CLEANING

• Afterspraying,cleanthetankthoroughly.Ifsomesprayliquid

is left inside, drain tank completely.

• Pumpingcausesairtobetakeninandtheremainingliquid

tobedischarged.Pumpuntilliquidandairarecomingout

through the nozzle.

• Relltankwithafewlitresofcleanwaterandpumpthewater

out as explained above (if necessary, repeat this procedure

several times).

• IftheLanceisremoved,thepumpcanbeushedquickly.

Improper spray distribution is the result of a clogged nozzle,

which is easily removed and cleaned.

• Soapandwatermayalsobeusedtocleantank.

• Donotuseaggressivecleaningagentsorabrasives.

• Followtherecommendationsofthechemicalmanufacturer

for disposal of waste water and chemicals.

• Activatedcharcoalinliquidorotherformmaybeusedto

absorb chemicals in tanks or spills.

NOTE: When cleaning the sprayer after working with hormone weed killers, follow the

instructions of the herbicide producers. Neutralize with activated charcoal. (Example:

add 1g. of activated charcoal to 1 liter of water and leave this detergent in the tank

and the lines approximately for 24 hours.) This is very important if other chemicals

should be sprayed as the residues of the herbicide may damage susceptible plants.

Cleaning after application of products containing carbolineum, if they are not water

soluble,shouldbedonewitha5%sodalyehavingatemperatureof40°C.Rinsewith

plenty of clean water.

