20GT-15

6

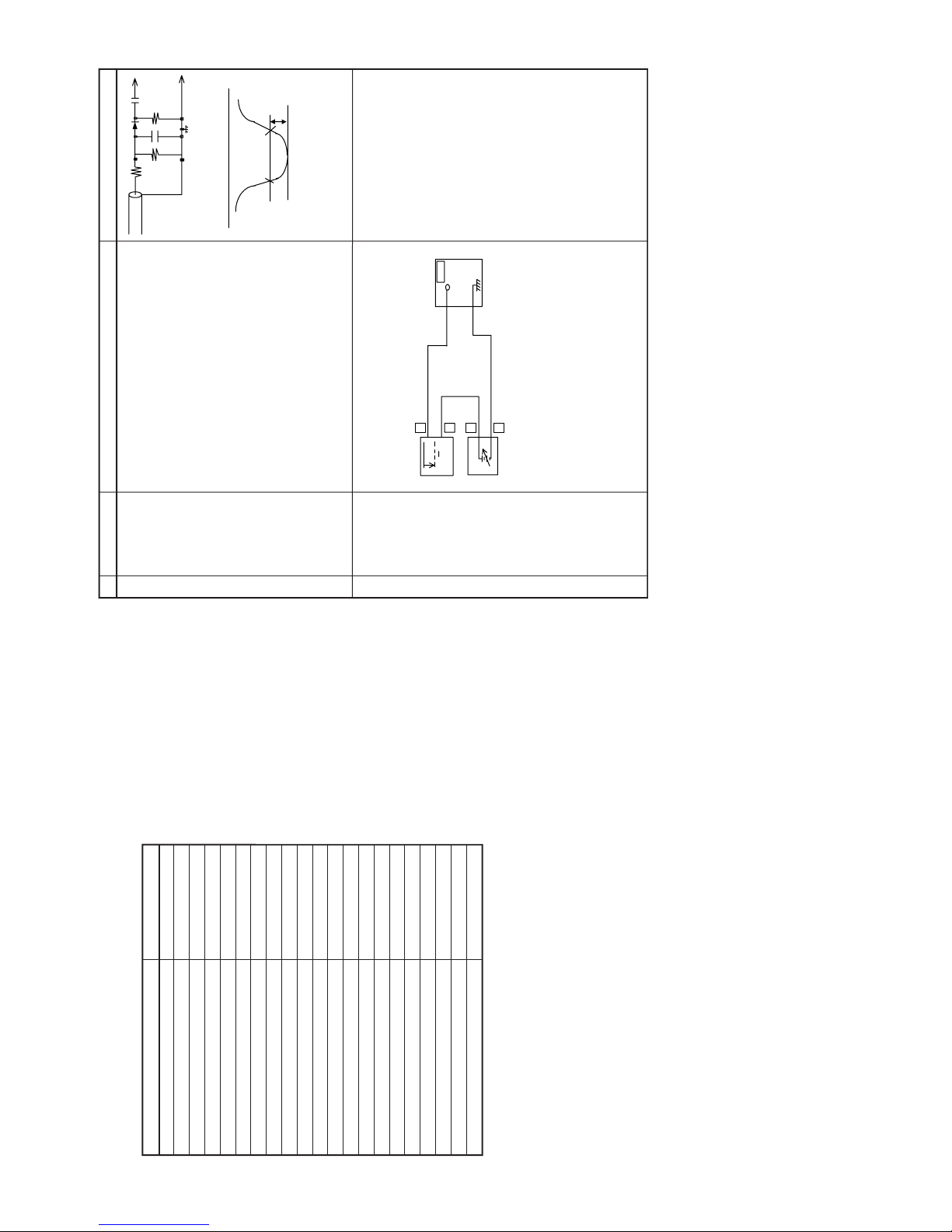

EEPROM ITEMS OSD

DATA LENGTH INITIAL DATA

FIX/ADJ REMARK

VERTICAL SCAN DISABLE VSD

0(DISABLE)/1(ENABLE)

0 FIX

BLACK STRETCH BKS

0(DISABLE)/1(ENABLE)

1 FIX

AUTOMATIC VOLUME LEVELING AVL

0(DISABLE)/1(ENABLE)

1 FIX

FAST FILTER IF-PLL FFI

0(DISABLE)/1(ENABLE)

