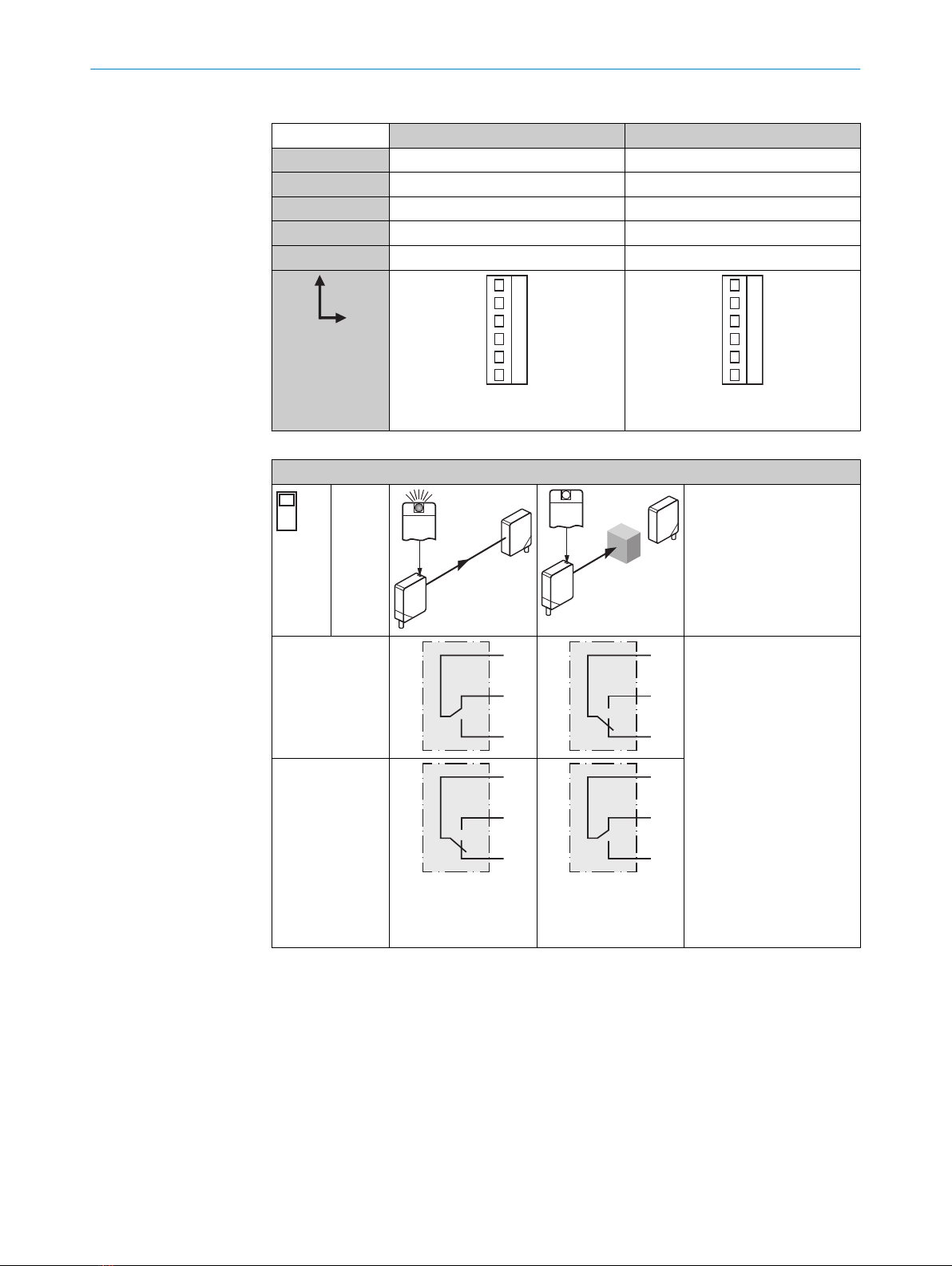

3Switch: light (L) / dark

(D)

4Switch: NPN / PNP

5Potentiometer: adjust‐

ment of time delay t2

6Potentiometer: adjust‐

ment of time delay t1

7Potentiometer: adjust‐

ment of time stage

3Switch: light (L) / dark

(D)

4Switch: NPN / PNP

3Switch: light (L) / dark

(D)

4Potentiometer: adjust‐

ment of time delay t2

5Potentiometer: adjust‐

ment of time delay t1

6Potentiometer: adjust‐

ment of time stage

3Switch: light (L) / dark

(D)

