8

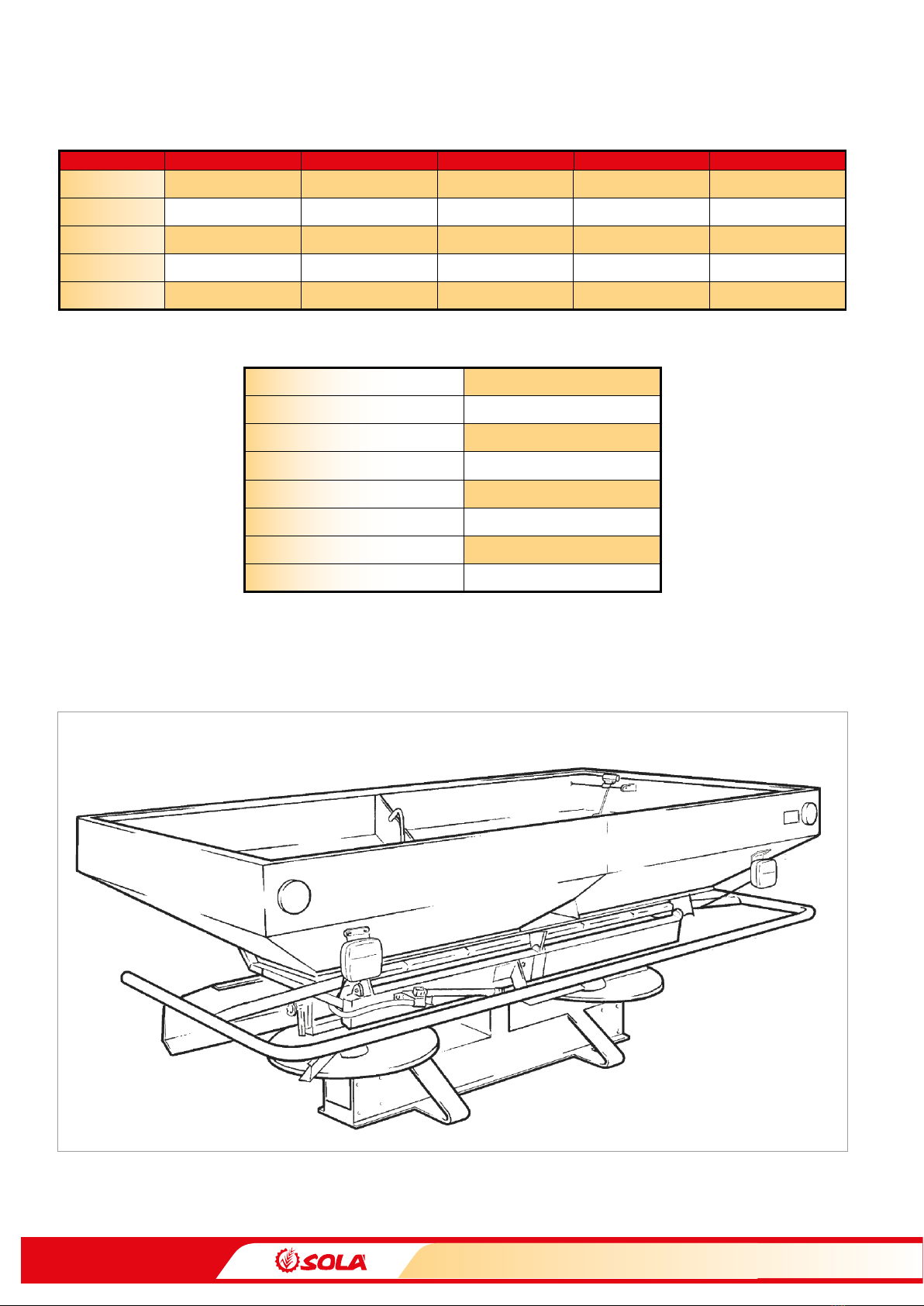

TECHNICAL CHARACTERISTICS

3.2 USE ACCORDING TO DESIGN

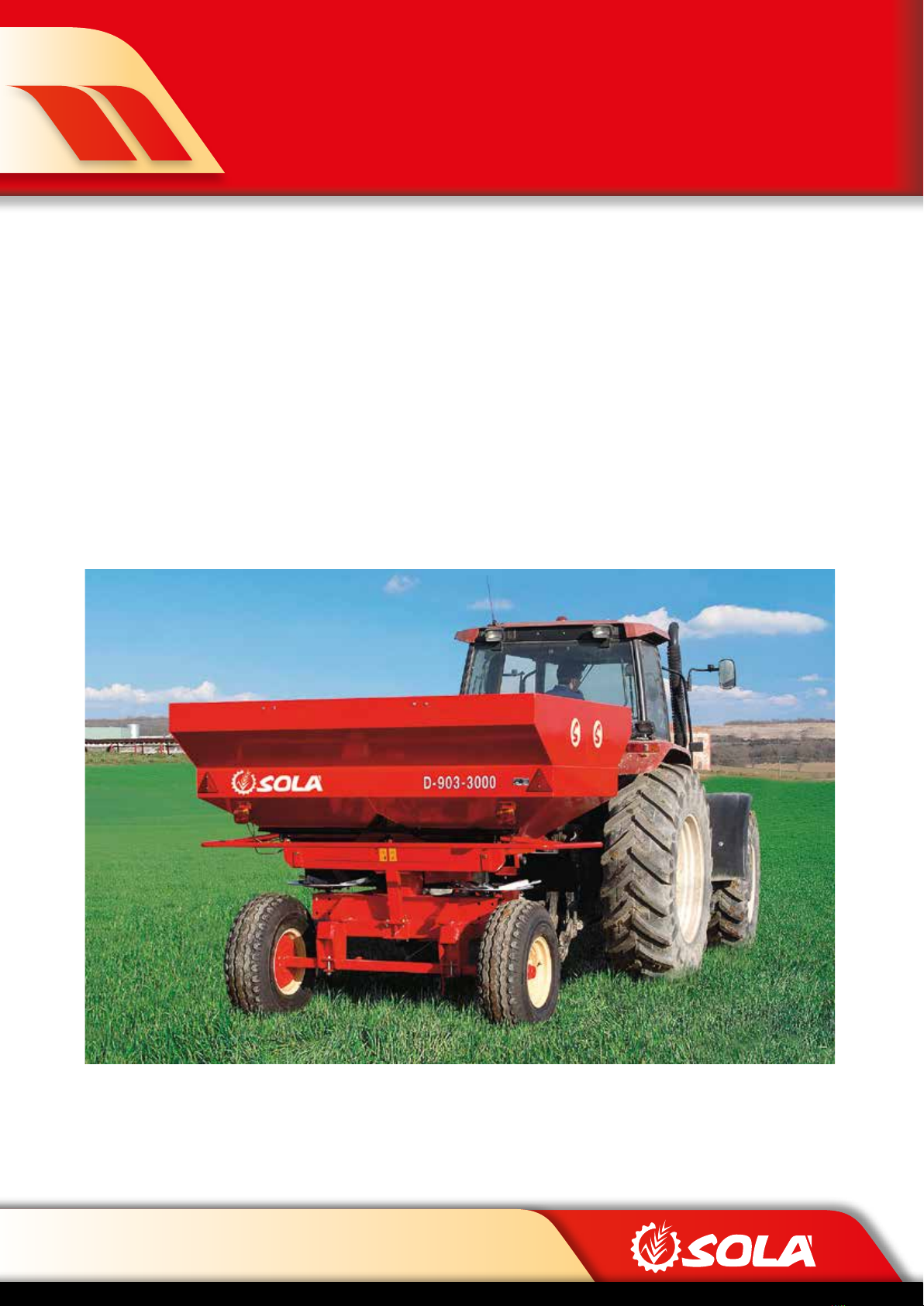

- Fertiliser spreaders D-903 & D-903 PLUS have been de-

signed for normal use in agricultural work, especially for

spreading with mineral products.

- If the machine is used in circumstances other than the above,

SOLÁ will not be held responsible for any damage caused.

- The user must observe all regulations concerning safety, traf-

c and hygiene.

- If the machine is modied by the user, the manufacturer’s

warranty is cancelled.

- SOLÁ will not be held responsible for any damage caused.

3.3 GENERAL SAFETY INSTRUCTIONS

BEFORE STARTING THE MACHINE, PLEASE CHECK

THE MACHINE IS IN GOOD CONDITION FOR WORK

AND IS SAFE FOR ROAD USE.

CHECK THAT VISIBILITY IS CLEAR AROUND THE MA

CHINE AND THERE IS NO PERSON IN THE WORKING

AREA.

IN THOROUGHFARE, PLEASE OBSERVE TRAFFIC

SIGNS AND REGULATIONS.