0 FIX

ENABLE VERTICAL GUARD (RGB BLANKING)

EVG

0(DISABLE)/1(ENABLE)

1 FIX ONLY BLK

EHT TRACKING MODE (HCO) EHT

0(DISABLE)/1(ENABLE)

1 FIX

OVERSCAN SWITCH OFF OSO

0(DISABLE)/1(ENABLE)

0 FIX

AUTO COLOUR LIMIT ACL

0(DISABLE)/1(ENABLE)

0 FIX

FORCED COLOUR LIMIT FCO

0(DISABLE)/1(ENABLE)

0 FIX

SOUND SYSTEM M S-M

0(DISABLE)/1(ENABLE)

0 FIX

SOUND SYSTEM DK S-DK

0(DISABLE)/1(ENABLE)

1 FIX *3

SOUND SYSTEM I S-I

0(DISABLE)/1(ENABLE)

1 FIX *3

SOUND SYSTEM BG S-BG

0(DISABLE)/1(ENABLE)

1 FIX

PLAYBACK SECAM P-SECAM

0(DISABLE)/1(ENABLE)

1 FIX *3

FE (RF) NTSC 3.58 F-N358

0(DISABLE)/1(ENABLE)

0 FIX

FE (RF) NTSC 4.43 F-N443

0(DISABLE)/1(ENABLE)

1 FIX *4

FE (RF) SECAM F-SECAM

0(DISABLE)/1(ENABLE)

1 FIX *5

VIDEO MUTE AT IDENT LOSS VMI

0(DISABLE)/1(ENABLE)

1 FIX

VIDEO MUTE AT PROGRAM/SOURCE CHANGE

VMC

0(DISABLE)/1(ENABLE)

1 FIX

HOTEL MODE HTL

0(DISABLE)/1(ENABLE)

0 FIX

REDUCED FM DEMODULATOR GAIN FOR BTSC SIGNAL

BTSC

0(DISABLE)/1(ENABLE)

0 FIX

NUMBER OF EXTERNAL AV SOURCE AV

0 FOR1 AV/1 FOR 2AV

1 ADJ *6

FM WINDOW SELECTION FMWS

0(DISABLE)/1(ENABLE)

0 FIX

SOUND MUTE BIT 0 SM0

0(DISABLE)/1(ENABLE)

1 FIX

SOUND MUTE BIT 1 SM1

0(DISABLE)/1(ENABLE)

0 FIX

THAI LANGUAGE THA

0(DISABLE)/1(ENABLE)

0 FIX *7

ARABIC LANGUAGE ARA

0(DISABLE)/1(ENABLE)

1 FIX *3

MALAY LANGUAGE MAL

0(DISABLE)/1(ENABLE)

1 FIX *3

CHINESE LANGUAGE CHI

0(DISABLE)/1(ENABLE)

1 FIX *3

FRENCH LANGUAGE FRE

0(DISABLE)/1(ENABLE)

1 FIX *3

RUSSIAN LANGUAGE RUS

0(DISABLE)/1(ENABLE)

1 FIX *3

FORCED V-SYNC SLICING LEVEL FSL

0(DISABLE)/1(ENABLE)

0 FIX

SYNC OF OSD HP2

0(DISABLE)/1(ENABLE)

0 FIX

TUNER CPT CPT

0(DISABLE)/1(ENABLE)

0 FIX

BILINGUAL BIL

0(DISABLE)/1(ENABLE)

0 ADJ *8

IF AGC SPEED BIT 0 AGC0

0(DISABLE)/1(ENABLE)

1 FIX

IF AGC SPEED BIT 1 AGC1

0(DISABLE)/1(ENABLE)

0 FIX

PHI-1 TIME CONSTANT (RF) FOA-FE

0(DISABLE)/1(ENABLE)

0 FIX

PHI-1 TIME CONSTANT (RF) FOB-FE

0(DISABLE)/1(ENABLE)

0 FIX

PHI-1 TIME CONSTANT (OFF AIR) FOA-AV

0(DISABLE)/1(ENABLE)

1 FIX

PHI-1 TIME CONSTANT (OFF AIR) FOB-AV

0(DISABLE)/1(ENABLE)

1 FIX

NOTE :

FIXED DATA, PLEASE DO NOT CHANGE WITHOUT SPECIFIC INSTRUCTION.

