VACUUM SEALING BASICS

1. Foods that normally require

refrigeration or freezing should still

be refrigerated or frozen even when

vacuum sealed. Vacuum sealing will

help retain your food’s flavor and

texture. Vacuum sealing may not

stop the growth of certain kind of

bacteria and yeast fermentation.

Vacuum sealing is not a substitute

for heat preserving or canning.

Do not serve or consume food that

VACUUM SEALING BASICS

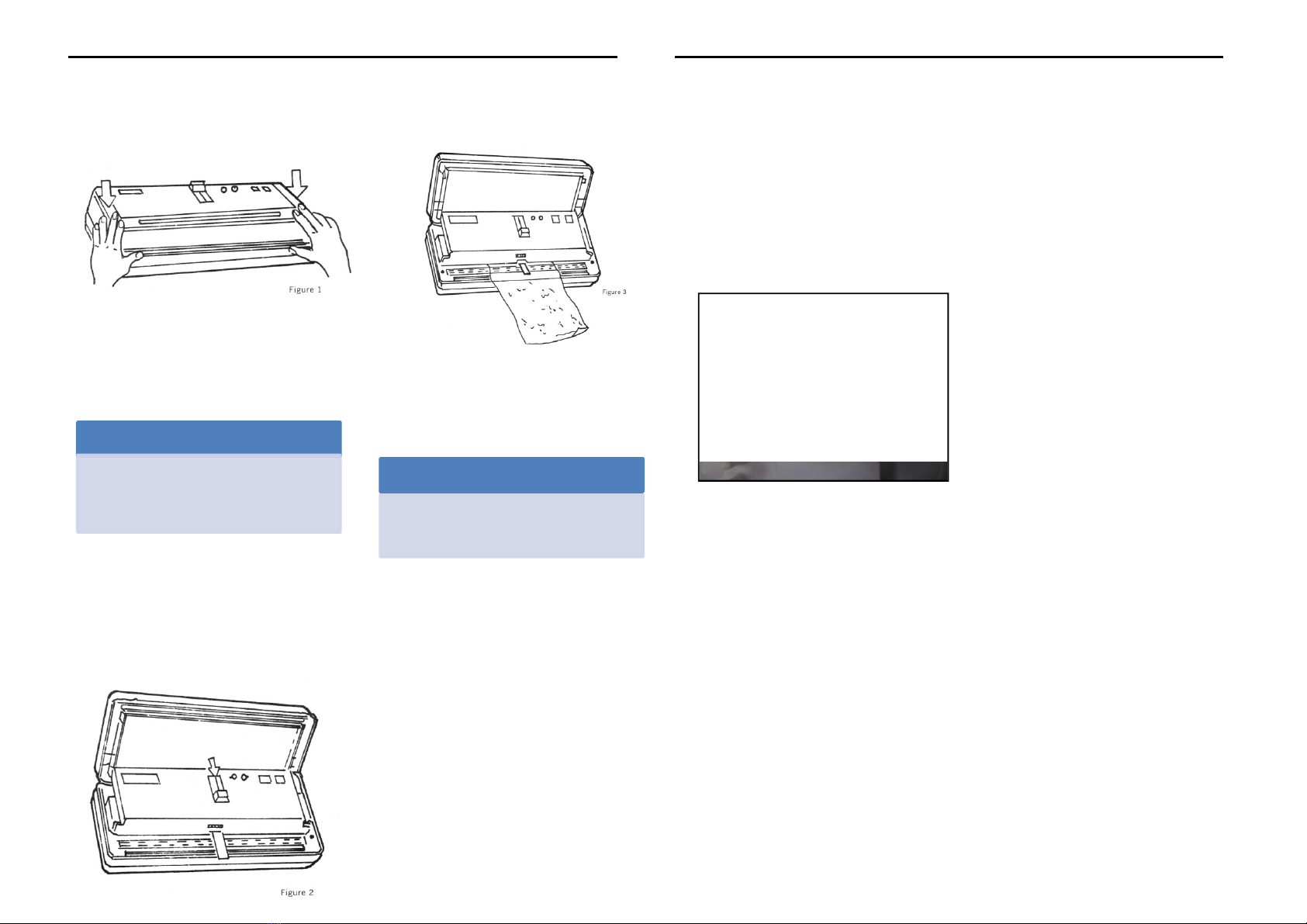

Vacuum sealing is an easy and convenient way to help preserve the freshness of your

food. FOOD STORAGE STANDARD

SHELF LIFE

VACUUM

SHELF LIFE

Large cuts of meat: beef,

poultry, lamb and pork

Freezer 6 months 2-3 years

Ground meat: beef, poultry,

lamb and pork

Freezer 4 months 1 year

Fish Freezer 4 months 1 year

Coffee beans Room temp 4 weeks 16 months

Berries: strawberries,

raspberries, blackberries

Refrigerator 1-3 days 1 week

Cheese Refrigerator 1-2 weeks 4-8 months

Cookies, crackers Room temp 1-2 weeks 3-6 weeks

Flour, sugar, rice Room temp 6 months 1-2 years

TIPS & NOTES

•Vacuum sealing is NOT intended to

replace refrigeration or freezing

•Do not reuse bags after exposure to raw

meat, fish, or poultry or if heated or

microwaved

Soups and Sauces

1. To vacuum seal soups and sauces,

place filled bag upright in freezer

and allow liquid to freeze. Remove

frozen bag and proceed with

vacuum.

2. Model DZ-280/2SE can seal

liquids as the sealer is

accompanied with a filter cup.

Fruit and Vegetables

1. For best results, fruits can be frozen

before vacuum sealing. Wash and

dry fruit. Freeze for about 2 hours

before vacuuming.

2. Frozen vegetables may sometimes

turn black if they are not blanched

before freezing.

Mushrooms need to breathe and

Do not serve or consume food that

has an odd odor, texture or

appearance.

Freezing

1. Vacuum sealing helps prevent

freezer burn by removing the air in

a bag.

2. For best results, thaw frozen foods

in a refrigerator. Never thaw raw

meats, fish, dairy or poultry at room

temperature. Thawing by

microwave may affect the texture of

foods. If thawing by microwave,

begin cooking process immediately

after thawing to prevent bacteria

growth.

Microwaving and Simmering

1. Do not reuse bags once used in

microwave or cooked in a pot.

Lettuce Refrigerator 3-6 days 2 weeks

Nuts Room temp 6 months 2 years

Mushrooms need to breathe and

should never be sealed in plastic.

Meats, Fish & Poultry

1. For best results, pre-freeze prior to

vacuum sealing for 1-2 hours to

retain moisture and shape of the

meat.

2. Vacuum sealing may cause meat to

darken. This is due to the removal

of oxygen and does not indicate

spoilage.

3. Do not reuse bags after exposure

to raw meat, fish or poultry.

Ground Coffee or Other Powders

1. Wrap paper towel around coffee or

place coffee in a bag or the original

packaging prior to vacuum sealing.

Source: Dr. G.K. York, Department of Food Science & Technology, University of California, Davis

Non Edible Items

Vacuum seal non edible items

1. Helps prevent oxidation and rust –

vacuum seal silver or any other

items which are sensitive to oxygen.

2. Keep items dry – pack items that

need to stay dry such as camping

items – matches, film, passport.

3. When vacuuming items with sharp

edges (spaghetti, silverware, etc)

protect bag from puncture by

wrapping item in cushioning

material.