Installation and Maintenance Manual

Connector type manifold

Series VV100

1 Safety Instructions

• This manual contains essential information for the protection of users

and others from possible injury and/or equipment damage.

• Read this manual before using the product, to ensure correct

handling, and read the manuals of related apparatus before use.

• Keep this manual in a safe place for future reference.

• These instructions indicate the level of potential hazard by label of

"DANGER", "WARNING" or "CAUTION", followed by important safety

information which must be carefully followed.

• To ensure safety of personnel and equipment the safety instructions in

this manual and the product catalogue must be observed, along with

other relevant safety practices.

VV100**-TFL0002

WARNING

• The compatibility of pneumatic equipment is the responsibility of

the person who designs the pneumatic system or decides its

specifications.

Since the products specified here can be used in various operating

conditions, their compatibility with the specific pneumatic system must

be based on specifications or after analysis and/or tests to meet

specific requirements.

• Only trained personnel should operate pneumatically operated

machinery and equipment.

Compressed air can be dangerous if an operator is unfamiliar with it.

Assembly, handling or repair of pneumatic systems should be

performed by trained and experienced personnel.

• Do not service machinery/equipment or attempt to remove

components until safety is confirmed.

1) Inspection and maintenance of machinery/equipment should only

be performed after confirmation of safe locked-out control positions.

2) When equipment is to be removed, confirm the safety process as

mentioned above. Switch off air and electrical supplies and exhaust all

residual compressed air in the system.

3) Before machinery/equipment is re-started, ensure all safety

measures to prevent sudden movement of cylinders etc. (Supply air

into the system gradually to create back pressure, i.e. incorporate a

soft-start valve).

• Do not use this product outside of the specifications.

Contact SMC if it is to be used in any of the following conditions:

1) Conditions and environments beyond the given specifications, or if

the product is to be used outdoors.

2) Installations in conjunction with atomic energy, railway, air

navigation, vehicles, medical equipment, food and beverage, recreation

equipment, emergency stop circuits, press applications, or safety

equipment.

3) An application which has the possibility of having negative effects on

people, property, or animals, requiring special safety analysis.

CAUTION

• Ensure that the air supply system is filtered to 5 microns.

1 Safety Instructions

(continued)

Exemption from Liability.

1) SMC, its officers and employees shall be exempt from liability for any

loss or damage arising out of earthquake or fire, action by a third person,

accidents, customer error with or without intention, product misuse and

any other damages caused by abnormal operating conditions.

2) SMC, its officers, and its employees shall be exempt from liability for

any incidental damage that is caused by the use or the inability to use this

product (loss of business interests, business interruptions, etc)

3) SMC is exempt from liability for any damages caused by operations not

contained in the catalogs and/or instruction manuals, and operations

outside of the specification range.

4) SMC is exempt from liability for any loss or damage whatsoever caused

by malfunctions of its products when combined with other devices or

software.

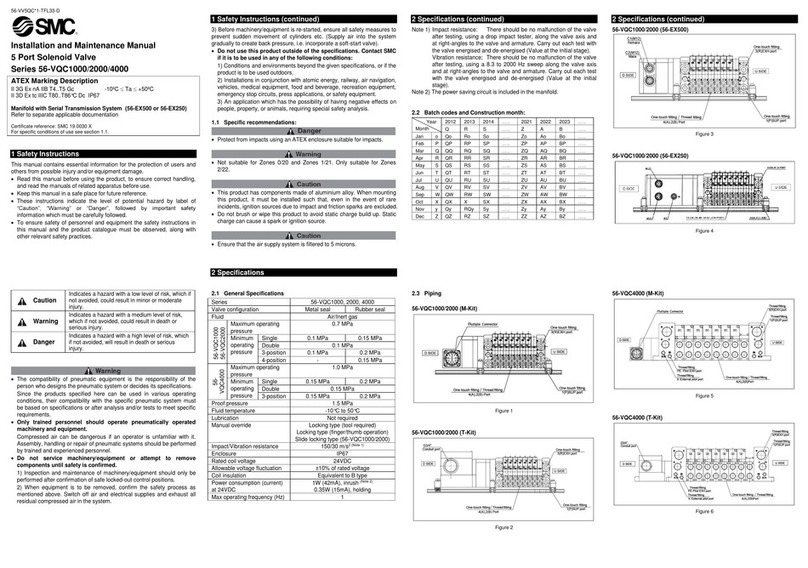

2 Specifications

2.1 Valve specifications

Note :

Impact resistance: No malfunction occurred when it was tested with a drop

tester in the axial direction and at right angles to the main valve & armature;

in both energized & de-energised states and for every time in each condition

(Values at the initial period.)

