Contents

1 About this document........................................................................ 5

1.1 Further information................................................................................... 5

1.2 Explanation of symbols............................................................................ 5

2 Safety information............................................................................ 6

2.1 Intended use............................................................................................. 6

2.2 Improper use............................................................................................. 6

2.3 General safety notes................................................................................ 7

2.4 Notes on UL approval............................................................................... 7

3 Product description........................................................................... 8

3.1 General information.................................................................................. 8

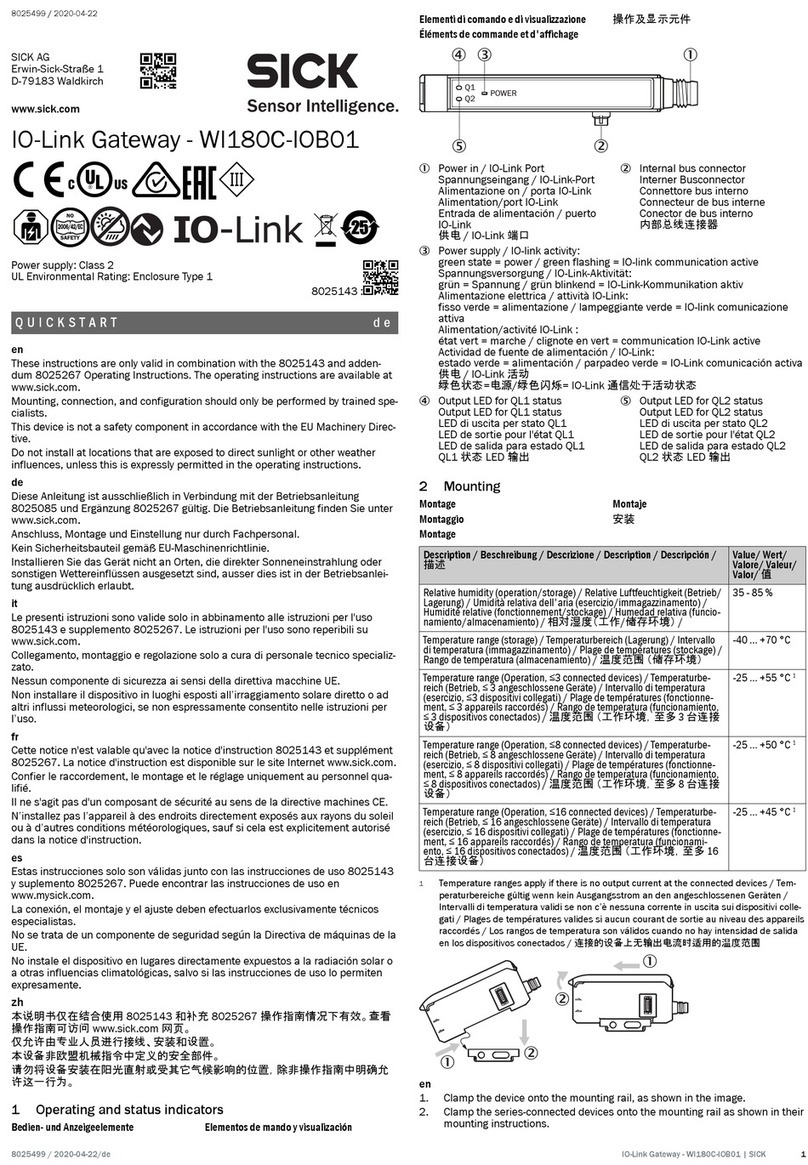

3.2 Operating elements and status indicators.............................................. 11

4 Transport and storage....................................................................... 15

4.1 Transport................................................................................................... 15

4.2 Transport inspection................................................................................. 15

4.3 Storage...................................................................................................... 15

5 Mounting............................................................................................. 16

5.1 Prerequisites............................................................................................. 16

5.2 Module mounting...................................................................................... 16

5.3 Mounting of functional earth................................................................... 17

5.4 Rotary switch cover................................................................................... 18

5.5 Scope of delivery....................................................................................... 19

6 Electrical installation........................................................................ 20

6.1 Electrical installation................................................................................ 20

6.2 Pin assignment......................................................................................... 20

6.3 Supply concept......................................................................................... 22

6.4 Derating..................................................................................................... 23

7 Commissioning.................................................................................. 24

7.1 IP address................................................................................................. 24

7.2 MAC address............................................................................................. 25

7.3 Rotary switch............................................................................................. 25

7.4 Data security............................................................................................. 26

8 Operation............................................................................................ 27

8.1 EtherNet/IP integration............................................................................ 27

8.2 Dual Talk.................................................................................................... 43

8.3 Web interface............................................................................................ 60

8.4 SOPAS Engineering Tool........................................................................... 70

9 Troubleshooting................................................................................. 73

CONTENTS

8027834./2022-06-10 | SICK O P E R A T I N G I N S T R U C T I O N S | Sensor Integration Gateway - SIG350 3

Subject to change without notice