US9469701 (02-14)

Operator's Manual & Spare Parts List

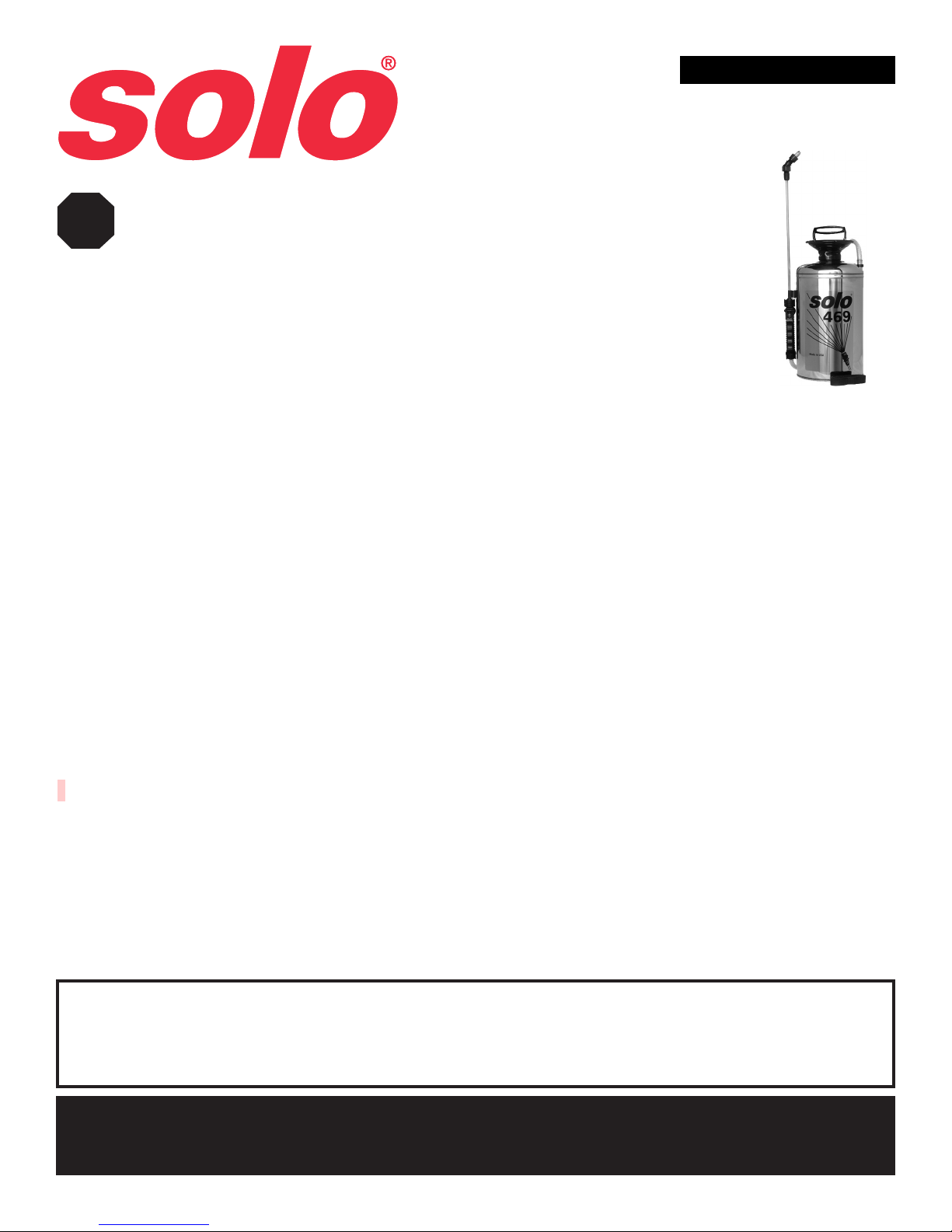

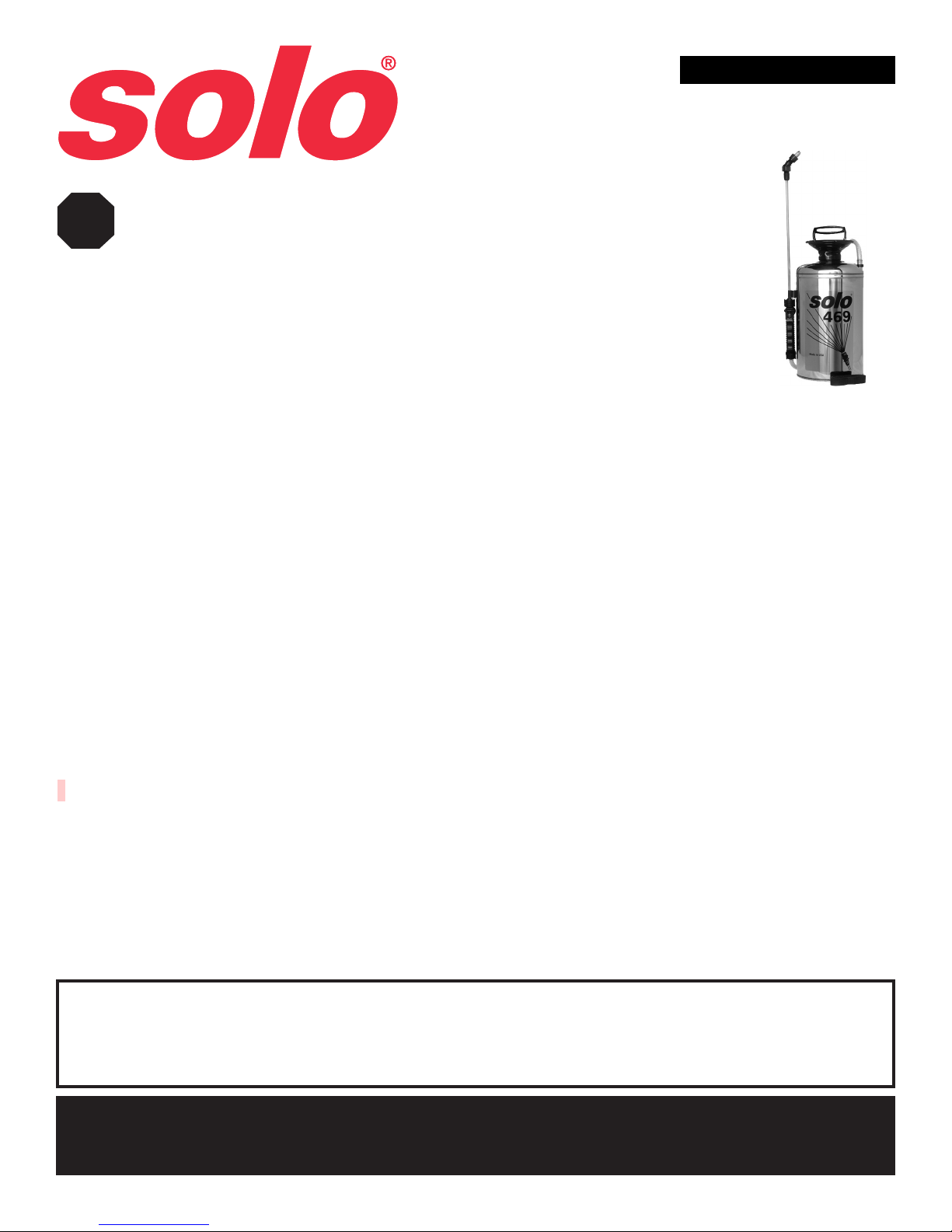

Model 469 Professional Stainless Steel

Compression Sprayer

SAFETY PRECAUTIONS:

Do not fill with, use, or spray flammable materials.

Do not use gasoline, acid, caustic or potentially injurious chemicals.

At the time of manufacture of this sprayer, we are not aware of any approved plant protection or pest control chemi-

cals which would adversely affect this sprayer when applied in their recommended concentration.

Always observe the recommendations of the chemical manufacturer.

