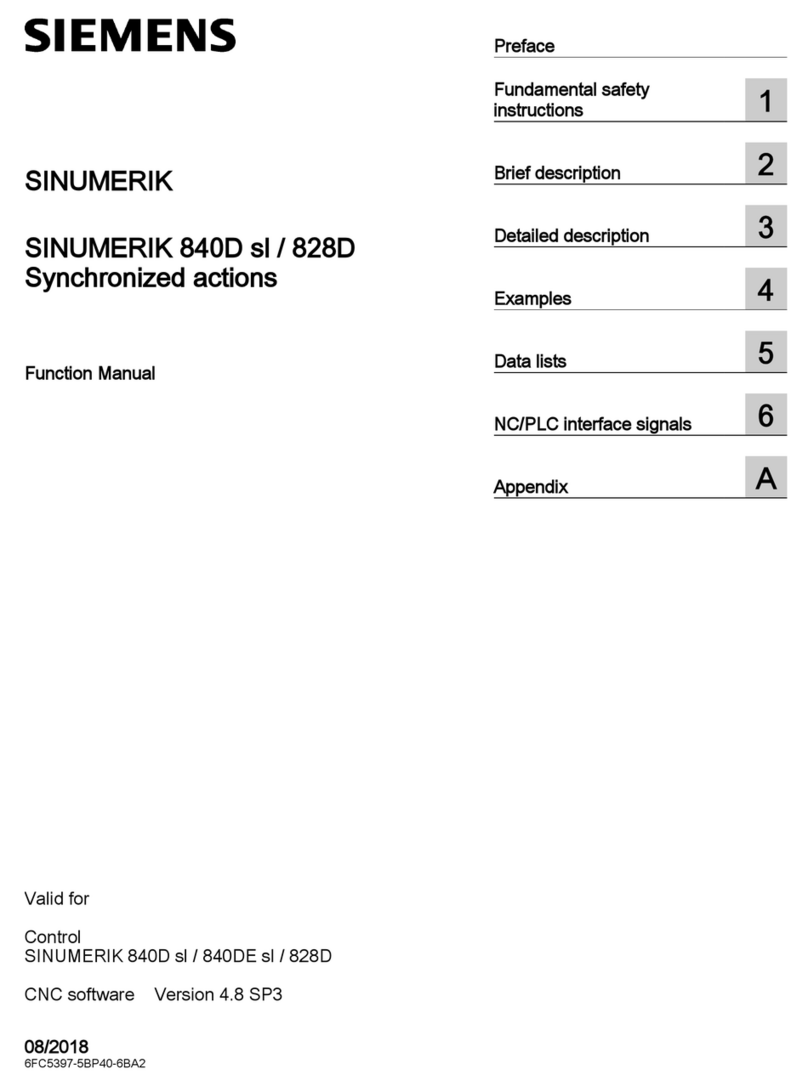

0

IHO

I2 * IHO

1.5 * IHO

3 s 57 s 240 s

300 s

t[s]

Load cycle 300 s based on

High Overload

t[s]

