DTC-

300ES

sEcTtoN

3

ADJUSTMENTS

3-1. MECHANICAL

ADJUSTMENT

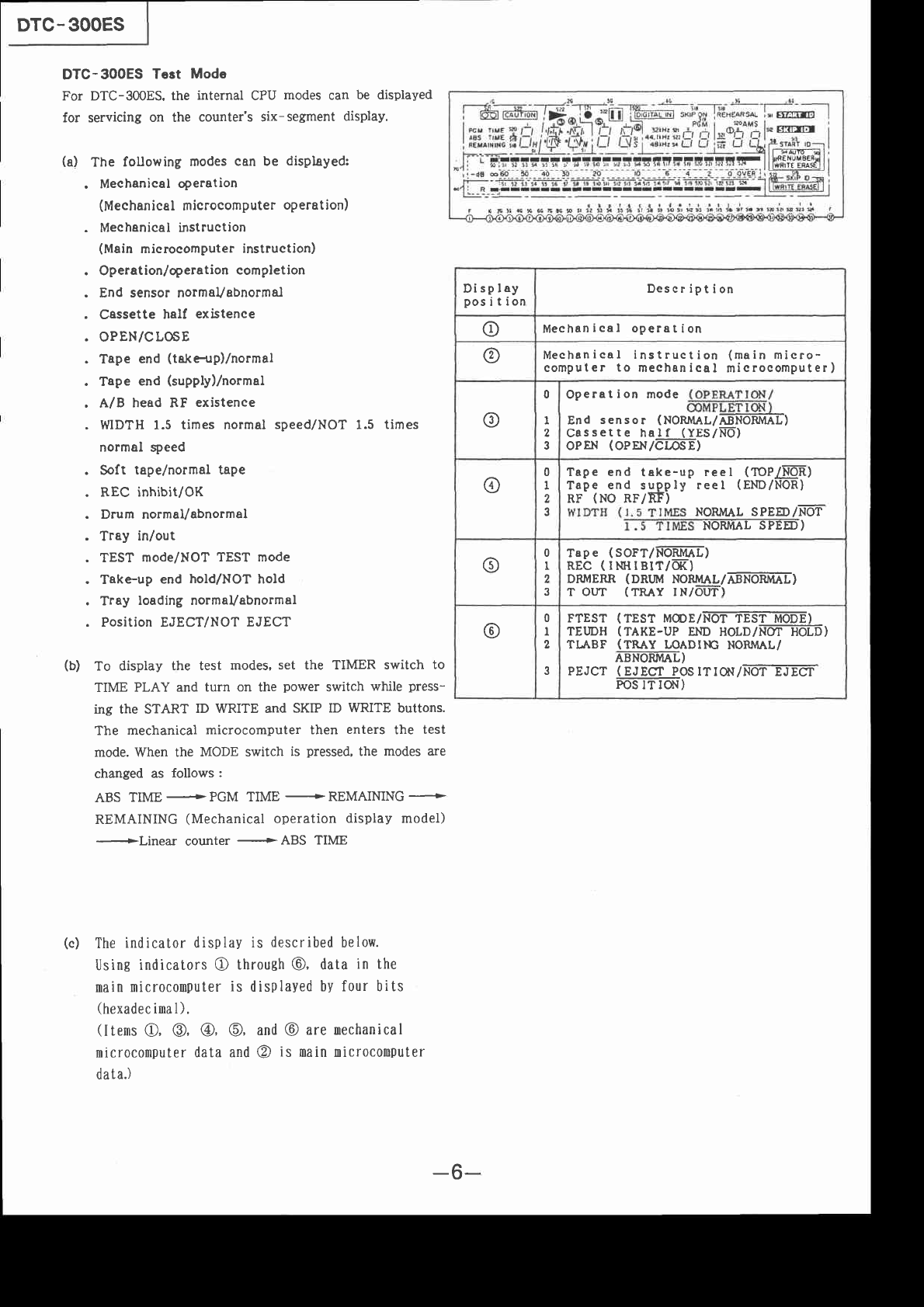

When replacing the drum, finely adjust the tape path (in l.b times normal speed FWD mode).

