XL-30V

– 6 –

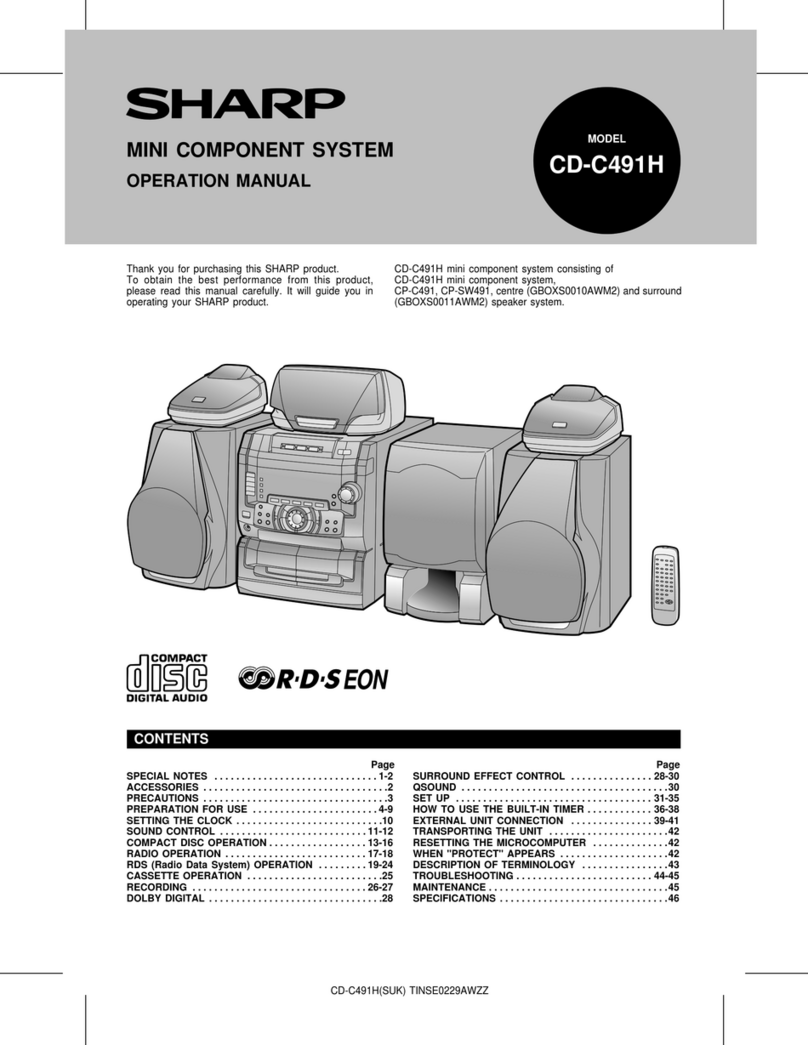

OPERATION MANUAL

PREPARATION FOR USE PREPARATION FOR USE

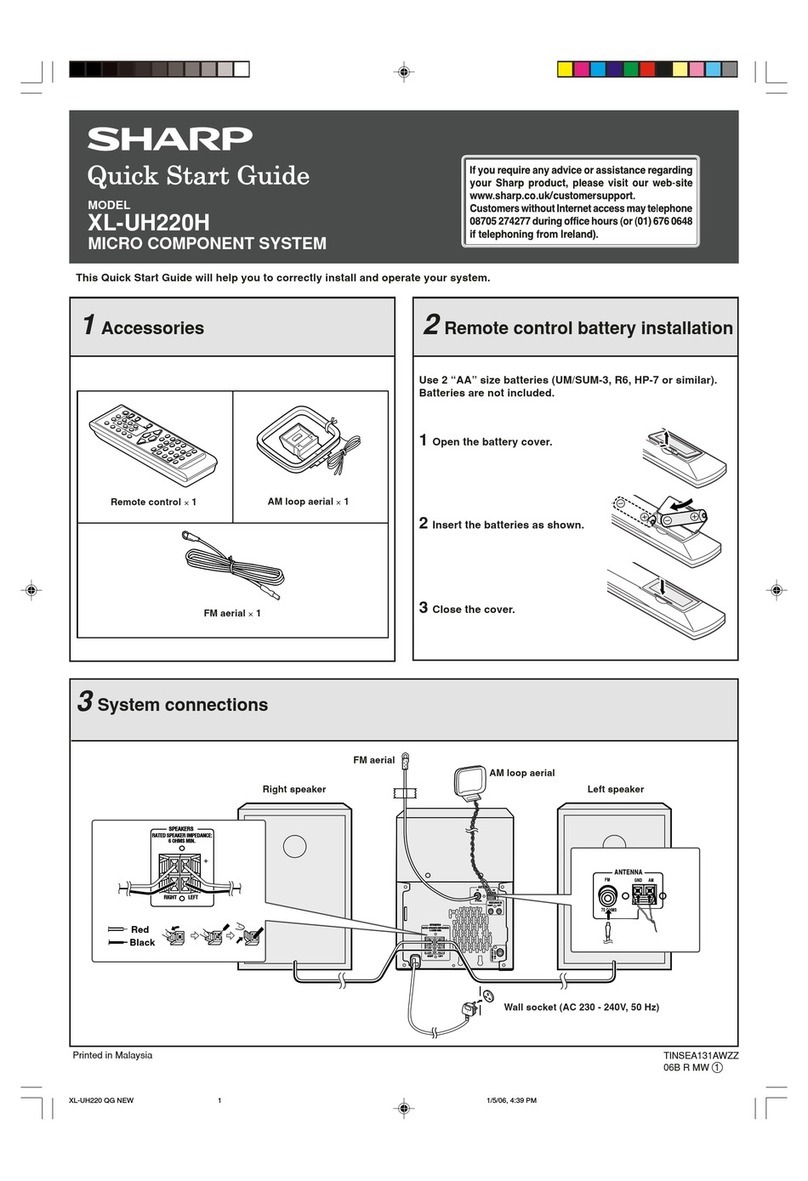

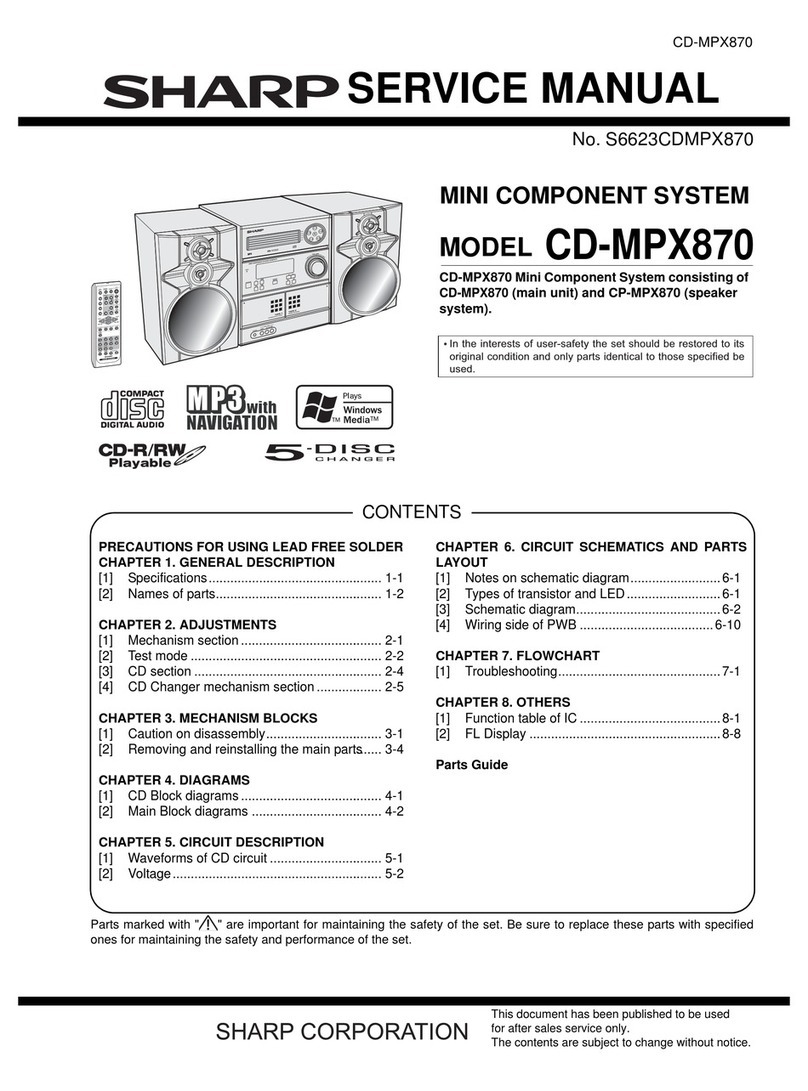

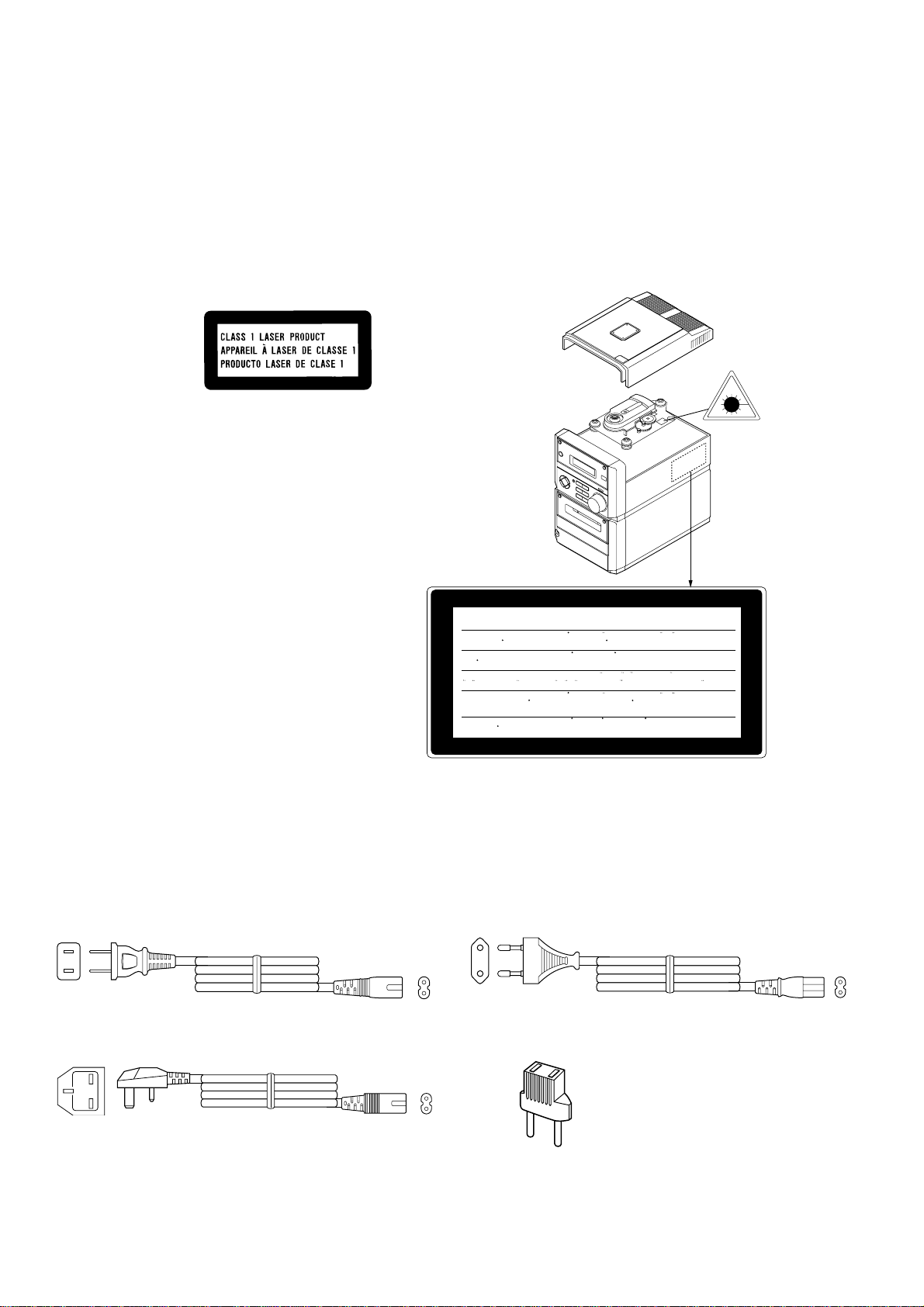

■Connecting the AC power lead

Check thesetting of theAC voltage selector located

on the rear panel before plugging the unit into an