Load cycle 300 s based on

Low Overload

0

ILO

I1.5 * ILO

1.1 * ILO

3 s 57 s 240 s

300 s

*A5E35088648-AE*

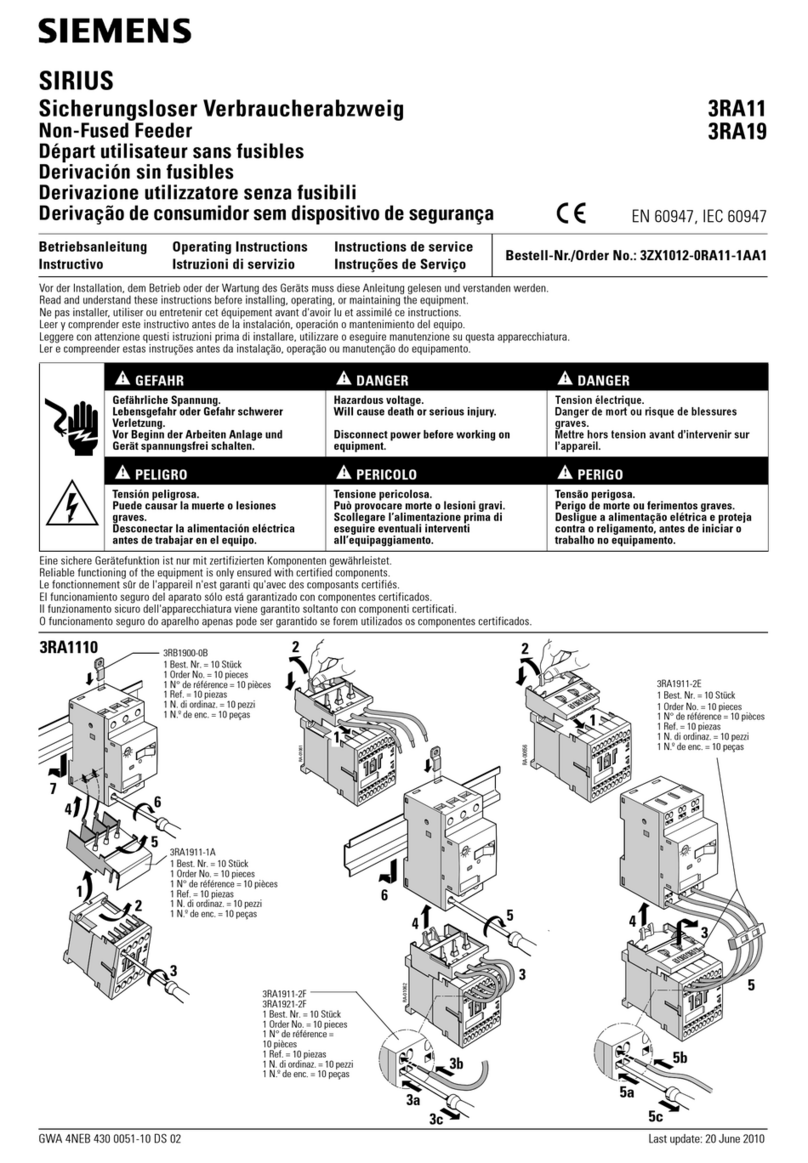

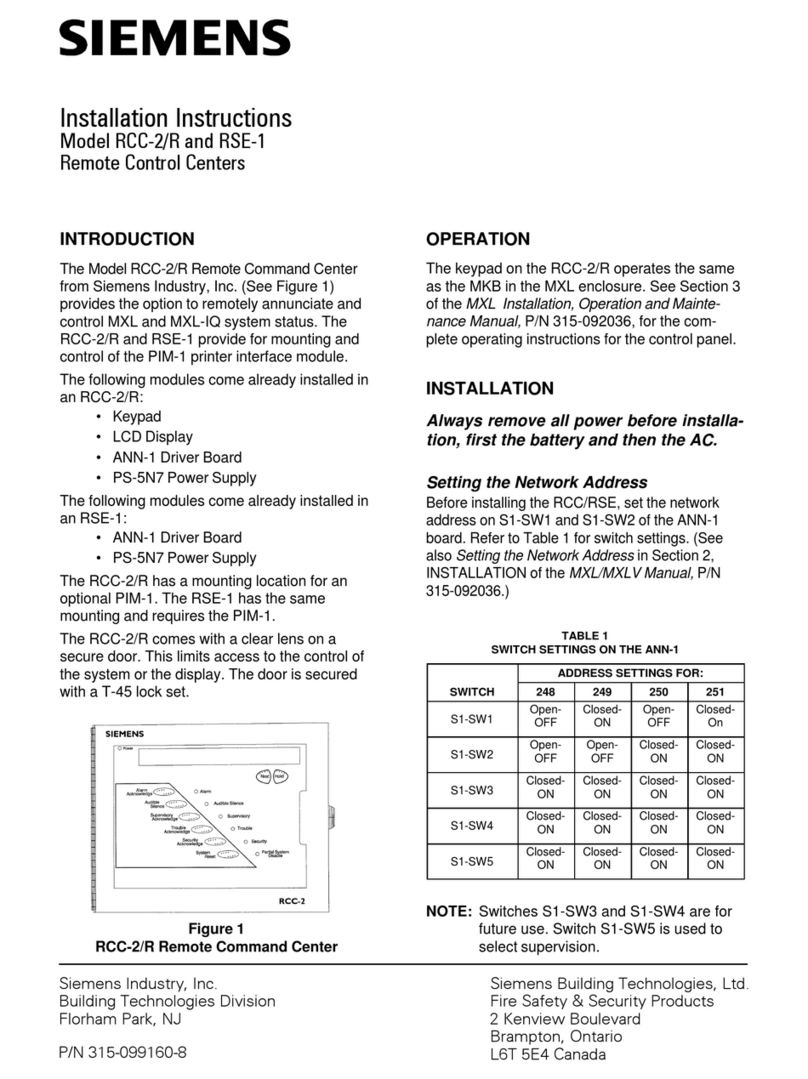

Lifting

1

2

3

Mounting lower shielding plate

Compact Operating Instructions SINAMICS G120

Power Module, PM240-2, FSD, FSE, FSF

Siemens AG,

Frauenauracher Str. 80,

DE-91056 Erlangen Issue 09/2015

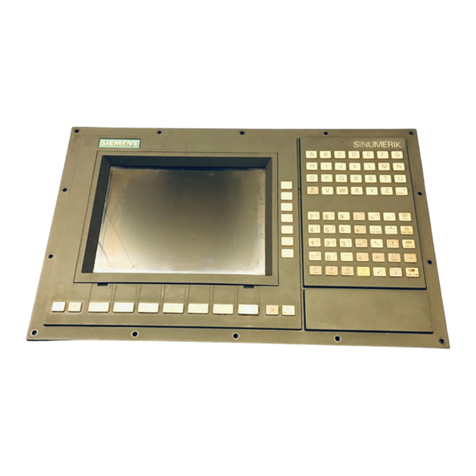

FSD

FSE

FSF

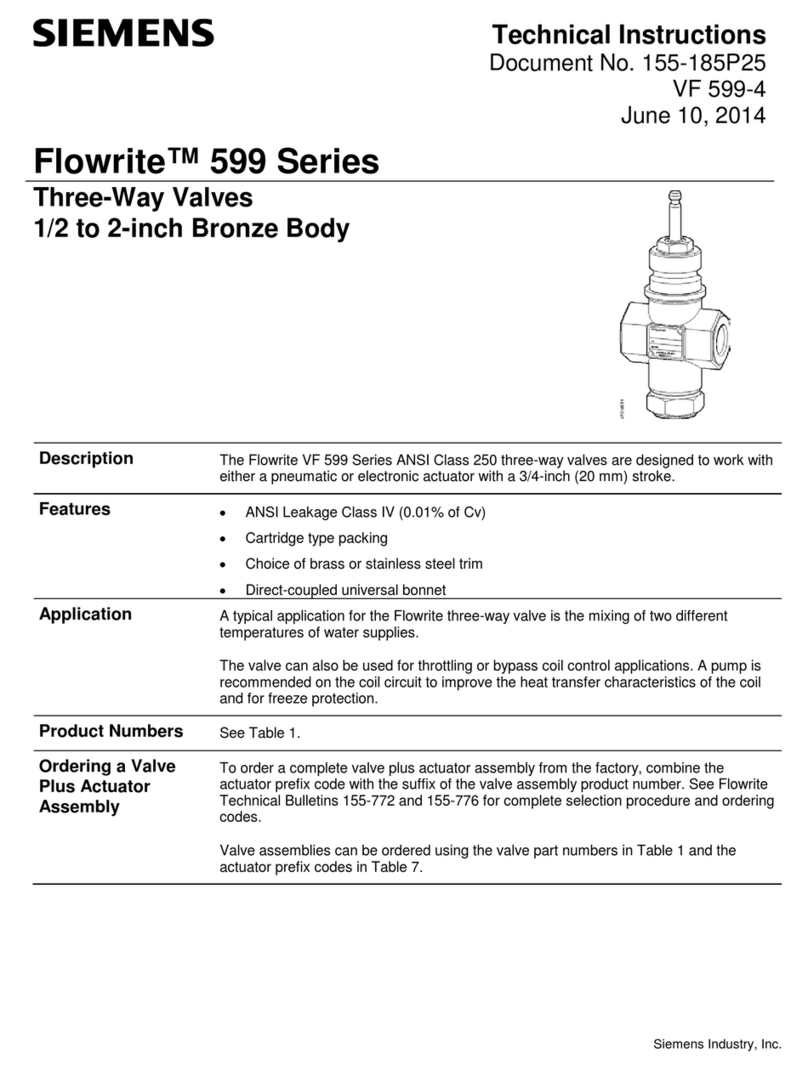

Contents of delivery

Compact Operating Instructions

CSA Warning labels for Canadian plants

EMC connection lug (separating plate)

Contact protection for Power connection

– if power connection not used

1) Increasing the pulse frequencies leads to an output current reduction. For more details refer to the Hardware Installation Manual.

2) The maximum surrounding air temperature is determined by the component (Power Module, Control Unit or Operator panel) with the

lowest maximum temperature

0 Hz … 550 Hz, depending on the control mode

Less than rated input current

(Increasable in 2 kHz steps 1))

200 V Units, factory setting: 4 kHz

setting range: < 37 kW: 4 kHz … 16 kHz

≥37 kW 4 kHz … 8 kHz

