1 General safety notes

■Read the operating instructions before commissioning.

■

Connection, mounting, and configuration may only be performed by trained

specialists.

■

Not a safety component in accordance with the EU Machinery Directive.

■

Do not install the sensor at locations that are exposed to direct sunlight

or other weather influences, unless this is expressly permitted in the operating

instructions.

■These operating instructions contain information required during the life cycle of

the sensor.

2 Notes on UL approval

The device shall be supplied from an isolating transformer having a secondary overcur‐

rent protective device that complies with UL 248 to be installed in the field rated either:

a) max 5 amps for voltages 0 ~ 20 V (0 ~ 28.3 V peak), or

b) 100 / Vp for voltages of 20 ~ 30 V (28.3 ~ 42.4 V peak).

Alternatively, they can be supplied from a Class 2 power supply.

UL Environmental Rating: Enclosure type 1

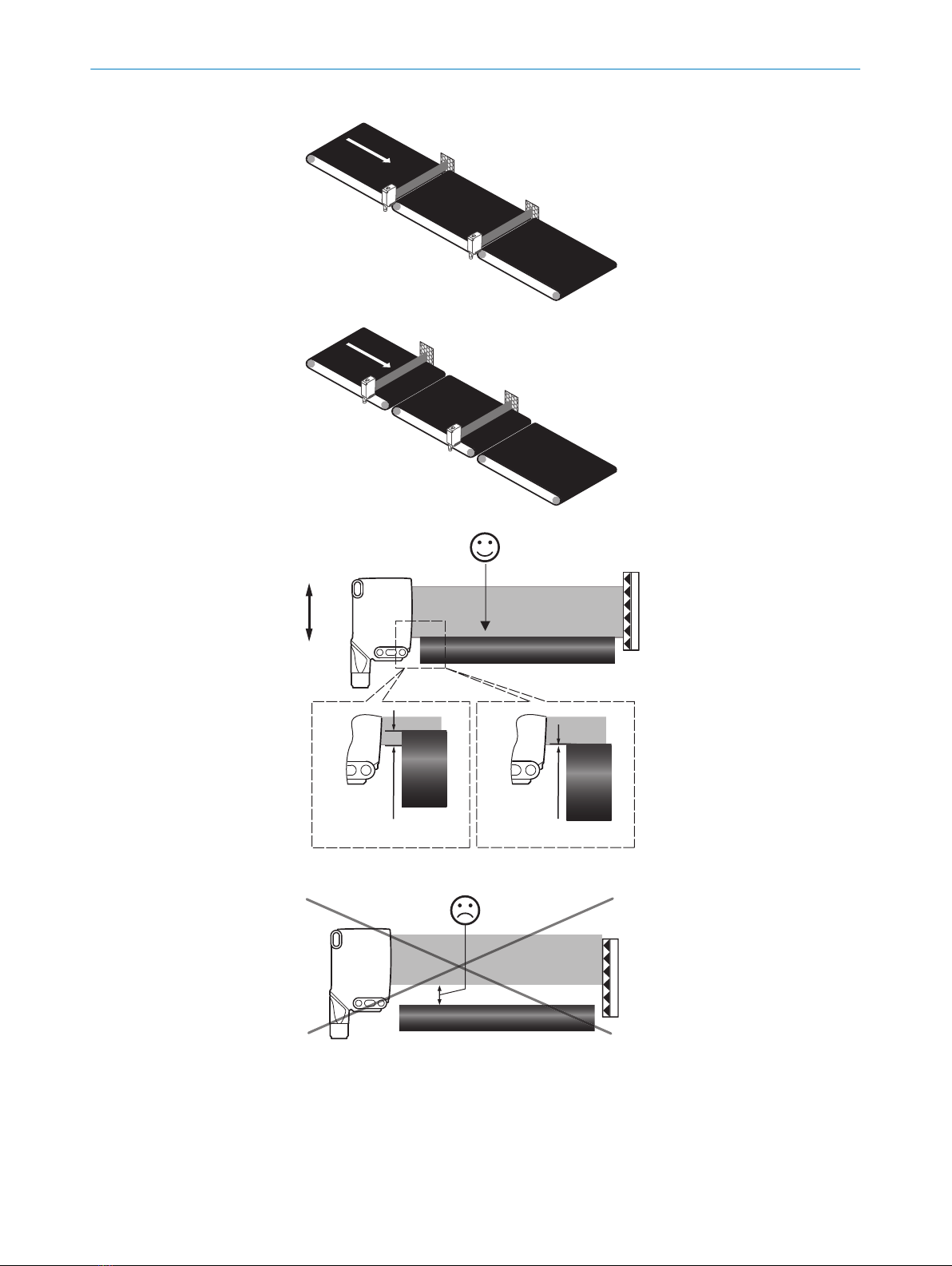

3 Intended use

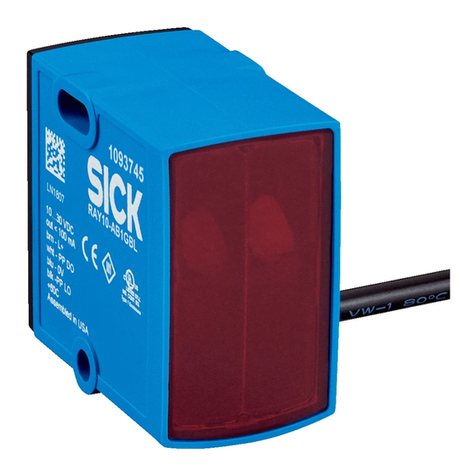

The RAY26 is an opto-electronic photoelectric retro-reflective sensor (referred to as

“sensor” in the following) for the optical, non-contact detection of objects, animals, and

persons. A reflector is required for this product to function. If the product is used for any

other purpose or modified in any way, any warranty claim against SICK AG shall become

void.

4 Operating and status indicators

1LED indicator green: supply voltage active

2BluePilot blue: AutoAdapt indicator during run mode

3Teach-in button

4LED indicator yellow: status of received light beam

GENERAL SAFETY NOTES 1

8022178.19RH 08.01.2021 | SICK

Subject to change without notice 5