65

LT50/60 CMO and LT50 RTS CMO

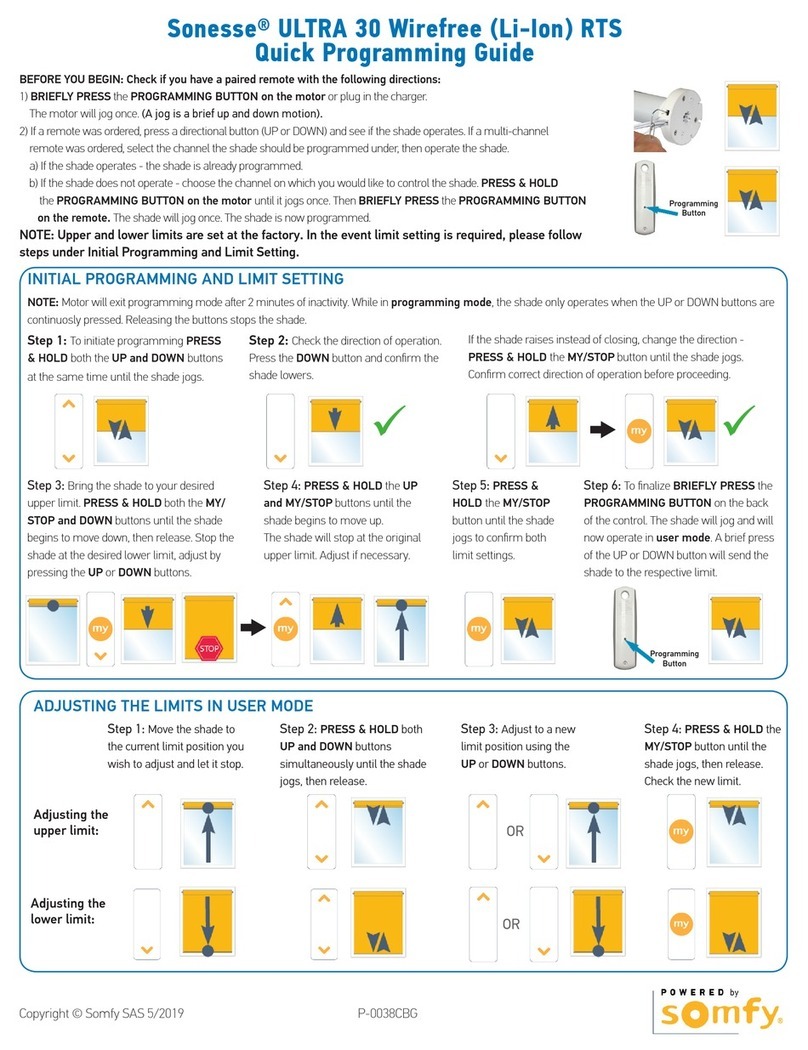

1) Provide power to the motor.

Remove cap as shown in Fig. (2) and depress both limit switch

buttons until they lock in the down position.

To assign the transmitter to communicate with the motor, push the

UP

and

DOWN

buttons on the transmitter simultaneously until the

motor jogs briefly up and down then release. See Fig. (3).

2) Check the direction of operation.

The

DOWN

button should correspond with the down direction of the end product (for awnings

DOWN

extends the

awning).

If the direction is wrong, press the

STOP

button on the transmitter as shown in Fig. (4) until the motor jogs. Check

the direction again to make sure it is correct.

3) Setting the UP and DOWN limits

Press the

UP

button of the transmitter until the end product

reaches the required UP position, then stop it.

Unlock the UP limit switch on the motor head by pressing

and releasing it. The UP limit is now set.

Repeat the above operation to set the DOWN limit.

4) Recording the settings on your transmitter

Press the programming button on the back of the transmitter

and release when the product jogs briefly UP and DOWN.

The transmitter is now memorized into the motor.

Note: On 4 channel transmitters, verify the desired channel

selection before pressing the programming button.

65

LT50/60 CMO and LT50 RTS CMO

1) Provide power to the motor.

Remove cap as shown in Fig. (2) and depress both limit switch

buttons until they lock in the down position.

To assign the transmitter to communicate with the motor, push the

UP

and

DOWN

buttons on the transmitter simultaneously until the

motor jogs briefly up and down then release. See Fig. (3).

2) Check the direction of operation.

The

DOWN

button should correspond with the down direction of the end product (for awnings

DOWN

extends the

awning).

If the direction is wrong, press the

STOP

button on the transmitter as shown in Fig. (4) until the motor jogs. Check

the direction again to make sure it is correct.

