or redundancy

14

2.6.4 Measurement of thermocouple with two sensors:

PRIMARY_VALUE_UNIT .......= K, °C, °F or °R

LIN_TYPE....................= Any TC

LIN_TYPE_2 .................= Any TC

SENSOR_MEAS_TYPE.........= Anything, but not "PV = SV_1, SV_2 not available"

SENSOR_CONNECTION .......= N/A (ignored in setup check)

SENSOR_CONNECTION_2 .....= N/A (ignored in setup check)

RJ_TYPE .....................= No RJ, Internal, External (constant value) or Sensor 2-wire

Connections:

2.6.5 Measurement of combined sensors (Sensor 1 = TC and Sensor 2 = RTD):

PRIMARY_VALUE_UNIT .......= K, °C, °F or °R

LIN_TYPE....................= Any TC

LIN_TYPE_2 .................= Any RTD

SENSOR_MEAS_TYPE.........= Anything, but not "PV = SV_1, SV_2 not available"

SENSOR_CONNECTION .......= N/A (ignored in setup check)

SENSOR_CONNECTION_2 .....= 2- or 3-wire

RJ_TYPE ....................= No Reference Junction, Internal, External (constant value)

Connections:

2.6.6 Measurement of resistance (linear) with one sensor:

PRIMARY_VALUE_UNIT .......= Ohm or kOhm

LIN_TYPE....................= No linearisation

LIN_TYPE_2 .................= N/A (ignored in setup check)

SENSOR_MEAS_TYPE.........= PV = SV_1, SV_2 not available

SENSOR_CONNECTION .......= 2-, 3- or 4-wire

SENSOR_CONNECTION_2 .....= N/A (ignored in setup check)

RJ_TYPE .....................= N/A (ignored in setup check)

Connections:

Connections with two sensors

can be configured for

2 measurements, dierence,

average or redundancy

Connections with two sensors

can be configured for

2 measurements, dierence,

average or redundancy

15

2.6.7 Measurement of resistance (linear) with two sensors:

PRIMARY_VALUE_UNIT .......= Ohm or kOhm

LIN_TYPE....................= No linearisation

LIN_TYPE_2 .................= No linearisation

SENSOR_MEAS_TYPE.........= Anything, but not "PV = SV_1, SV_2 not available"

SENSOR_CONNECTION .......= 2- or 3-wire

SENSOR_CONNECTION_2 .....= Default set to 2-wire

RJ_TYPE .....................= N/A (ignored in setup check)

Connections:

2.6.8 Measurement of potentiometer (linear) with one sensor:

PRIMARY_VALUE_UNIT .......= %

LIN_TYPE....................= No linearisation

LIN_TYPE_2 .................= N/A (ignored in setup check)

SENSOR_MEAS_TYPE.........= PV = SV_1, SV_2 not available

SENSOR_CONNECTION .......= 3- or 4-wire

SENSOR_CONNECTION_2 .....= N/A (ignored in setup check)

RJ_TYPE .....................= N/A (ignored in setup check)

Connections:

2.6.9 Measurement of potentiometer (linear) with two sensors:

PRIMARY_VALUE_UNIT .......= %

LIN_TYPE....................= No linearisation

LIN_TYPE_2 .................= No linearisation

SENSOR_MEAS_TYPE.........= Anything, but not "PV = SV_1, SV_2 not available"

SENSOR_CONNECTION .......= Default set to 3-wire

SENSOR_CONNECTION_2 .....= Default set to 3-wire

RJ_TYPE .....................= N/A (ignored in setup check)

Connections:

Connections with two sensors

can be configured for

2 measurements, dierence,

average or redundancy

Connections with two sensors

can be configured for

2 measurements, dierence,

average or redundancy

16

2.6.10 Measurement of voltage (linear) with one sensor:

PRIMARY_VALUE_UNIT .......= µV, mV or V

LIN_TYPE....................= No linearisation

LIN_TYPE_2 .................= N/A (ignored in setup check)

SENSOR_MEAS_TYPE.........= PV = SV_1, SV_2 not available

SENSOR_CONNECTION .......= N/A (ignored in setup check)

SENSOR_CONNECTION_2 .....= N/A (ignored in setup check)

RJ_TYPE .....................= N/A (ignored in setup check)

Connections:

