Fieldbus device

Operation Manual

EX250 Series for PROFIBUS DP

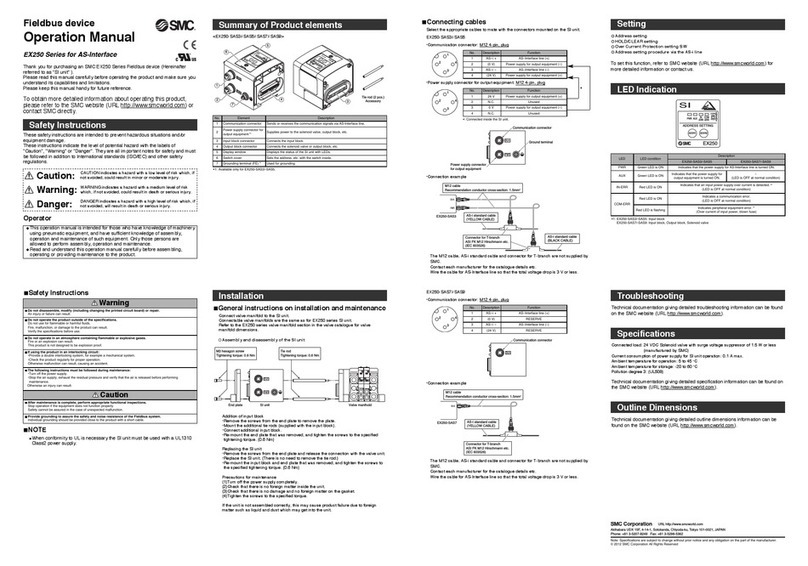

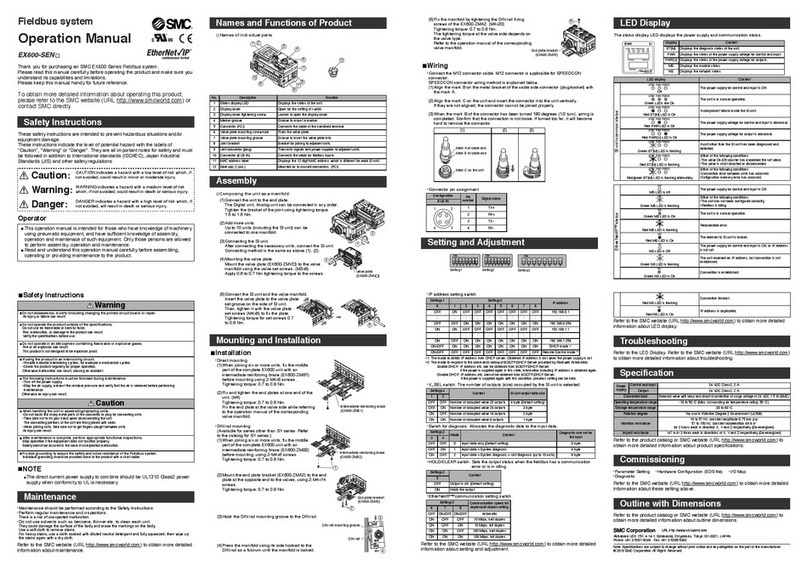

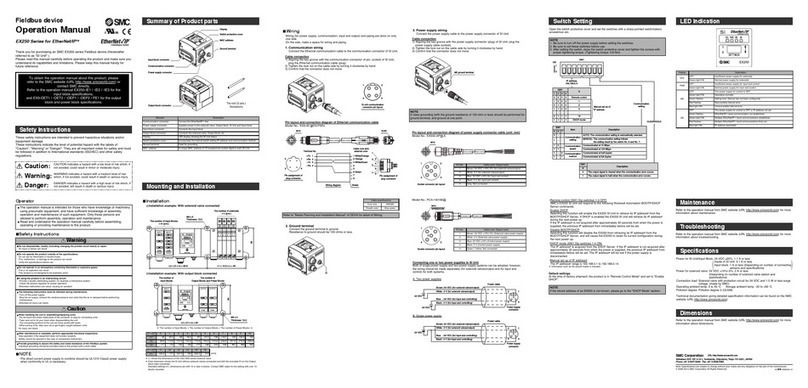

Su ary of Product ele ents

3:59

581

$''5(66

5

2,%86

352&(66),(/'%86

)53

',$

%)

