Siemens C65 Setup guide

Other Siemens Cell Phone manuals

Siemens

Siemens S46 User manual

Siemens

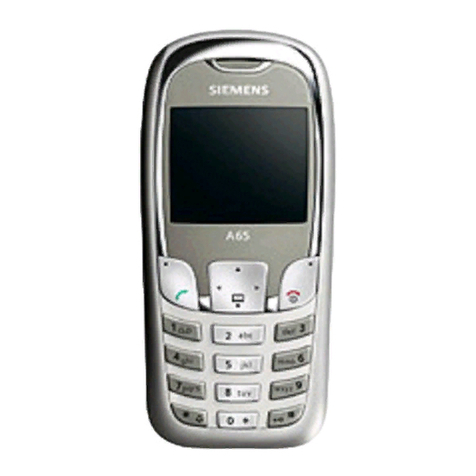

Siemens A65 User manual

Siemens

Siemens C72 User manual

Siemens

Siemens Gigaset Gigaset S1 User manual

Siemens

Siemens A31 User manual

Siemens

Siemens CF75 Setup guide

Siemens

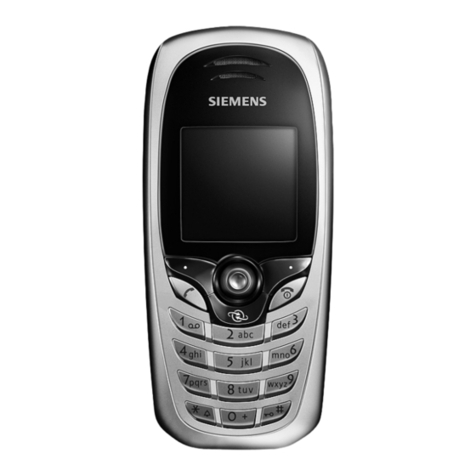

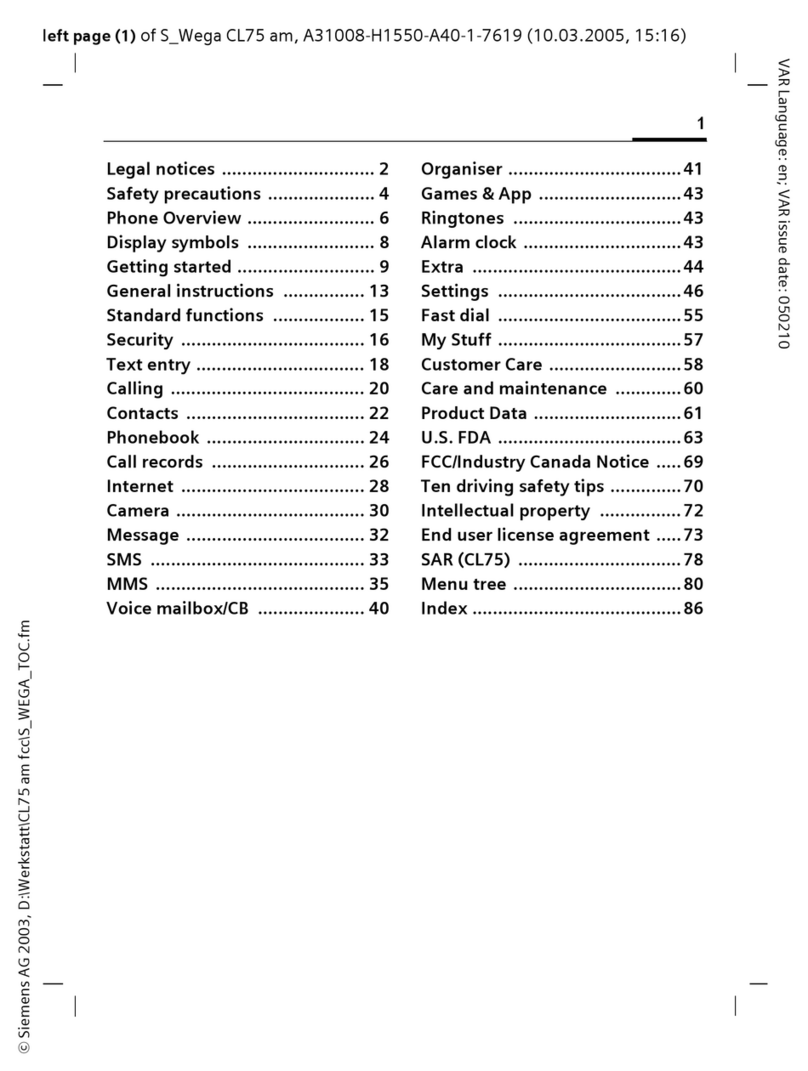

Siemens CL75 User manual

Siemens

Siemens RF182C User manual

Siemens

Siemens S75 User manual

Siemens

Siemens C25 User manual

Siemens

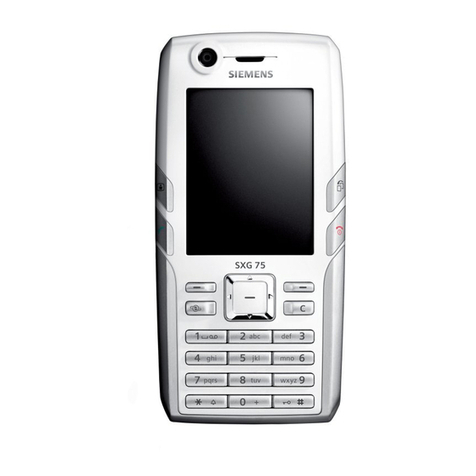