2.6.11 Measurement of voltage (linear) with two sensors:

PRIMARY_VALUE_UNIT .......= µV, mV or V

LIN_TYPE....................= No linearisation

LIN_TYPE_2 .................= No linearisation

SENSOR_MEAS_TYPE.........= Anything, but not "PV = SV_1, SV_2 not available"

SENSOR_CONNECTION .......= N/A (ignored in setup check)

SENSOR_CONNECTION_2 .....= N/A (ignored in setup check)

RJ_TYPE .....................= N/A (ignored in setup check)

Connections:

2.6.12 Measurement of 2 potentiometers (with Linear interpolation linearisation):

PRIMARY_VALUE_UNIT ....... = %

LIN_TYPE.................... = Table Linearisation

LIN_TYPE_2 ................. = Table Linearisation (same table as sensor 1)

SENSOR_MEAS_TYPE......... = Anything, but not "PV = SV_1, SV_2 not available"

SENSOR_CONNECTION ....... = Default set to 3-wire

SENSOR_CONNECTION_2 ..... = Default set to 3-wire

RJ_TYPE ..................... = N/A (ignored in setup check)

Connections:

The coordinates (x,y) describing the linear interpolation linearisation must be entered in PR_

CUST_LIN Block (PA Slot 4). See 2.9.2 Linear Interpolation Linearisation, Paramter List for

further details.

Example:

The coordinates for converting the signal from a logarithmic potentiometer to a linear signal.

TAB_ACTUAL_NUMBER = 10 (number of linearisation points to follow up to max 50)

TAB_XY_VALUE1 = 0,0; -100

TAB_XY_VALUE2 = 0,1; 0

TAB_XY_VALUE3 = 0,2; 100

TAB_XY_VALUE4 = 0,4; 200

Connections with two sensors

can be configured for

2 measurements, dierence,

average or redundancy

Connections with two sensors

can be configured for

2 measurements, dierence,

average or redundancy

17

TAB_XY_VALUE5 = 0,8; 300

TAB_XY_VALUE6 = 1,6; 400

TAB_XY_VALUE7 = 3,2; 500

TAB_XY_VALUE8 = 6,4; 600

TAB_XY_VALUE9 = 12,8; 700

TAB_XY_VALUE10 = 25,6; 800

(Output will readout 325% with 1,0% potentiometer value)

2.6.13 Measurement of TC (with Custom Polynomial Linearisation) on sensor 1

PRIMARY_VALUE_UNIT = K, °C, °F or °R

LIN_TYPE = Custom defined TC

LIN_TYPE_2 = N/A (ignored in setup check)

SENSOR_MEAS_TYPE = PV = SV_1, SV_2 not available

SENSOR_CONNECTION = N/A (ignored in setup check)

SENSOR_CONNECTION_2 = N/A (ignored in setup check)

RJ_TYPE = No Reference Junction, Internal, External (constant value) or

Sensor 2-wire or Sensor 3-wire

Connections:

Now enter the Custom TC parameters in PR_CUST_LIN Block (PA Slot 4). See 2.9.4 Custom Pol-

ynomial Linearisation, Parameter List for further details.

Remember to enter values for the RJ polynomial if RJ_TYPE is any value other than “No refer-

ence Junction”.

Example:

The parameters and coecients for converting a special TC to a linear temperature signal.

CUSTOM_TC_NAME = Custom TC Example

CUSTOM_TC_POLY_COUNT = 5

CUSTOM_TC_MIN_IN = -6500.0

CUSTOM_TC_MIN_OUT = -100.0

CUSTOM_TC_MAX_OUT = 1200.0

A TC input of 5000 µV and an RJ temperature of 25ºC will make POLY_3 the active and the out-

put will be:

URJ = -3.94 *10-1 + 3.94 * 101* 25 + 2.65 * 10-2 * 252- 1.11 * 10-4 * 253= 1000 µV

This voltage is to be added to the TC voltage (5000 + 1000), and the resulting temperature will be:

4.18 + 2.26

*10-2 *6000 +1.41*10-7 *60002+ 1.50 *10-11 *60003- 1.35 *10-15 *60004=

146.3 °C

See 2.9.3 Custom polynomial linearisation, Description for formula and further details.

