XT323-4-TFK57GB

Installation and Maintenance Manual

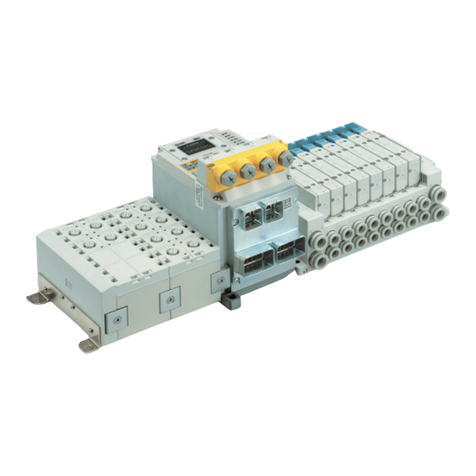

3 Port Solenoid Valve

XT323-4, XT323-4Y, XT323-4YF

1 Safety Instructions

• This manual contains essential information for the protection of users

and others from possible injury and/or equipment damage.

• Read this manual before using the product, to ensure correct handling,

and read the manuals of related apparatus before use.

• Keep this manual in a safe place for future reference.

• These instructions indicate the level of potential hazard by label of

“Caution”, “Warning” or “Danger”, followed by important safety

information which must be carefully followed.

• To ensure safety of personnel and equipment the safety instructions in

this manual and the product catalogue must be observed, along with

other relevant safety practices.

Warning

• The compatibility of pneumatic equipment is the responsibility of the

person who designs the pneumatic system or decides its specifications.

Since the products specified here can be used in various operating

conditions, their compatibility with the specific pneumatic system must

be based on specifications or after analysis and/or tests to meet

specific requirements.

• Only trained personnel should operate pneumatically operated

machinery and equipment.

Compressed air can be dangerous if an operator is unfamiliar with it.

Assembly, handling or repair of pneumatic systems should be

performed by trained and experienced personnel.

• Do not service machinery/equipment or attempt to remove

components until safety is confirmed.

1) Inspection and maintenance of machinery/equipment should only be

performed after confirmation of safe locked-out control positions.

2) When equipment is to be removed, confirm the safety process as

mentioned above. Switch off air and electrical supplies and exhaust all

residual compressed air in the system.

3) Before machinery/equipment is re-started, ensure all safety

measures to prevent sudden movement of cylinders etc. (Supply air

into the system gradually to create back pressure, i.e. incorporate a

soft-start valve).

• Do not use this product outside of the specifications. Contact

SMC if it is to be used in any of the following conditions:

1) Conditions and environments beyond the given specifications, or if

the product is to be used outdoors.

2) Installations in conjunction with atomic energy, railway, air

navigation, vehicles, medical equipment, food and beverage, recreation

equipment, emergency stop circuits, press applications, or safety

equipment.

3) An application which has the possibility of having negative effects on

people, property, or animals, requiring special safety analysis.

Caution

• Ensure that the air supply system is filtered to 5 microns.

2 Specifications

2.1 General Specifications

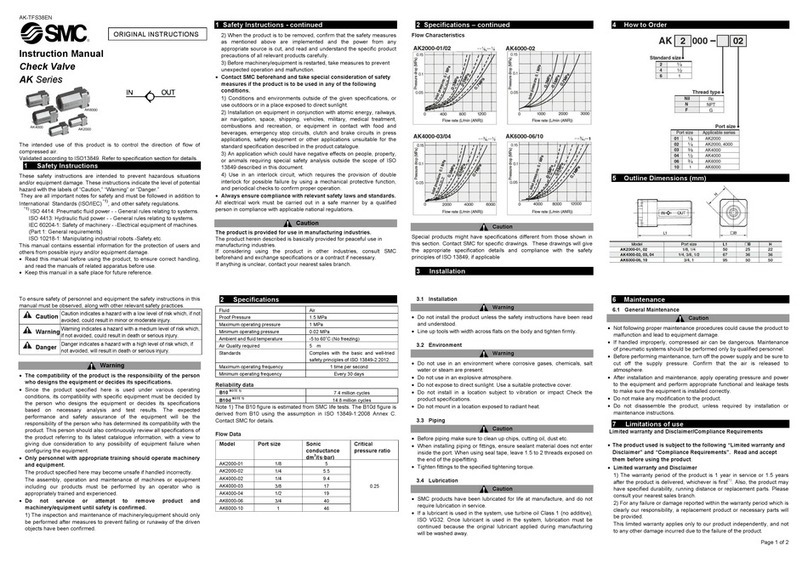

2.2 Symbol

2.3 Piping

3 Installation

3.1 Installation

Warning

• Do not install the product unless the safety instructions have been read

and understood.

3.2 Environment

Warning

• Do not use in an environment where the product is directly exposed to

corrosive gases, chemicals, salt water or steam.

• Do not use in an explosive atmosphere.

• The product should not be exposed to prolonged sunlight.

Use a protective cover.

• Do not mount the product in a location where it is subject to strong

vibrations and/or shock. Check the product specifications.

• Do not mount the product in a location exposed to radiant heat.

3.3 Piping

Caution

• Before piping make sure to clean up chips, cutting oil, dust etc.