*1: UNLESS CUSTOMER REQUEST, OR ELSE FIX THE ADJUSTMENT.

*2: CDL DATA=2 , FOR 20” & 21” ONLY

*3: MANUAL CHANGE TO ‘0’

*4: MANUAL CHANGE TO ‘0’

*5: MANUAL CHANGE TO ‘0’

*6: IF 1 AV-OUT, SET TO‘0’

IF 2 AV-OUT, SET ‘1’

*7: MANUAL CHANGE TO ‘1’

*8: IF BILINGUAL MODEL PLEASE CHANGE TO ‘1’

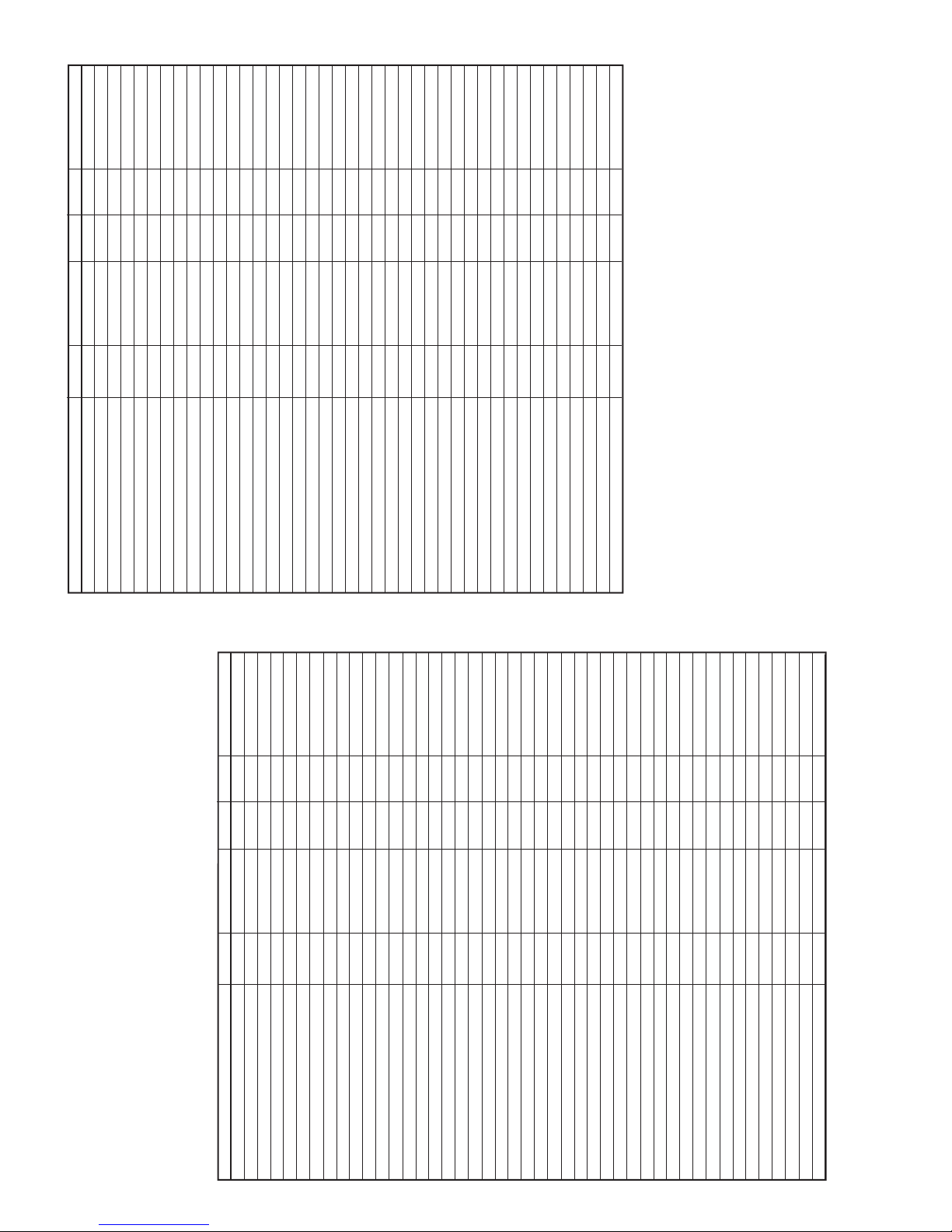

AFTERSHORTJA 122& JA124, ANDTURNONTHE MAIN POWERSWITCH,READ

DATA

FROM EEPROM ADDRESS 00H ~ 03H, AND COMPARE TO THE LIST BELOW, IF

DIFFERENT, INITIALIZE THE EEPROM.