CUSTOM_TC_POLY_X

max. input

limit in μV

for POLY_X

4th degree

coefficient

for POLY_X

3th degree

coefficient

for POLY_X

2th degree

coefficient

for POLY_X

1st degree

coefficient

for POLY_X

0 degree

coefficient

for POLY_X

CUSTOM_TC_POLY_1 -3200.0 -3.84E-13 -5.65E-9 -3.36E-5 -6.10E-2 -8.44E1

CUSTOM_TC_POLY_2 3500.0 -8.13E-15 7.29E-11 -4.18E-7 2.53E-2 -1.08E-2

CUSTOM_TC_POLY_3 10000.0 -1.35E-15 1.50E-11 1.41E-7 2.26E-2 4.18

CUSTOM_TC_POLY_4 30000.0 3.49E-18 2.19E-12 -1.53E-7 2.68E-2 -9.26

CUSTOM_TC_POLY_5 70000.0 6.27E-17 -8.76E-12 5.34E-7 8.69E-3 1.65E2

3th degree

coefficient

2th degree

coefficient

1st degree

coefficient

0 degree

coefficient

CUSTOM_TC_RJ_POLY -1.11E-4 2.65E-2 3.94E1 3.94E-1

18

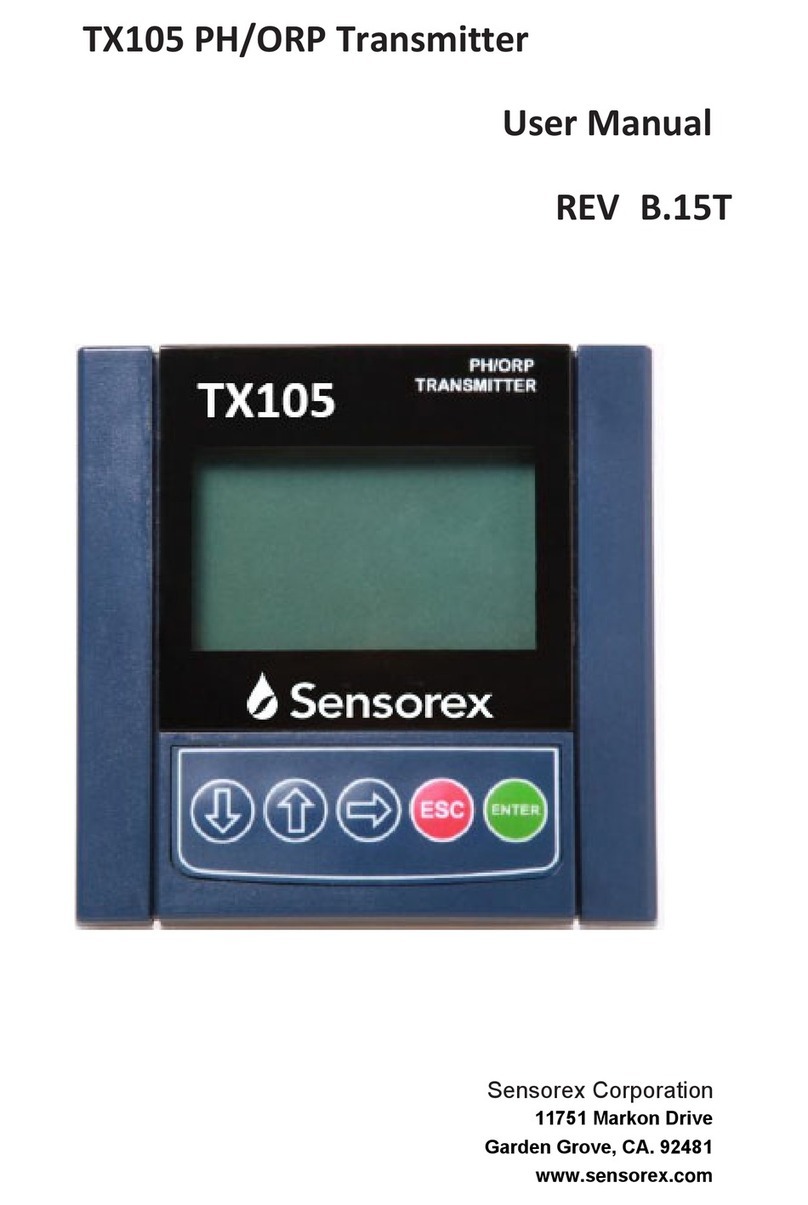

RJ

temp.

