1 (E)

UP-CX2

Table of Contents

1-10. Cleaning ..................................................................1-34 (E)

1-10-1. Cleaning the Inside of the Printer ..................1-34 (E)

1-10-2. Cleaning the Printer Roller ............................1-37 (E)

1-10-3. Cleaning the Cabinet...................................... 1-37 (E)

1-10-4. Cleaning the Filter for

the Ventilation Holes......................................1-37 (E)

2. Adjustment

2-1. Operation during Replacement of Parts ....................2-1 (E)

2-2. Thermal Head............................................................2-2 (E)

2-2-1. Thermal Head Cleaning...................................2-3 (E)

2-2-2. Print of Test Pattern (16STEP) ........................2-4 (E)

2-2-3. Setting of Thermal Head Resistance Value...... 2-5 (E)

2-2-4. Position Adjustment.........................................2-6 (E)

2-2-5. Density Adjustment .........................................2-8 (E)

2-2-6. History Reset....................................................2-9 (E)

2-3. Ribbon Drive Assembly ..........................................2-10 (E)

2-3-1. Setting of Takeup Tension Ratio....................2-10 (E)

2-4. DC Fan (for Inside) ................................................. 2-11 (E)

2-5. MA-140 Board ........................................................ 2-11 (E)

2-5-1. Backup of Various Information Items............2-12 (E)

2-5-2. Write of Firmware..........................................2-14 (E)

2-5-3. Write of Backed Up Information Items .........2-15 (E)

2-5-4. Processing Required When Information

Items Cannot Be Backed Up.......................... 2-16 (E)

2-5-5. Setting of USB Serial Number.......................2-16 (E)

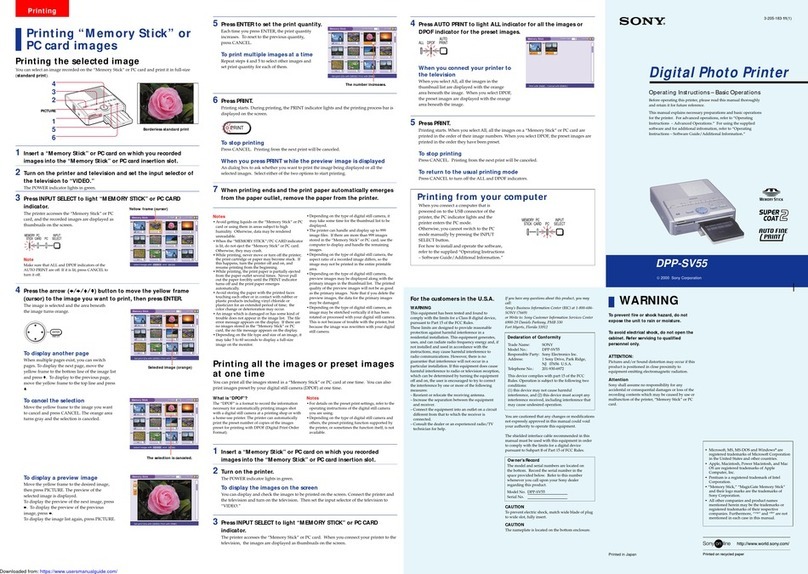

3. Mechanical Behavior Description

3-1. Mechanical Flow.......................................................3-1 (E)

3-2. Print Flow..................................................................3-2 (E)

3-3. Print ...........................................................................3-4 (E)

4. Circuit Description

4-1. System Control..........................................................4-1 (E)

4-2. Mechanical Control...................................................4-1 (E)

4-3. Power System............................................................4-2 (E)

Manual Structure

Purpose of this manual............................................................ 3 (E)

Related manuals...................................................................... 3 (E)

1. Service Overview

1-1. Precaution in Transportation of the Unit ................... 1-1 (E)

1-2. Board Location..........................................................1-1 (E)

1-3. Main Parts Location and Sensor Location ................1-2 (E)