(;

+/

3

7

1

2

5

6

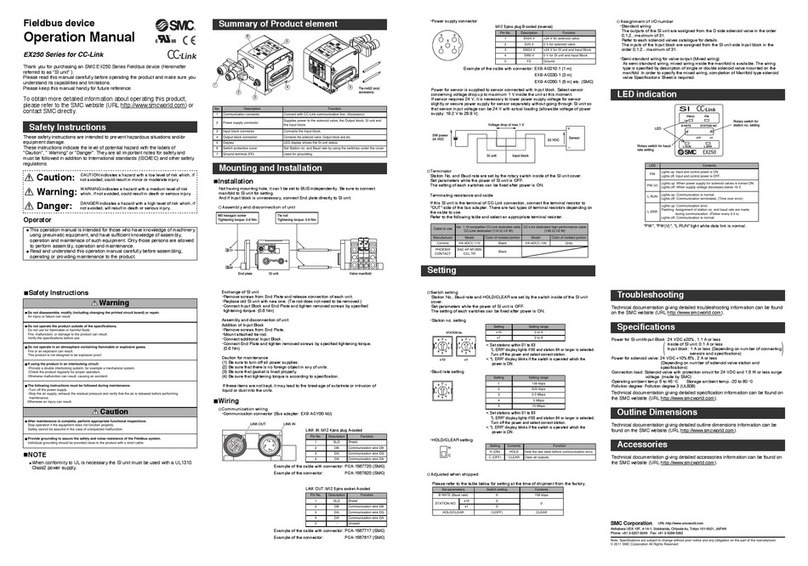

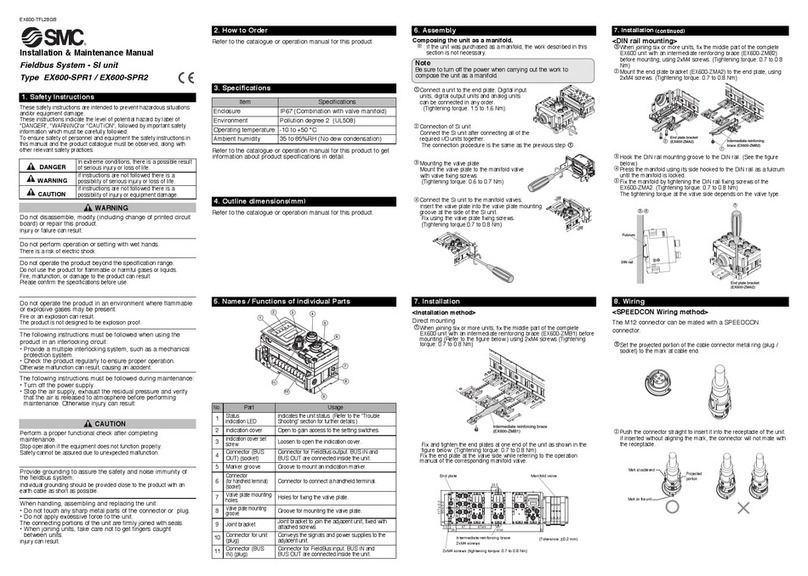

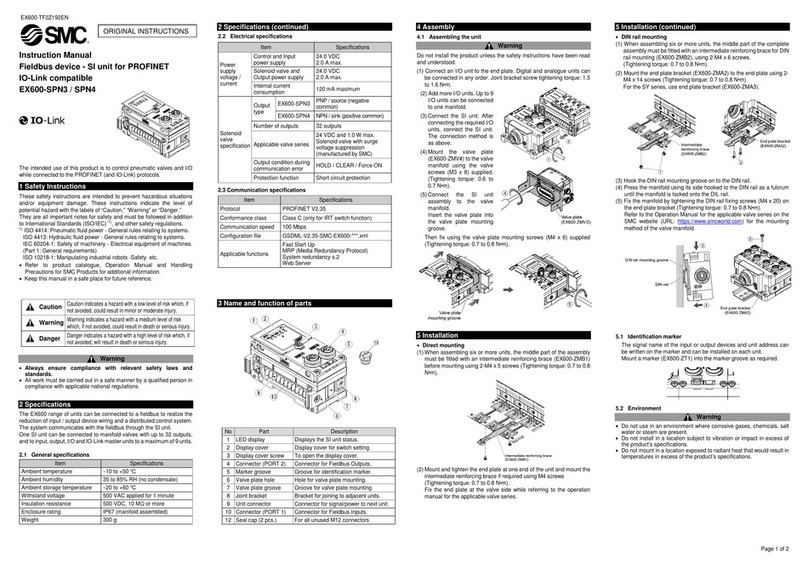

Mounting and Installation

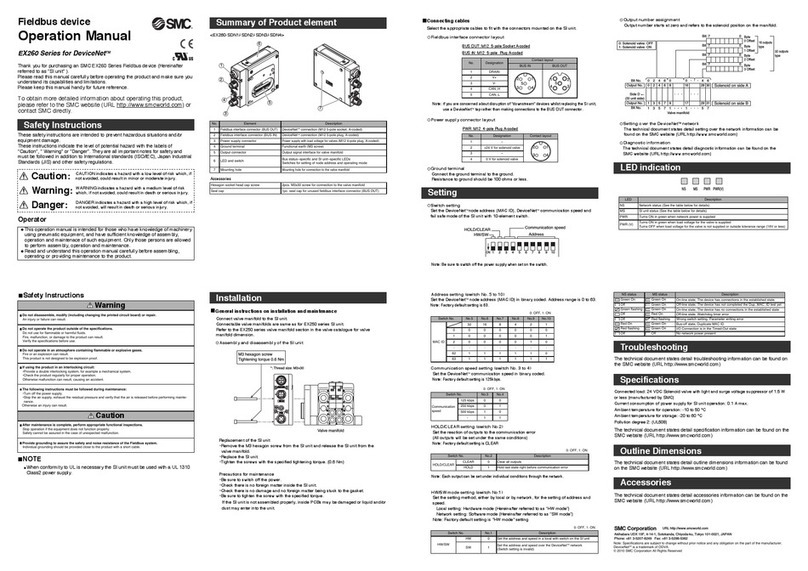

Address setting

Be sure to turn power supply off before setting the switches off before setting the switches of SI

unit. Switch installed in cover of SI unit is available for setting of address.

Software setting mode

Address is set in network by

using ET200 hand held unit

or PG(programing tool).

Once address is set, it is

saved even if power is cut.

Setting range: 1 to 125(10 dec.)

Value set on shipment: 125.

Hardware setting mode

ЍAddress27(10 dec.)

Address setting mode

change over switch

x10 x1

Address setting switch

Address of unit is set with address setting switches.

There are two decimal rotary switches for address

setting; one for ten,s place and the other for unit,s.

Setting range: 1 to 99(10 dec.)

Example: 2

7

SW

HW

SW

HW

SW

HW

SW

HW

3:59

581

$''5(66

5

2,%86

352&(66),(/'%86

)53

',$

%)

(;

+/

4

Tie-rod(2 pcs)

accessory

Communication connector

Description Function

Connect with PROFIBUS DP communication line.

Power supply connector Supplies power to the solenoid valve, the Output block, SI unit and

the Input block.

Input block connector Connects the Input block.

Display LED display shows the SI unit status.

Switch protective cover Set Station no. and Baud rate by using the switches under the cover.

1

No.

2

3

5

6

Ground terminal Used for grounding.

7

Output block connector

Connects the solenoid valve, Output block etc.

