VQD1000-TF2Z545EN

Page 2 of 2

3 Installation - continued

3.11 Countermeasure for surge voltage

Caution

•At times of sudden interruption of the power supply, the energy stored

in a large inductive device may cause non-polar type valves in a de-

energised state to switch.

•When installing a breaker circuit to isolate the power, consider a valve

with polarity (with polarity protection diode), or install a surge

absorption diode across the output of the breaker.

3.12 Extended period of continuous energization

Warning

•If a valve will be continuously energized for an extended period of time,

or is mounted in a control panel, the temperature of the valve will

increase due to the heat generated by the coil assembly. This will likely

adversely affect the performance of the valve and any nearby

peripheral equipment. Therefore, if the valve is to be energized for

periods of longer than 30 minutes at a time or if during the hours of

operation the energized period perday is longer than the de-energized

period, we advise using a direct operated continuous duty type valve

such as the VK series or the VT series, or consider use of the latching

type for which continuous energization is not required.

•Coil temperature may get high due to ambient temperature or

energizing duration. Do not touch the valve by hand directly. When

there is such a dangerous case to be touched by hands directly, install

a protective cover.

•The latching type should not be energized over 30 seconds. Ensure

the de-energised period is longer than the energised time (both A and

B should be turned off.) before the next operation.

3.13 Effect of back pressure when using a manifold

Warning

Use caution when valves are used on a manifold, because an actuator

may malfunction due to back-pressure.

3.14 Latching type Caution

•Use in a circuit that does not have simultaneous energization of A-ON

and B-ON signals.

•The minimum energization time required for self-holding is 50 ms.

•Although there is no problem for normal operations and environments.

please consult SMC when operating in an environment with vibration

(10G or more) or strong magnetic fields.

•When there is the magnetic body at the valve side, it may cause

malfunction. Allow a space over 10 mm between the valve and

magnetic body.

•Even though this valve is held on to B-ON position (passage: P →B),

it may switch to the set position during transportation or due to impact

when mounting valves, etc. Therefore, check the initial position by

means of power supply or manual override prior to use.

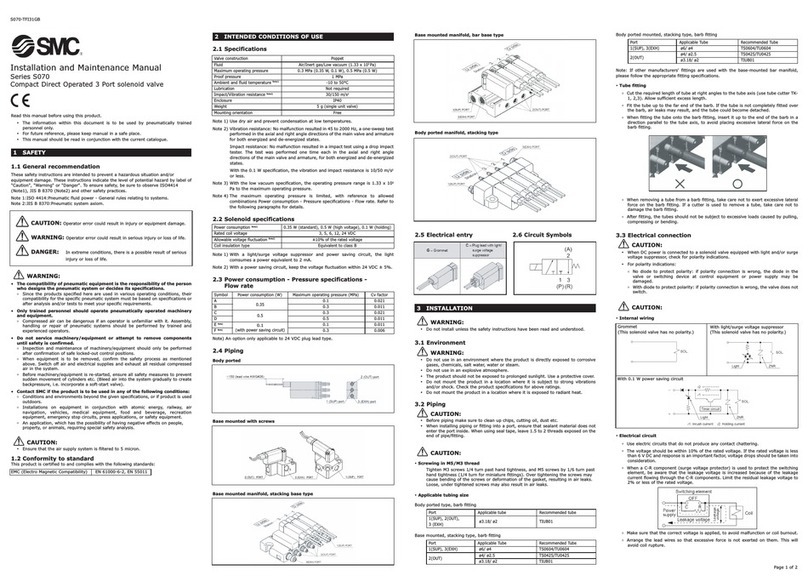

Table 5.

Note) For positive common.

4 How to Order

Refer to catalogue for ‘How to Order’.

5 Outline Dimensions

Refer to catalogue for outline dimensions.

6 Maintenance

6.1 General maintenance Caution

•Not following proper maintenance procedures could cause the product

to malfunction and lead to equipment damage.

•If handled improperly, compressed air can be dangerous.

•Maintenance of pneumatic systems should be performed only by

qualified personnel.

6 Maintenance - continued

•Before performing maintenance, turn off the power supply and be sure

to cut off the supply pressure. Confirm that the air is released to

atmosphere.

•After installation and maintenance, apply operating pressure and

power to the equipment and perform appropriate functional and

leakage tests to make sure the equipment is installed correctly.

•If any electricalconnections are disturbed during maintenance, ensure

they are reconnected correctly and safety checks are carried out as

required to ensure continued compliance with applicable national

regulations.

