SGM LB-100 User manual

LB·100

LED BALLS

2

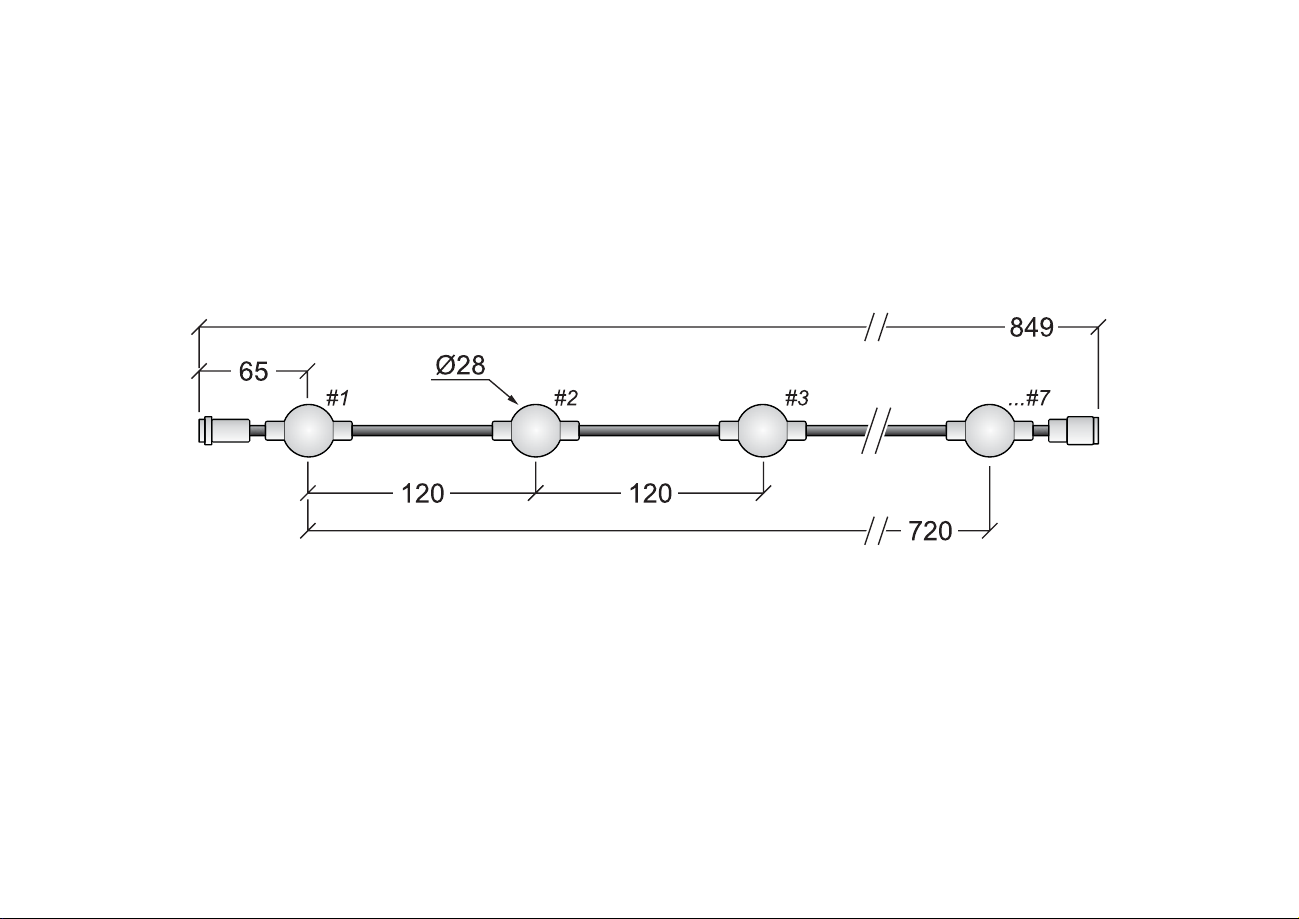

Dimensions of LB-100 LED Balls

All dimensions in mm.

Drawing not to scale.

3

LB-100 LED BALLS

USER MANUAL REV. 2

© 2010-2013 SGMTM,QIRUPDWLRQ VXEMHFW WR FKDQJH ZLWKRXW QRWLFH SGM DQG DOO DI¿OLDWHG

companies disclaim liability for any injury, damage, direct or indirect loss, consequential

or economic loss or any other loss occasioned by the use of, inability to use or reliance

on the information contained in this manual. The SGM logo, the SGM name and all other

trademarNs in this document pertaining to serYices or products by SGM or its af¿liates and

subsidiaries are trademarNs oZned or licensed by SGM or its af¿liates or subsidiaries.