3-1-1. Tapc

Path

Fine-Adjustment

(x1.5 FWD

Mode)

Adjustment

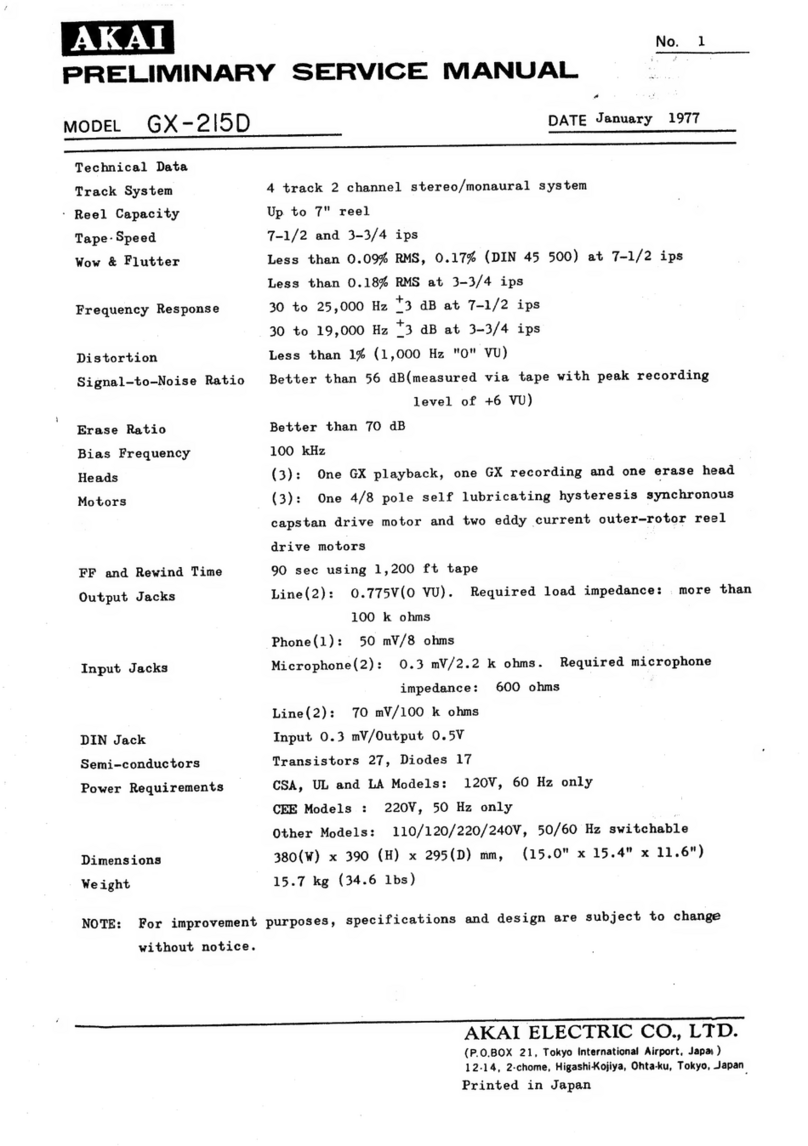

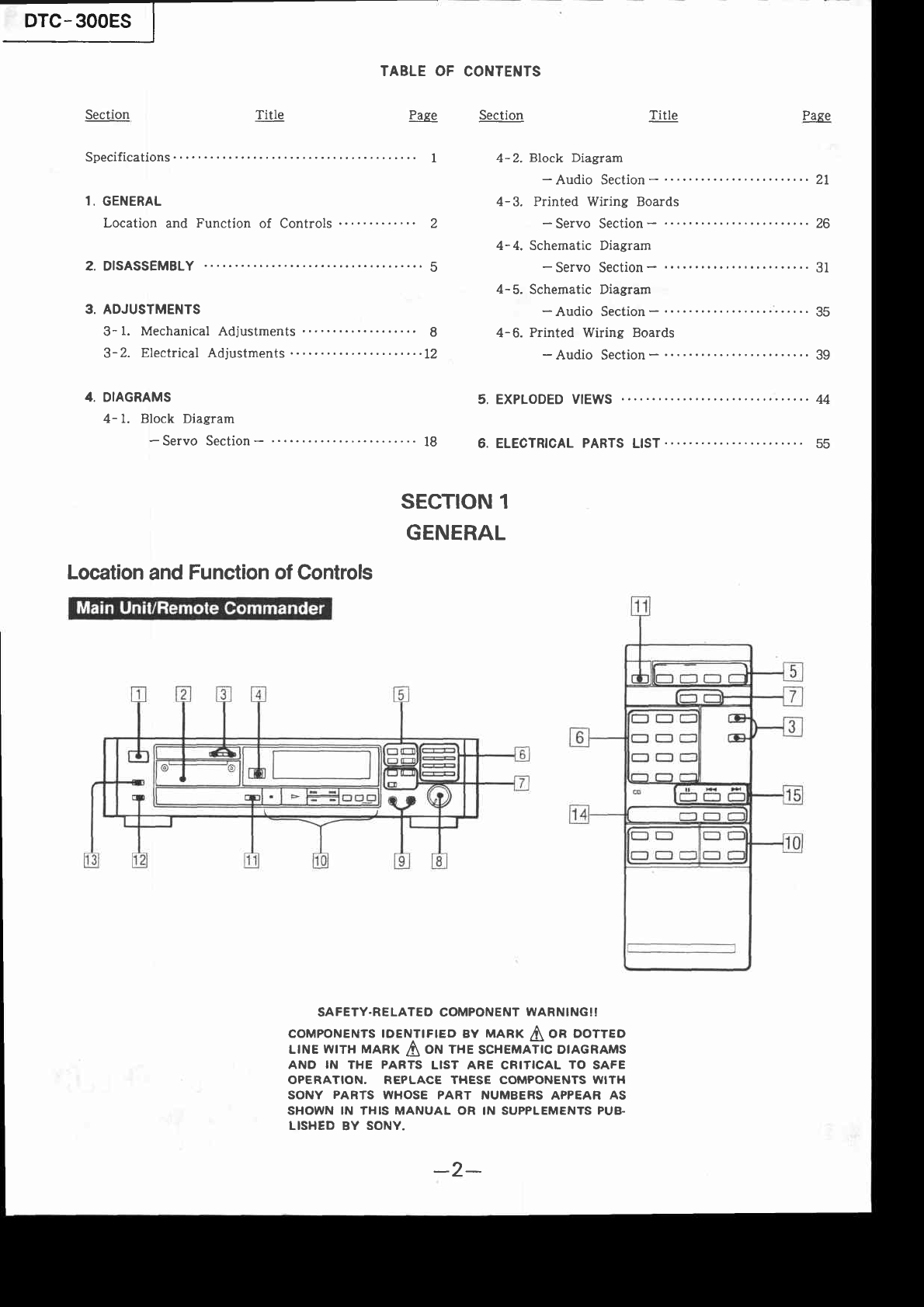

l. Connect

CH-I of an oscilloscope

to pin@ of an offset

jig and CH-Z to pin

@ of the offset jig.

2. Connect

a 3.3k-ohmresistor

between

pins7 (GAIN2)

and 6 (GAIN l) of IC52b.

3. Connect

the offset jig as shownbelow.

L

INES

4. Turn on the power switch, insert alignment tape Ty-

725L,and put the set into the TEST mode.

5. Press the AMS (>>l) button.

6. Remove the YEL and RED leads of the offset jig and

adjust guides Sl and Tl so that the shape of the RF

signal waveform on the oscilloscope is close to a square.

7. Connect the YEL and RED leads of the offset jig, turn

the offset jig's volume control, and fix the RF signal

waveform to a half level. At that time, finely adjust

guidesSl and Tl again so that the shape

of the wave-

form is close to a square.

8. Turn the offset jig's volume control, slowly change the

RF signal waveform in the vertical direction,and check

that the waveform uniformly changes

in the horizontal

direction.

9. Removethe two leads (YEL and RED) of the jig from

cNTs1.

(l) Check

that peakvalue

(B) of the RF signal

wave-

form is 60mV or more.

(2) Checkthat the undershoot

level of the RF signal

waveform's

flat portion is within l0%.

10.If the specification

is not satisfied,

repeatSteps

3

through 9.

11.Check

that thereis no gapbetween

thetape

andlower

flangein guides

S2,T2, T3,and F. Checkthat no curl *

occurswhen the tape touches

the lower flange.

If there

is a gap or a curl occurs,

adjusteach

guide

according

to the adjustment

on the next page. -8-

Adjustment Location

:

Mechanical

guides

51 and T1

Guide Sl

A 4,/5

xo

Guide

T1

A' 4,/5 or less

B,/10 or less

t:î )--r tn

,-__-,F--

B,/10 or less

The curl indicates

the distortion

which occurs

on the

tapein the FWDmode.

When

light is shone

on the tape,

the curl can be viewed

morevisually.

ATF PRogE

ôqar |ôqrnpç

oFFSET JIG \ i::::=::::-:- SERVO BOARD