4

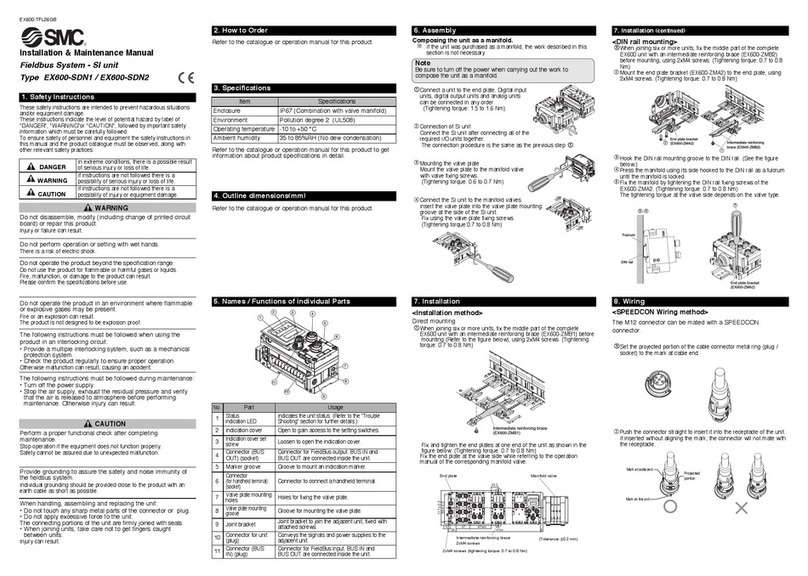

Installation

Not having mounting hole, it can’t be set to BUS independently. Be sure to connect

manifold to SI unit for setting.

And if Input block is unnecessary, connect End plate directly to SI unit.

Setting

End plate SI unit Valve manifold

BUS

PWR

M3 hexagon screw

Tightening torque: 0.6 Nm

Tie rod

Tightening torque: 0.6 Nm RR33XP11P1212XBBAA

Exchange of SI unit

•Remove screws from End Plate and release connection of each unit.

•Replace old SI unit with new one. (Tie rod does not need to be removed.)

•Connect Input Block and End Plate and tighten removed screws by specified

tightening torque. (0.6 Nm)

Assembly and disconnection of unit

Addition of Input Block

•Remove screws from End Plate.

• ount attached tie rod.

•Connect additional Input Block.

•Connect End Plate and tighten removed screws by specified tightening torque.

(0.6 Nm)

Caution for maintenance

(1) Be sure to turn-off all power supplies.

(2) Be sure that there is no foreign object in any of units.

(3) Be sure that gasket is lined properly.

(4) Be sure that tightening torque is according to specification.

If these items are not kept, it may lead to the breakage of substrate or intrusion of

liquid or dust into the units.

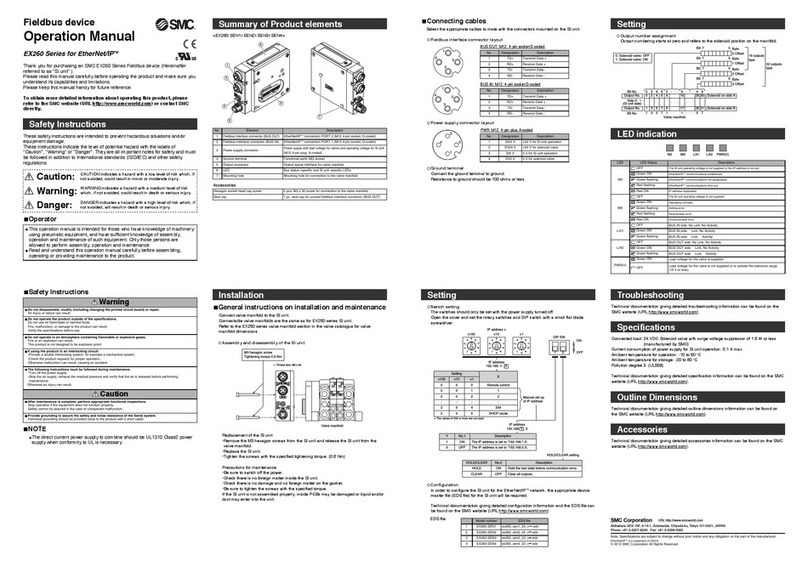

LED indication

EX250

PWR(V) RUN

ADDRESS

HL

DIA BF

52,%86352&(66),(/'%86)53

BF

Indication Content

Red lights up when bus failure is detected.

DIA Red lights up when some failure is detected by self-diagnosis.

PWR(V)

Green lights up when power supply for solenoid valves is turned on.

Disappear when solenoid valve power supply voltage decreases

below 19 V.

RUN Green lights up during operation (when power supply for SI unit is

turned on.)