LB-100 LED Balls uk

4

Contents

Safety Information....................................................................................................5

Read the Manual................................................................................................................................................6

Protection from Injury.........................................................................................................................................6

Introduction..........................................................................................................................7

Parts Identi¿cation and 7erminology...................................................................................................................

Features.................................................................................................................................................8

Connections Overview........................................................................................................................................9

Connecting to 6*M 7ouring /(D Driver 7/D6..............................................................................................

8sing custom Sower suSSly and 6*M adaStor caEle....................................................................................

Service................................................................................................................................12

Cleaning......................................................................................................................................................

Troubleshooting.............................................................................................................13

Speci¿cations/%-100 3art 000001...........................................................................14

Users notes........................................................................................................................16

5

Safety Information

• This product is for professional use only. It is not for household use.

This product presents risNs of severe injury or death due to ¿re ha]ards.

• When using a 12V DC custom power supply, always use an AC power source that complies with local building

and electrical codes and has both overload and earth

leakage protection.

• 1ever attempt to bypass the fuse. Always replace defective fuses with ones of the speci¿ed type and rating.

• Verify that the power feed cable is rated for the current draw of all connected ¿[tures. See application informa-

tion on page 11.

• Do not modify the ¿[ture or install other than genuine SGM parts.

• Do not operate the system if the ambient air temperature Tae[ceeds 40 ÛC 104 Û)

WARNING! Read the safety precautions in this section before

installing, powering, operating or servicing this product.

6

Read the manual

5ead this manual before installing or powering the /(D %alls, and follow the safety precautions.

Always observe all warnings in this manual and printed on the system. If you have questions about how to oper-

ate the system safely, please contact your SGM representative.

Protection from injury

• (nsure that any structure used for support as well as all fastened and connected hardware can hold at least 10

times the weight of all supported devices and equipment.

• Use a minimum of two approved secondary attachments such as safety wiresto secure each product as de-

scribed in this manual. Safety wires must be approved by an of¿cial body such e.g. ThVas a safety attach

ment for the weight of all the products it secures. Safety wires must be capable of supporting a static suspended

load ten times the weight of the product.

• Check that all e[ternal covers and rigging hardware are securely fastened.

• %lock access below the work area and work from a stable platform whenever installing, servicing or moving the

product.

Read this manual before installing, powering or servicing.