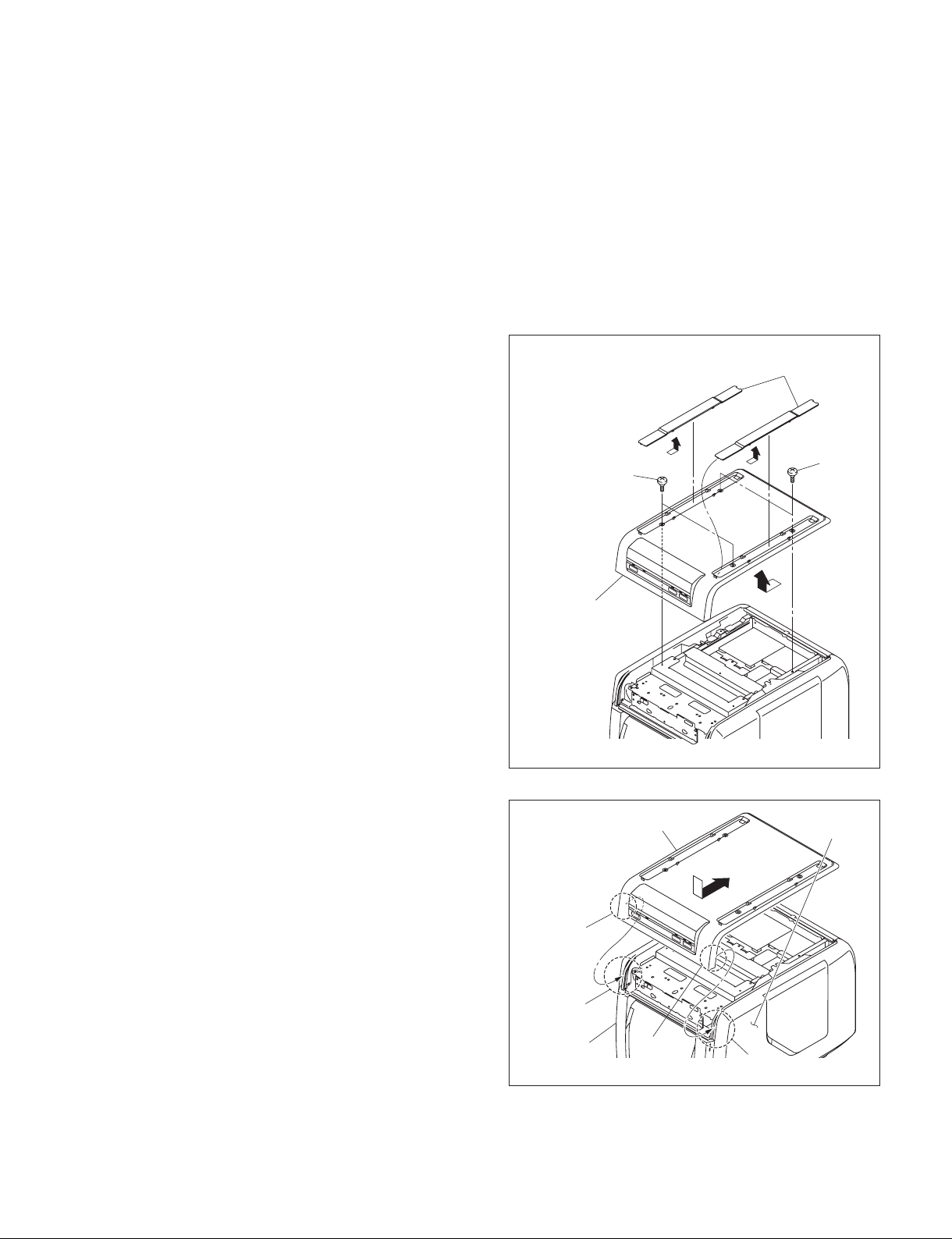

1-4. Installing/Removing the Cabinet............................... 1-3 (E)

1-4-1. Top Panel (C2) Assembly ................................1-3 (E)

1-4-2. Side Panel (R) Assembly/Side Panel (L) ......... 1-4 (E)

1-4-3. Rear Panel (C1) Assembly...............................1-5 (E)

1-4-4. Inner Cover (Front) Assembly ......................... 1-5 (E)

1-4-5. Door Panel (C2) Assembly ..............................1-6 (E)

1-5. Replacing the Board..................................................1-7 (E)

1-5-1. MEC-33 Board.................................................1-7 (E)

1-5-2. MA-140 Board.................................................1-8 (E)

1-5-3. KY-617 Board..................................................1-9 (E)

1-5-4. SE-1056 Board.................................................1-9 (E)

1-6. Replacing the Main Parts ........................................ 1-10 (E)

1-6-1. Switching Regulator ......................................1-10 (E)

1-6-2. Ribbon Drive Assembly................................. 1-11 (E)

1-6-3. Ribbon (T) Motor Assembly/

Ribbon (S) Motor Assembly.......................... 1-12 (E)

1-6-4. Stepping Motor ..............................................1-14 (E)

1-6-5. Position Motor ............................................... 1-14 (E)

1-6-6. DC Fan (for Inside)........................................1-15 (E)

1-6-7. DC Fan (for Thermal Head)...........................1-16 (E)

1-6-8. Cutter Unit .....................................................1-17 (E)

1-6-9. Paper Eject Guide Assembly..........................1-18 (E)

1-6-10. Paper Drive Roller .........................................1-19 (E)

1-6-11. Platen Roller ..................................................1-21 (E)

1-6-12. Capstan Roller................................................1-22 (E)

1-6-13. Thermal Head ................................................1-24 (E)

1-6-14. Pinch Roller/Cam (L)/Cam (M)/Cam (R)...... 1-27 (E)

1-6-15. Filter...............................................................1-30 (E)

1-7. Lead-free Solder......................................................1-31 (E)

1-8. Recommended Power Cord..................................... 1-32 (E)

1-9. Periodical Replacement Recommended Parts......... 1-33 (E)