5

Use top guard for every operation for which it can be used.

Do not reach in back of the saw blade with either hand to hold down or support the

workpiece, remove scraps, or for any other reason. The proximity of the spinning tile blade

to your hand may not be obvious and you may be seriously injured.

Always disconnect the power cord from the power source before making any

adjustments or attaching any accessories. You may unintentionally start the saw, leading

to serious personal injury.

Do not use the saw until the table is clear of all tools, scraps, etc., except the workpiece

and related feed or supported devices for the operation planned. Small debris or loose

pieces of tile or other objects that contact the revolving blade can be thrown with high speed

at the operator.

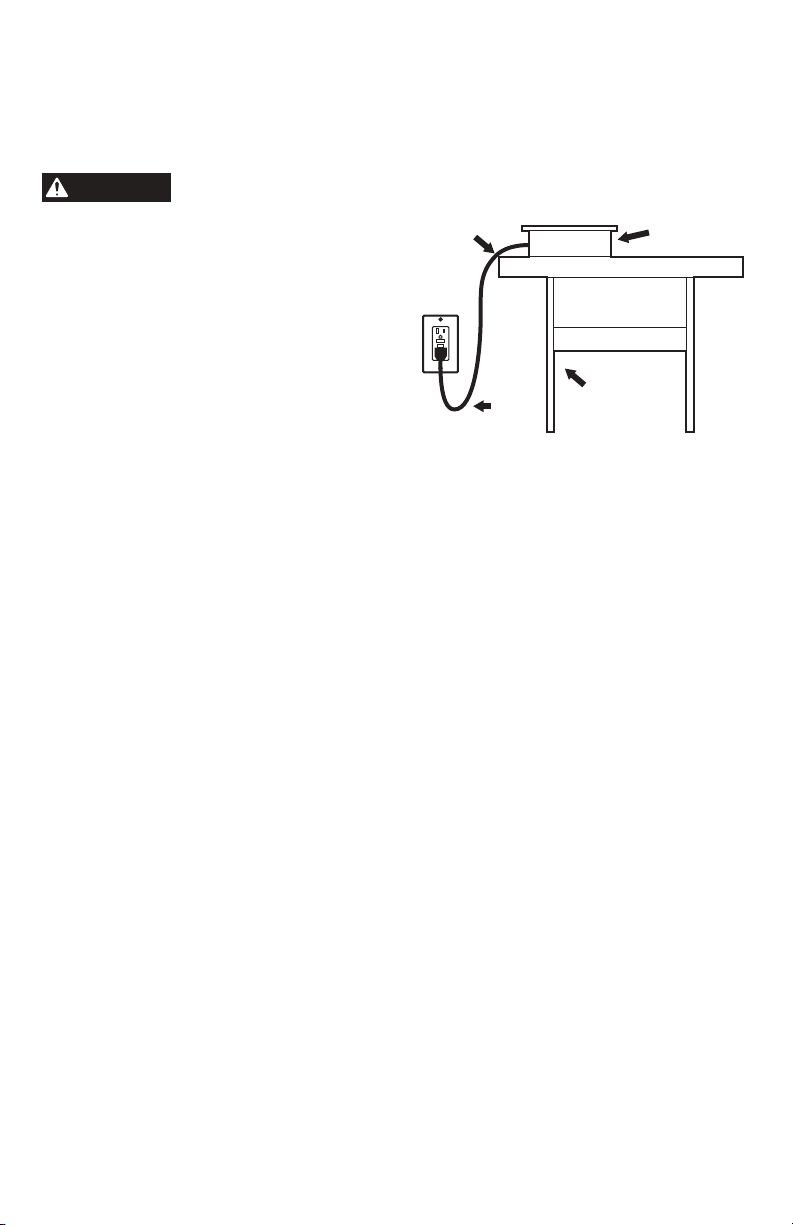

Empty water from tile saw base before transporting. Water left in base can splash into

electrical components.

Cut only one workpiece at a time. Multiple workpieces cannot be adequately clamped or

braced and may bind on the blade or shift during cutting.

Be certain the tile saw is mounted or placed on a level, rm work surface before using.

A level and rm work surface reduces the risk of the tile saw becoming unstable.

This tool is not equipped with provisions for attaching an auxiliary fence. Insure that the

work piece is supported by the fence before cutting.

Do not use another person as a substitute for a table extension or as additional

support. Unstable support for the workpiece can cause the blade to bind or the workpiece to

shift during the cutting operation pulling you and the helper into the spinning wheel.

The cutoff piece must not be jammed against or pressured by any other means against

the spinning tile blade. If conned, i.e. using length stops, it could get wedged against the

blade and thrown toward you.

Let the blade reach full speed before contacting the workpiece. This will help avoid

thrown workpieces.

If the workpiece or blade becomes jammed or bogged down, turn tile saw “OFF” by

releasing switch. Wait for all moving parts to stop and unplug the tile saw, then work

to free the jammed material. Continued sawing with jammed workpiece could cause loss of

control or damage to tile saw.

WARNING Some dust created by power sanding, sawing, grinding, drilling, and

other construction activities contains chemicals known to cause

cancer, birth defects or other reproductive harm. Some examples of these chemicals

are:

• Lead from lead-based paints,

• Crystalline silica from bricks and cement and other masonry products, and

• Arsenic and chromium from chemically treated lumber.

Your risk from these exposures varies, depending on how often you do this type of work.

To reduce your exposure to these chemicals: work in a well ventilated area, and work with

approved safety equipment, such as those dust masks that are specially designed to lter out

microscopic particles.

There are additional safety instructions for particular operations of the saw in the

operating section. Read the rest of the manual for safe operation.

Location

Use the tile saw in a well lit area and on a level surface, clean and smooth enough to reduce

the risk of trips and falls. Use it where neither the operator nor the casual observer is forced to

stand in line with the blade.