7

Introduction

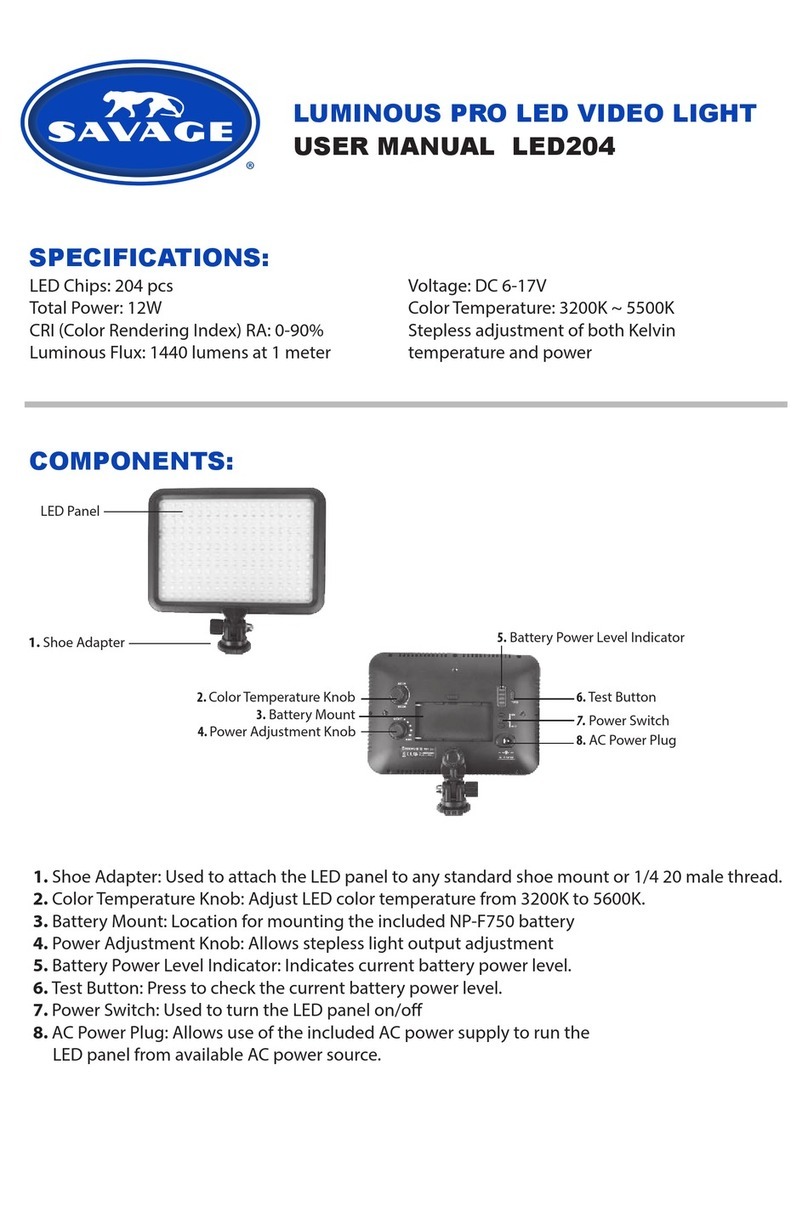

PartVidenti¿cation and terminoloJy

See )ig. 1 for part terminology and identi¿cation.

A. 2ne string /(D %alls 7 /(D balls

%. 2ne row of /(D %alls consisting of 1 to strings

Ma[. 56 /(D balls.

Fig.

Features

The SGM /(D %alls form a modular semi-transparent /(D video curtain with a 12cm pi[el pitch, which can be

viewed in a 360angle. 2ne /(D %all driver is capable of producing a seamless image of 6.6 meters vertically

and for as long in the hori]ontal direction as the number of drivers permit )ig.2.

The system features

• 12cm pi[el is capable of producing a seamless image at 3.6m2per Touring /(D driver.

• 5ich 5G%color

• Color resolution of bits per color

• 360° viewing angle

(ach string consists of 7 balls with 5G%color /(Ds and each string connects to both

the driver as well as to the corresponding string with 4 pin RJ765 connectors. As many

as strings can be linked to form a row of strings with a total of 56 balls on each row.

Fig.

6 meters 60 centimeters

Connections Overview

The /(D ball string has a female 4 pin RJ765 connector at the inlet before ball 1, and a male 4 pin RJ765 con-

nector at the outlet after ball 7. )ig. 3 shows the pin layout.

pin female R-6connector

Connector front shown

Fig. 3

10

&onnectinJto

6G0TourinJ/(' 'riYer

T/'

