Siemens Industry, Inc.

BuildingTechnologies Division

A6V10323926_a_en_--

These instructions are written in accordance with the installation

guidelines of NFPA 72, National Fire Alarm Code, The Installation

of Fire Alarm Systems.

CAUTION

Detection Device Storage

DO NOT install this detection device until all construction

is completed.

DO NOT store this detection device where it can be

contaminated by dirt, dust, or humidity.

DETECTOR PLACEMENT

Although no specific spacings are set for the detectors used for

a clean air application, use 30 foot center spacing (900 sq ft)

from NFPA Standard 72 initiating devices chapter, if practical,

as a guide or starting point for a detector installation layout.

This spacing, however, is based on ideal conditions–smooth

ceiling, no air movement, and no physical obstructions. In some

applications, therefore, considerably less area is protected

adequately by each smoke detector. This is why it is mandatory

to closely follow the installation drawings. In all installations place

the detector on the ceiling, a minimum of 6 inches from a side

wall, or on a wall, 6 inches from the ceiling.

If you have any questions regarding detector placement, follow

the drawings provided or approved by Siemens Industry, Inc.,

or by its authorized distributors. This is extremely important! The

detector placements shown on these drawings were chosen after

a careful evaluation of the area that is protected. Such factors

as air currents, temperature, humidity, pressure, and the nature

of the fire load were carefully considered. Especially noted were

the room or area configuration and the type of ceiling (sloped or

flat, smooth or beamed). Siemens Industry, Inc.’s extensive

experience in the design of the system assures the best detector

placement by following these drawings.

TO AVOID NUISANCE ALARMS

Do not locate the detectors where excessive smoke

concentrations exist under normal conditions, or in areas of

prolonged high relative humidity where condensation occurs.

Do not locate the detectors next to an oil burner, kitchen, or

garage where exhaust fumes can trigger an alarm. Other causes

of false alarms are dust accumulation, heavy concentrations of

steam, heavy pipe or cigar smoke, and certain aerosol sprays.

AIR CURRENTS

Before a detector can sense a fire, the products of combustion

or smoke must travel from the fire to the detector. This travel is

especially influenced by air currents; therefore, consider air

movement when designing the system. While combustion

products tend to rise, drafts from hallways, air diffusers, fans,

etc., may help or hinder the travel of combustion products to the

detector. When positioning a detector at a particular location,

give consideration to windows and doors, both open and closed,

to ventilating systems, both in and out of operation, and to other

factors influencing air movement. Do not install a detector in the

air stream of a room air supply diffuser. It is better to position a

detector closer to an air return.

The distance that products of combustion or smoke travel from

a fire to the detector is not usually the shortest linear route.

Combustion products or smoke usually rise to the ceiling, then

spread out. Average ceiling heights of 8 to 10 feet do not

abnormally affect detector response. High ceilings, located in

churches, warehouses, auditoriums, etc., do affect detector

response and should be considered.

SPECIAL CEILING CONSTRUCTION FACTORS

Ceiling obstructions change the natural movement of air and

combustion products. Depending on the direction of smoke

travel, joists and beams can slow the movement of heated air

and smoke, while pockets between them can contain a reduced

level of smoke. Take obstructions created by girders, joists,

beams, air conditioning ducts, or architectural design into

consideration when determining area protection. Refer to the

Initiating Devices chapter of NFPA Standard 72 for Location and

Spacing requirements for specific types of construction; e.g.

beam, suspended, level, sloped and peaked ceilings. The

detector is also compatible with the following mechanical

protection guard model: STI-9604 (see www.STI-USA.com for

details).

TEMPERATURE – HUMIDITY – PRESSURE – AIR

VELOCITY

The temperature range for the FDO421 detector is 32°F (0°C)

to 120°F (49°C). Use the detector in environments where the

humidity does not exceed 95% (non-condensing). Normal

changes of atmospheric pressure do not affect detector

sensitivity. The air velocity range is 0-4000 ft/min for open areas

applications and direct in air duct applications. Follow detector

spacing and location requirements in NFPA 72 Chapter for High

Air Movement Areas and Control of Smoke Spread.

LED INDICATOR OPERATION

The Model FDO421 contains an LED indicator capable of

flashing either one of three distinct colors: green, yellow, or red.

During each flash interval, the microprocessor-based detector

monitors the following:

