iii

Shor-Line.com

INTRODUCTION

Introduction.................................................................................................. ii

GENERAL INFORMATION

General information .....................................................................................1

Safety Alert Symbol ............................................................................................................ 1

Personal Protective Equipment (PPE)................................................................................ 1

Safety Warnings Included In This Guide ............................................................................ 2

SECTION ONE, PRE-ASSEMBLY

Shipment Inventory And Inspection .............................................................3

Shipment Inventory....................................................................................................... 3

Shipment Inspection ..................................................................................................... 3

Damage Reporting........................................................................................................ 3

Hole Template..................................................................................................................... 3

Parts List............................................................................................................................. 4

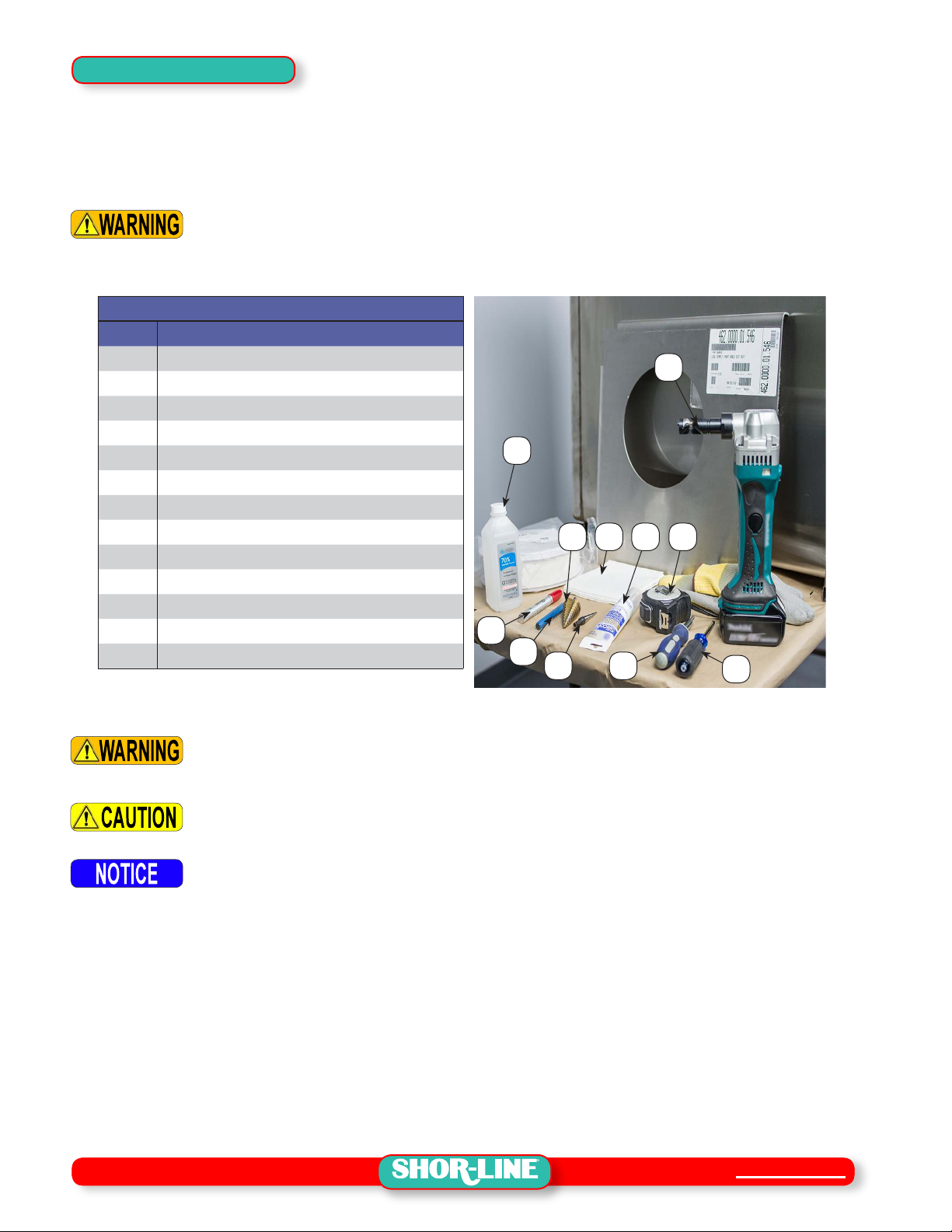

Tools And Equipment.......................................................................................................... 5