T/D-612

3art 0070201

11

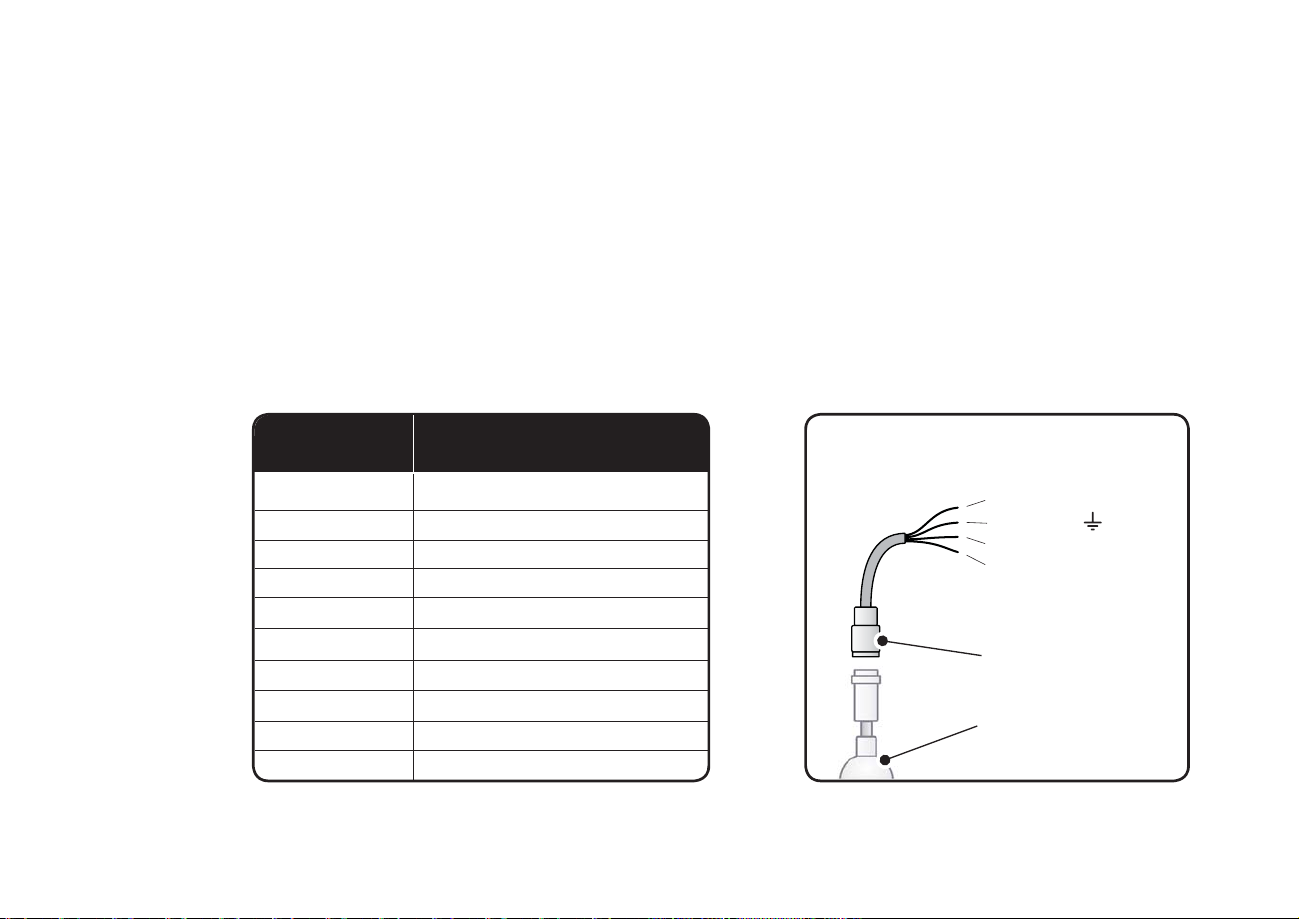

8sinJ&ustom SoZer suSSly and 6G0adaStor caEle

When e[tending the supply cable between the adaptor 3art 3060201and a user speci¿ed 12VDC 3SU,

make sure to use cables according to speci¿cations in the table below.

When using a 12V DC custom power supply, it must be protected with a T12.5A fuse.

Use only an AC power source that complies with local building and electrical codes and has both overload and

earth leakage protection.

0 - 3

3 - 4,5

4,5 - 6

6 -

- 12

12 - 15

15 - 1

1- 22

22 - 2

2- 32

Cable length

(meters)

Cross sectional area

(mm)

