EX500-TF2Z180EN

Page 1 of 2

Instruction Manual

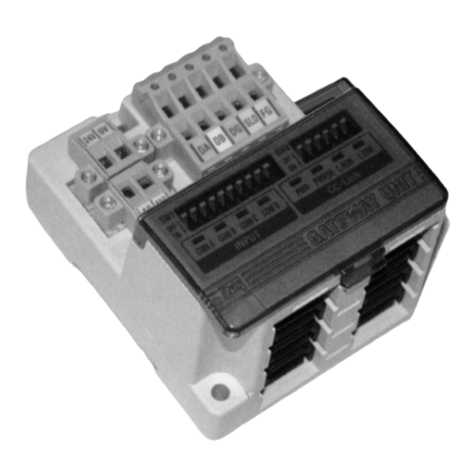

Gateway unit – PROFINET compatible

Series EX500-GPN2

The intended use of the Gateway unit is for connection to SI units and

input devices for the control of pneumatic valves.

1 Safety Instructions

These safety instructions are intended to prevent hazardous situations

and/or equipment damage. These instructions indicate the level of

potential hazard with the labels of “Caution,” “Warning” or “Danger.”

They are all important notes for safety and must be followed in addition

to International Standards (ISO/IEC)*1), and other safety regulations.

*1) ISO 4414: Pneumatic fluid power - General rules relating to systems.

ISO 4413: Hydraulic fluid power - General rules relating to systems.

IEC 60204-1: Safety of machinery - Electrical equipment of machines.

(Part 1: General requirements)

ISO 10218-1: Manipulating industrial robots -Safety. etc.

•Refer to product catalogue, Operation Manual and Handling

Precautions for SMC Products for additional information.

•Keep this manual in a safe place for future reference.

Caution indicates a hazard with a low level of risk which, if

not avoided, could result in minor or moderate injury.

Warning indicates a hazard with a medium level of risk

which, if not avoided, could result in death or serious injury.

Danger indicates a hazard with a high level of risk which, if

not avoided, will result in death or serious injury.

Warning

•Always ensure compliance with relevant safety laws and

standards.

•All work must be carried out in a safe manner by a qualified person in

compliance with applicable national regulations.

•Refer to the operation manual on the SMC website (URL:

https://www.smcworld.com) for more Safety instructions.

2 Specifications

General specifications

Ambient operating temperature

o

35 to 85% RH (no condensate)

Ambient storage temperature

o

1000 VAC applied for 1 minute

Electrical specifications

3 Name and function of parts

Connection to PROFINET line.

Connection for power supply.

Connection to SI units (with manifold

valves) or input units using a branch

cable.

Displays the unit status.

Cover should not be opened.

4 Installation

4.1 Direct mounting

Secure in position using 4 x M5 screws, 15 mm minimum thread length.

4.2 Wiring connections

•Communication Connector

Select the appropriate Ethernet cables to mate with the connectors

on the SI unit. The PROFINET connection has 2 ports, PORT 1 and

PORT 2, and both ports can be used for connection.

M12 4-pin Socket (D-coded)

Pin No. Signal name

•Power Supply Connector

Connect the power supply to the power supply connector on the

Gateway unit. With this cable, power is supplied to the output devices

(such as solenoid valve) and the input devices and for control.

•Both single and two power supply systems can be adopted, however

the wiring should be made separately (for solenoid valves / outputs

and for input and control) for either system.

The M12 connector cable has two types,

SPEEDCON compatible. If both plug and socket have SPEEDCON

connectors, the cable can be inserted and connected by turning it a

1/2 rotation.

A standard connector can be connected to a SPEEDCON connector.

•Branch Connector

Connect SI units (solenoid valves) and input devices to the Branch

port connectors (COM A - D) using an M12 (8-pin) connector cable

(EX500-AC###-S#P#).

As each cable contains power supply wiring, there is no need to

supply power to the SI unit (solenoid valves) or input devices

separately.

Warning

•Be sure to fit a seal cap (EX9-AWTS) on any unused connectors.

Proper use of the seal cap enables the enclosure to maintain IP65

specification. Tightening torque: 0.1 N•m.

4.3 Ground Connection

•Connect the FE terminal (M3) to ground.

•Individual grounding should be provided close to the product with a

short cable to assure the safety and noise resistance of the system.

•Resistance to ground should be 100 Ω or less.

4 Installation (continued)

4.4 Environment Warning

•Do not use in an environment where corrosive gases, chemicals, salt

water or steam are present.

•Do not install in a location subject to vibration or impact in excess of

the product’s specifications.

•Do not mount in a location exposed to radiant heat that would result

in temperatures in excess of the product’s specifications.

5 Setting

5.1 Hardware Configuration

An applicable GSDML file is required to configure the Gateway unit for

the PROFINET network.

Download the latest GSDML file from the SMC website (URL:

https://www.smcworld.com).

EX500-GPN2

∗∗∗∗∗∗∗∗

GSDML-0083-000B-EX500_N.bmp

Technical documentation giving detailed configuration information can

be found in the operation manual on the SMC website (URL:

https://www.smcworld.com).

6 LED Display

Item Specifications

Power supply voltage

Control and Input: 24.0 VDC ±10%

Solenoid valves: 24.0 VDC +10% / -5%

Rated Current

Power supply for control and input: 6.2 A

(GW current consumption: 200 mA max.).

Power supply for solenoid valve: 4 A

Number of Inputs / Outputs 128 Inputs / 128 Outputs

Communication specifications

Item Specifications

100BASE-TX (Cat5 or more)

Full Duplex / Half Duplex (auto. selected)

Device Information

Vendor ID: 0x0083 (SMC Corporation)

Low level bus specifications

Item Specifications

Number of inputs / outputs

Gateway distribution system 2 (128 point)

Number of branch ports

4 (input: Max. 32 points / Output: Max. 32

points per branch)

Number of connected slaves

16 max. (input unit: 2 pcs. / SI unit: 2 pcs.

per branch)

Power supply for control and input

24 VDC, Max. 1.5 A per one branch port

Power supply for Solenoid valve

24 VDC, Max. 1.0 A per one branch port

Total length 20 m or less per branch

24 VDC (control and input)

LED Description

SF

BF

PROFINET communication established

PROFINET communication not established

PWR

Power supply for control and inputs is OFF

Power supply for control and inputs is ON

PWR(V)

Power supply for solenoid valves is OFF

Power supply for solenoid valves is ON

L/A1

No Link, No Activity (Port1)

Link, No Activity (Port1)

Link, Activity (Port1)

L/A2

No Link, No Activity (Port2)

Link, No Activity (Port2)

Link, Activity (Port2)