1. Type of fluids

Please consult with SMC when using the product in applications

other than compressed air.

2. When there is a large amount of drainage

Compressed air containing a large amount of drainage can

cause the malfunction of pneumatic equipment.An air dryer or

water separator should be installed upstream from filters.

3. Drain flushing

If condensation in the drain bowl is not emptied on a regular

basis, the bowl will overflow. This may cause the malfunction

of pneumatic equipment.

If the drain bowl is difficult to check and remove, the

installation of a drain bowl with an auto drain option is

recommended

For compressed air quality, refer to SMC’s Best Pneumatics

catalog.

4. Use clean air.

Do not use compressed air that contains chemicals, synthetic

oils that include organic solvents, salt, corrosive gases, etc.,

as it can cause damage or malfunction.

1. When extremely dry air is used as the fluid, degradation

of the lubrication properties inside the equipment

may occur, resulting in reduced reliability (or reduced

service life) of the equipment. Please consult with

SMC.

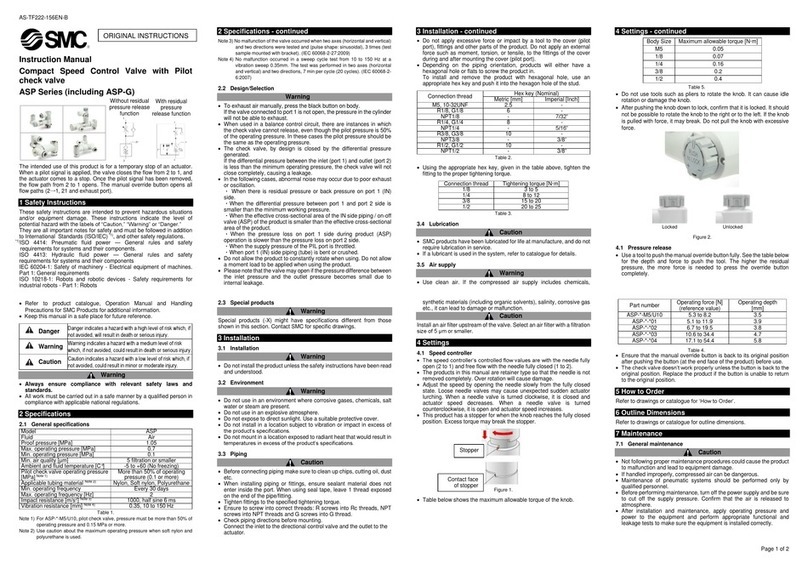

2. Install an air filter.

IInstall an air filter upstream near the valve. Select an air filter

with a filtration size of 5 μm or smaller.

3. Take measures to ensure air quality, such as by

installing an aftercooler, air dryer, or water separator.

Compressed air that contains a large amount of drainage can

cause the malfunction of pneumatic equipment, such as valves.

Therefore, take appropriate measures to ensure air quality, such

as by providing an aftercooler, air dryer, or water separator.

4. If an excessive amount of carbon powder is present,

install a mist separator on the upstream side of the

valve.

If excessive carbon dust is generated by the compressor, it

may adhere to the inside of a valve and cause it to malfunction.

For compressed air quality, refer to SMC’s Best Pneumatics

catalog.

1. Do not use in an atmosphere containing corrosive

gases, chemicals, sea water, water, water steam, or

where there is direct contact with any of these.

2. Do not use in an environment where flammable gas

or explosive gas exists. Usage may cause a fire or

explosion. The products do not have an explosion

proof construction.

3. Do not use in a place subject to heavy vibration

and/or shock.

4. The valve should not be exposed to prolonged

sunlight. Use a protective cover. Note that the valve

is not for outdoor use.

5. Remove any sources of excessive heat.

6. If it is used in an environment where there is possible

contact with oil, weld spatter, etc., exercise preventive

measures.

1. Temperature of ambient environment

Use the valve within the range of the ambient temperature

specification of valve. In addition, pay attention when using the

valve in environments where the temperature changes drastically.

2. Temperature of ambient environment

If the humidity rises, take measures to prevent the adhesion of

water droplets on the valve.

1. Perform maintenance and inspection according to

the procedures indicated in the operation manual.

If handled improperly, human injury and/or malfunction or

damage of machinery and equipment may occur.

2. Removal of equipment, and supply/exhaust of

compressed air

Before components are removed, first confirm that measures

are in place to prevent workpieces from dropping, run-away

equipment, etc. Then, cut off the supply air and electric power,

and exhaust all air pressure from the system using the

residual pressure release function.

When the equipment is operated after remounting or

replacement, first confirm that measures are in place to

prevent the lurching of actuators, etc. Then, confirm that the

equipment is operating normally.

3. Low-frequency operation

Valves should be operated at least once every 30 days to

prevent malfunction. (Use caution regarding the air supply.)

4. If the volume of air leakage increases or the valve

does not operate normally, do not use the valve.

Perform periodic maintenance on the valve to

confirm the operating condition and check for any

air leakage.

1. Drain flushing

Remove drainage from the air filters regularly.

2. Lubrication

In the case of rubber seals, once lubrication has been started,

it must be continued.

Use class 1 turbine oil (with no additives), VG32. If other

lubricant oil is used, it may cause a malfunction. Please

contact SMC for information on the suggested class 2 turbine

oil (with additives), VG32.

3. Protection

Make sure that dust and/or other foreign matter cannot enter

the valve from the unused port (e.g. exhaust port).

VTA301 Series

3 Port Air Operated Valve / Precautions 3

Be sure to read before handling

.

- 6 -VT301**-OMH0007-B