Troubleshooting

Technical documentation giving detailed troubleshooting information can be found

on the S C website (URL http://www.smcworld.com).

Specifications

Power for SI unit/Input Block: 24 VDC ±20%, 1.1 A or less

Inside of SI unit: 0.1 A or less

Input block: 1 A or less (Depending on number of connecting

sensors and specifications)

Power for solenoid valve: 24 VDC +10%/5%, 2 A or less

(Depending on number of solenoid valve station and

specifications)

Connection load: Solenoid valve with protection circuit for 24 VDC and 1.5 W or less surge

voltage. (made by S C)

Operating ambient temp: -10 to 50 oC Storage ambient temp: -20 to 60 oC

Pollution degree: Pollution degree 3 (UL508)

Technical documentation giving detailed specification information can be found on

the S C website (URL http://www.smcworld.com).

Outline Di ensions

Technical documentation giving detailed outline dimensions information can be

found on the S C website (URL http://www.smcworld.com).

Accessories

Technical documentation giving detailed accessories information can be found on

the S C website (URL http://www.smcworld.com).

Asse bly and disconnection of unit

NOTE

When conformity to UL is necessary the SI unit must be used with a UL1310

Class2 power supply.

Safety Instructions

Do not operate the product outside of the specifications.

Do not use for flammable or harmful fluids.

Fire, malfunction, or damage to the product can result.

Verify the specifications before use.

Do not disasse ble, odify (including changing the printed circuit board) or repair.

An injury or failure can result.

Do not operate in an at osphere containing fla able or explosive gases.

Fire or an explosion can result.

This product is not designed to be explosion proof.

If using the product in an interlocking circuit:

•Provide a double interlocking system, for example a mechanical system.

•Check the product regularly for proper operation.

Otherwise malfunction can result, causing an accident.

The following instructions ust be followed during aintenance:

•Turn off the power supply.

•Stop the air supply, exhaust the residual pressure and verify that the air is released before performing

maintenance.

Otherwise an injury can result.

Provide grounding to assure the safety and noise resistance of the Fieldbus syste .

Individual grounding should be provided close to the product with a short cable.

Thank you for purchasing an S C EX250 Series Fieldbus device (Hereinafter

referred to as "SI unit" ).

Please read this manual carefully before operating the product and make sure you

understand its capabilities and limitations.

Please keep this manual handy for future reference.

To obtain more detailed information about operating this product,

please refer to the S C website (URL http://www.smcworld.com) or

contact S C directly.

Safety Instructions

These safety instructions are intended to prevent hazardous situations and/or

equipment damage.

These instructions indicate the level of potential hazard with the labels of

"Caution", " Warning" or "Danger". They are all important notes for safety and

must be followed in addition to International standards (ISO/IEC) and other safety

regulations.

Warning

Caution

After aintenance is co plete, perfor appropriate functional inspections.

Stop operation if the equipment does not function properly.

Safety cannot be assured in the case of unexpected malfunction.

CAUTION indicates a hazard with a low level of risk which, if

not avoided, could result in minor or moderate injury.

Caution:

Warning:

Danger:

WARNING indicates a hazard with a medium level of risk

which, if not avoided, could result in death or serious injury.

DANGER indicates a hazard with a high level of risk which, if

not avoided, will result in death or serious injury.

Operator

This operation manual is intended for those who have knowledge of machinery

using pneumatic equipment, and have sufficient knowledge of assembly,

operation and maintenace of such equipment. Only those persons are allowed

to perform assembly, operation and maintenance.

Read and understand this operation manual carefully before assembling,

operating or providing maintenance to the product.