Intern

temp. INTERN_TEMP

EXTERNAL_RJ_VALUE

LIN

R.J. Comp.

RJ_TYPE

Input

INPUT1

INPUT2

T1

T2

Linearisation

+

+ LIN

LIN

RJ_TEMP

(none)

Arithmetic

+

+

+,-, redund.

SECONDARY_VALUE_1

SECONDARY_VALUE_2

PRIMARY_VALUE

SENSOR_MEAS_TYPE

BIAS_1 BIAS_2

LIN

LIN_TYPE_1/2

SENSOR_CONNECTION_1/2

COMP_WIRE_1/2

Process

calibration

+

+

Min/Max hold

min/

max

min/

max

MIN_SENSOR_VALUE_1/2

MAX_SENSOR_VALUE_1/2

RTDX_FACTOR_1/2

CAL_POINT_HI_1/2

CAL_ACTUAL_HI_1/2

CABLE_RES1/2

RJ

RJ_COMP_WIRE

SENSOR_WIRE_CHECK_1/2

SENSOR_WIRE_CHECK_RJ

CUSTOM_TC_..

TAB_X_Y_VALUE

CUSTOM_RTD_..

(Channel_4)

(Channel_1)

(Channel_2)

(Channel_3)

AI_TRANSDUCER and PR_CUST_LIN schematic

CAL_POINT_LO_1/2

CAL_ACTUAL_LO_1/2

2.7 AI_Transducer and PR_CUST_LIN Block, Schematic

19

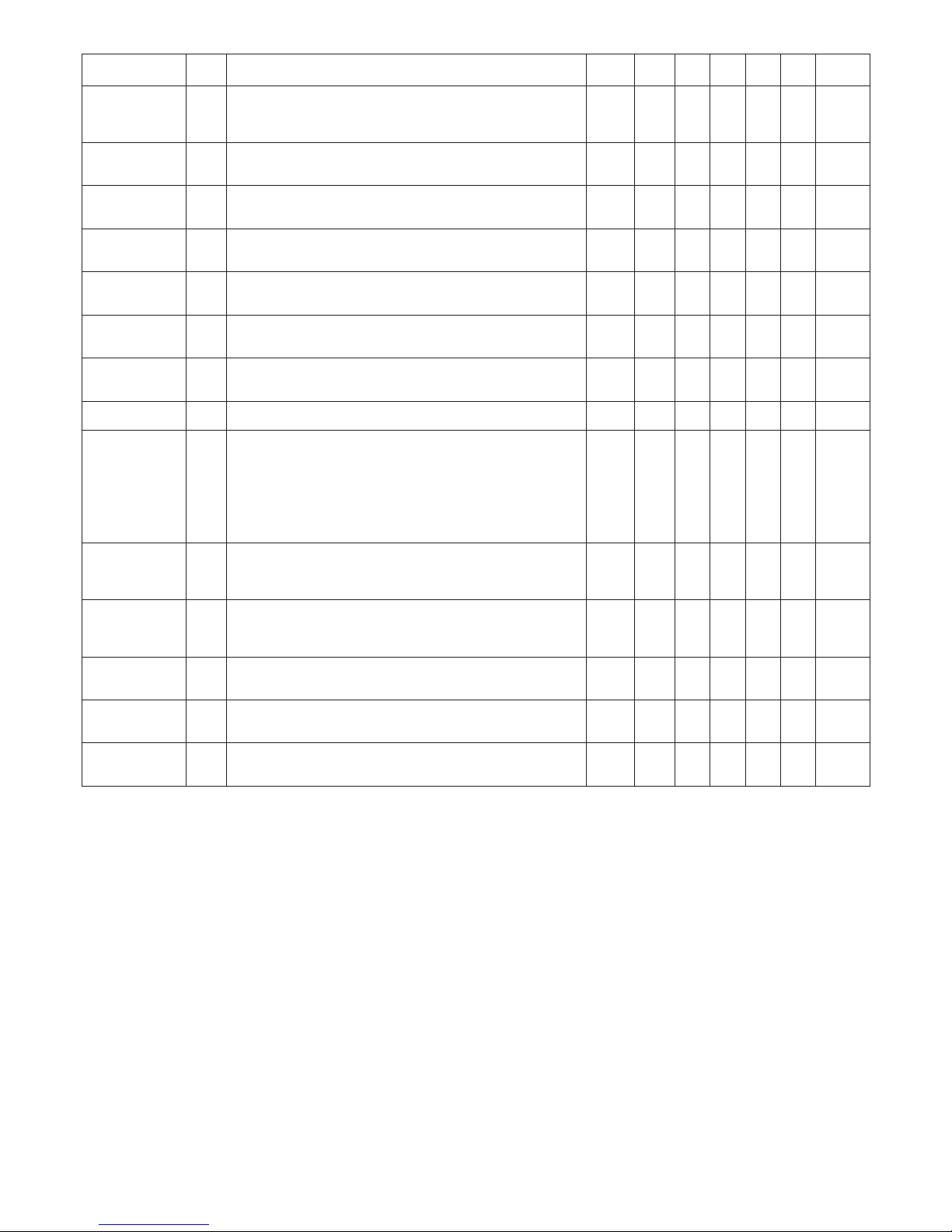

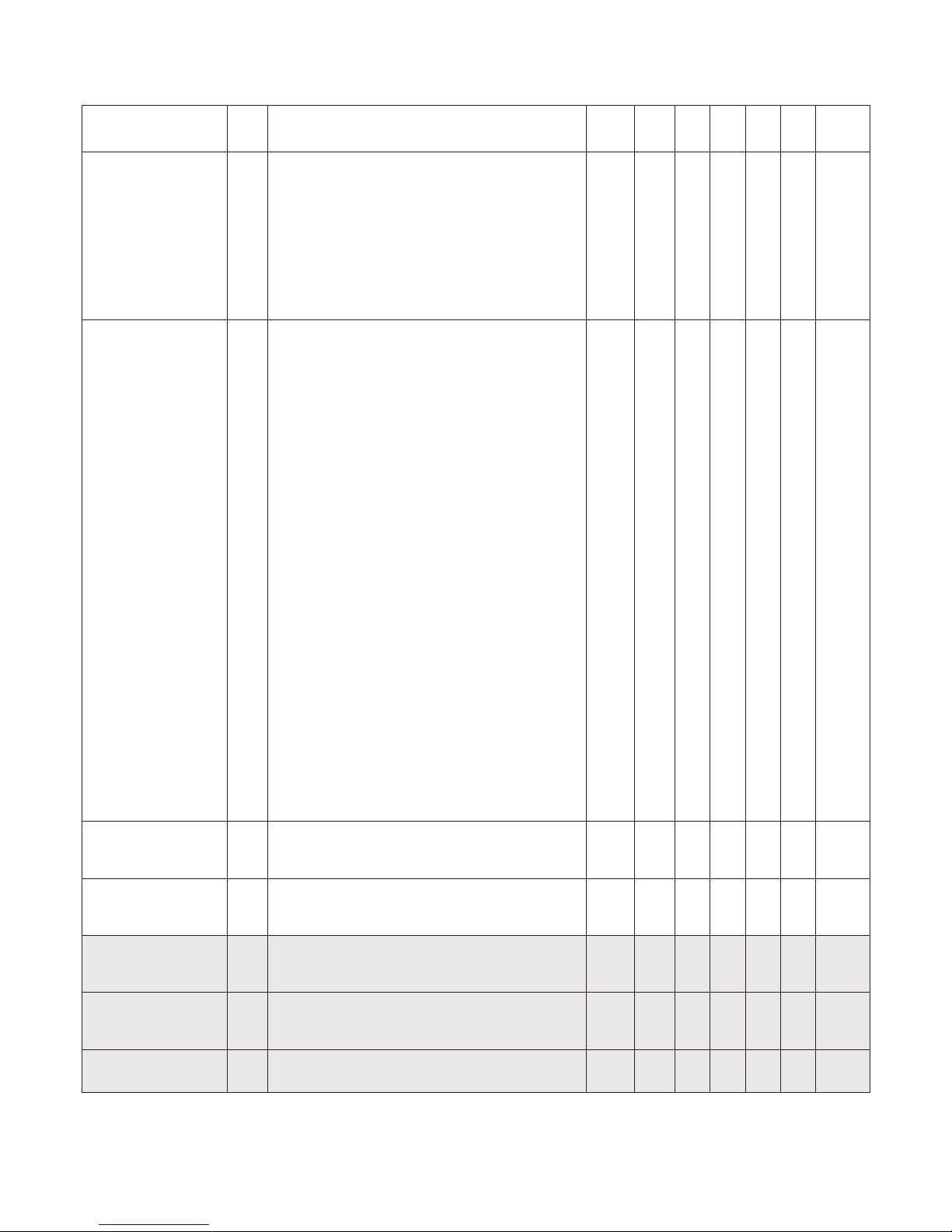

2.8 AI_TRANSDUCER Block Parameter List

2.8.1 Sensor characterising parameters

Parameter

Rel.