MAINTENANCE AND STORAGE TIPS

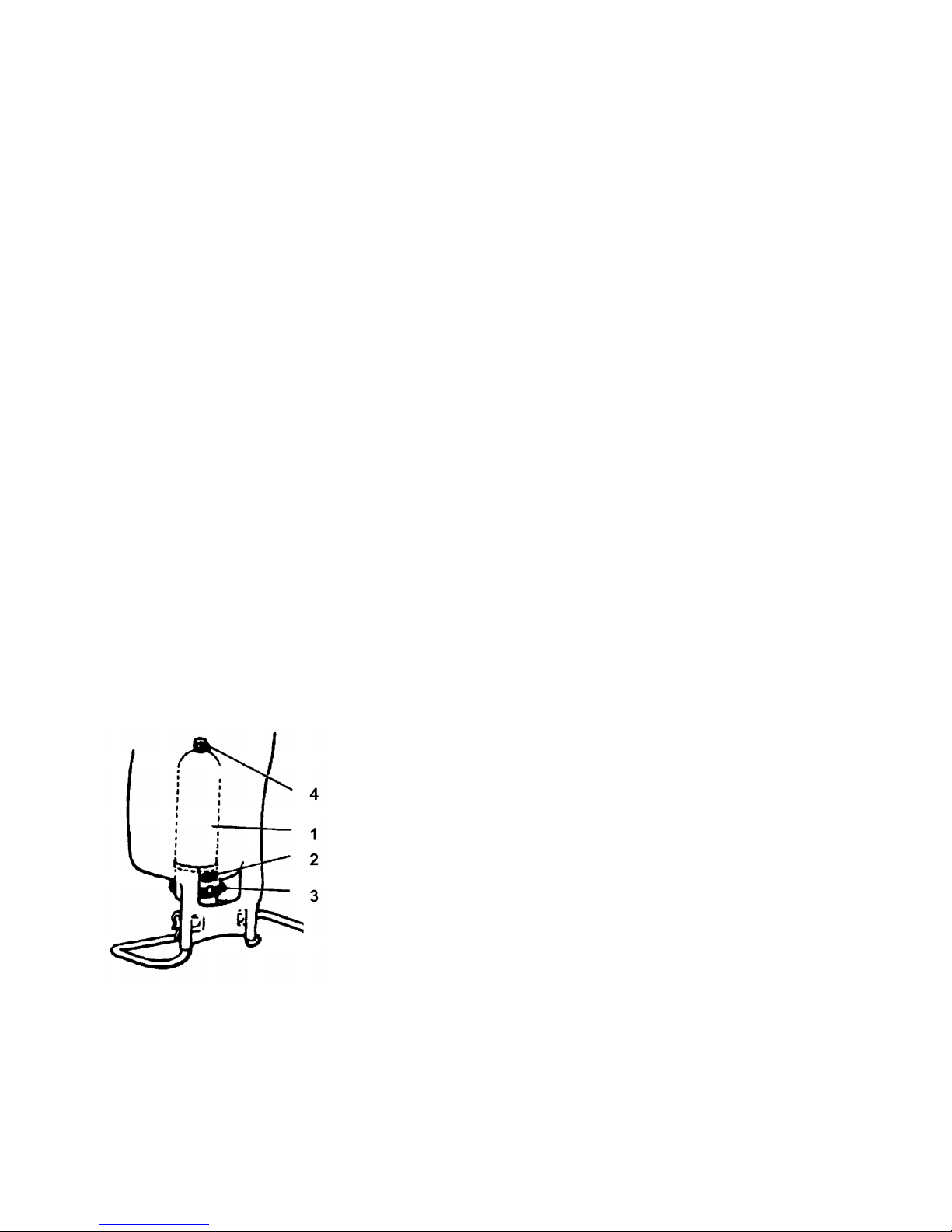

To protect the piston, cylinder and Viton®collar, a fine mesh,

stainless steel screen is located on the pressure cylinder inlet.

If you find that your sprayer will not empty the formula tank,

check for a clogged inlet screen (2). The inlet screen is located

at the bottom of the pressure cylinder on the side that faces your

back.

One indication that it needs cleaning is that when you let

go of the pump handle, it “springs” to the down position.

The screen can be cleaned with a small bristle brush or a

discarded toothbrush. See diagram for location of screen.

• Afteroperation,thesprayershouldbestoredawayfrom

direct sunlight to prevent UV damage.

• AfterremovingthepumporwhenmountinganewViton®

collar, treat both the collar and the piston with water resistant

grease.*

• Beforewinter,drainallliquidintank,linesandairchamber.

(See “Cleaning.”) Leave shut-off valve locked in the “open”

position.

• Forservice,visitourwebsitetolocateyournearest

Solo dealer. Always insist on original Solo spare parts.

• Regularlyinspecthose,wand,pump,tankandshut-offvalve

for wear, damage or leaks. Repair promptly.

• Occasionallylubricatecapgasket.*

Avoid excessive wear by:

1. Regular lubrication of Viton®collar, cylinder and piston

with water resistant grease.*

2. Prompt and thorough cleaning and flushing of sprayer.

Soap and water work well.

*Use Petroleum jelly.

SOLO WARRANTY

Solo Australia warrant the product from the date of purchase, for

a period as stated below. The warranty covers manufacturer’s

defects in material or workmanship. The warranty does not

cover malfunctions due to misuse or due to failure to follow the

instructions in this manual. Any alterations to the product are

to be performed by a Solo Australia approved service agent.

Any repairs performed by non approved personnel may void the

warranty.

To make a claim, contact Clayton Engineering, 26 French Ave,

Brendale, Q, 4500 on phone 1300 798 022 or email sales@

claytonengineering.com.au.You will be asked to provide proof

of purchase and then will be instructed on the procedure for

repairing or replacement of the product under warranty. All costs

incurred for repair or replace, and additional claims can be

discussed at this stage.

This warranty is provided in addition to other rights and remedies

you have under law: Our goods come with guarantees that

cannot be excluded under the Australian Consumer Law. You

are entitled to a replacement or refund for a major failure and

for compensation for any other reasonably foreseeable loss or

damage.You are also entitled to have the goods repaired or

replacedifthegoodsfailtobeofacceptablequalityandthe

failure does not amount to a major failure.

CONSUMER WARRANTY

Solo equipment purchased forconsumer use is covered by this

Warranty for a period of 5 years (Models 425 & 475) and 2 years

(Model 425D

& 425LC

).

COMMERCIAL WARRANTY

Solo equipment purchased for commercial use is covered by

this Warranty for a period of 2 years (Models 425 & 475) and

6 months (Model 425D

& 425LC

).

ITEMS NOT COVERED BY WARRANTY

Provisions of the Warranty will not apply to the following:

Normalservicerequirementsarisingduringthewarrantyperiod,

such as cleaning, normal wear, lubrication, filter, spray tips, etc.

Normal service work over and above the repair or replacement of

defective parts.

Any failure that results from an accident, customer abuse, normal

wear, neglect or failure to operate the product in accordance

with the instructions provided in the operator’s manual or

provided with the product. When an alteration or modification

has been performed on a Solo product, Solo is responsible

only for products as originally furnished by Solo, provided the

alterations or modifications do not adversely affect the product’s

operation, performance or durability. Parts or accessories that

are incompatible with the product are not approved by Solo.

Full disclosure of Solo’s Warranty is available from your local

Solo dealer or SOLO Australia.

1. Pressure Cylinder

2. Inlet Screen

3. Pump Clamp

4. Pressure Control Valve

(425 & 475 Models Only)