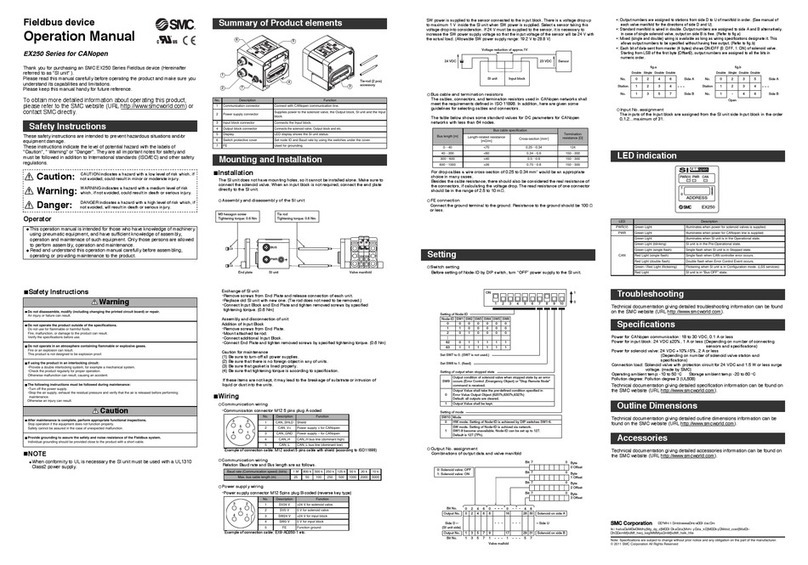

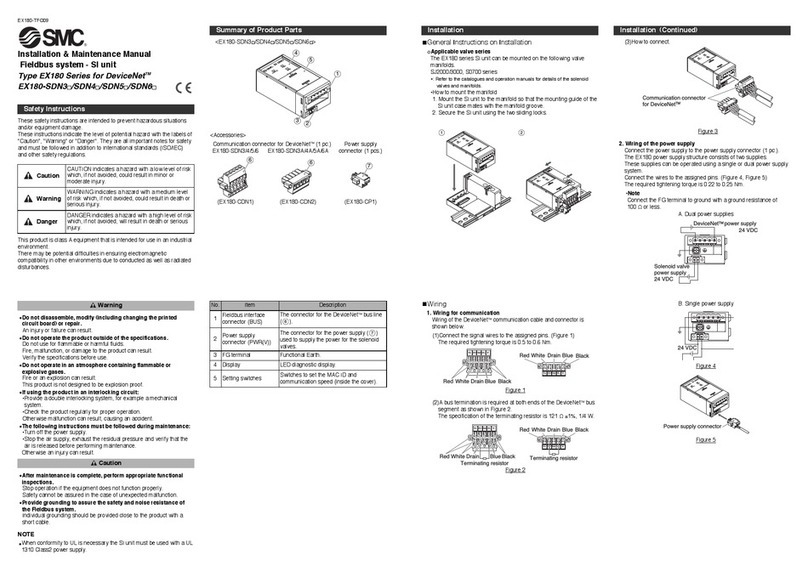

Wiring

Co unication wiring

•Communication connector

12 5pin reverse (Socket)

Example of connected Bus Tee: TURCK VB2/FSW/FKW/FSW45 etc.

VP

Description Function

Supply voltage for Terminating Resistor

A-N inus to send/receive data

DGND Ground for Terminating Resistor

- Unused

1

Pin No.

2

3

5

B -P Plus to send/receive data4

SV24 V

Description Function

+24 V for solenoid valve.

SV0 V 0 V for solenoid valve

SW24 V +24 V for SI unit and Input Block

FE Ground

1

Pin No.

2

3

5

SW0 V 0 V for SI unit and Input Block4

Power supply wiring

Power supply line inside the unit has individual power supplies for solenoid valve

actuation (SV power supply) and for Control parts and Input block (SI•SW power

supply). Supply 24 VDC for each of them. Either single or dual power supply is

available.

•Communication connector

12 5pin (Plug)

Example of connected cable: S C EX500-AP0∗0-S etc.

Power for sensor is supplied to sensor connected with Input block. Select sensor concerning

voltage drop up to maximum 1 V inside the unit at this moment.

If sensor requires 24 V, it is necessary to lower power supply voltage for sensor slightly or

secure power supply for sensor separately without going through SI unit so that sensor input

voltage can be 24 V with actual loading

(allowable voltage of power supply: 19.2 V to 28.8

V)

.gle or dual power supply is available.

Voltage drop of max.1 V

23 VDC Sensor

㸩㸫Input block

SI unit

SW power

24 VDC

Ter inator

It is necessary to attach bus terminating resistance to the units located at the ends of

transmission line.

Communication cable

PCA-1557688/PCA-1557691 etc.