AC socket. If necessary, adjust the selector to cor-

respond totheAC power voltage usedin your area.

Selector adjustment:

Turn the selector with a screwdriver until the ap-

propriate voltage number appears in the window

(110V - 127V or 220V - 240V AC).

Notes:

●Unplug theAC power lead from the AC socket if

the unit is not to be used for a prolonged period

of time.

●Never use a power lead other than the one sup-

plied.

Otherwise, a malfunction or an accident may

occur.

●AC Plug Adaptor

In areas (or countries) where an AC socket as

shown in illustration

2

is used, connect the unit

using the AC plug adaptor supplied with the unit,

as illustrated. The AC plug adaptor is not included

in areas where the AC wall socket and AC power

plug can be directly connected (see illustration

1

).

Note for users in Australia and New Zealand:

An AC plug adaptor is not supplied if the lead has

an Australian Standard plug.

1

2

RATED

LINE VOLTAGE

220V

ı

240V

To an AC socket

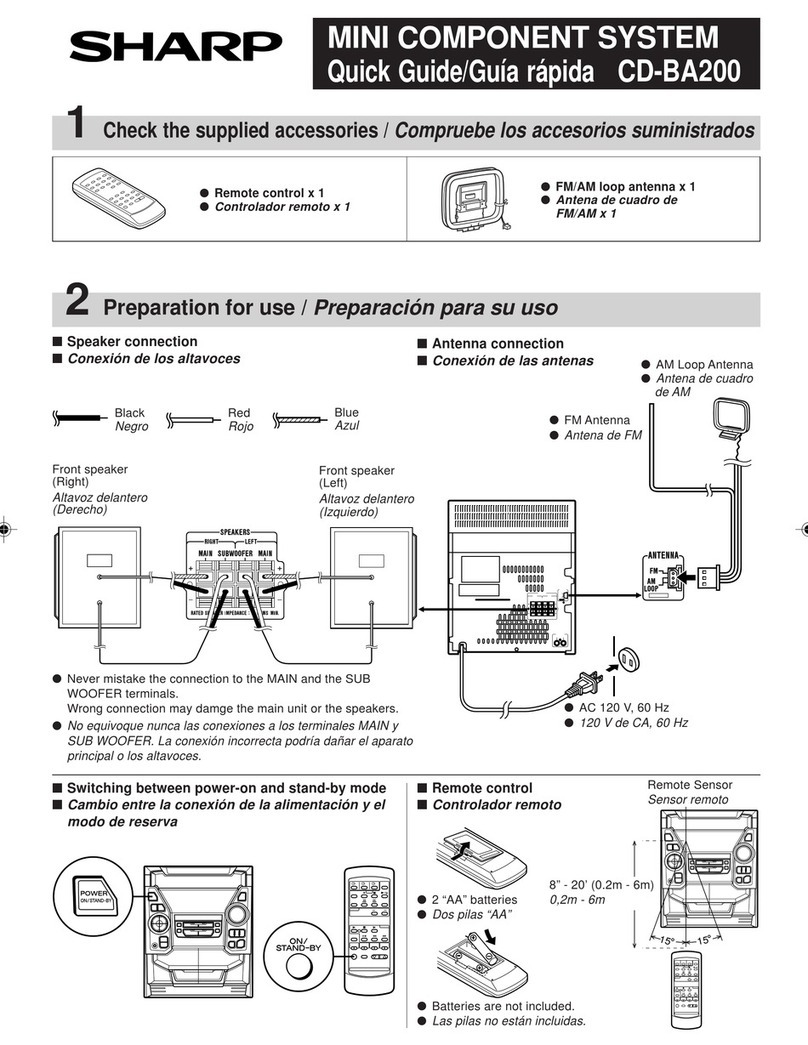

Precautions for battery use:

●Insertthe batteries according to the direction in-

dicated in the battery compartment.