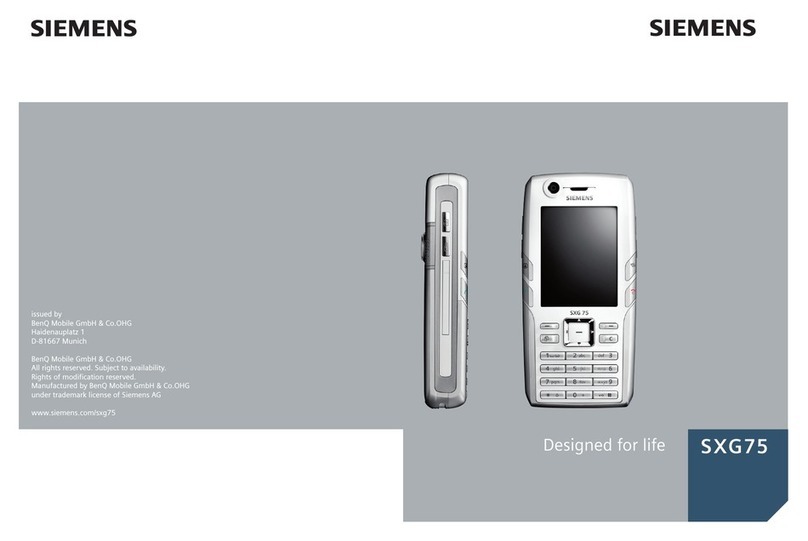

Siemens SXG75 Setup guide

Siemens

Siemens Gigaset SL55 User manual

Siemens

Siemens XELIBRI 2 User manual

Siemens

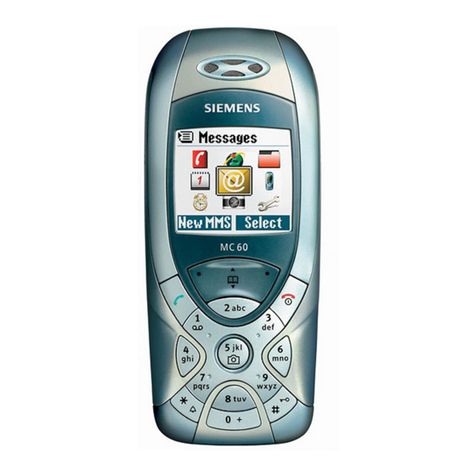

Siemens MC60 User manual

Siemens

Siemens SOMATOM Sensation Cardiac Version A60 User manual

Siemens

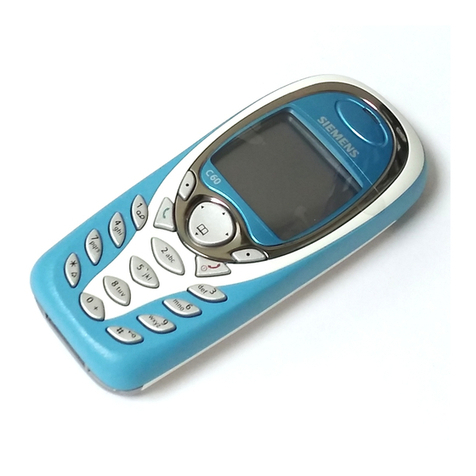

Siemens C60 User manual

Siemens

Siemens SXG75 User manual

Siemens

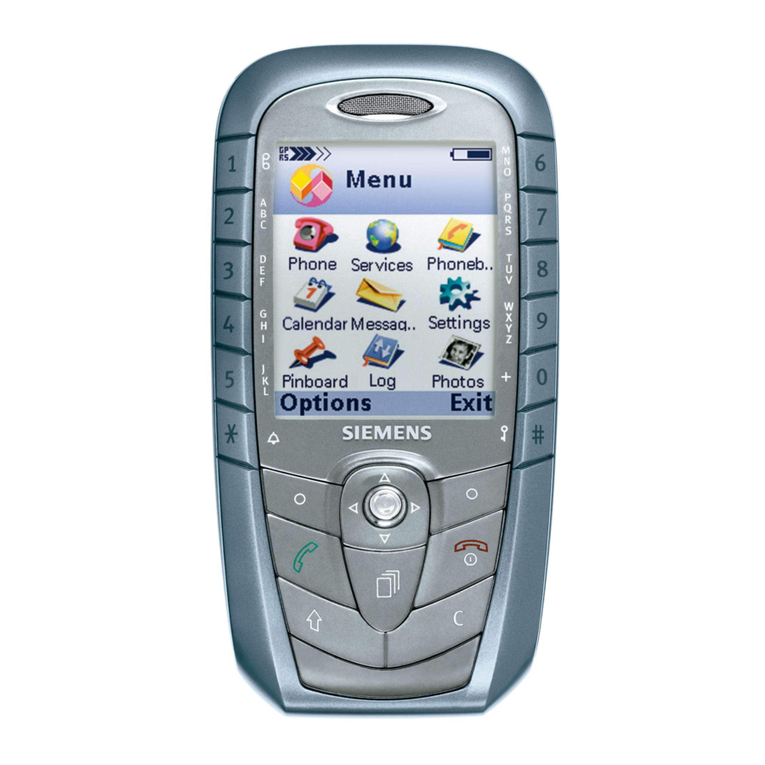

Siemens SX1 Operator's manual

Siemens

Siemens COM060 User manual

Siemens

Siemens A70 Setup guide