3) Setting the UP and DOWN limits

Press the

UP

button of the transmitter until the end product

reaches the required UP position, then stop it.

Unlock the UP limit switch on the motor head by pressing

and releasing it. The UP limit is now set.

Repeat the above operation to set the DOWN limit.

4) Recording the settings on your transmitter

Press the programming button on the back of the transmitter

and release when the product jogs briefly UP and DOWN.

The transmitter is now memorized into the motor.

Note: On 4 channel transmitters, verify the desired channel

selection before pressing the programming button.

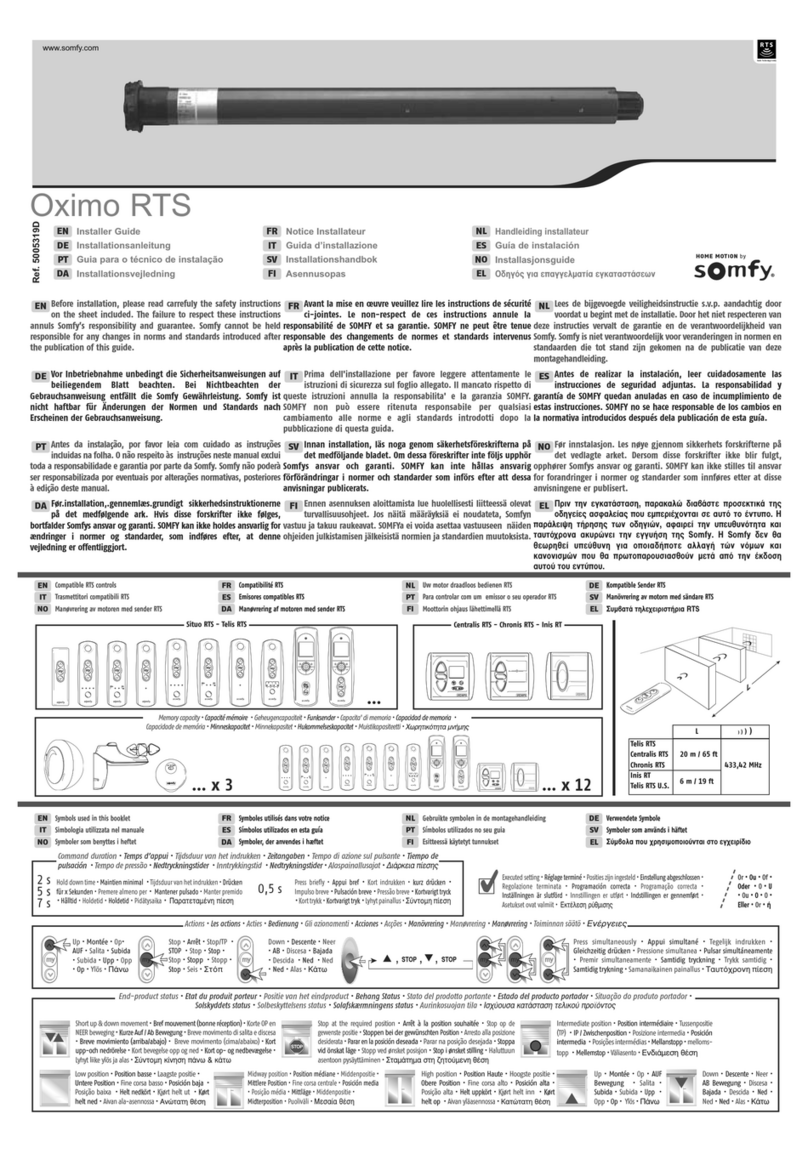

UP

STOP

DOWN

White Button

Yellow Button

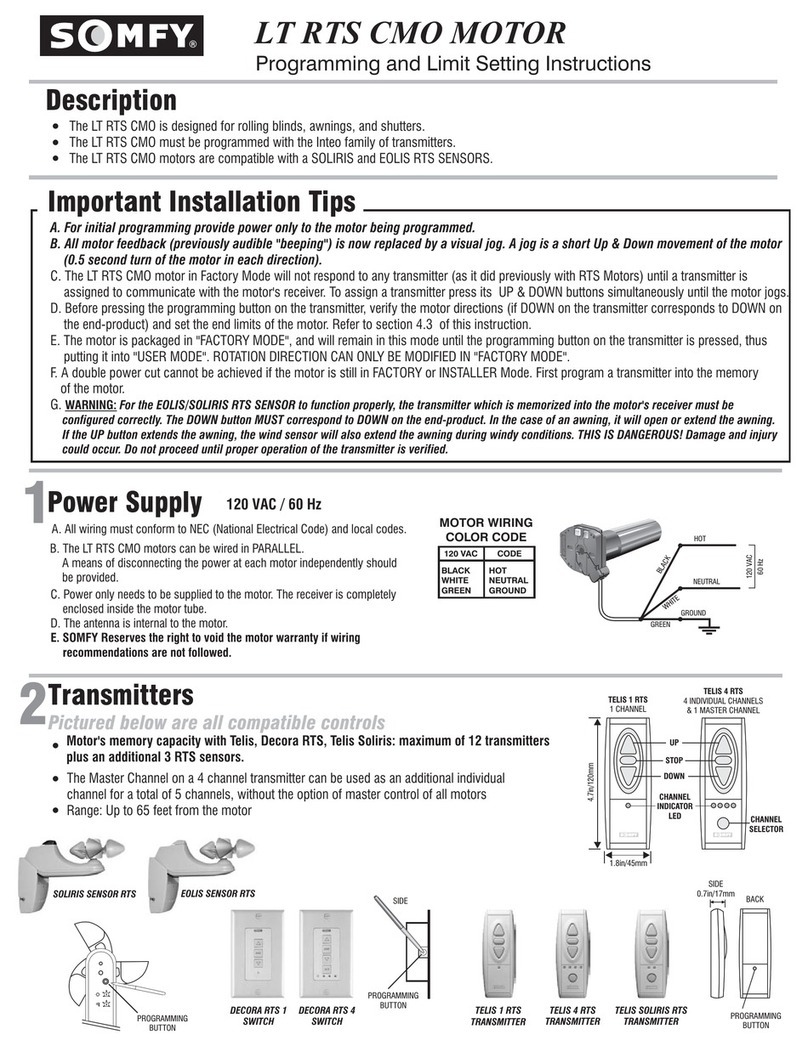

Programming and Limit Setting Instructions

120 VAC

60 Hz

NEUTRAL

GROUND

GREEN

WHITE

HOT

BLACK

5) Setting the intermediate position

Upper Intermediate Position:

Bring the product to its upper limit. Press the

STOP

and

DOWN

buttons

simultaneously then release. When the product reaches the desired intermediate position, press the

STOP

button.

Make adjustments if needed. Press the

STOP

button again until the motor jogs then release.

Lower Intermediate Position:

Bring the product to its lower limit. Press the

STOP

and

UP

buttons simultaneously

then release. When the product reaches the desired intermediate position, press the

STOP

button. Make

adjustments if needed. Press the

STOP

button again until the motor jogs then release.

6) Adding and deleting a transmitter or transmitter channel

To

Add

a transmitter/channel, press the programming button of an already recorded one until the motor jogs.

Select the transmitter/channel to add and press the programming button until the motor jogs.

To

Delete

a transmitter/channel, press the programming button of an already recorded one until the motor jogs.