• When installing piping or fittings, ensure sealant material does not enter

inside the port. When using seal tape, leave 1.5 to 2 threads exposed on

the end of the pipe/fitting.

• Tighten fittings according to appropriate tightening torque.

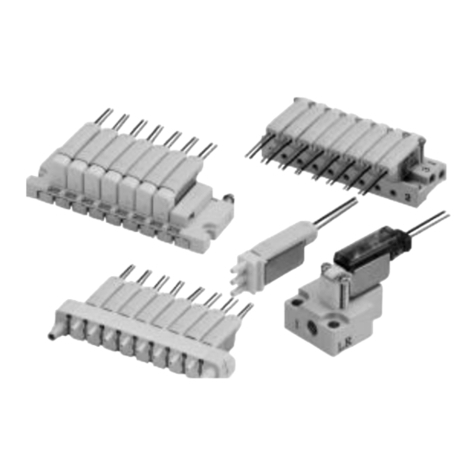

XT323-4

IN

IN

EXH EXH

OUT

Electrical

connection

Electrical

connection

OUT

XT323-4Y(F)

3 Installation (continued)

• The arrow on the base of the valve denotes the flow direction.

• Connect piping and fittings by holding the valve body with a spanner.

3.4 Electrical connection

Caution

• The coil of the XT323-4 has been designed for a fast response time so

cannot be continuously energized.

Thread Appropriate tightening torque (Nm)

XT323-4

XT323-4Y Rc1/8 7 to 9

XT323-4YF G1/8 See specification of fitting used

Seal

Tape

1.5 or 2 threads

Direction

of winding

Fitting

3.5 Mounting

Caution

• If air leakage increases or equipment does not operate properly,

stop operation.

After mounting or maintenance, connect the compressed air and power

supply, check for leakage and operate the valve to confirm that the unit is

mounted properly.

• Instruction manual

Mount and operate the product after reading the manual carefully and

understanding its contents. Keep the manual where it can be referred to

as necessary.

• Painting and coating

Warnings and specifications printed on the product should not be erased,

removed or covered.

• For mounting use the two threads in the base of the valve.

3.6 Lubrication

Caution

• SMC products have been lubricated for life at manufacture, and do not

require lubrication in service.

• If a lubricant is used in the system, use turbine oil Class 1(no additive), ISO

VG32. Once lubricant is used in the system, lubrication must be continued

because the original lubricant applied during manufacturing will be washed

away.

Thread Appropriate tightening torque (Nm)

6 Contacts

URL http://www.smcworld.com (Global) http://www.smceu.com (Europe)

Specifications are subject to change without prior notice from the manufacturer.

© 2009 SMC Corporation All Rights Reserved.

4 Maintenance

4.1 General Maintenance

Caution

• Not following proper maintenance procedures could cause the product

to malfunction and lead to equipment damage.

• If handled improperly, compressed air can be dangerous. Maintenance

of pneumatic systems should be performed only by qualified personnel.

• Before performing maintenance, ensure the supply pressure is shut off

and all residual air pressure is released from the system.

• After maintenance apply operating pressure and power to the

equipment and check for proper operation and possible air leaks. If

operation is abnormal, verify product set-up parameters.

• Do not make any modification to the product.

• Do not disassemble the product, unless required by installation or

maintenance instructions.

Please inquire to SMC.

5 Limitations of Use

Warning

• Do not exceed any of the specifications laid out in section 2 of this

document or the specified product catalogue.

Caution If instructions are not followed there is a

possibility of injury or equipment damage.

Warning If instructions are not followed there is a

possibility of serious injury or loss of life.

Danger In extreme conditions, there is a possibility of

serious injury or loss of life.

AUSTRIA (43) 2262 62280 NETHERLANDS (31) 20 531 8888

BELGIUM (32) 3 355 1464 NORWAY (47) 67 12 90 20

CZECH REP. (420) 541 424 611 POLAND (48) 22 211 9600

DENMARK (45) 7025 2900 PORTUGAL (351) 21 471 1880

FINLAND (358) 207 513513 SLOVAKIA (421) 2 444 56725

FRANCE (33) 1 6476 1000 SLOVENIA (386) 73 885 412

GERMANY (49) 6103 4020 SPAIN (34) 945 184 100

GREECE (30) 210 271 7265 SWEDEN (46) 8 603 1200

HUNGARY (36) 23 511 390 SWITZERLAND (41) 52 396 3131

IRELAND (353) 1 403 9000 UNITED KINGDOM (44) 1908 563 888

ITALY (39) 02 92711

Operating Fluid Air

Operating Pressure Range 0 ~0.7 MPa

Ambient and Operating

Air Temperature 5~60°C

Effective Sectional Area 10mm²

Port Size XT323-4, XT323-4Y Rc1/8

XT323-4YF G1/8

Mass XT323-4 116g

XT323-4Y, XT323-4YF 137g

Resistance 44Ω

Operating Voltage

Duty Ratio = Less than 50%

T1: Time per cycle, T2 Energizing time

Duty ratio is the percentage of energizing

time per cycle.

Duty Ratio = T2/T1x100%

Frequency 300~1500 c.p.m.