5

TECHNICAL DATA (continued)

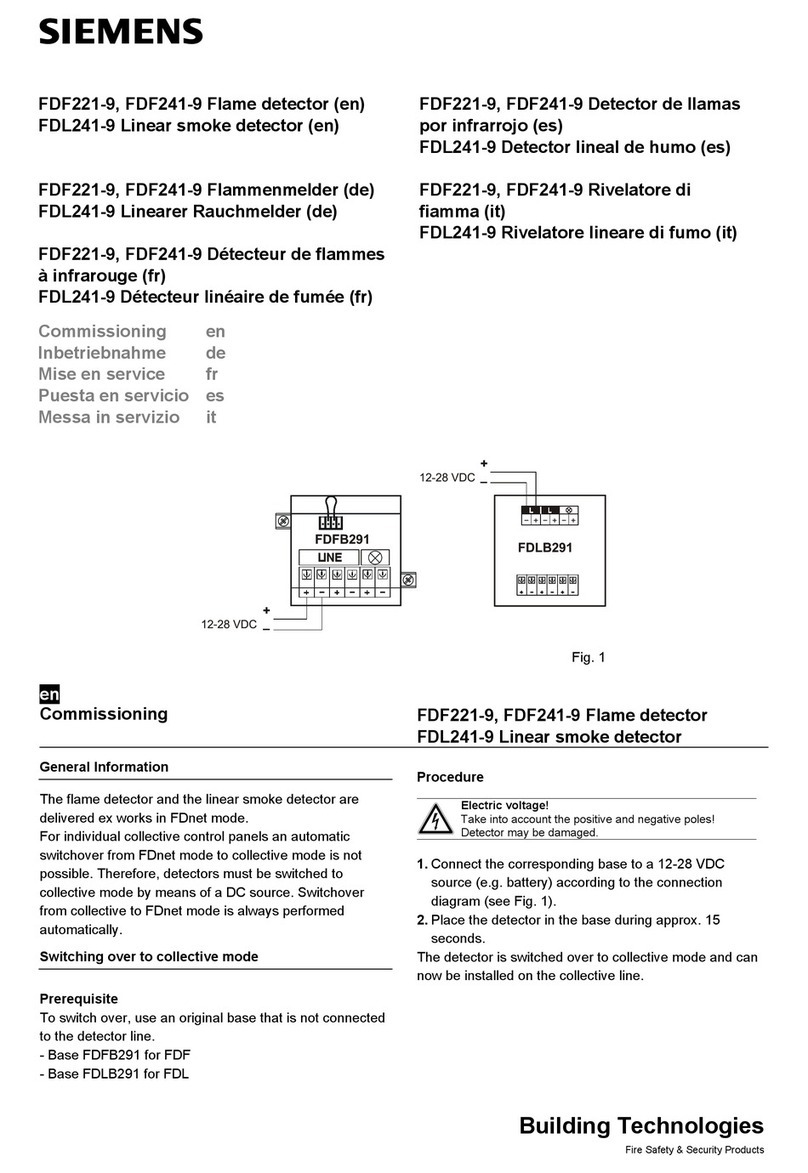

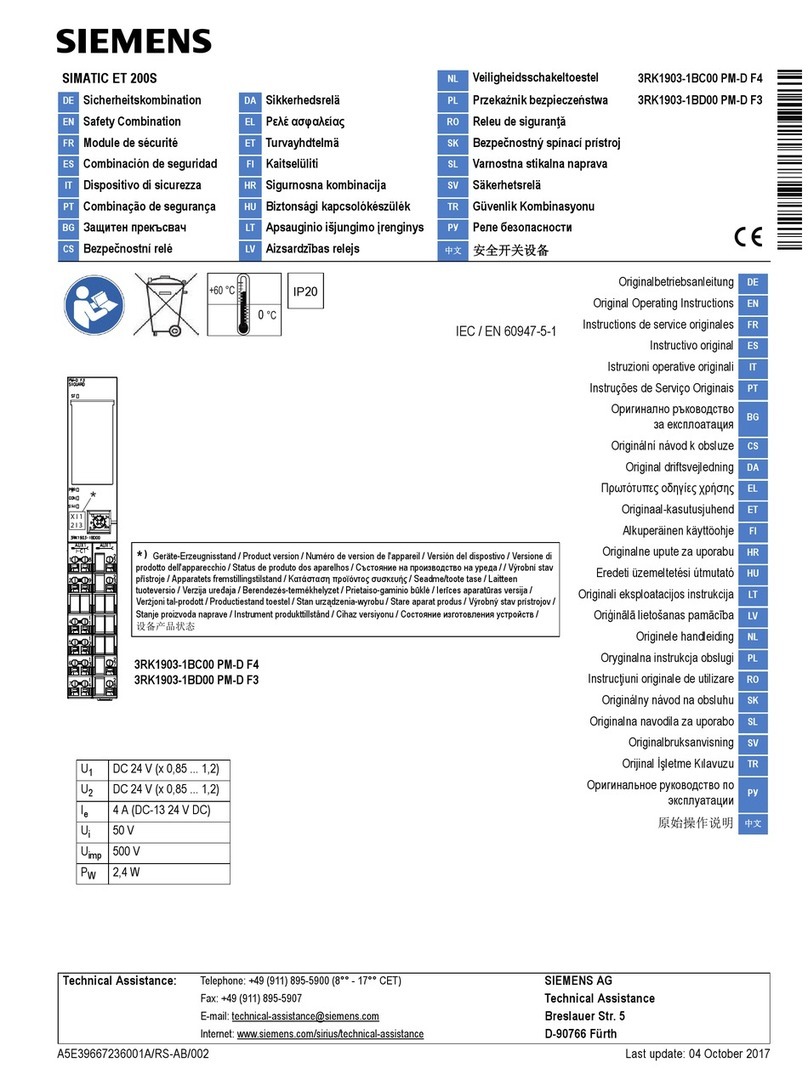

Electrical Connection Through base with screw/clamp

terminals

Physical Size 5e in (143 mm) width

(See Figure 1)

Electrical Wiring Two-wire 18 AWG thermoplastic

in conduit. 18 AWG limited energy

shield cable

Weight 1 pound (45 kilograms)

