1-1

DCU-8000 IM

Section 1

Installation

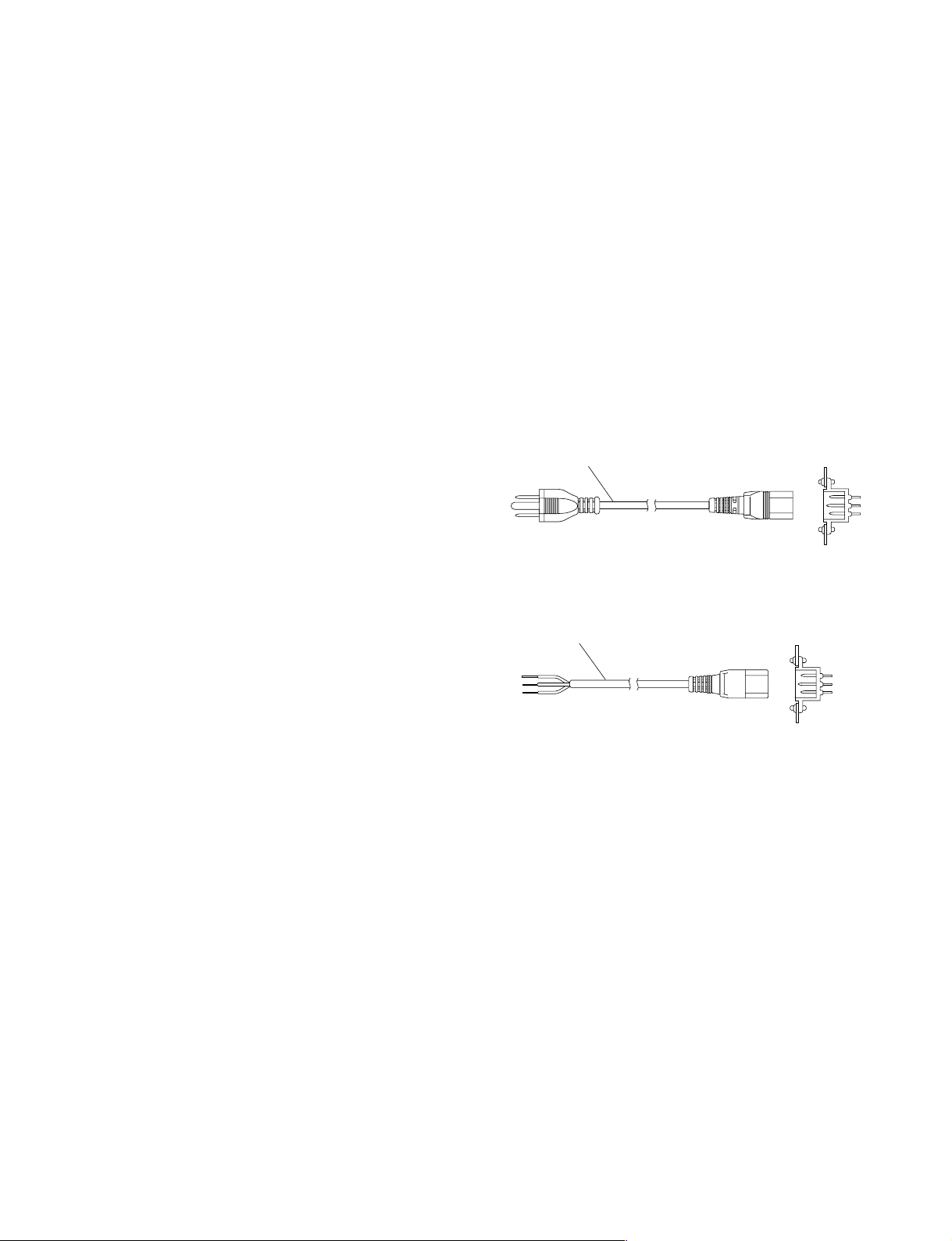

1-2-2. Recommended Power Cord

w

.The power cord is not supplied with the DCU-8000.

Be sure to use the power cord that is applicable to places

in the area.

To avoid a fire or an electric shock, be sure to use the

designated power cord.

.Do not damage the power cord a otherwise fire or

electric shock may result.

For customers in the U.S.A. and Canada

1Power cord, 125 V 10 A (2.4 m) : !1-557-377-11

AC inlet

1

For customers in the all Europian countories

1Power cord, 250 V 10 A (2.4 m) : !1-782-929-21

1

AC inlet

1-1. Operating Environment

Operating guaranteed temperature : +5 dC to +40 dC

Performance guaranteed temperature : +10 dC to +35 dC

Operating humidity : 10 % to 90 %

Storage temperature : _20 dC to +60 dC

Mass : Approx. 18 kg

(with all options

installed)

Prohibited locations for installation

.Areas where the unit will be exposed do direct sunlight

or any other strong lights.

.Dusty areas

.Areas is subject to vibration.

