P.T.O.

instabus®

Technical Manual

Switch/Dimming Actuator

N526E02

5WG1 526–1EB02

June 2015 / Page 1

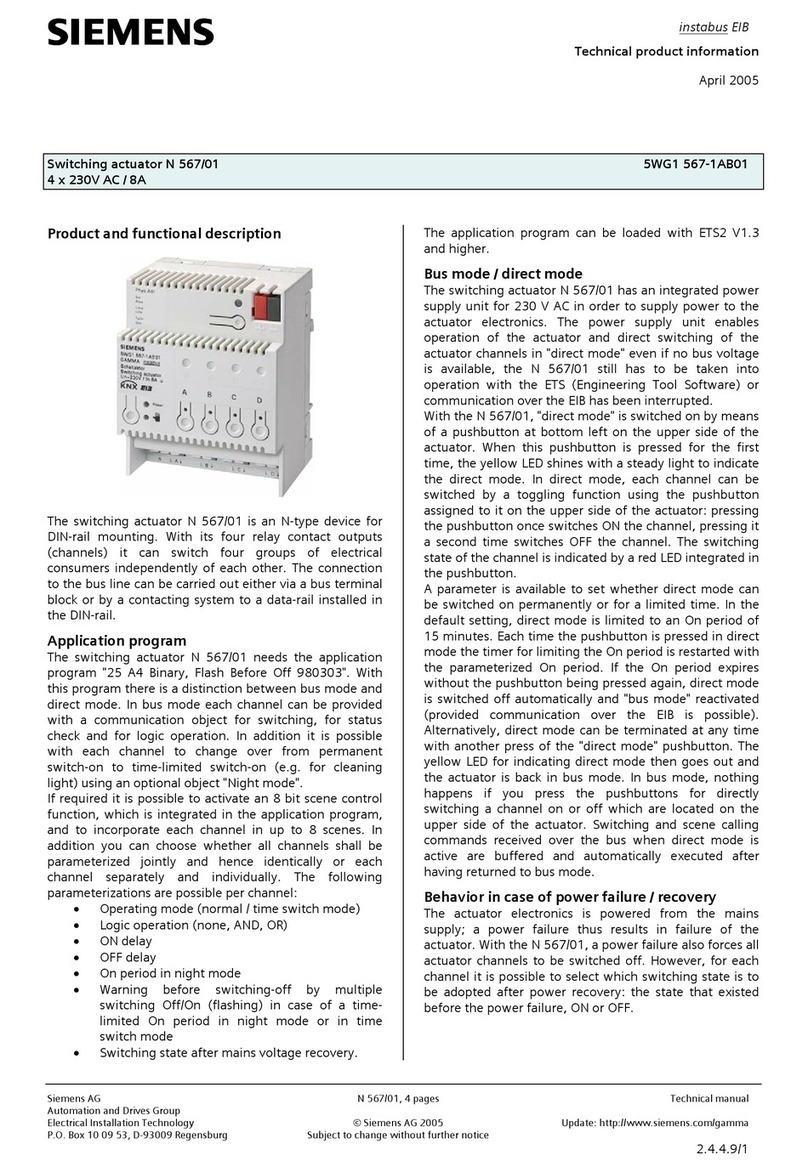

Product and Applications Description

The switching/dimming actuator N 526E02 is a N-

system DIN-rail mounted device for controlling up

to eight groups (channels) of fluorescent lamps via

the DC 1-10 V control terminal of dimmable elec-

tronic ballasts (e.g. ECG-Dynamic-type from Osram).

In addition there is per channel a switching contact

for direct switching on/off of the connected fluores-

cent lamps. This contact can be operated manually

via a slide switch which also indicates the actual

switching state of the channel (when switching

manually as well as when switching via the bus). A

channel is switched on when the slide is in the

lower position.

Different functions can be configured per channel

such as for switching on/off fluorescent lamps,

dimming up / down or setting a particular dimming

level.

With the ETS (Engineering Tool Software) the appli-

cation program is selected, its parameters and ad-

dresses are assigned appropriately and downloaded

into the switching/dimming actuator.