IT IS FORBIDDEN TO RIDE ON THE MACHINE OR

CLIMB INTO THE MACHINE WHEN IT IS RUNNING.

BEFORE USING THE MACHINE, THE USER MUST BE FA

MILIAR WITH ALL OPERATING ELEMENTS.

PLEASE BE EXTREMELY CAREFUL WHEN COUPLING

AND UNCOUPLING THE MACHINE TO THE TRACTOR.

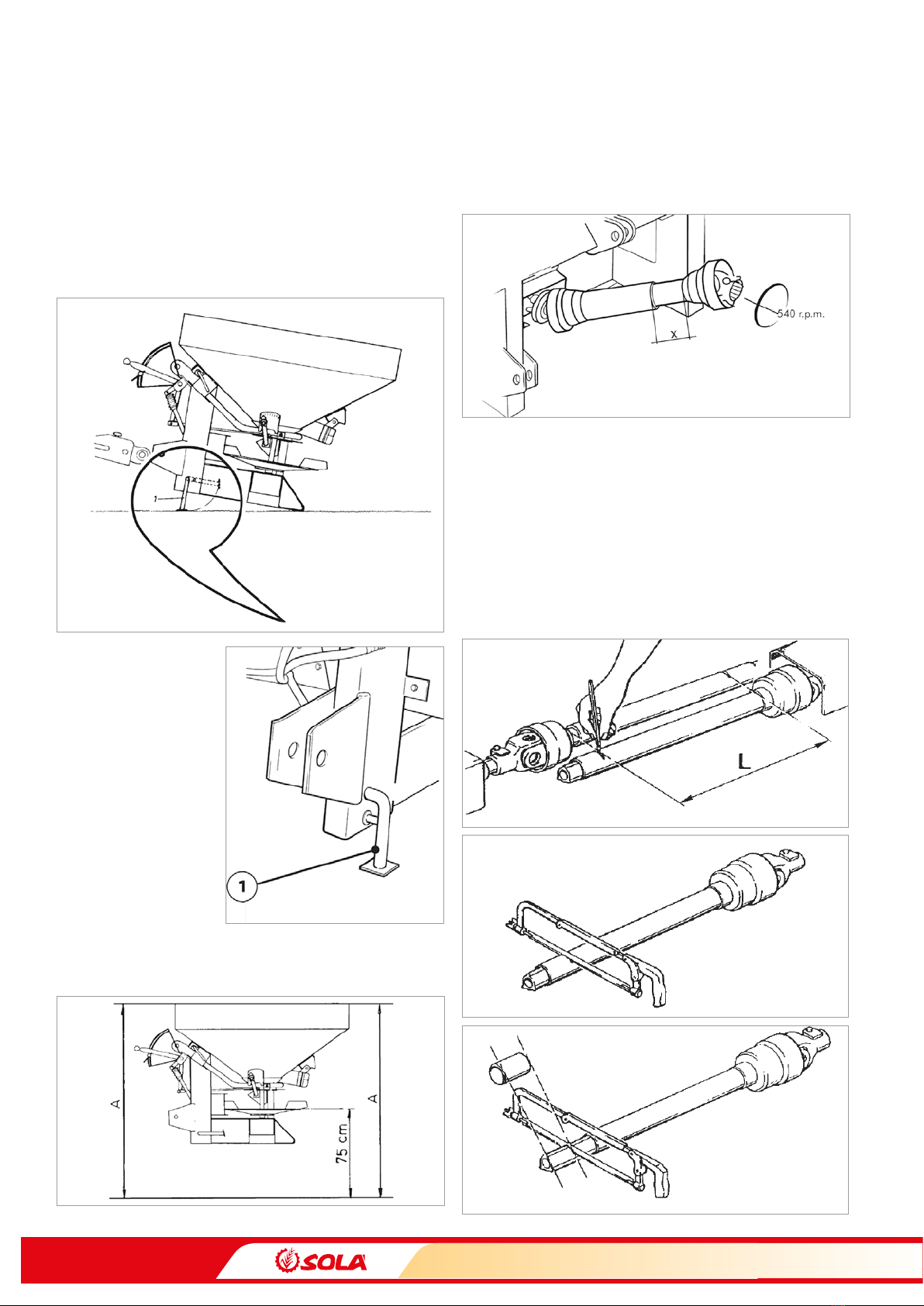

PLEASE CHECK THAT THE PTO SHAFT IS IN GOOD

CONDITION AND WELL PROTECTED. PREVENT THE

PROTECTIVE TUBE FROM TURNING BY HOLDING

BOTH THE TUBE AND CHAIN PROVIDED FOR THIS

PURPOSE.