Maximum detectors per

circuit (ZN-30 or ZU-35) 5 detectors

APPLICATION DATA

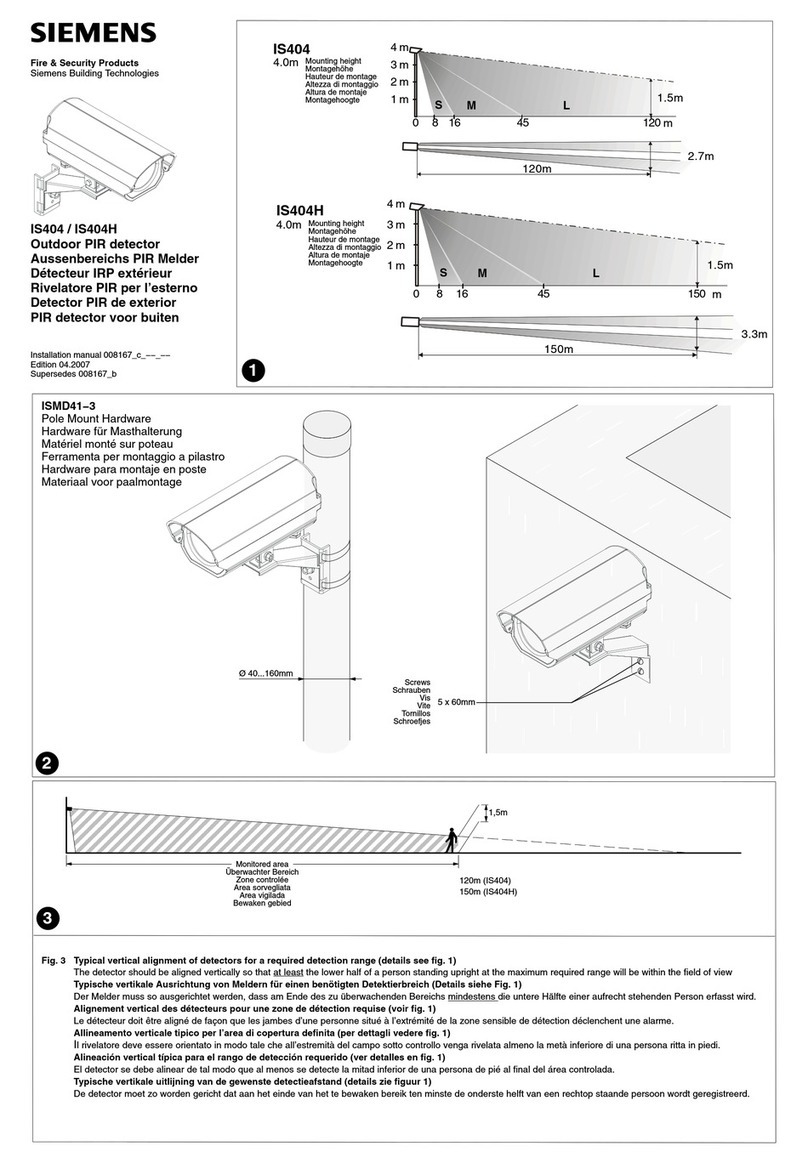

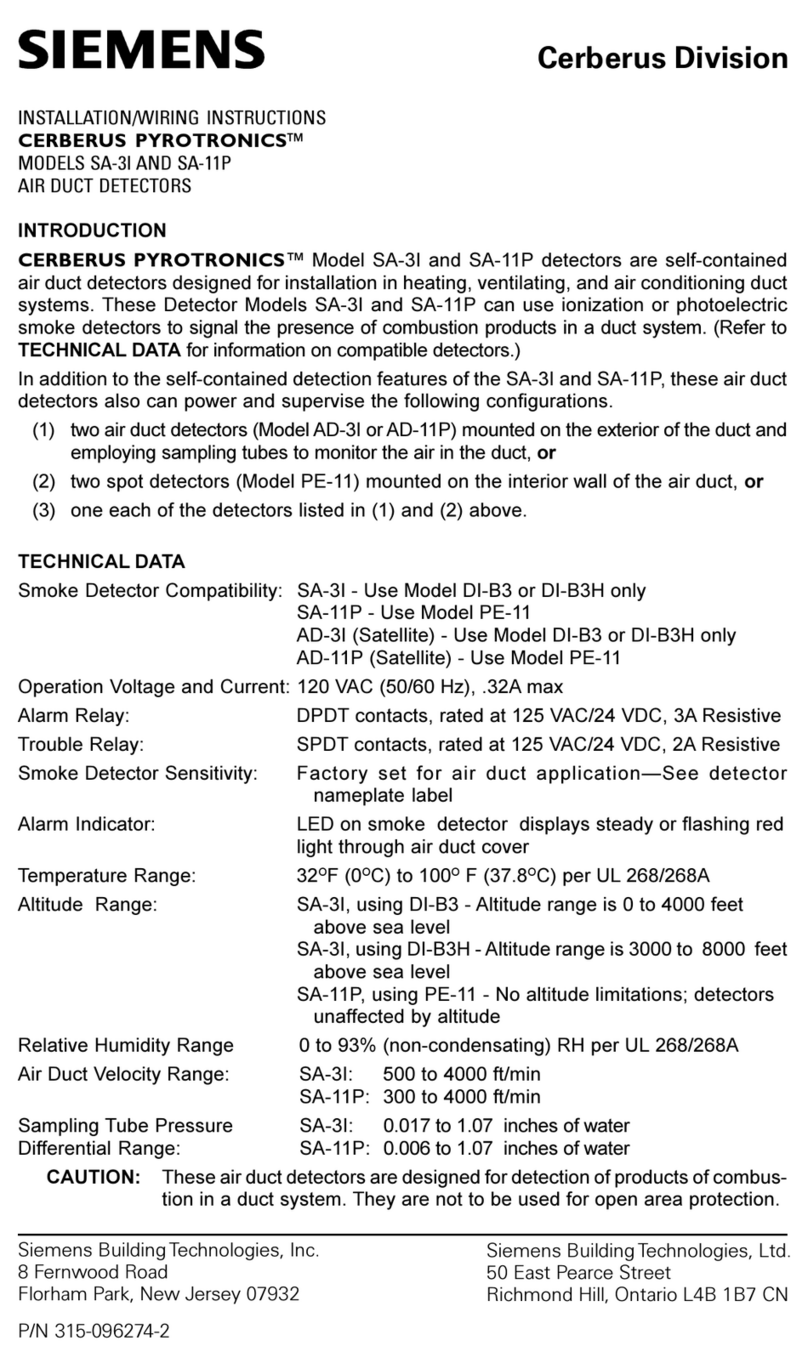

Flame detectors are essentially line-of-sight devices. That is, the

detector must be mounted where it can see the flame directly.

Pay particular attention to blind spots, such as intervening struc-

tural beams and columns, ducts, chutes, or belts. Any other

opaque objects or materials including heavy personnel traffic

must also be considered.

In hazards which include conveyor belts, the line-of-sight of the

detector must clear not only the belt, but a full conveyor load as

well.

Among the materials that are opaque (non-transmitting) to ultra-

violet radiation are ordinary glass and transparent plastics.

The DF-30 detector alarms after a 5-second view of a flame of

sufficient intensity and should be used in hazards where a fast

response is necessary, such as volatile material handling areas,

and where there are no other sources of ultraviolet rays which

may cause false alarms. The DF-30A responds after a 10-second

exposure to flame (at the design intensity) and can be used in

hazards where the fire is expected to develop at a slower rate.

Signal interference substances that must be considered are UV

absorbing gases and vapors. Ammonia is such a vapor, but others

of more importance in the industrial environment are toluene,

ethylene, and similar sol ents. Therefore, when considering

protection of equipment where paint is in use, be sure to con-

sider the concentrations of the sol ents present.