Index

FF

Description Type Store Size

byte

RO /

R/W Min. Max. Default

PRIMARY_VALUE_UNIT 14

Selects the unit code of the PRIMARY_VALUE and other

values.

1000 = K (Kelvin)

1001 = °C (degree Celsius)

1002 = °F (degree Fahrenheit)

1003 = Rk (Rankine)

1240 = V (volt)

1243 = mV millivolt

1244 = µV microvolt

1281 = Ohm Ohm

1284 = kOhm kiloOhm

1342 = % (percent)

Un-

signed

16

SRC 2 R/W 1001

(°C)

LIN_TYPE 18

Select the type of sensor 1:

0 = no linearisation

1 = linearisation table

100 = RTD Pt10 a = 0.003850 (IEC 60751)

101 = RTD Pt50 a = 0.003850 (IEC 60751)

102 = RTD Pt100 a = 0.003850 (IEC 60751))

103 = RTD Pt200 a = 0.003850 (IEC 60751))

104 = RTD Pt500 a = 0.003850 (IEC 60751))

105 = RTD Pt1000 a = 0.003850 (IEC 60751)

106 = RTD Pt10 a = 0.003916 (JIS C1604-81)

107 = RTD Pt50 a = 0.003916 (JIS C1604-81)

108 = RTD Pt100 a = 0.003916 (JIS C1604-81)

122 = RTD Ni50 a = 0.006180 (DIN 43760)

123 = RTD Ni100 a = 0.006180 (DIN 43760)

124 = RTD Ni120 a = 0.006180 (DIN 43760)

125 = RTD Ni1000 a = 0.006180 (DIN 43760)

126 = RTD Cu10 a = 0.004270

127 = RTD Cu100 a = 0.004270

128 = TC Type B, Pt30Rh-Pt6Rh (IEC 584)

129 = TC Type C (W5), W5-W26Rh (ASTM E 988)

130 = TC Type D (W3), W3-W25Rh (ASTM E 988)

131 = TC Type E, Ni10Cr-Cu45Ni (IEC 584)

133 = TC Type J, Fe-Cu45Ni (IEC 584)

134 = TC Type K, Ni10Cr-Ni5 (IEC 584)

135 = TC Type N, Ni14CrSi-NiSi (IEC 584)

136 = TC Type R, Pt13Rh-Pt (IEC 584)

137 = TC Type S, Pt10Rh-Pt (IEC 584)

138 = TC Type T, Cu-Cu45Ni (IEC 584)

139 = TC Type L, Fe-CuNi (DIN 43710)

140 = TC Type U, Cu-CuNi (DIN 43710)

240 = Custom-defined TC

241 = Custom-defined RTD

242 = Custom-defined RTD PtX a=0.003850 (X factor of Pt1)

243 = Custom-defined RTD NiX a=0.006180 (X factor of Ni1)

244 = Custom-defined RTD CuX a=0.004270 (X factor of Cu1)

245 = Custom-defined RTD PtX a=0.003916 (X factor of Pt1)

Un-

signed

8

SRC 1 R/W 102

(Pt100)

UPPER_SENSOR_LIMIT 21

Physical upper limit function of sensor1 (e.g. Pt 100 =

850°C) and input range.

The unit of UPPER_SENSOR_LIMIT is the PRIMARY_

VALUE_UNIT.

Float N 4 RO 850

LOWER_SENSOR_LIMIT 22

Physical lower limit function of sensor1 (e.g. Pt 100 =

-200°C) and input range.

The unit of LOWER_SENSOR_LIMIT is the PRIMARY_

VALUE_UNIT.

Float N 4 RO -200

LOWER_SENSOR_LIMIT_2 39

Physical lower limit function of sensor2 (e.g. Pt 100 =

-200°C) and input range.