MOUNT THE PTO SHAFT’S TRANSMISSION ONLY

WHEN THE TRACTOR’S ENGINE IS OFF.

BEFORE CONNECTING THE PTO SHAFT, BE SURE THAT

THE DANGER ZONE SURROUNDING THE MACHINE IS

CLEAR.

NEVER LEAVE THE TRACTOR’S DRIVER’S SEAT WHILE

THE MACHINE IS IN OPERATION.

DO NOT DEPOSIT EXTERNAL ELEMENTS INSIDE THE

HOPPER.

WHEN MANTAINING THE HYDRAULIC SYSTEM OF

THE FERTILISER SPREADER, MAKE SURE THAT IT IS

DEPRESSURISED AND THE TRACTOR’S ENGINE IS OFF.

PLEASE REGULARLY CHECK THE CONDITION OF THE

TUBES AND HOSEPIPES IN THE HYDRAULIC SYS

TEM. THESE PARTS AGE NATURALLY AND THEIR LIFE

SHOULD NOT SURPASS 6 YEARS. PLEASE REPLACE

WHEN NECESSARY.

WHEN RAISING THE FERTILISER SPREADER, THE

FRONT AXLE IS UNLOADED. ENSURE THAT THE MA

CHINE HAS ENOUGH LOAD TO PREVENT IT OVER

TURNING. AT THIS TIME YOU MUST ENSURE THAT

THE CONDITION OF BOTH THE STEERING AND THE

BRAKES IS OPTIMAL.

DURING TRANSIT WITH THE RAISED FERTILISER

SPREADER, BLOCK THE LOWERING SWITCH. BEFORE

LEAVING THE TRACTOR, LOWER THE FERTILISER

SPREADER ONTO THE GROUND AND REMOVE THE

TRACTOR’S STARTING KEY.

ALWAYS USE ENOUGH SUPPORTING ELEMENTS

WHEN MAINTAINING THE MACHINE IN A RAISED PO

SITION TO PREVENT THE MACHINE FROM LOWERING

OR FALLING.

FILL THE FERTILISER SPREADER WHEN IT IS IN ON THE

GROUND, ENSURE THE TRACTOR ENGINE IS OFF AND

THE FERTILISER OUTLET OPENINGS ARE CLOSED.

ALWAYS CONNECT GENTLY THE PTO SHAFT’S CLUTCH

IN ORDER TO PROTECT THE FERTILISER SPREADER.

OTHERWISE THE MACHINE COULD BE SERIOUSLY

DAMAGED.

BE CAREFUL WHEN FILLING THE FERTILISER SPREAD

ER AND TAKING INTO A FIELD WHICH IS FAR AWAY. IT

IS POSSIBLE THAT THE FERTILISER COMPACTS AT THE

BOTTOM OF THE HOPPER AND THE OUTLET OPEN

INGS ARE OBSTRUCTED. IN THIS CASE IT WILL BE NEC

ESSARY TO COMPLETELY OPEN THE OUTLETS, LET THE

PTO SHAFT’S CLUTCH SLOWLY IN AND SPREAD SOME

FERTILISER. AFTER THIS OPERATION, PLACE THE AD

JUSTING LEVERS IN THE POSITION CORRESPONDING

TO THE CHOSEN FLOW AND SPREAD NORMALLY.

NEVER DELIBERATELY CAUSE THE EXIT OF THE FERTIL

ISER FROM THE UPPER PART OF THE HOPPER. THERE

IS A SERIOUS RISK OF OBSTRUCTING THE AGITATOR.

AFTER EACH WORKING DAY, THE SPREADING VANES

AND THEIR TIGHTING SCREWS SHOULD BE CHECKED.

THEY SHOULD BE REPLACED WHEN THEY ARE VISI

BLY WORN OUT, SINCE THE WEAR IS CAUSED BY THE

CONTACT WITH THE FERTILISER AND IT IS BECOMES

WORSE WHEN THE FERTILISER IS MORE ABRASIVE.

CONSEQUENCES OF WORN OUT SPREADING VANES

ARE A BAD IRREGULAR SPREADING AND, ESPECIALLY,

THE RISK CAUSED BY FRAGMENTS DETACHED FROM

THE SPREADING VANES.