• Smoke in its sensing chamber

• Smoke sensitivity is within the range indicated on the

nameplate label

• Internal sensors and electronics

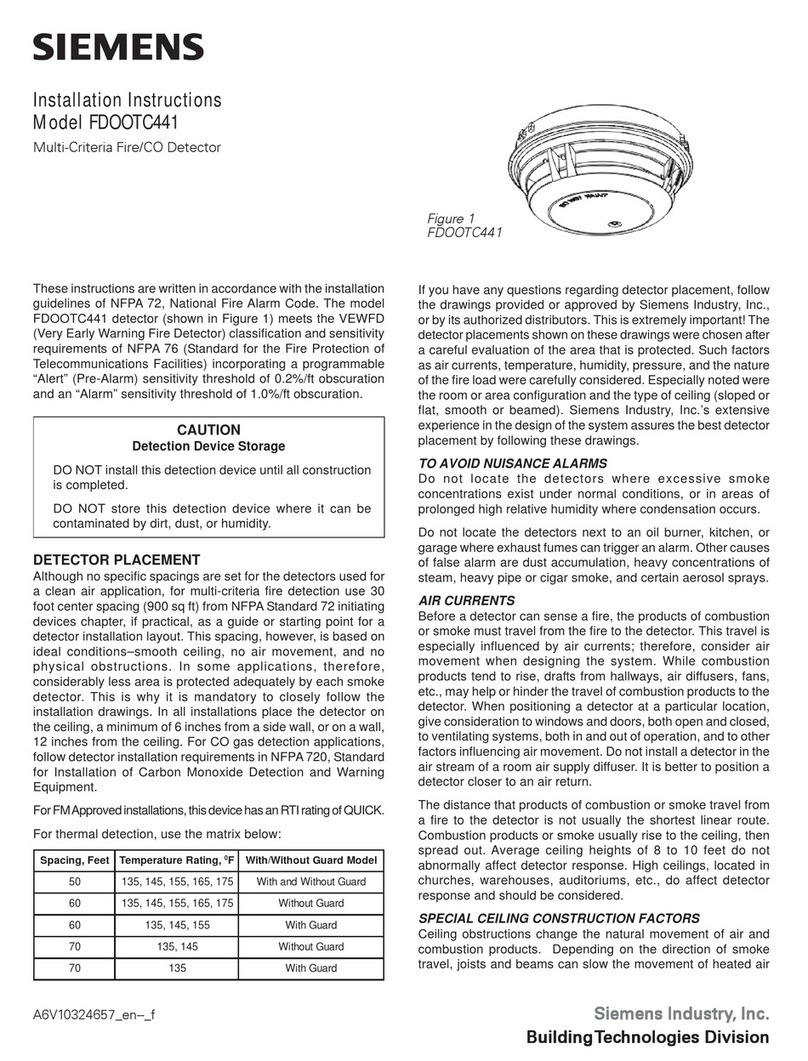

Photoelectric Detector

Installation Instructions

Model FDO421

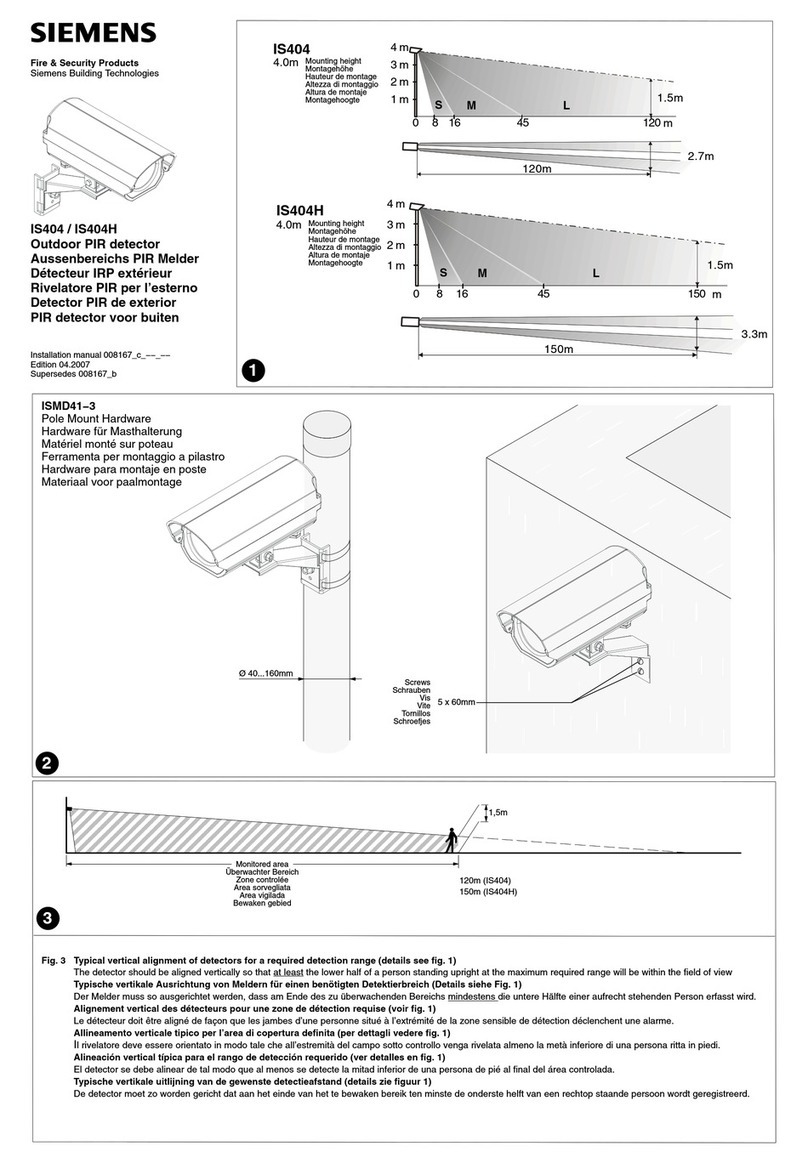

Figure 1

FDO421