TABLE OF CONTENTS

1. INTRODUCTION .................................................................................4

2. TECHNICAL SPECIFICATIONS .........................................................5

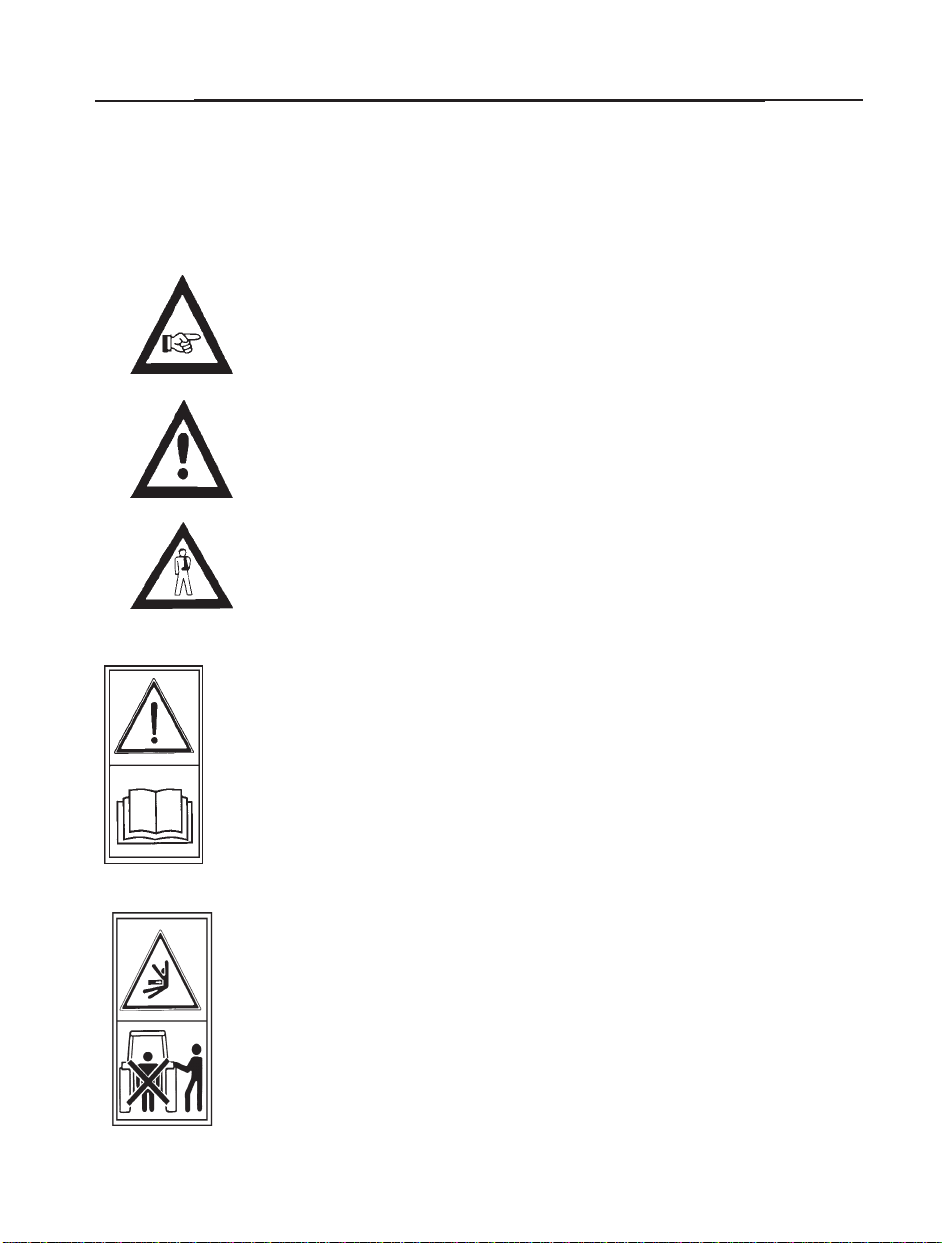

3. SAFETY INSTRUCTIONS ...................................................................6

3.1 Safety symbols ..................................................................................6

3.2 Proper use .........................................................................................8

3.3 General specifications .......................................................................8

4. ESSENTIAL CONCEPTS FOR FERTILIZING....................................10

5. FERTILIZER SPREADER SETTINGS ...............................................11

5.1 Shorten method ................................................................................11

5.2 Physical knowledge of the fertilizer...................................................12

5.3 Working width settings......................................................................13

5.4 Flow setting ......................................................................................15

6. BORDER FERTILIZED ......................................................................17

7. FLOW TEST............... .......................................................................18

8. CARE AND MAINTENANCE..............................................................19

9. DOSAGE TABLES..............................................................................20

10.SPARE PARTS..................................................................................24

10.1 TRANSMISION UNIT......................................................................25

10.2 SHAKER..........................................................................................26

10.3 REAR PROTECTION......................................................................27

10.4 TRANSMISSION PROTECTION....................................................28

10.5 GRADATION UNIT.........................................................................29

10.6 DRIER.............................................................................................30

10.7 COMPLETE MACHINE...................................................................31

10.8 HYDRAULIC EQUIPMENT OPENING AND CLOSING..................32

10.9 BRAKE UNIT...................................................................................33

10.10 ELECTRONIC EQUIPMENT.........................................................34

10.11 DISTRIBUTION EQUIPMENT.......................................................35