Vibration resistance: No malfunction occurred in a one-sweep test between

45 and 2000 Hz. Tests ere performed at both energized and de-energized

states in the axial direction and at right angles to the main valve & armature.

(Valves at the initial period.)

2.2 Coil specifications

Note) Keep the following voltage range for Z type and T type (with power

saving circuit) because it might have voltage drop due to internal circuit.

Z type T type

24VDC : -7 ~ +10% 24VDC : -5 ~ +10%

12VDC : -6 ~ +10% 12VDC : -6 ~ +10%

2.3 Symbol

3 Installation

3.1 Installation

WARNING

• Do not install the product unless the safety instructions have been read

and understood.

•Interlock circuit

If the products are used in an interlock circuit, prepare a double interlock

style circuit with a mechanical protection function for the prevention of a

breakdown. Examine these.

3.2 Environment

WARNING

• Do not use in an environment where the product is directly exposed to

corrosive gases, chemicals, salt water, water or steam.

• Do not use in an explosive atmosphere.

• The product should not be exposed to prolonged sunlight. Use a protective

cover.

• Do not mount the product in a location where it is subject to strong

vibrations and/or shock. Check the product specifications.

• Do not mount the product in a location exposed to radiant heat.

If using in an atmosphere where there is possible contact with water drop-

lets, oil, weld spatter, etc., take suitable preventative measures.

• When the solenoid valve is mounted in a control panel or its energized for

a long time, make sure that the ambient temperature is within the valve's

specified range

3.3 Piping

CAUTION

• Before piping make sure to clean up chips, cutting oil, dust etc.

• When installing piping or fittings, ensure sealant material does not enter

inside the port. When using seal tape, leave 1.5 to 2 threads exposed on

the end of the pipe/fitting.

• Tighten fittings according to appropriate tightening torque.

3.4 One-touch fitting

CAUTION

Tube attachment

• Take a tube having no flaws on its periphery and cut it off at a right angle.

When cutting the tube, use tube cutters TK-1, 2 or 3. Do not use pincers,

nippers or scissors etc. If cutting is done with tools other than tube cutters,

the tube may be cut diagonally or become flattened. This makes a secure

installation impossible, and causes problems such as air leakage or the

tube being pulled out after installation. Allow some extra length in the tube.

Hold down part of the release bush

with your finger or a similar tool, as

shown in the diagram, and pull out in

the direction indicated by the arrow.

• Grasp the tube and push it in slowly, inserting it securely all the way into

the fitting.

• After inserting the tube, pull on it lightly to confirm that it will not come out.

Problems such as air leakage or the tube being pulled out can occur if the

tube is not inserted securely all the way into the fittings.

Tube detachment

• Push in the release bushing and the collar at the same time.

• Pull out the tube while holding down the release bushing so that it does not

come out. If the release bushing is not pressed down sufficiently there will

be increased bite on the tube and it will become more difficult to pull out.

• When the removed tube is to be used again, cut off the portion which has

been chewed before reusing it. If this is not done then the chewed portion

of the tube can cause problems such as air leakage or difficulty in

removing the tube from the fitting.

3 Installation

(continued)

3.5 Precautions on other tube brands

CAUTION

• When using non-SMC brand tubes, confirm that the following

specifications are satisfied with respect to the outside diameter

tolerance of the tube.

Nylon tube ±0.1mm

Soft nylon tube ±0.1mm

Polyurethane tube +0.15mm

-0.2mm

xDo not use tubes that do not meet these outside diameter tolerances. It

may not be possible to connect them, or they may cause other

problems, such as air leakage or the tube pulling out after connection.

3.6 Indicator Light/Surge Voltage Suppressor

• Non-polar type

When the solenoid valve has no polarity:

In extreme conditions, there is a possibility of

serious injury or loss of life.

WARNING If instructions are not followed there is a

possibility of serious injury or loss of life.

CAUTION If instructions are not followed there is a

possibility of injury or equipment damage.

DANGER