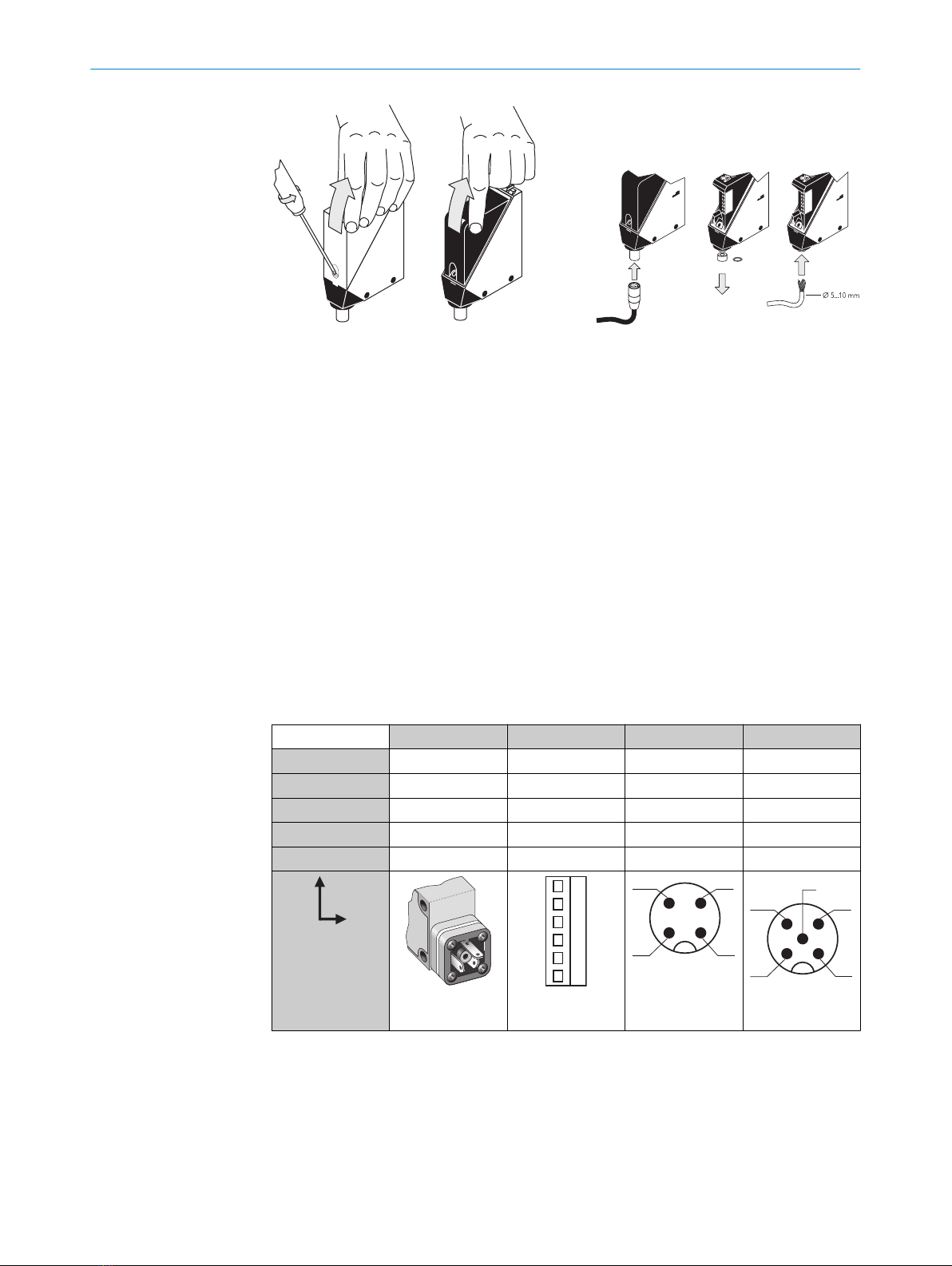

5 Mounting

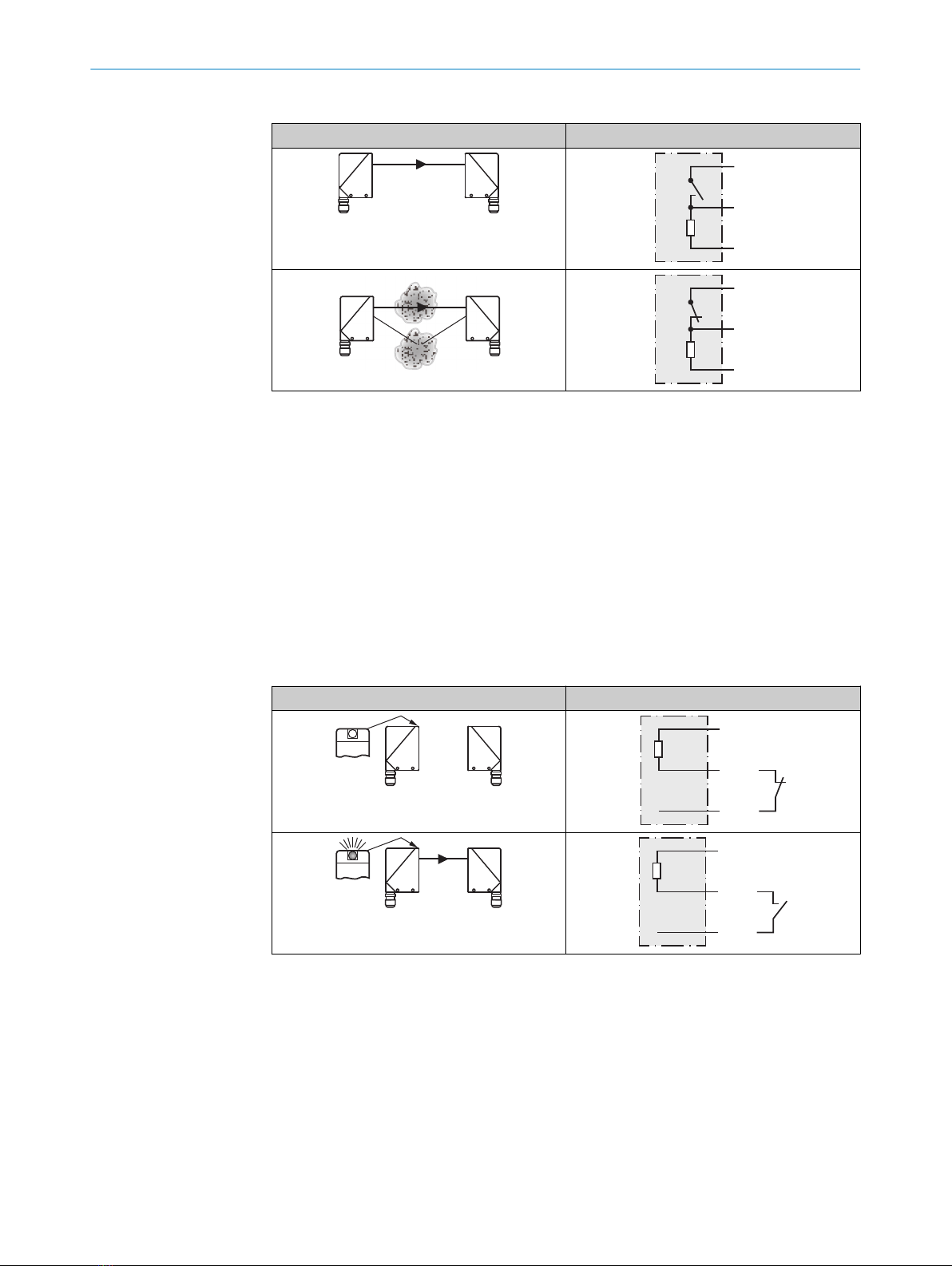

Mount sensors (sender and receiver) using suitable mounting brackets (see the SICK

range of accessories). Align the sender and receiver with each other.

NOTE

Swap the sender and receiver arrangement at every second through-beam photoelec‐

tric sensor and ensure that there is sufficient distance between the through-beam pho‐

toelectric sensors.

Receiver (WE)

Receiver (WE)

Sender (WS)

Sender (WS)

Sender (WS)

Receiver (WE)

Figure 1: Arrangement of several through-beam photoelectric sensors

Note the sensor’s maximum permissible tightening torque of 2 Nm.

6 Electrical installation

The sensors must be connected in a voltage-free state. The following information must

be observed, depending on the connection type:

– Plug connection: note pin assignment: when the cover is open, the male connector

can be swiveled horizontally and vertically.

– Terminal connection: note the permissible cable diameter of 5 to 10 mm. When

the cover is open, the M16 fitting can be swiveled horizontally and vertically.

Unscrew the M16 fitting and remove sealing plug. Lead voltage-free supply cable

through and connect sensor in accordance with table 2 and table 5. Retighten

M16 fitting with seal so that the IP enclosure rating of the device is ensured.

5 MOUNTING

68009200.11O1 | SICK

Subject to change without notice