●Replace all old batteries with new ones at the

same time.

●Do not mix old and new batteries.

●Remove the batteries if they are weak or if the

unit willnot beused for long periodsof time.This

willprevent potentialdamagedueto batteryleak-

age.

Caution:

Do notuse rechargeable batteries(nickel-cadmium

battery, etc.).

Notes concerning use:

●Replace the batteries ifthe operating distance is

reduced or if the operation becomes erratic.

●Periodically clean the transmitter LED on the re-

mote control and the sensor on the main unit

with a soft cloth.

●Exposing the sensor on the main unit to strong

light may interfere with operation. Change the

lighting or the direction of the unit.

●Keep the remote control away from moisture,

excessive heat, shock, and vibrations.

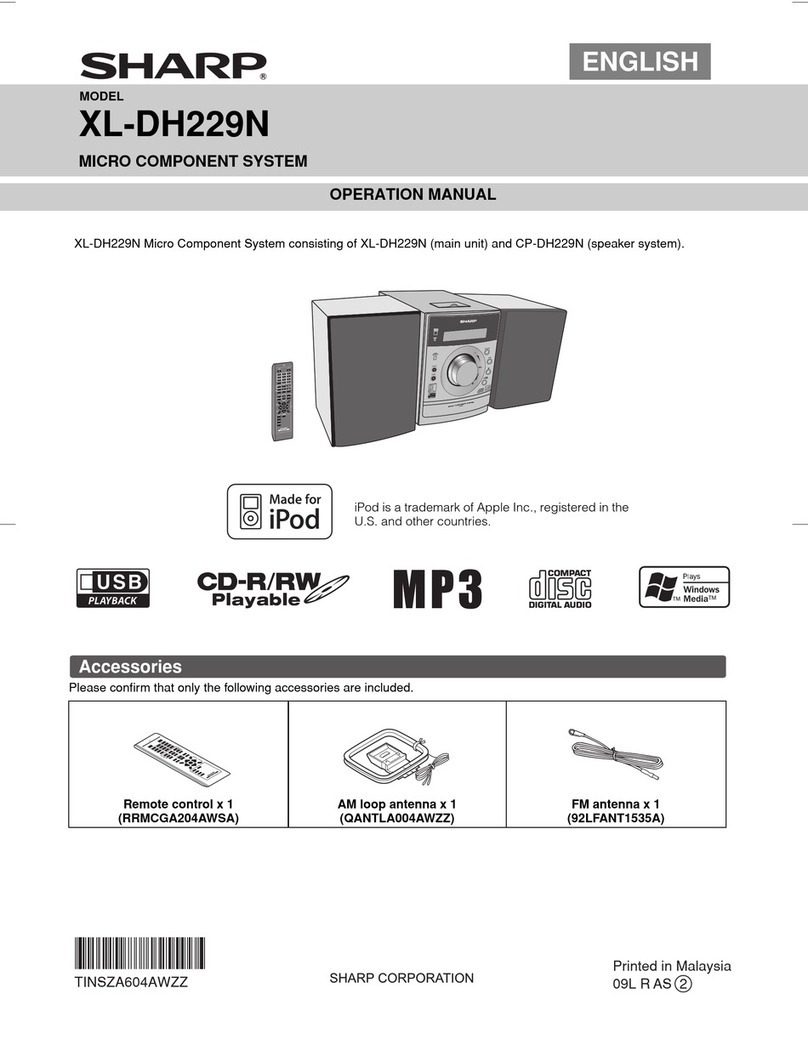

■Remote control

15

15

●2 “AA” size batteries (UM/SUM-3, R6, HP-7

or similar)

0.2m - 6m

(8"- 20')

●When inserting or removing the batteries, push

them towards the battery terminals.