.Areas with strong electric or magnetic fields.

.Areas near heat sources.

.Areas subject to electrical noise.

.Areas subject to static electricity.

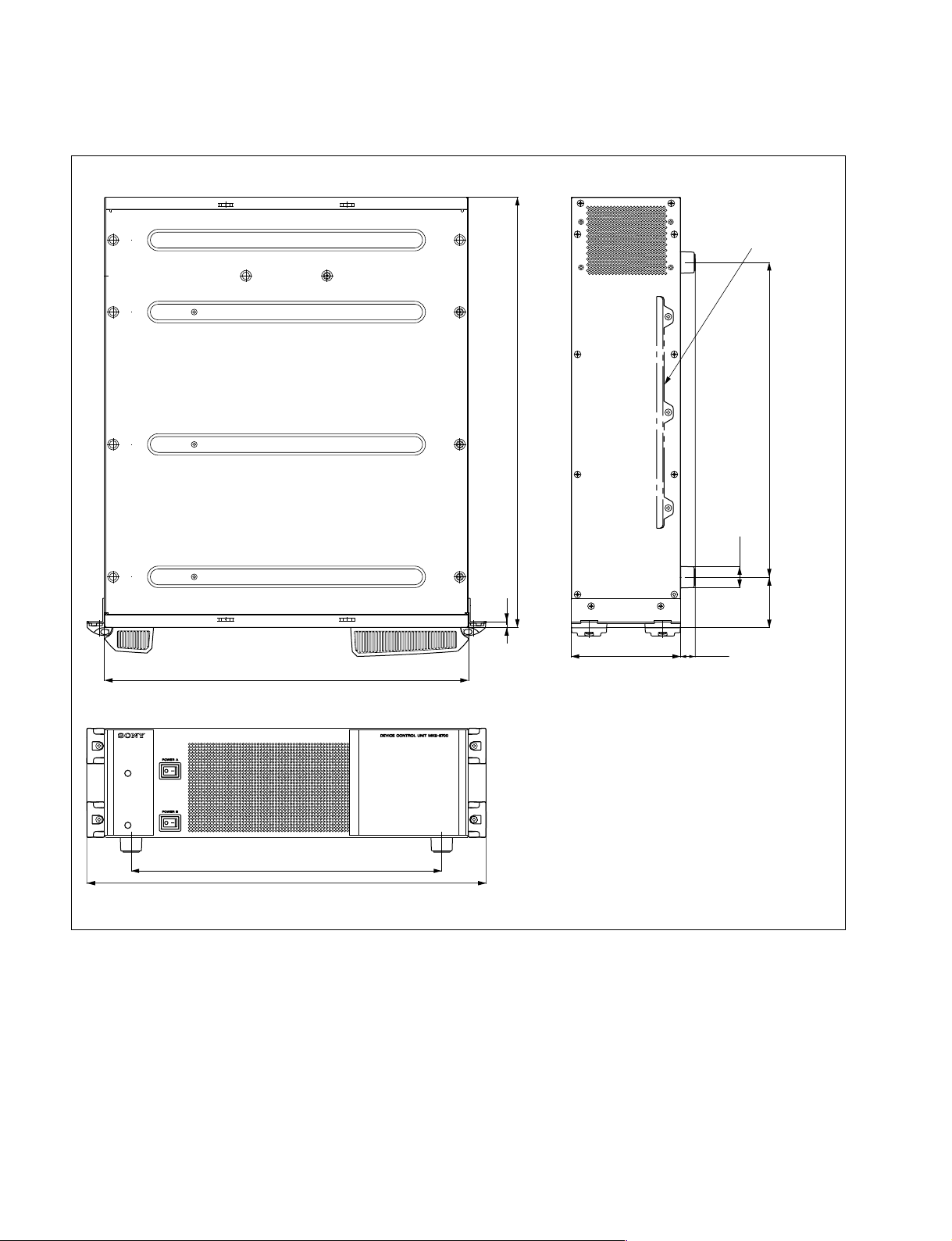

Ventilation

The inside of the DCU-8000 is cooled by a fan (both sides

on the rear).

The power supply can be damaged if the exhaust vent

(both sides on the rear) and air intake (front panel) are

blocked or the fan is stopped.

Therefore, leave a blank space of more than 10 cm in the

front and back of the DCU-8000.

1-2. Power Supply

1-2-1. Power Specifications

A switching regulator is used for the power supply of this

unit. A voltage within the range of 100 V to 240 V can be

used without changing the supply voltage.

Power requirements : AC 100 to 240 V ±10 %

Power frequency : 50/60 Hz

Current consumption : Maximum 1.4 A

n

As the inrush current at turn-on is a maximum 20 A (at 100

V)/60 A (at 230 V), the capacity of the AC power must be

commensurate with this source load.

If the capacity of the AC power is not adequately large, the

AC power source breaker will operate or the unit will

abnormally operate.