3

TABLE OF CONTENTS

1 INTRODUCTION......................................................................................................................................5

2. GENERAL DESCRIPTION OF THE MACHINE ...........................................................................................6

2.1 OVERVIEW...............................................................................................................................................................6

2.2 STANTDARD EQUIPAMENT.................................................................................................................................6

2.3 OPTIONAL EQUIPAMENT ....................................................................................................................................6

2.4 TECHNICAL CHARACTERISTICS.........................................................................................................................7

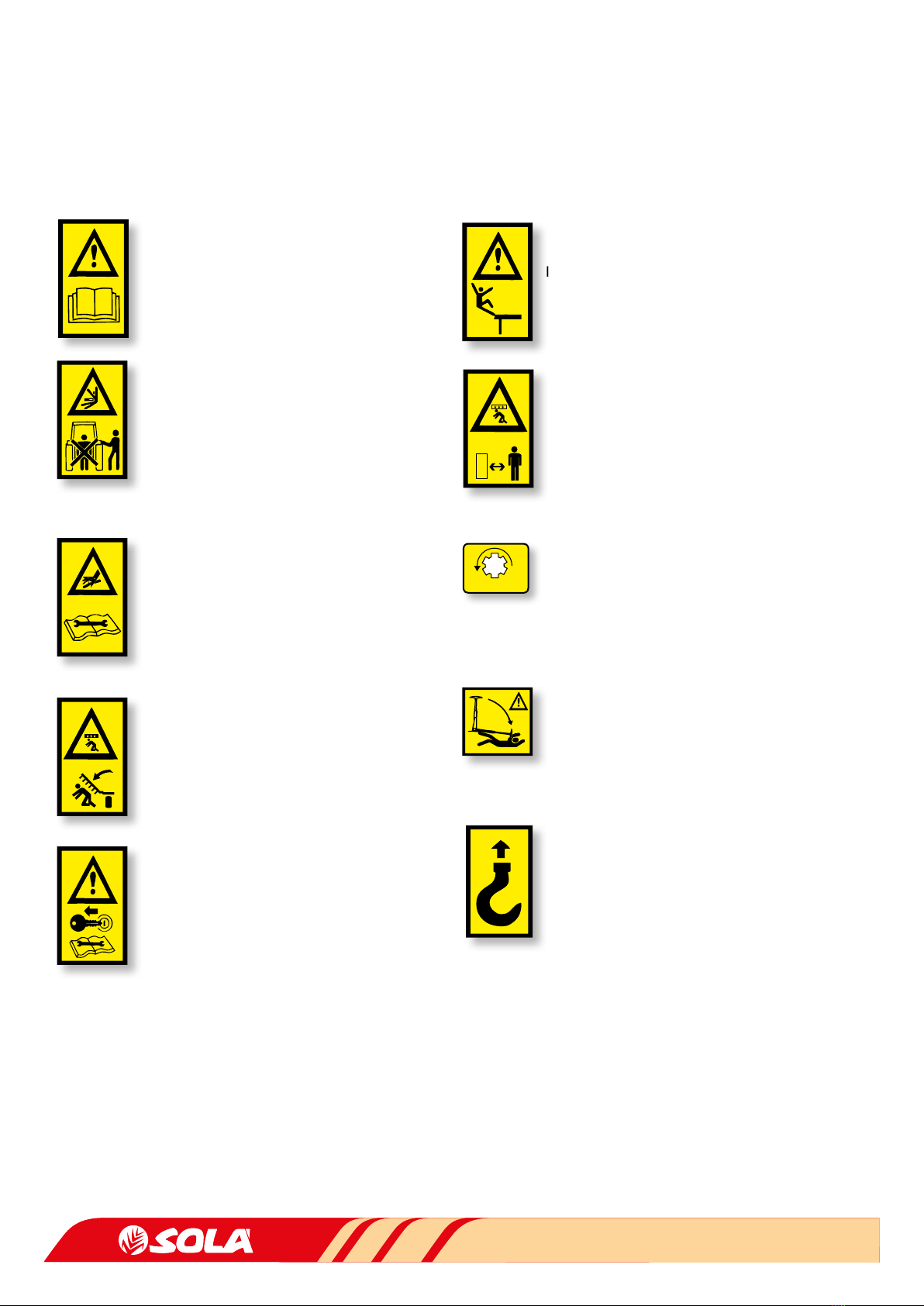

3 SAFETY INSTRUCTIONS .........................................................................................................................8

3.1 SAFETY SYMBOLS .................................................................................................................................................8

3.2 USE ACCORDING TO DESIGN..............................................................................................................................8

3.3 GENERAL SAFETY INSTRUCTIONS....................................................................................................................9