SECTION TWO, ASSEMBLY PROCEDURES

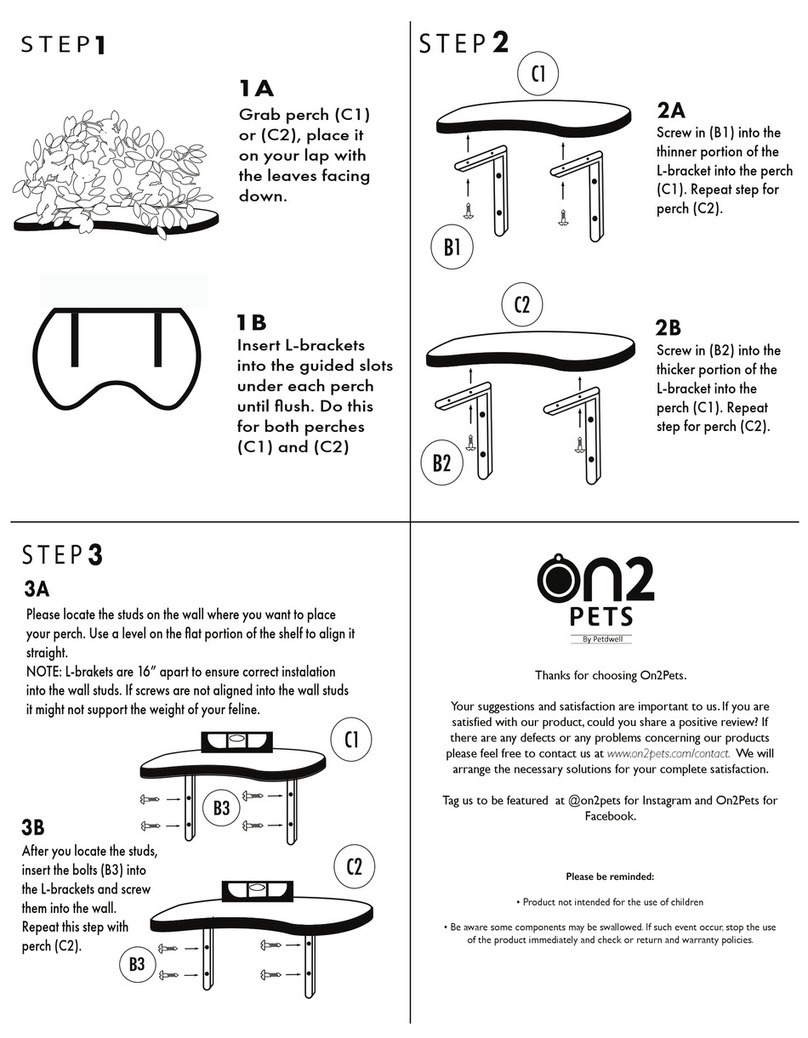

Assembly Procedures..................................................................................6

Cage Preparation ............................................................................................................... 6

Portal Location.............................................................................................................. 6

Cage Door Removal ..................................................................................................... 7

Portal Hole.......................................................................................................................... 8

Template ....................................................................................................................... 8

Mark/Punch Starter Hole .............................................................................................. 9

Drill Starter Hole ......................................................................................................... 10

Portal Hole Cut ........................................................................................................... 10

Portal Installation .............................................................................................................. 12

Spacer Installation ...................................................................................................... 12

Flange Components Installation ................................................................................. 13

Door Installation.......................................................................................................... 14

SECTION THREE, OPERATION & MAINTENANCE

Portal Use And Care ..................................................................................16

Door Operation ................................................................................................................. 16

Opening and Closing the Portal Door ......................................................................... 16

General Maintenance & Care ........................................................................................... 17

Maintenance Recommendations ................................................................................ 17

Care Recommendations ............................................................................................ 17

SECTION FOUR, TERMS & CONDITIONS

Terms And Conditions................................................................................18

Damaged Freight Procedures .......................................................................................... 18

Limited Warranty ......................................................................................20

Limitation Of Liability................................................................................................... 20

Contact Information ...................................................................................21

CONTENTS