5/6

Siemens Differential pressure sensor QBM4000…/ QBM4100… CE1N1919en01

Smart Infrastructure 2019-10-09

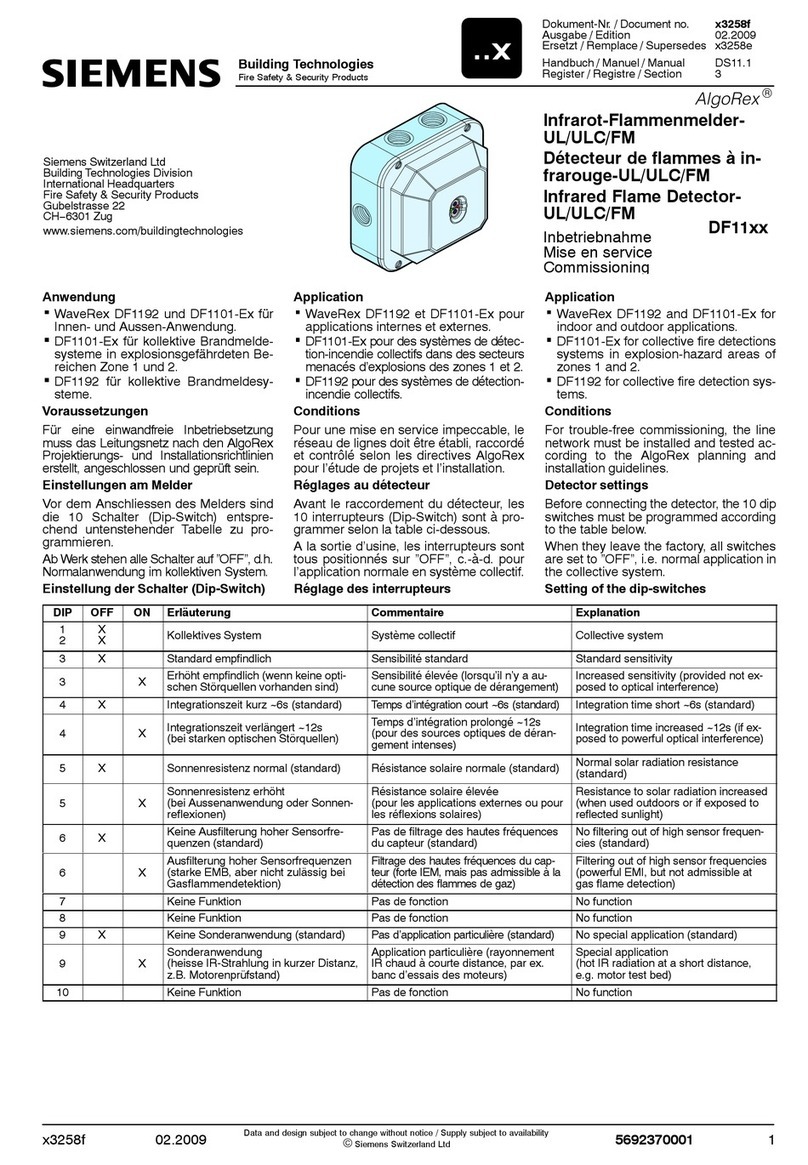

QBM4000-1

QBM4100-1D Zero point

Sum from linearity, reproducible and hysteresis.

TC zero point

<±1.0 % FS

<±1 % FS

<±0.1 % FS/°C

QBM4000-3 Zero point

Sum from linearity, reproducible and hysteresis.

<±0.7 % FS

<±1 % FS

<±0.05 % FS/°C

QBM4000-10

QBM4000-25

Zero point

Sum from linearity, reproducible and hysteresis.

<±0.7 % FS

<±1 % FS

<±0.04 % FS/°C

±1.0% FS as per DIN IEC 60 770

Response time

<20 ms

Tolerable overload on one side

on P1.

5,000 Pa

(10,000 Pa for types QBM4000 -10, -25)

Rupture pressure

at room temperature

2 × overload

Display (QBM4100-1D only)

LCD, 2-line, 8 position each, alphanumeric, not

background lit

Differential pressure in Pa.

Media

Admissible medium temperature.

Air and slightly aggressive gases

Degree of protection Protection degree of housing at recommended

IP54 according to EN 60529

III according to EN 60730-1

Connections Electrical connections 3-pin round plug with screw terminals 1.5 mm2

Pressure connections PVC nipples

6.2 mm, under pressure side is

designated as 'P2' or ' – '.

Environmental conditions Permissible ambient temperature

Operation

0...70 °C

Permissible ambient humidity

<90 % r.h. (without condensation).

Product standard EN 61326-1

Electrical equipment for measurement,

control and laboratory use. EMC require-

ments. General requirements

EU Conformity (CE)

CE1T1910xx_01 *)

*)

UL 60730-1 / UL 60730-2-6,

bility

The product environmental declaration

CE1E1916*) contains data on environmentally compat-

ible product design and assessments (RoHS compliance

, materials composition, packaging,

environmental benefit, disposal).

0.250 kg (with round plug connector).

Weight (with packaging), with display

0.263 kg (with round plug connector).

*) The documents can be downloaded from http://siemens.com/bt/download.