Select the transmitter/channel to delete and press the programming button until it jogs.

Note: These instructions are for reference only. For more detailed instructions please refer to the installation

instructions packaged with the motor or at www.somfysystems.com under “Technical Documentation”.

For initial programming, provide power only to the motor being programmed.

For awning installations, an awning hood is strongly recommended and a drip loop should be formed to

prevent water from entering the head of the motor as shown in Fig. (1).

Follow the steps below to program the motor and set the limits.

DRIP

LOOP

Fig. (4)Fig. (3)Fig. (2)

Fig. (1)

65

LT50/60 CMO and LT50 RTS CMO

1) Provide power to the motor.

Remove cap as shown in Fig. (2) and depress both limit switch

buttons until they lock in the down position.

To assign the transmitter to communicate with the motor, push the

UP

and

DOWN

buttons on the transmitter simultaneously until the

motor jogs briefly up and down then release. See Fig. (3).

2) Check the direction of operation.

The

DOWN

button should correspond with the down direction of the end product (for awnings

DOWN

extends the

awning).

If the direction is wrong, press the

STOP

button on the transmitter as shown in Fig. (4) until the motor jogs. Check

the direction again to make sure it is correct.

3) Setting the UP and DOWN limits

Press the

UP

button of the transmitter until the end product

reaches the required UP position, then stop it.

Unlock the UP limit switch on the motor head by pressing

and releasing it. The UP limit is now set.

Repeat the above operation to set the DOWN limit.

4) Recording the settings on your transmitter

Press the programming button on the back of the transmitter

and release when the product jogs briefly UP and DOWN.