●Installing thebatteries incorrectlymay causethe

unit to malfunction.

-

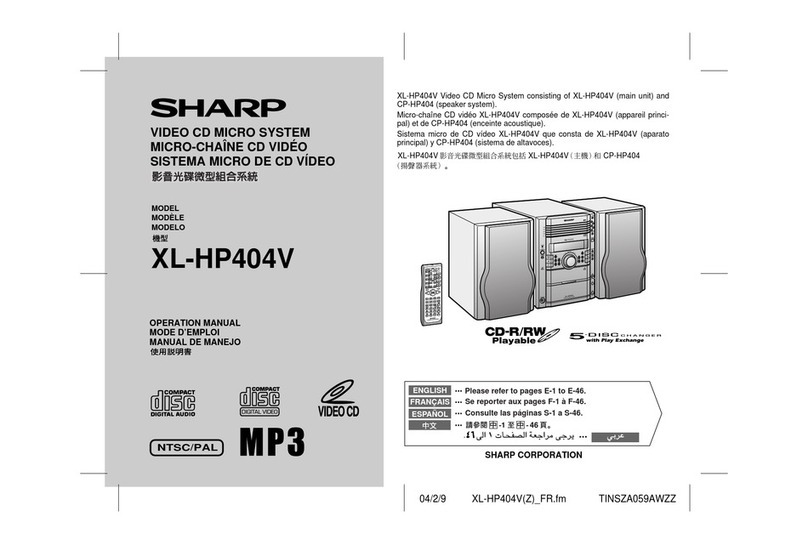

■AM/FM interval (span)

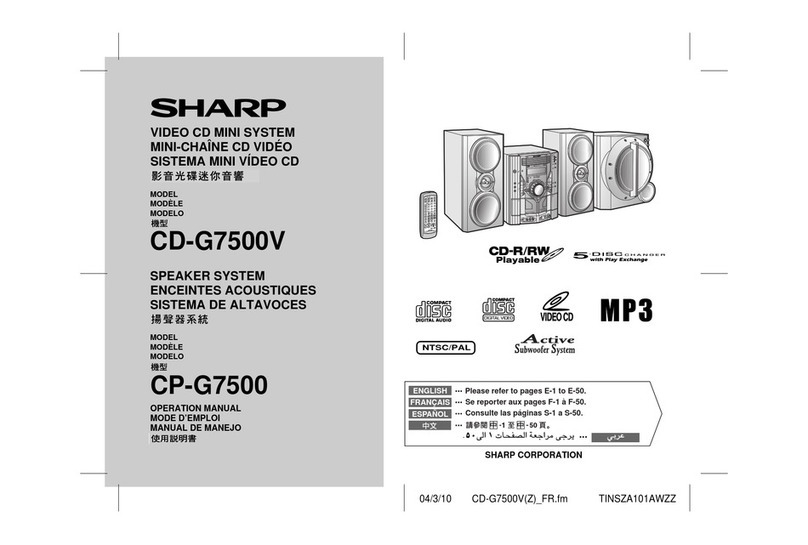

The International Telecommunication Union (ITU)

has established that member countries should

maintain either a 10 kHz or a 9 kHz interval be-

tween broadcasting frequencies of anyAM station.

The illustration shows the 9 kHz interval zones (re-

gions 1 and 3), and the 10 kHz interval zone (re-

gion 2).

This product is not equipped with a span selector.

However, it will be adjusted to 9 kHz AM interval

(50 kHz FM interval) when shipped from the fac-

tory.

Before using the unit, be sure to set it for the AM

tuning interval (span) used in your area.