ADDRESS DATA ADDRESS DATA

00H: 55H 02H: 43H

01H: 4FH 03H: A1H

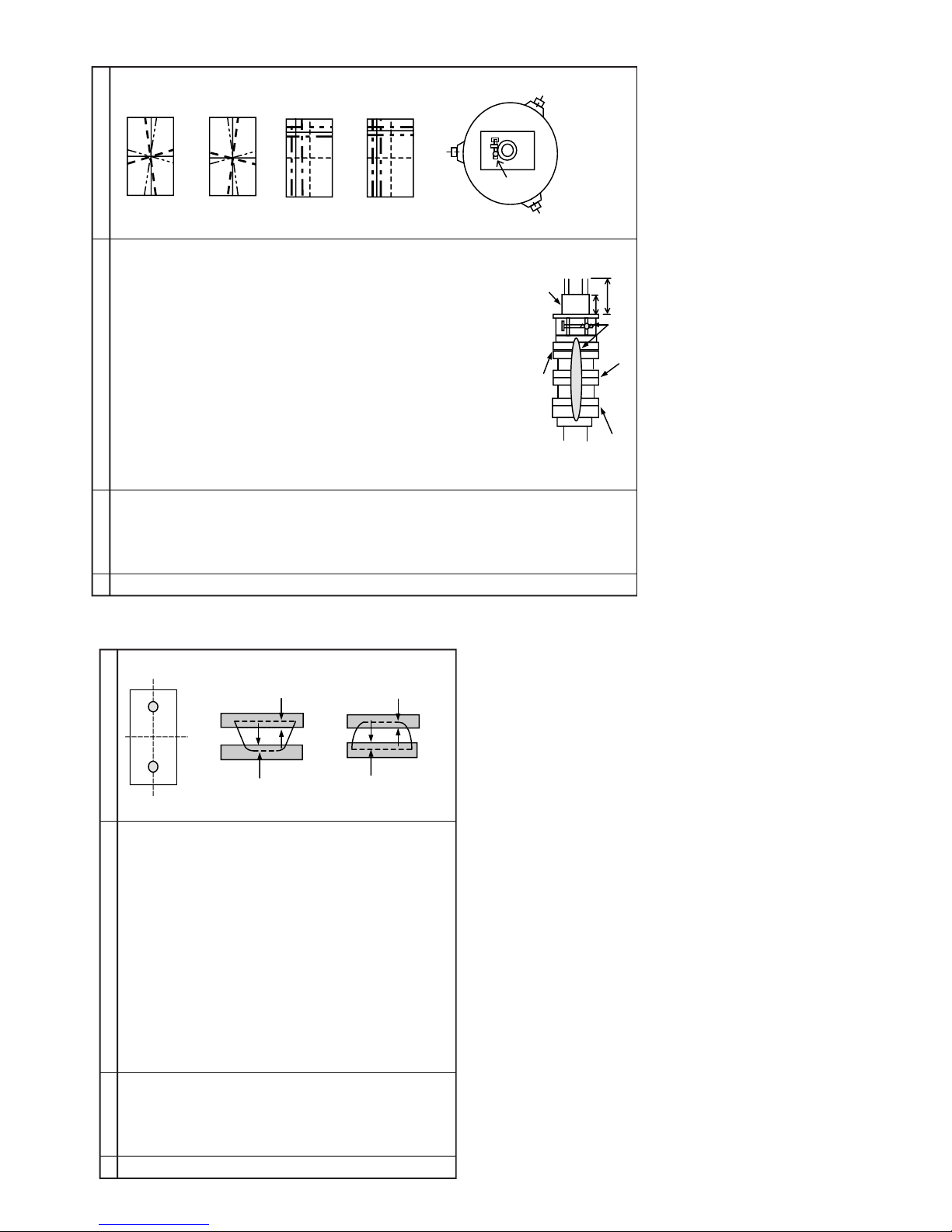

EEPROM ITEMS OSD

DATA LENGTH INITIAL DATA

FIX/ADJ REMARK

AGCTAKE OVER POINT AGC 0~63 14 ADJ

VERTICAL SLOPE V-LIN 0~63 32 ADJ

VERTICAL AMPLITUDE V-AMP 0~63 32 ADJ

VERTICAL SHIFT V-CENT 0~63 32 ADJ

HORIZONTAL SHIFT H-CENT 0~63 32 ADJ

S-CORRECTION S-COR 0~63 0 FIX

WHITE POINT RED STD WHITETEMP DRI-RS 0~63 32 FIX

WHITE POINT GREEN STD WHITE TEMP DRI-GS 0~63 32 ADJ

WHITE POINT BLUE STD WHITETEMP DRI-BS 0~63 32 ADJ

WHITE POINT RED WARM WHITE TEMP DRI-RW 0~63 32 FIX

WHITE POINT GREEN WARMWHITE TEMP DRI-GW 0~63 32 FIX (DRI-GS)-7 DATA

WHITE POINT BLUE WARMWHITE TEMP DRI-BW 0~63 32 FIX (DRI-BS)-7 DATA

WHITE POINT RED COOL WHITE TEMP DRI-RC 0~63 25 FIX (DRI-BS)-7 DATA

WHITE POINT GREEN COOL WHITE TEMP DRI-GC 0~63 32 FIX (DRI-GS)-7 DATA

WHITE POINT BLUE COOL WHITE TEMP DRI-BC 0~63 32 FIX (DRI-BS) SAME DATA

MAX VOLUME SUB-VOL 0~63 63 FIX

SUB CONTRAST SUB-CON 0~63 63 FIX

SUB COLOUR SUB-COL 0~63 32 ADJ

SUB BRIGHTNESS SUB-BRI 0~63 32 ADJ

SUB TINT SUB-TINT 0~63 32 ADJ

SUB SHARPNESS SUB-SHP 0~63 32 FIX