The transmitter is now memorized into the motor.

Note: On 4 channel transmitters, verify the desired channel

selection before pressing the programming button.

UP

STOP

DOWN

White Button

Yellow Button

Programming and Limit Setting Instructions

120 VAC

60 Hz

NEUTRAL

GROUND

GREEN

WHITE

HOT

BLACK

5) Setting the intermediate position

Upper Intermediate Position:

Bring the product to its upper limit. Press the

STOP

and

DOWN

buttons

simultaneously then release. When the product reaches the desired intermediate position, press the

STOP

button.

Make adjustments if needed. Press the

STOP

button again until the motor jogs then release.

Lower Intermediate Position:

Bring the product to its lower limit. Press the

STOP

and

UP

buttons simultaneously

then release. When the product reaches the desired intermediate position, press the

STOP

button. Make

adjustments if needed. Press the

STOP

button again until the motor jogs then release.

6) Adding and deleting a transmitter or transmitter channel

To

Add

a transmitter/channel, press the programming button of an already recorded one until the motor jogs.

Select the transmitter/channel to add and press the programming button until the motor jogs.

To

Delete

a transmitter/channel, press the programming button of an already recorded one until the motor jogs.

Select the transmitter/channel to delete and press the programming button until it jogs.

Note: These instructions are for reference only. For more detailed instructions please refer to the installation

instructions packaged with the motor or at www.somfysystems.com under “Technical Documentation”.

For initial programming, provide power only to the motor being programmed.

For awning installations, an awning hood is strongly recommended and a drip loop should be formed to

prevent water from entering the head of the motor as shown in Fig. (1).

Follow the steps below to program the motor and set the limits.

DRIP

LOOP

Fig. (4)Fig. (3)Fig. (2)

Fig. (1)

65

LT50/60 CMO and LT50 RTS CMO

1) Provide power to the motor.

Remove cap as shown in Fig. (2) and depress both limit switch

buttons until they lock in the down position.

To assign the transmitter to communicate with the motor, push the

UP

and

DOWN

buttons on the transmitter simultaneously until the

motor jogs briefly up and down then release. See Fig. (3).

2) Check the direction of operation.

The

DOWN

button should correspond with the down direction of the end product (for awnings

DOWN

extends the

awning).

If the direction is wrong, press the

STOP

button on the transmitter as shown in Fig. (4) until the motor jogs. Check

the direction again to make sure it is correct.

3) Setting the UP and DOWN limits

Press the

UP

button of the transmitter until the end product

reaches the required UP position, then stop it.

Unlock the UP limit switch on the motor head by pressing

and releasing it. The UP limit is now set.

Repeat the above operation to set the DOWN limit.

4) Recording the settings on your transmitter

Press the programming button on the back of the transmitter

and release when the product jogs briefly UP and DOWN.

The transmitter is now memorized into the motor.

Note: On 4 channel transmitters, verify the desired channel

selection before pressing the programming button.

UP

STOP

DOWN

White Button

Yellow Button

Programming and Limit Setting Instructions

120 VAC

60 Hz

NEUTRAL

GROUND

GREEN

WHITE

HOT

BLACK

5) Setting the intermediate position

Upper Intermediate Position:

Bring the product to its upper limit. Press the

STOP

and

DOWN

buttons

simultaneously then release. When the product reaches the desired intermediate position, press the

STOP

button.

Make adjustments if needed. Press the

STOP

button again until the motor jogs then release.

Lower Intermediate Position:

Bring the product to its lower limit. Press the

STOP

and

UP

buttons simultaneously

then release. When the product reaches the desired intermediate position, press the

STOP

button. Make

adjustments if needed. Press the

STOP

button again until the motor jogs then release.

6) Adding and deleting a transmitter or transmitter channel

To

Add

a transmitter/channel, press the programming button of an already recorded one until the motor jogs.

Select the transmitter/channel to add and press the programming button until the motor jogs.

To

Delete

a transmitter/channel, press the programming button of an already recorded one until the motor jogs.

Select the transmitter/channel to delete and press the programming button until it jogs.

Note: These instructions are for reference only. For more detailed instructions please refer to the installation

instructions packaged with the motor or at www.somfysystems.com under “Technical Documentation”.

For initial programming, provide power only to the motor being programmed.

For awning installations, an awning hood is strongly recommended and a drip loop should be formed to

prevent water from entering the head of the motor as shown in Fig. (1).

Follow the steps below to program the motor and set the limits.

DRIP

LOOP

Fig. (4)Fig. (3)Fig. (2)

Fig. (1)