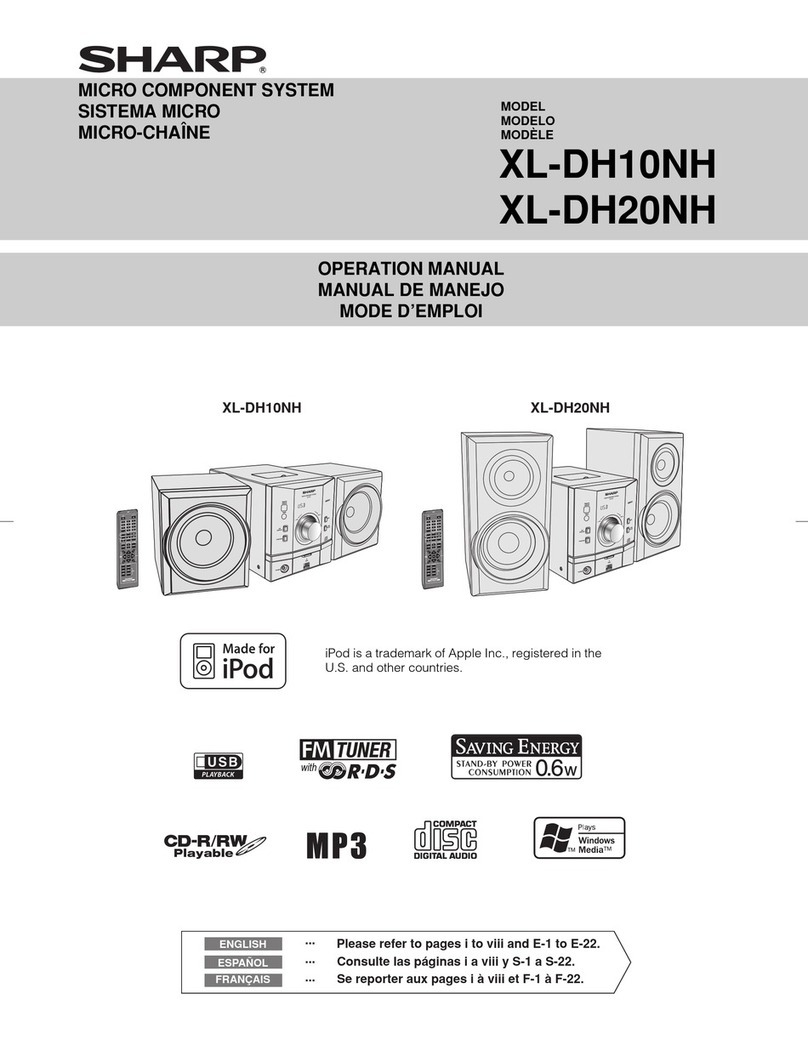

To check the tuning span currently selected:

1

Press the ON/STAND-BY button to turn the

power on.

2

Press the FUNCTION button until “FM” or

“AM” appears in the display.

3

Press the BAND button to select the AM

band.

●If “AM 531 kHz” is displayed, it means that the

radio has been adjusted for a 9 kHz span. If “AM

530 kHz” is displayed, it means that the radio

has been adjusted for a 10 kHz span.

To change from a 9 kHz AM (50 kHz FM) interval

to a 10 kHz AM (100 kHz FM) interval:

1

Press the ON/STAND-BY button to enter the

stand-by mode.

2

Hold down the button and the MEMORY/

SET button for at least 4 seconds. Release

the buttons when “AM SP 10 kHz” and “FM

SP 100 kHz” are displayed alternately.

●The unit will return to the clock display.

To return to a 9 kHz AM (50 kHz FM) interval:

1

Press the ON/STAND-BY button to enter the

stand-by mode.

2

Hold down the button and the MEMORY/

SET button for at least 4 seconds. Release

the buttons when “AM SP 9 kHz” and “FM

SP 50 kHz” are displayed alternately.

●The unit will return to the clock display.

Caution:

●When the unit is left for a few hours after the

span has been switched andAC power lead dis-

connected, it will be automatically returned to a

9 kHz span. If this happens, set the span again.

●When the span is switched, any stations that are

memorised will be cancelled.

MEMORY/

SET

FUNCTION

BAND

ON/

STAND-BY

kHz

kHz kHz

kHz

kHz

kHz kHz

kHz