400 V Units, factory setting: < 75 kW 4 kHz

≥75 kW 2 kHz

setting range: < 55 kW: 2 kHz … 16 kHz

≥55 kW 2 kHz … 8 kHz

690 V Units, factory setting: 2 kHz

setting range: 2 kHz … 4 kHz

Electromagnetic compatibility

Filtered devices comply with EN 61800-3: 2012 and are suitable for Category C2 / C3. For more

details refer to the Hardware Installation Manual.

DC braking, Compound braking, Resistor braking

IP20 according to EN60529 (IEC) / open type (UL)

Motor overload protection

This equipment is capable of providing internal motor overload protection according to UL61800-5-1.

The protection level is 115 % of full load current of the equipment. This is adjusted via parameter

p0640 and assumes the equipment has had basic motor commissioning for the motor used as

described in the documentation.

2)

-20 °C … 40 °C (-4 °F … 104 °F) without derating / up to 60 °C (140 °F) with derating

- 40 °C … +70 °C (- 40 °F … 158 °F)

Installation altitude above sea level

Up to 1000 m (3300 ft) without derating / Up to 4000 m (13000 ft) with derating

< 95 % RH - non-condensing

Suitable for environmental class 3C3 according to IEC 60721-3-3 against damaging chemical

substances

Protected against pollution according to pollution degree level 2.

If protection against conductive pollution is required, the unit must be installed in an IP54 cabinet.

Long-term storage in the transport packaging according to Class 1M2 to EN 60721-3-1. Transport in

the transport packaging according to Class 2M3 to EN 60721-3-2. Vibration during operation

according to Class 3M2 to EN 60721-3-3

values

(LO)

input

current

Size

Line fuses, fuses for branch

circuit protection

Power

(IEC)

Output

current

Power

(IEC)

Output

current

acc. IEC/UL

Siemens 2)

class J

acc. UL

600 V ac

in

3 AC 200 … 240 V ± 10 %, U

out

in

* 0.95, brake output volt. 410 V

in

3 AC 380 … 480 V – 20 %, + 10 %, U

out

in

* 0.95, brake output volt. 820 V

in

3 AC 500 … 690 V – 20 %, + 10 %,

3)

out

in

* 0.95, brake output volt. 1210 V

1) _: A = filtered unit, U = unfiltered unit

2) must be installed in the same overall assembly

3) for UL applications 3 AC 500 V ... 600 V only

SCCR: The Short Circuit Current Rating of the supply circuit

shall not exceed 65 kA rms (Symmetrical Amperes),

240/480/600/690 Vac*) maximum, when protected by Listed

Class J Fuses or Semiconductor Fuses as referred in this

instruction manual.