•Do not make any modification to the product.

•Do not disassemble the product, unless required by installation or

maintenance instructions.

6.2 Mounting Caution

Refer to 3.7 Mounting for guidance on how to mount valve to base.

6.3 Maintainable parts Caution

Refer to catalogue for how to order manifold accessories, sub-plates or

electrical connector assemblies.

7 Limitations of Use

7.1 Limited warranty and disclaimer/compliance requirements

Caution

Refer to Handling Precautions for SMC Products.

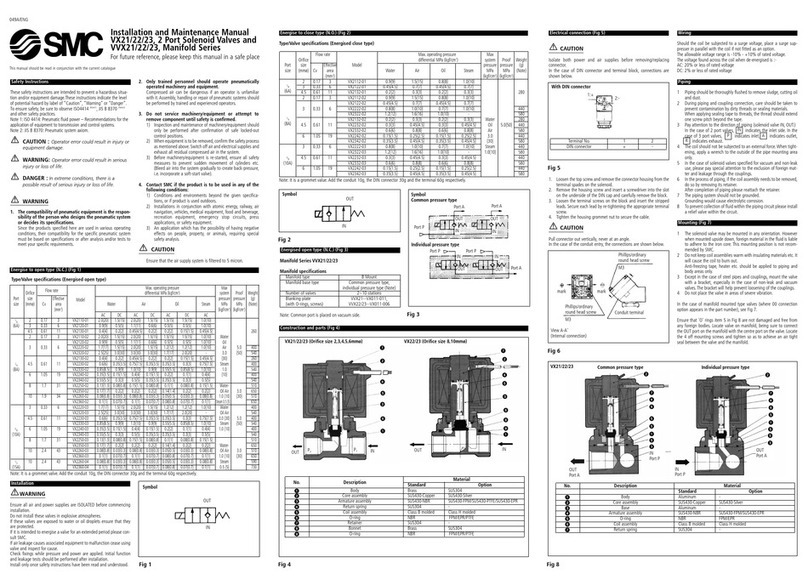

7.2 Effect of energy loss on valve switching

Warning

Air supply present,

electrical supply cut

Valve spool

returns to OFF

position by spring

force.

Valve spool holds position until

reset signal is sent (B-ON), spool

then returns to OFF position by

spring force.

Electrical supply

present, air supply cut

Valve operation is not dependent on presence of air

supply. Spool position/movement is unaffected by

loss of air supply.

Table 6.

Note) Refer to 3.14 and catalogue for Latching type operation guidance.

7.3 Holding of pressure Warning

Since valves are subject to air leakage, they cannot be used for

applications such as holding pressure (including vacuum) in a system.

7.4 Cannot be used as an emergency shut-off valve

Warning

This product is not designed for safety applications such as an

emergency shut-off valve. If the valves are used in this type of system,

other reliable safety assurance measures should be adopted.

7.5 Leakage voltage Caution

Ensure that any leakage voltagecaused by the leakage current when the

switching element is OFF causes ≤ 2% of the rated voltage across the

valve.

7.6 Low temperature operation

Caution

Unless otherwise indicated in the specifications for each valve, operation

is possible to -10˚C, but appropriate measures should be taken to avoid

solidification or freezing of drainage and moisture, etc.

7 Limitations of Use - continued

7.7 Vacuum applications and use as a 3 port valve.

Caution

•Use a VQD(1/2)(2/3/5)1(V/W) valve for vacuum applications.

•Connect the vacuum source to the 3(R) port.

•Refer to catalogue for diagram.

•Air pressure cannot be applied to the 3(R) port.

•When used as a 3 port valve, conversion from N.O. to N.C. and vice

versa is possible by plugging either port 4(A) or 2(B).

•The valve cannot be used as a 2 port valve.

8 Product Disposal

This product shall not be disposed of as municipal waste. Check your

local regulations and guidelines to dispose this product correctly, in order

to reduce the impact on human health and the environment.

9 Contacts

Refer to www.smcworld.com or www.smc.eu for your local

distributor/importer.

URL : https:// www.smcworld.com (Global) https:// www.smc.eu (Europe)

SMC Corporation, 4-14-1, Sotokanda, Chiyoda-ku, Tokyo 101-0021, Japan

Specifications are subject to change without prior notice from the manufacturer.

© 2022 SMC Corporation All Rights Reserved.

Template DKP50047-F-085M