64

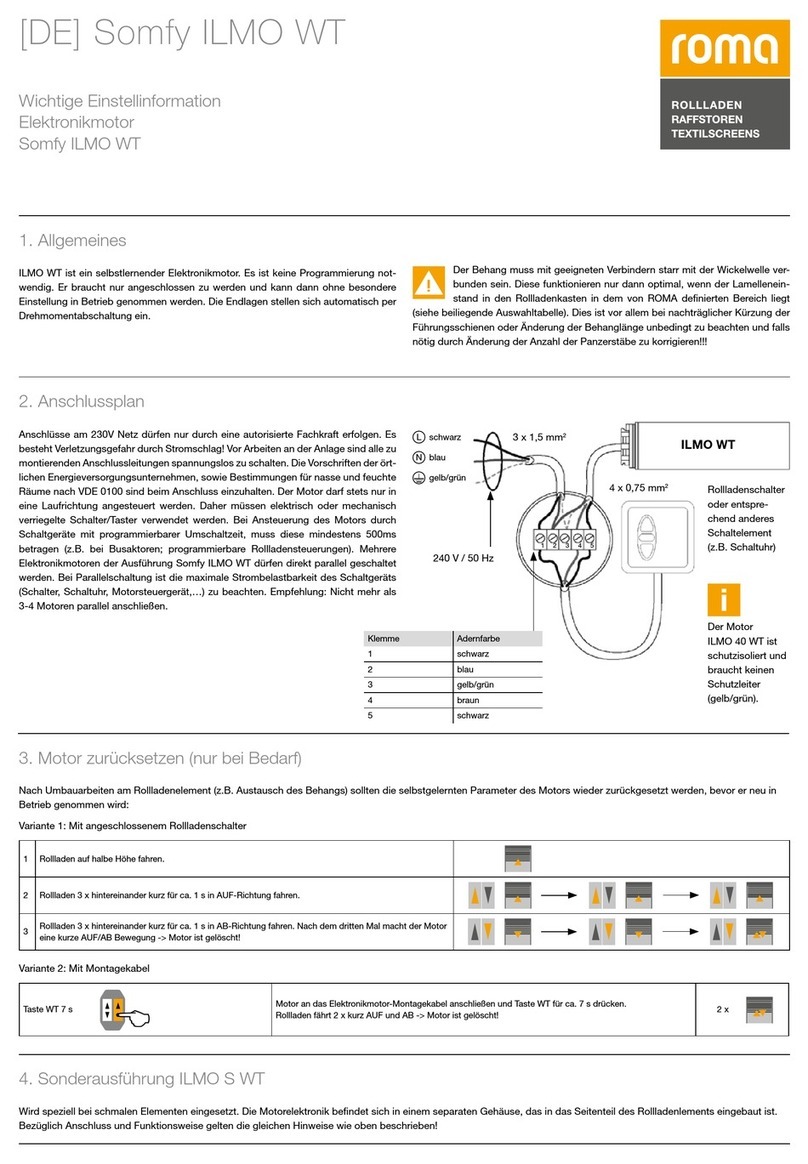

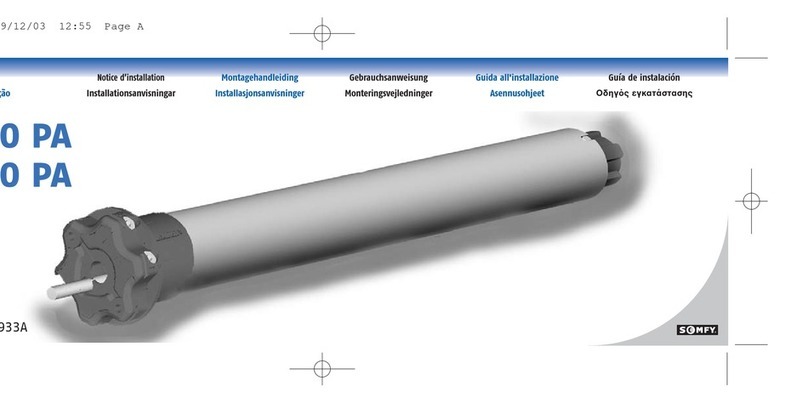

LS40

Stop Position 1

Depending upon type of installation

Motor on Left

Motor on Left

Motor on Right

Motor on Right

Stop Position 2

Stop Position 1

Depending upon type of installation

Motor on Left

Motor on Left

Motor on Right

Motor on Right

Position 2

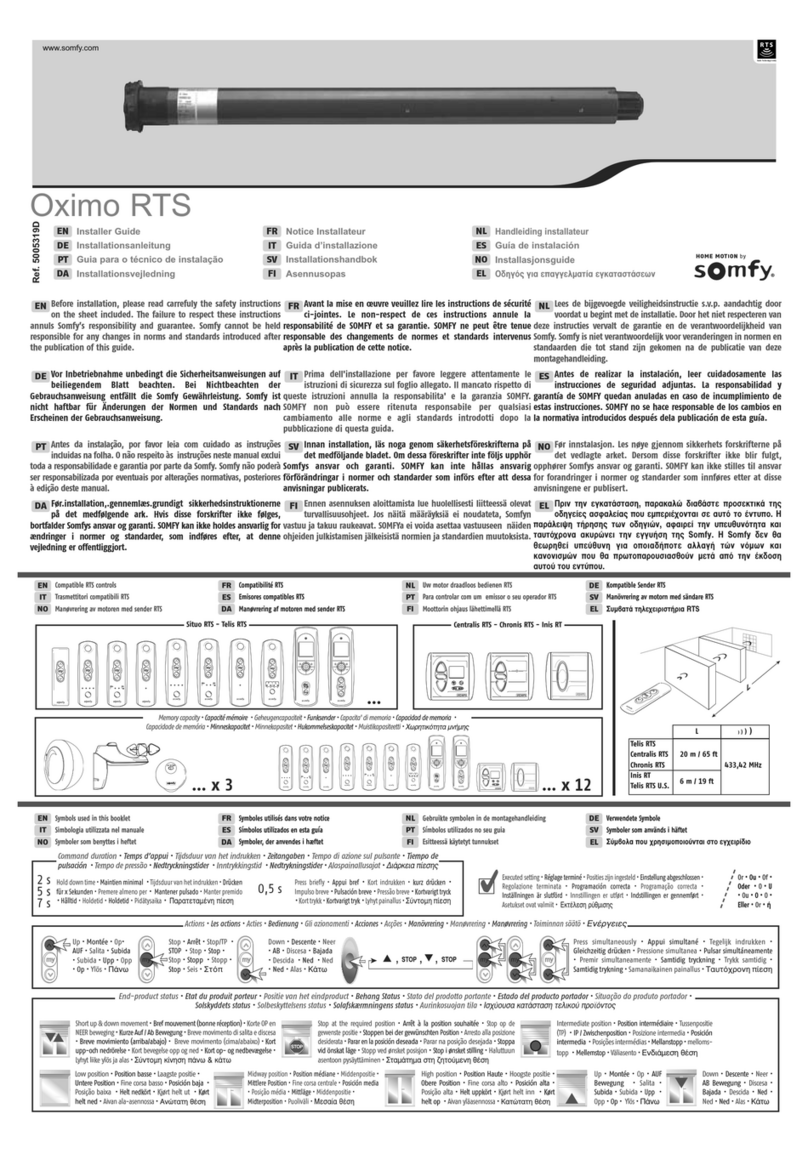

LT50/60 and LT50RH

Installation Instructions

LS40, LT50/60, LT50 RH

Stop position 2

- Bring end product into stop position 2

(direction of rotation 2)

- Release the limit switch adjustment button that lies in the

direction of rotation 2 by pressing it down again.

Stop position is now set.

Always attach protective cap over limit switch adjustment

buttons.

NOTE: It is important to note that SOMFY motors are

weatherproof, but NOT WATERPROOF and therefore the

motor head should not be exposed to direct rainfall.

Test Run 2

Allow the motor to run in both directions, until it shuts off in the

stop positions. Because of the built-in thermal protection

feature, the motor may shut off automatically after running

without interruption for an extended period of time. Please wait

until the motor has cooled off and is ready for operation again

(approximately 10-15 minutes).