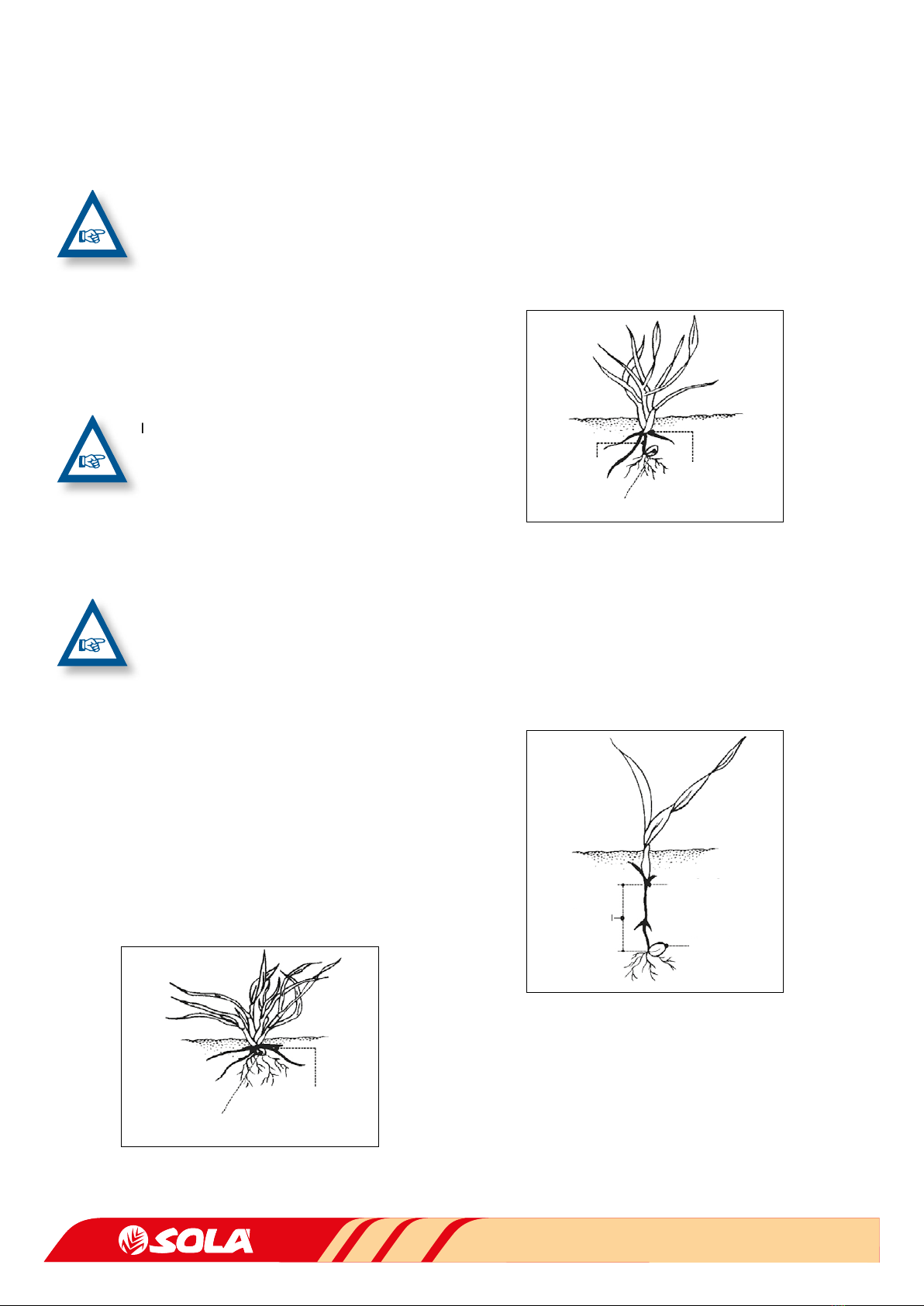

4 ESSENTIAL SOWING CONCEPTS ..........................................................................................................10

4.1 TERRAIN .................................................................................................................................................................10

4.2 THE SEED...............................................................................................................................................................10

4.3 SEED PLANTING DEPTH ....................................................................................................................................10

5. STARTING..............................................................................................................................................12

5.1 COUPLING THE SEED DRILL..............................................................................................................................12

5.2 HYDRAULIC CONNECTIONS ............................................................................................................................12

5.2.1 HYDRAULIC SYSTEM...............................................................................................................13

5.3 TRANSPORT POSITION ......................................................................................................................................14

5.4 LOADING THE SEED DRILL MANUALLY..........................................................................................................14

5.5 THE BUILTIN SUPPORTING LEGS....................................................................................................................14

6. DOSAGE ................................................................................................................................................15

6.1 REGULAR SEEDS POSITION N ........................................................................................................................16

6.2 FINE SEEDS MICRODOSING POSITION F..................................................................................................16

6.3 PREVIOUS FLOW TEST........................................................................................................................................17

6.4 COMPLEMENTARY CHECKING TESTS .............................................................................................................18

6.4.1 TEST TO DETERMINE THE NUMBER OF WHEEL TURNS...................................................18

6.4.2 SEED DOSING ADJUSTMENTS ..............................................................................................19

7 ADJUSTING SEED PLANTING DEPTH...................................................................................................20

7.1 ADJUSTING RATCHETS AND SPINDLES......................................................................................................... 20

7.2 INCLINATION OF THE FOLDING PARTS......................................................................................................... 20

7.3 TRACK ERASERS...................................................................................................................................................21

7.4 LEVELLER OPTIONAL .......................................................................................................................................21

7.5 SEEDING ARM.......................................................................................................................................................21

7.5.1 TINE COULTER ...........................................................................................................................21

7. 5. 2 P T .................................................................................................................................................21

7.5.3 DISCO......................................................................................................................................... 22

7.5.4 SUFFOLK COULTERS ............................................................................................................... 22

7. 6 H A R R OW ............................................................................................................................................................... 22

7.7 HYDRAULIC TRACK MARKERS......................................................................................................................... 23

7.7.1 ADJUSTING TRACK MARKER’S LENGTH. ............................................................................ 23

7.7.2 ADJUSTING TRACK MARKER’S INCLINATION ................................................................... 23

8 TYPES OF DISTRIBUTION.....................................................................................................................24

8.1 SEED DISTRIBUTION BY MECHANICAL FAN................................................................................................. 24

8.2 SEED DISTRIBUTION BY HYDRAULIC FAN.................................................................................................... 24