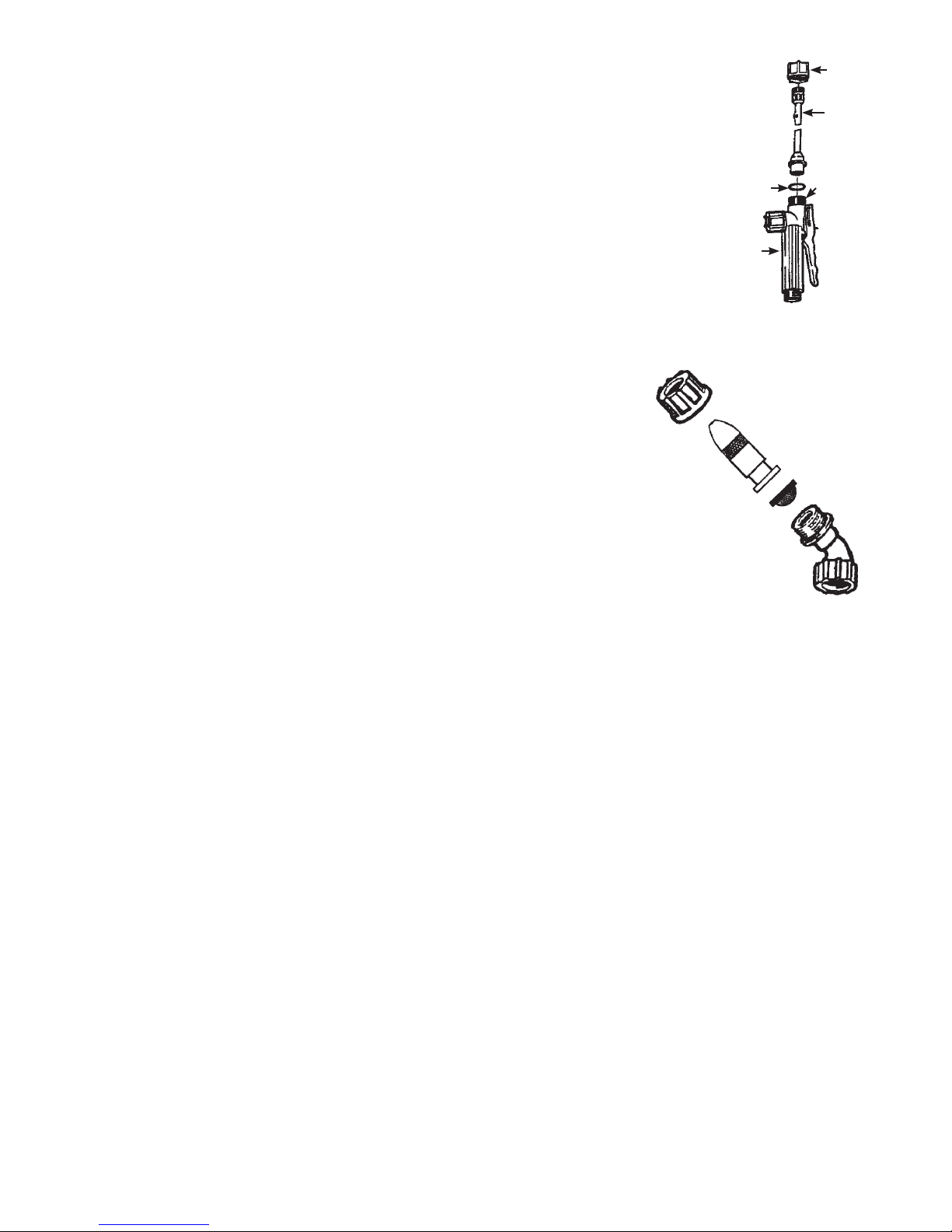

Prior to removing any part of the sprayer, squeeze the shut-off valve to release any pressure in the tank.

Wear rubber gloves, safety goggles and appropriate protective clothing.

After pressurizing the sprayer, be sure the handle is in the locked down position.

Individuals should be trained in the proper use of this sprayer. Where training is not available, individuals should

study and follow the procedures detailed in this manual.

•

•

•

•

•

•

•

•

WARNING:

Chemicals can be harmful to individuals and the environment if improperly used. In addition, some chemicals are caustic,

corrosive, or poisonous and should be avoided. Read warnings and follow chemical manufacturer's instructions. Solo

sprayers are fitted with Viton®seals, which are resistant to a wide variety of agricultural and household chemicals;

however, care should be exercised to ensure that sprayer components are clean, functioning properly, and in a good

state of repair before and during use. If in doubt about a particular chemical, check with manufacturer. If you suspect or

observe indications that the material may be unsafe in a Solo sprayer... STOP! Do not use or apply chemical!

ALWAYS WEAR RUBBER GLOVES, SAFETY GOGGLES AND APPROPRIATE PROTECTIVE CLOTHING.

Read and follow operating instructions. Test sprayer with plain water to familiarize yourself with sprayer features.

Do not fill sprayer over maximum fill mark. Releasing pressure in an overfill condition can cause harmful venting of

sprayer contents. Only release pressure by spraying chemical into a suitable container for later use.

Only relieve pressure with sprayer upright.

CAUTION: To prevent injury from ejected pump assembly and/or solution, never stand with face or body over the

top of the tank when pumping, or while loosening pump.

Do not modify sprayer.

Never spray in the direction of humans, animals or property which might be injured or damaged by spray formula.

Do not use disinfectants, solvents or impregnating agents unless first tested to ensure they are not harmful to the

environment or the sprayer.

Do not use liquids with a temperature above 110°F (43°C).

A sprayer filled with liquid is a significant amount of weight (8 lbs. per gallon). When carrying, use caution when

bending, leaning or walking. Bend only at the knees and support yourself as necessary to ensure personal safety.

Do not pressurize sprayer without liquid in the tank.

Do not climb on ladders, trees or other unsteady or potentially unsafe structures while using sprayer.

•

•

•

•

•

•

•

•

•

•

•

Customer Service Commitment From Solo's Service Department

In the event the sprayer you have purchased has missing or damaged parts, please call 1-800-765-6462, 9:00 AM - 5:00 PM EST.

In order to assist your service representative, please have the following information available: sprayer model number, part

description and part number. A parts list is included in your operator's manual.

Solo is committed to your satisfaction and is continuing its efforts to earn your future business.

Visit us on the web at www.solousa.com

Parts available on-line, or by calling Solo’s order desk at (757) 245-5531.

WARRANTY:

Solo model 469 Professional sprayers are covered by Solo's 5-YEAR LIMITED WARRANTY. Solo

manufactured parts, which fail due to defective material or workmanship, will be repaired or replaced

without charge. See page 3 for full details.

STOP! If you are missing parts, instructions or have questions, DO NOT take this unit back to the

store. Call 1-800-SOLO-INC. Solo will send the missing parts/information to you promptly.