BUS Tee

VB2/FSW/FKW/FSW45

:TURCK etc

SI unit SI unit

Terminating Resistor

PCA-1557727

Configuration

In PROFIBUS DP, a device database file called the Generic Station Description (GSD)

file provides configuration information specific to the device (ID number, data format,

baud rate...).

The GSD file of the product depends on the address setting mode (selected by the

address setting mode switch).

GSD file : S CA1409.gsd (In hardware setting mode)

S CA1408.gsd (In software setting mode)

Assign ent of I/O No.

Correspondence between output data and valve manifold

•Output data

Bit: 7 0

Bit: 7 0

Bit: 7 0

Bit: 7 0

0

1

246

357

8

9

16

17

30

31

28

29

64 64

13571 1 57

Output No.

Output No.

Bit No.

Bit No.

Valve manifold

Solenoid on side A

Solenoid on side B

Side D

0: Solenoid valve: OFF

1: Solenoid valve: ON

Byte

0 Offset

Byte

1 Offset

Byte

2 Offset

Byte

3 Offset

(SI unit side)

200

0

No.

Station

fig.a

No.

4

4

6 Side A

Side B

2

2

3

0

Double Single Double Double

1

1357

No.

Station

fig.b

No.

3

4

5 Side A

Side B

2

2

3

0

Double Single

Free

Double Double

1

1-46

Correspondence between output data and valve anifold

•Intput data

Bit

Offset 0:

70

Bit

Offset 1:

70

Bit

Offset 2:

70

Bit

Offset 3:

70

30

31

28

29

26

27

24

25

22

23

20

21

16

17

18

19

12

15

8

11

0

3

4

13 915

14 10 26

7

642064204040

753175317373

Input No.

Input side SI unit side

Bit No.

0: Sensor: OFF

1: Sensor: ON

SI unit

Ѝ

EX250-IE1 x 8 EX250-IE2/3 x 4

∗: Input numbers are assigned to stations from SI unit side to input side in order.

∗: Each bit of data read into master 4bytes shows ON/OFF of sensor connected to input block.

Starting from LSB of first byte (Offset 0), input numbers are assigned to all bits in numeric order.

Diagnosis infor ation

Diagnosis information of the SI unit is composed of 6 bytes standard diagnosis

information and 7 bytes SI unit status information, 13 bytes in total, as specified in

PROFIBUS DP.

When the SI unit is in a non-standard state, it will send an error message to the master

as diagnosis information, and light up the DIA display.

Technical documentation giving detailed diagnosis information and set-up steps

information can be found on the S C website (URL http://www.smcworld.com).

It detects when the voltage of the solenoid valve lowers

to approximately 19 V or less.

Contents

Detection of communication error in A to D on the input

side due to the broken fuse of the Input block.

Surveillance of Solenoid valve power

supply voltage

Function

Input block open fuse surveillance

SI unit status information is as follows

Refer to PROFIBUS specifications and manual of the master, etc. for how to refer to

diagnosis information on the master.

∗: Output numbers are assigned to stations from side D to U of manifold in order. (See manual of

each valve manifold for the directions of side D and U)

∗: Standard manifold is wired in double. Output numbers are assigned to side A and B alternatively.

In case of single solenoid valve, output on side B is free. (Refer to fig.a)

∗: ixed (single and double) wiring is available as long as wiring specifications designate it.

This allows output numbers to be specified without having free output. (Refer to fig.b)

∗: Each bit of data sent from master (4 bytes) shows ON/OFF (0: OFF, 1: ON) of solenoid valve.

Starting from LSB of the first byte (Offset 0), output numbers are assigned to all the bits in

numeric order.

∗: When software setting mode is selected, address setting switches are not effectual. oreover,

software setting mode and hardware setting mode differ in ID numbers of units.

Note: Specifications are subject to change without prior notice and any obligation on the part of the manufacturer.

© 2011 S C Corporation All Rights Reserved

Akihabara UDX 15F, 4-14-1, Sotokanda, Chiyoda-ku, Tokyo 101-0021, JAPAN

Phone: +81 3-5207-8249 Fax: +81 3-5298-5362

URL http://www.smcworld.com