5/44

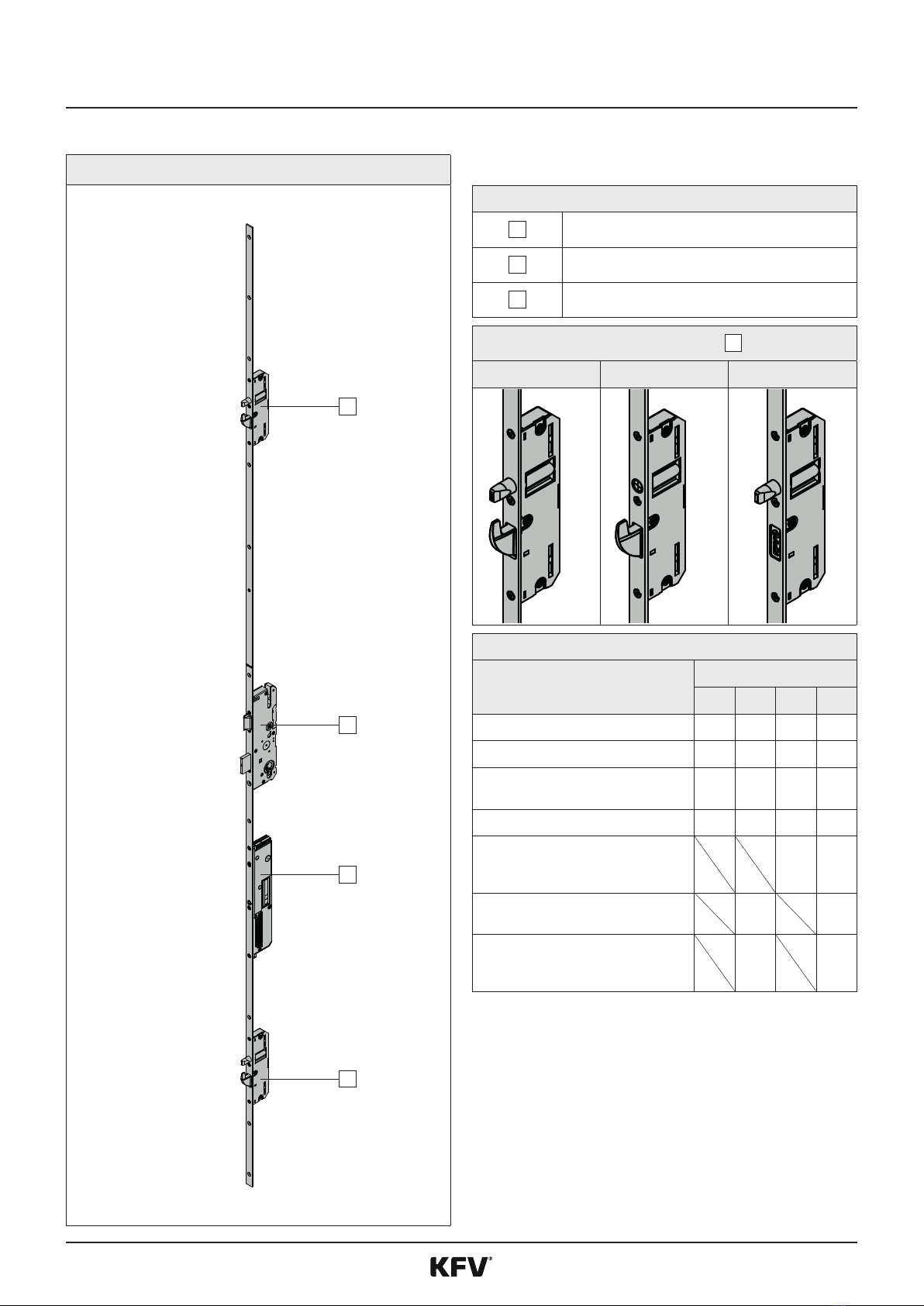

GENIUS 2.2, Electromechanical mul-point lock

5/4402.2020H39.ELEKS013EN-00

2

We assume and require that fabricators possess the

following knowledge and skills:

• knowledge of the regulaons concerning occupa-

onal safety and accident prevenon

• comprehension of technical correlaons according

to state-of-the-art science and technology

• knowledge of professional work steps

• knowledge of the applicable standards and direc-

ves

• knowledge of applicable tesng regulaons

• knowledge and skills with regard to material pro-

cessing of the respecve material (mber, PVC,

aluminium)

• knowledge and skills with regard to the professional

use of tooling, machines and systems for the pro-

ducon of door elements

• knowledge and skills with regard to the professional

xing of technical elements

• knowledge in funconal tesng and operaon of

door elements

• knowledge of the requirements of prole system

providers

If the door elements are equipped with an electrome-

chanical drive, the following knowledge and skills are

presumed and required:

• knowledge and skills with regard to the professional

fabricaon of electrical components

We assume and require that ers and retroers

possess the following knowledge and skills:

• knowledge of the regulaons concerning occupa-

onal safety and accident prevenon

• comprehension of technical correlaons according

to state-of-the-art science and technology

• knowledge of professional work steps

• knowledge of the applicable standards and direc-

ves

• knowledge and skills with regard to the professional

use of electrical and mechanical tooling

• knowledge and skills with regard to the professional

xing of technical elements

• knowledge and skills with regard to the retrot of

mechanical security technology on window or door

elements

If the door elements are equipped with an electrome-

chanical drive or a sensor, the following knowledge and

skills are presumed and required:

• knowledge and skills with regard to the professional

fabricaon of electrical components

• knowledge and skills with regard to the work steps,

connecng electrical components, commissioning

and funconal tesng

KFV oers training courses for the acquision of some

of the required knowledge and skills. Contact your KFV

sales consultant in case of requirement.

• The GENIUS 2.2 is suitable for installaon in mber,

aluminium, steel and PVC entrance doors.

• Use the GENIUS 2.2 as shown below:

– with a non-restricve cylinder in accordance with

DIN 18252 and the designaon „FZG“

– in vercal installaon

– in a technically sound condion

– only with original KFV products and accessories

• Do not use the GENIUS 2.2 as shown below:

– for escape doors in accordance with EN 179 or

EN 1125

– in doors for wet rooms or rooms in which the air

contains aggressive or corrosive components

• Do not interfere with and/or make any modica-

ons to the GENIUS 2.2.

• Foreign objects and/or materials which impede or

prevent proper use must not be placed within the

opening range, the locking system or the striker

plates.

• Locking elements must not be misused to hold the

door open.

• The transit support provided must remain in the

main lock during the transport of a pre-assembled

door without cylinder lock.

• In the installed and non-installed status of the mul-

-point lock, ensure that the locking elements are in

the release posion.

• Mul-point locks are sensive components and

must therefore be handled with care. For example,

they must not be thrown, hit hard or bent.

• Do not carry the door by the lever handle or hard-

ware when transporng it.