MAX HOTEL VOLUME HTL-VOL 0~63 32 FIX *1

HOTEL PROGRAM NUMBER HTL-PRG

0~99 OR>99FOR NONE

255 FIX

OSD GRB REFERENCE RGB 0~15 15 FIX

BLACK LEVEL OFF-SET R CUT-R 0~15 8 FIX

BLACK LEVEL OFF-SET B CUT-G 0~15 8 FIX

CATHODE DRIVE LEVEL CDL 0~15 0 FIX *2

Y-DELAY TIME FOR PAL(TV) [YD] DL-PT 0~15 12 FIX

Y-DELAY TIME FOR SECAM(TV) [YD] DL-ST 0~15 15 FIX

Y-DELAY TIME FOR N358 (TV) [YD] DL-3T 0~15 12 FIX

Y-DELAY TIME FOR N443 (TV) [YD] DL-4T 0~15 12 FIX

Y-DELAY TIME FOR B/W (TV) [YD] DL-TV 0~15 12 FIX

Y-DELAY TIME FOR PAL (AV) [YD] DL-PA 0~15 12 FIX

Y-DELAY TIME FOR SECAM (AV) [YD] DL-SA 0~15 15 FIX

Y-DELAY TIME FOR N358 (AV) [YD] DL-3A 0~15 12 FIX

Y-DELAY TIME FOR N443 (AV) [YD] DL-4A 0~15 12 FIX

Y-DELAY TIME FOR B/W (AV) [YD] DL-AV 0~15 12 FIX

COLOUR OFFSET (PAL) COL-OP 0~15 8 FIX

COLOUR OFFSET (SECAM) COL-OS 0~15 8 FIX

COLOUR OFFSET (NTSC358) COL-O3 0~15 4 FIX

COLOUR OFFSET (NTSC443) COL-O4 0~15 4 FIX

SHARPNESS OFFSET (PAL) SHP-OP 0~15 8 FIX

SHARPNESS OFFSET (SECAM) SHP-OS 0~15 4 FIX

SHARPNESS OFFSET (NTSC358) SHP-O3 0~15 12 FIX

SHARPNESS OFFSET (NTSC443) SHP-O4 0~15 8 FIX