Technical information

EFI

8012622/Z098/2016-11-07 © SICK AG • Industrial Safety Systems • Germany • All rights reserved 3

Subject to change without notice

Contents

Contents

1 About this document.................................................................................................... 5

1.1 Function of this document................................................................................5

1.2 Abbreviations used...........................................................................................5

1.3 Symbols used ...................................................................................................5

2 On safety.......................................................................................................................6

2.1 General safety notes and protective measures................................................6

3 Basics ........................................................................................................................... 7

3.1 Devices with EFI................................................................................................7

3.2 Function expansion by connecting ESPE..........................................................8

3.3 Function expansion using switching amplifiers ..............................................10

3.4 Applications with safety controllers................................................................11

3.5 Network solutions...........................................................................................12

4 Technical realization..................................................................................................13

4.1 Data exchange via EFI ....................................................................................14

4.1.1 Addressing.....................................................................................15

4.1.2 Sending and receiving of information............................................16

4.2 Firmware compatibility of the EFI devices ......................................................17

4.2.1 C4000 safety light curtain.............................................................17

4.2.2 M4000 multiple light beam safety device.....................................18

4.2.3 S300/S3000 safety laser scanners..............................................19

4.3 Description of the bytes and bits of the EFI communication ..........................19

4.3.1 Bytes of the EFI communication....................................................19

4.4 Status information and control options for the EFI devices............................26

4.4.1 C4000 safety light curtain.............................................................26

4.4.2 M4000 multiple light beam safety device.....................................28

4.4.3 S3000 safety laser scanner..........................................................29

4.4.4 S300 safety laser scanner ............................................................32

4.4.5 S300 Mini safety laser scanner.....................................................34

4.4.6 Flexi Soft FX3-CPU1, -CPU2, -CPU3 safety controller.....................36

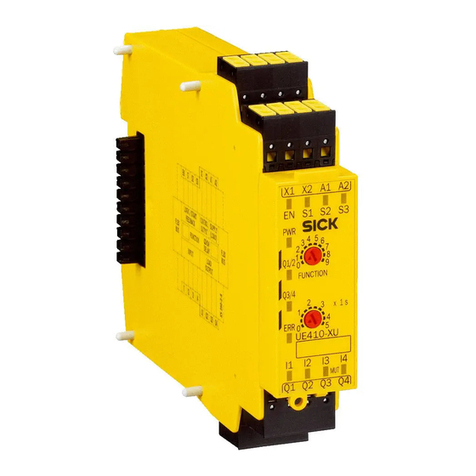

4.4.7 UE4740 EFI gateway.....................................................................37

4.5 Application examples......................................................................................38

4.5.1 EFI gateway with M4000 multiple light beam safety device .........38

4.5.2 EFI gateway with M4000 and UE403 switching amplifier.............39

4.5.3 EFI gateway with two S3000 safety laser scanners ......................40

4.5.4 EFI gateways with S3000 or S300 host/guest systems with

local inputs....................................................................................40

4.5.5 EFI gateway with two S300 safety laser scanners ........................41

4.5.6 EFI gateway with safety controllers ...............................................42

4.5.7 Flexi Soft safety controller with M4000 multiple light beam

safety device .................................................................................43

4.5.8 Flexi Soft safety controller with two S3000 or S300 Mini .............44

4.5.9 Flexi Soft safety controller with S3000 or S300 host/guest

system (with local inputs)..............................................................44