One channel of the N 526E02 switching/dimming

actuator can control several dimmable electronic

ballasts. Their number is limited by the switching

capacity and by the control power. If the on/off

function is not used via the switching contact of the

switching/dimming actuator, the number of control-

lable ECGs is only dependent on the load of the DC

1-10 V control voltage. This might allow to control a

larger number of ECGs (see Technical Specifications

below).

The power supply of the N 526E02 electronics is

provided via the bus (i.e. it requires no additional

power supply). When projecting an installation it

has to be considered that a N 526E02 represents a

double (and for short times even a triple) bus load

and takes up to 30 mA from the bus

.

Application Programs

The switching/dimming actuator N 526E02 works

only together with the application program 25 A8

Switch-/ Dimm Actuator 981301. This new applica-

tion program contains several modifications and

new functions (e.g. an integrated 8-bit scene con-

trol). The application program can be loaded from

ETS2 V1.3 onwards.

Technical Specifications

Power supply

·Bus voltage: DC 29V (Class 2) via the bus line

·Bus current:: Notice: the device represents at least a

double bus load and takes up to 30 mA from the bus.

Outputs

·8 outputs (latch relays, potential free contacts)

·rated voltage: AC 277 V, 50 ... 60 Hz

·rated current: 20 A, cos phi = 1

·switching current at AC 277 V: 0,1 ... 20 A, cos phi = 1

·DC switching current:

-DC 10 ... 30 V: max. 16 A, resistive load

- DC 230 V: max. 0,18 A, resistive load

·switching characteristic: to be set in parameter list (see

application program description)

Control voltage

·1 ... 10 V (provided by dimmable ballast)

·in case of bus voltage failure: 10 V

Control power

·dimmable electronic ballast: max 60 units

·signal amplifier: max 12 units

CAUTION

There is no protection of the control circuits against de-

struction by accidental connection to mains voltage!

Operating elements

·1 learning push button:

for toggling between normal mode/addressing mode

·8 slide switches for manual operation

(slide in upper position: relay contact open = OFF,

slide in lower position: relay contact closed = ON)

Display elements

·1 red LED:

for checking the bus voltage and for displaying normal

mode/addressing mode

·8 slide switches for displaying the switching position per

channel (see above)

Connections

·load and control circuit, physical:

insulation strip length 8 ... 9 mm

permissible conductor types/cross sections:

-0,5 ... 4 mm² single core

-0,5 ... 2,5 mm² flexible conductor

·load circuit, electrical:

-plain flexible conductor, min. 1 mm²:

current carrying capacity max. 6 A

-flexible conductor with terminal pin,

crimped on gas tight, min. 1,5 mm²:

current carrying capacity max. 10 A

-all other conductors, min. 1,5 mm²:

current carrying capacity max. 16 A

CAUTION

When looping through the L-conductor (connection blocks 1

and 2, 4 and 5, 7 and 8, 10 and 11, 13 and 14, 16 and 17,

19 and 20, 22 and 23), take care that the maximum connec-

tion current of 20 A (as governed by the maximum permissi-

ble printed conductor load) is not exceeded!

·Bus line:

-pressure contacts on data-rail

-screwless bus connection block,

Ø 0,6 ... 0,8 mm single core,

insulation strip length 5 mm

Physical specifications

·polymer casing

·N-system DIN-rail mounted device,

width: 8 MU (1 MU = 18 mm)

·weight: approx. 470 g (29oz)

·installation: rapid mounting on DIN rail complying with

EN 60715-TH35-7,5

Electromagnetic compatibility

complies with Part 15 of the FCC rules pursuant to the limits

for a Class A digital device

Environmental specifications

• ambient temperature operating: - 5 ... + 45° C (23...113°F)

• maximum ambient temperature range: - 25 ... + 70° C

(-13...158°F)

• relative humidity (non-condensing): 5 % to 93 %

Listings and Certifications

UL listed (E464611)

UL 916, Open Energy Management Equipment

CSA certified

CE marked

In accordance with the EMC guideline (residential and func-

tional buildings) and the low voltage guideline.

KNX / EIB certified

Markings

KNX, EIB, CE, UL

USA