*) value according to the voltage rating of the device; 690 V

are not applicable to Class J fuses)

The brake chopper is rated for 100 % inverter nominal

output power. Maximum load cycle will be 12 s nominal

power in a 240 s period. The brake chopper is protected by

a short circuit protection.

WARNING - The opening of the branch-circuit

protective device may be an indication that a fault current

has been interrupted. To reduce the risk of fire or electrical

shock, current-carrying parts and other components of the

controller should be examined and replaced if damaged. If

burnout of the current element of an overload relay occurs,

the complete overload relay must be replaced.

Applicable motors

Using 200 V or 400 V Power Modules, motors with a rated

current from 25 % … 150 % of the rated converter output

current can be used at full performance.

Using 600 V Power Modules, motors with a rated current

from 50 % … 150 % of the rated converter output current

can be used at full performance.

For United States / Canadian installations (UL/cUL):

The products are cULus listed under E192450.

Integral solid state short circuit protection does not provide

branch circuit protection. Branch circuit protection must be

provided in accordance with the NEC or CEC, Part I,

respectively, and any additional local codes. You find fuses

for branch circuit protection in the table on the right top of

this page.

Install power conductors sufficiently separated or isolated

against any low voltage circuits or other power circuits.

Use 60/75 °C copper conductors only.

On the brake resistor terminal of FSE use 75 °C rated

conductors only.

FSF line and motor terminals shall be connected with UL-

Listed (ZMVV) ring lugs with suitable voltage and current

rating (min. 125 % of input/output current).

For connecting the safety related function "Safe Torque

Off" (STO) or Brake Relay use 600 V insulated wire only.

Additional requirements for CSA compliance:

Overvoltage Category OVC III must be ensured for all

primary circuit connections of the equipment. This may

require Transient Surge Supression (SPD) to be installed

on the line side of the equipment. The voltage rating of the

SPD shall not be smaller than the supply voltage. It shall

provide protection for a rated impulse withstand voltage

peak of not more than the VPR shown in the table below.

For detailed information refer to Hardware Installation Manual PM240-2, Issue 08/2015 or younger under:

http://support.automation.siemens.com/WW/view/de/30563173/133300

For connecting the safety related function "Safe Torque

Off" (STO) or Brake Relay use 600 V insulated wire only.

Additional requirements for CSA compliance:

Overvoltage Category OVC III must be ensured for all

primary circuit connections of the equipment. This may

require Transient Surge Supression (SPD) to be installed

on the line side of the equipment. The voltage rating of the

SPD shall not be smaller than the supply voltage. It shall

provide protection for a rated impulse withstand voltage

peak of not more than the VPR shown in the table below.

For detailed information refer to Hardware Installation Manual PM240-2, Issue 08/2015 or younger under:

http://support.automation.siemens.com/WW/view/de/30563173/133300

Declaration of Conformity:

The Declaration of Conformity can be found at the following link:

http://support.automation.siemens.com/WW/view/en/30563514/134200

For connecting the safety related function "Safe Torque

Off" (STO) or Brake Relay use 600 V insulated wire only.

Additional requirements for CSA compliance:

Overvoltage Category OVC III must be ensured for all

primary circuit connections of the equipment. This may

require Transient Surge Supression (SPD) to be installed

on the line side of the equipment. The voltage rating of the

SPD shall not be smaller than the supply voltage. It shall

provide protection for a rated impulse withstand voltage

peak of not more than the VPR shown in the table below.

voltage

voltage

3 AC

200 … 240 V

3 AC

380 … 480 V

3 AC

500 … 600 V

For detailed information refer to Hardware Installation Manual PM240

http://support.automation.siemens.com/WW/view/de/30563173/133300