0,5

0,75

1

1,5

2

2,5

3

4

5

6

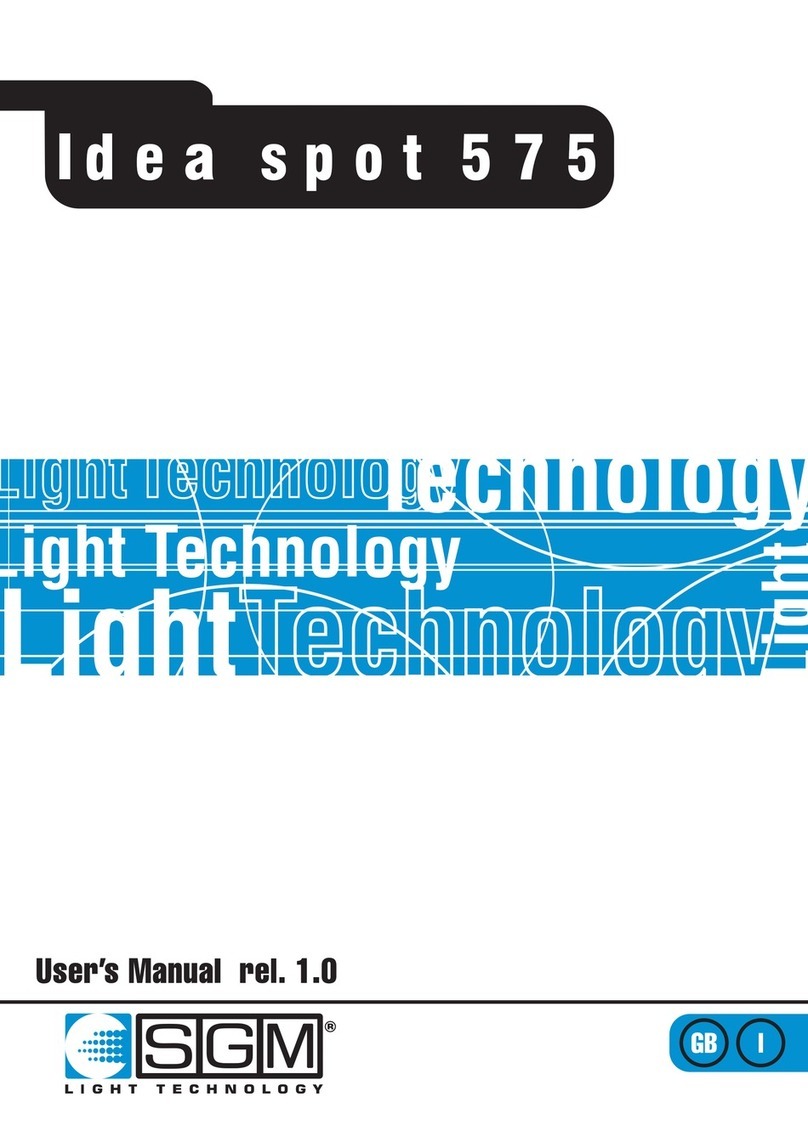

Adaptor IC-1

Part 836

Red12 V

%lack

GreenData -

%lueData

4 pin RJ765

female connector

/(D light source

/(D %alls shown

12

Service

&leaninJ

Regular cleaning is essential for the /(D %alls performance. Accumulation of dust and dirt degrades the /(D light output.

Cleaning schedules will vary greatly depending on the operating environment, and the installation should therefore

be checked at frequent intervals within the ¿rst few weeks of operation to see whether cleaning is necessary. This

procedure will allow you to assess cleaning requirements in your particular situation. If in doubt, consult your SGM

dealer for a suitable maintenance schedule. Clean the /(D %alls with a soft cloth dampened with a solution of water

and a mild detergent such as car shampoo. Do not use products that contain solvents, abrasives or caustic agents

for cleaning, as they can cause damage to the surface of the balls.

13

Troubleshooting

No light in

one /(D ball

No light in

one string of

/(D balls

/ow light output

from /(D balls

near end of

string

Problem

No DMX signal is

received from source

Defective DMX source

Incorrect addressing

Defective /(D

Defective DMX source

%ad data link

Short circuit at end

connector

Incorrect addressing

Defective /(D

Insuf¿cient voltage

from power source

Probable cause(s) Remedy

Replace DMX source

Check addresses and protocol settings

Replace DMX source

Check addresses and protocol settings

Replace /(D string

Replace DMX source

Inspect RJ765 connectors and correct poor connections

Remove any metal parts causing short circuit at the last

RJ764 pin connector in string

Check addresses and protocol settings

Replace /(D string

Check power source speci¿cations and replace power

source if necessary

Inspect power source for defects and repair or replace

power source

If e[tension cables are used, make sure that they comply with

the speci¿cations described in this manual

14

Speci¿cations /% (Part )

BALL DIMENSIONS

Diameter.......................................................................................................................................................2mm

3i[el pitch............................................................................................................................................................12cm

7 balls string length %alls CC.............................................................................................................................72cm

%all 3i[el weight....................................................................................................................................................20g

INSTALLATION

Orientation........................................................................................................................................Any

AMBIENT OPERATING CONDITIONS

Ma[imum ambient temperature Ta...................................................................................................40 °C 104 °)

Minimum ambient temperature Ta....................................................................................................-10 °C 14 °)

Operating humidity..............................................................................................................................................100%

I3rating................................................................................................................................................................I365

SIGNAL SOURCE

According to standard.........................................................................................................................USITT DMX 512

15

CONNECTIONS

Data input................................................................................................................Male locking 4 pin RJ765 socket

Data output.........................................................................................................)emale locking 4 pin RJ765 socket

ELECTRICAL

3ower supply voltage.................................................................................................................................12V -0.2V

3ower consumption per /%-100 7 pi[els...........................................................................................................5.4W

APPROVALS

Safety........................................................................................................................................................(N 6050-1

(MC.....................................................................................................................................(N 55103-1, (N 55103-2

INCLUDED PARTS

• /(D %alls string, /%-100 3art 000001

• User manual

ACCESSORIES

IC-1, 3ower adaptor cable...............................................................................................................3art 30060201

6Seci¿cations suEject to chanJe Zithout notice

16

Users notes

17

1

1

SGM A/S · Soeren Frichs Vej 51-53 · DK 8230 Aabyhoej · Denmark

Other manuals for LB-100

1

Table of contents

Other SGM Dj Equipment manuals

SGM

SGM SP-6 SIXPACK User manual

SGM

SGM Idea spot 575 User manual

SGM

SGM P-10 User manual

SGM

SGM Giotto profile 400 User manual

SGM

SGM PALCO 3+ User manual

SGM

SGM MOVING HEADS SERIES User manual

SGM

SGM X-5 User manual

SGM

SGM P-5 Wash Light User manual

SGM

SGM P-5 Series User manual

SGM

SGM G-4 RGBAM WASH User manual