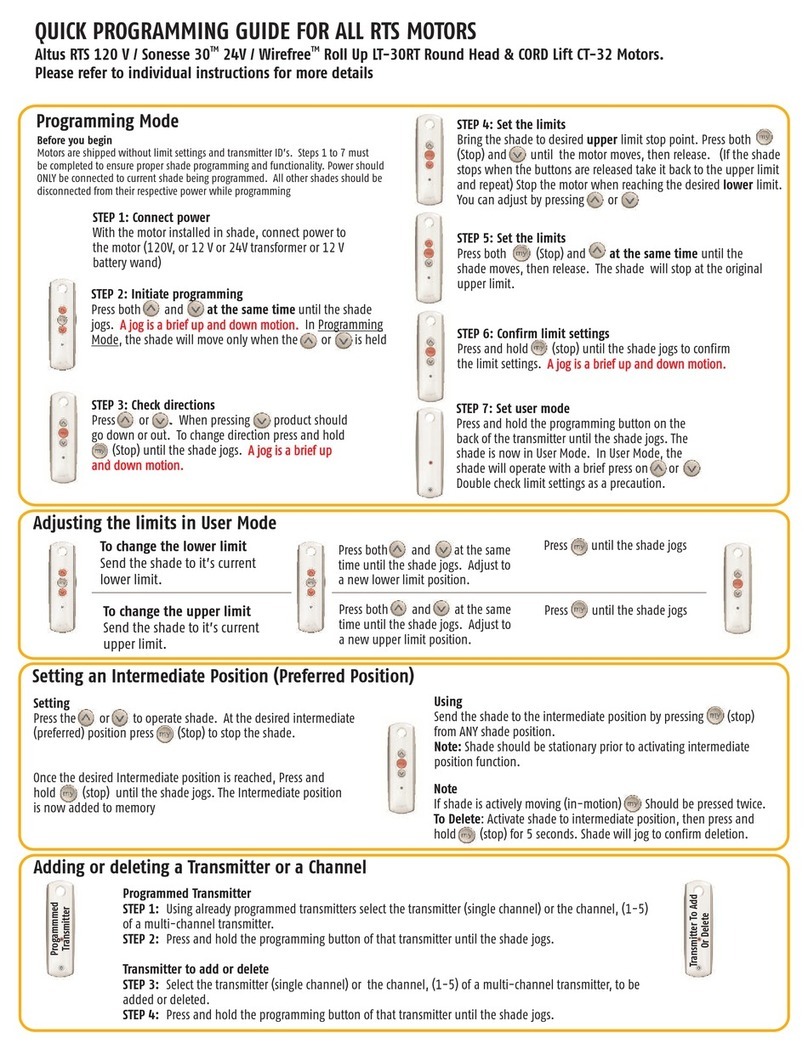

Changing a Set Stop Position...

- Press the limit switch adjustment button that lies in the

direction of rotation.

- Bring the end product into the desired stop positon.

- Release the limit switch adjustment button by pressing it

down again.

Adjustment of Upper and Lower P ositions for the

LS40 Motor

- Connect the motor tester cable (Cat. No. 6020086) to the

motor cable, match the wire colors and connect to power.

- Identify the UP recessed limit screw by finding the arrow on

the motor head which points in the direction that retracts

(rolls up) the system.

- Turn the power on to ensure that the switch is operating

properly (UP-raises, DOWN-lowers). If not, turn the power off

and simply reverse the black and red motor leads.

- Flip the tester cable switch in the UP direction. If the system

stops before its UP limit, turn the UP screw to "+" until

necessary. If the system does not stop at its UP limit, flip the

tester cable switch off and turn the UP screw to "-". Repeat

this until correct setting is achieved.

NOTE: 7 T urns of Hex Screws equals 1 turn of roller tube.

- Flip the tester cable switch in DOWN direction. If the system

stops before its DOWN limit, turn the DOWN limit screw to

"+". If not, flip the tester cable switch off and turn the DOWN

limit screw to "-". Repeat this until correct setting is achieved.

NOTE: Recessed thumbscrews can accomodate a flat

head screwdriver, SOMFY’s Allen wrench or Flexible limit

switch adjuster.