The unit of LOWER_SENSOR_LIMIT is the PRIMARY_

VALUE_UNIT.

Float N 4 RO -200

UPPER_SENSOR_LIMIT_2 40

Physical upper limit function of sensor2 (e.g. Pt 100 =

+850°C) and input range.

The unit of UPPER_SENSOR_LIMIT is the PRIMARY_

VALUE_UNIT.

Float N 4 RO 850

LIN_TYPE_2 41 Select the type of sensor 2:

See LIN_TYPE for selection and supported types

Un-

signed

8

SRC 1 R/W 102

20

AI_TRANSDUCER Block Parameter List

2.8.2 RTD / Resistor specific parameters

Parameter

Rel.

Index

FF

Description Type Store Size

byte

RO /

R/W Min. Max. Default

SENSOR_CONNECTION 35

Connection to sensor 1, select for 2-, 3- and 4-wire con-

nection. Ignored if sensor 1 is not a resistive sensor.

Defined codes:

0 = 2 wires

1 = 3 wires

2 = 4 wires

Un-

signed

8

SRC 1 R/W 1

COMP_WIRE1 36 Value in OHM to compensate line resistance when

Sensor 1 is a resistive sensor, connected with 2 wires. Float SRC 4 R/W 0 100 0

COMP_WIRE2 37 Value in OHM to compensate line resistance when

Sensor 2 is a resistive sensor, connected with 2 wires. Float SRC 4 R/W 0 100 0

SENSOR_CONNECTION_2 38

Connection to sensor 2, select for 2-, 3- and 4-wire con-

nection. Ignored if sensor 2 is not a resistive sensor.

Defined codes:

0 = 2 wires

1 = 3 wires

Un-

signed

8

SRC 1 R/W 0

CABLE_RES1 63

For 3- or 4-wire resistance measurements.

Indicates the measured cable resistance in the wire

connected to terminal 3. For 3-wire measurements it is

multiplied by 2

Float D 4 RO 0,0

CABLE_RES2 64

For 4-wire resistance measurements.

Indicates the measured cable resistance in the wire con-

nected to terminal 6.

Float D 4 RO 0,0

RTDX_FACTOR_1 65 Indicates the X factor for custom defined PtX, NiX, CuX

for LIN_TYPE

Un-

signed

16

SRC 2 R/W 100

RTDX_FACTOR_2 66 Indicates the X factor for custom defined PtX, NiX, CuX

for LIN_TYPE_2

Un-

signed

16

SRC 2 R/W 100

2.8.3 Thermocouple specific parameters

Parameter

Rel.

Index

FF

Description Type Store Size

byte

RO /

R/W Min. Max. Default

RJ_TEMP 32

Reference junction temperature. The unit of RJ_TEMP is

the PRIMARY_VALUE_UNIT. If PRIMARY_VALUE_UNIT is

no temperature unit (e.g. mV) RJ_TEMP is stated in °C.

Float D 4 RO 0

RJ_TYPE 33

Select reference junction from internal to fixed value.

Ignored for sensors which are not thermocouple types.

Defined codes:

0 = No reference: Compensation is not used (e.g. for

TC type B).

1 = Internal: Reference junction temperature is

measured by the device itself, via

an internally mounted sensor.

2 = External: The fixed value EXTERNAL_RJ_

VALUE is used for compensation.

The reference junction must be kept

at a constant temperature (e.g. by a

reference junction thermostat).

3 = Sensor, 2-w.: Reference junction temperature is

measured by external 2-wire con-

nected Pt100 sensor.

4 = Sensor, 3-w: Reference junction temperature is

measured by external 3-wire con-

nected Pt100 sensor.

Un-

signed

8

SRC 1 R/W 0

EXTERNAL_RJ_VALUE 34

Fixed temperature value of an external reference junc-

tion. The unit of EXTERNAL_RJ_VALUE is the PRIMARY_

VALUE_UNIT. If PRIMARY_VALUE_UNIT is no temperature

unit (e.g. mV) EXTERNAL_RJ_VALUE is stated in °C.

Float SRC 4 R/W -40

(°C)

135

(°C) 0

RJ_COMP_WIRE 42 Value in OHM to compensate line resistance when

External RJ sensor, connected with 2 wires is used. Float SRC 4 R/W 0 100 0

Table of contents

Other PR Transmitter manuals