1

0° WEDGE HARDWARE OPTIONS

Congratulations! The Specialized S-Works Rubymac handlebar/stem system you have chosen is among the finest of advanced composite

products available in cycling. Carbon fiber is a very special material that requires particular care during assembly, storage and riding.

This installation guide contains instructions and warnings, plus torque specifications, to be used in conjunction with the owner’s

manuals and instruction guides supplied with your bicycle.

THIS BRIEF INSTALLATION GUIDE CONTAINS IMPORTANT INFORMATION.

PLEASE READ CAREFULLY AND STORE IN A SAFE PLACE.

S-WORKS RUBYMAC WEDGE INSTALLATION GUIDE

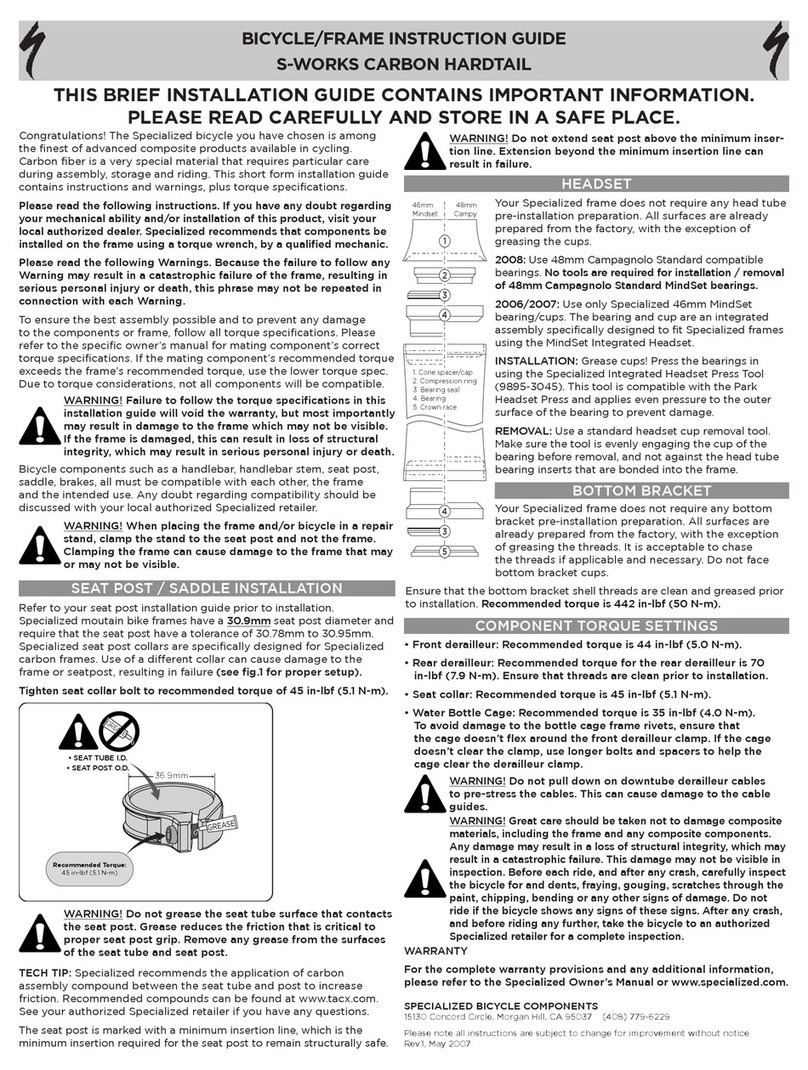

The S-Works Rubymac Wedge handlebar/stem system uses a shim and wedge assembly, which allows for multiple stem angle options.

The nominal position of the stem is +3°. There are 5 angle options available, using a system of shims, wedges and spacers. Determine

the desired stem angle, then assemble the required wedge hardware parts to achieve the correct angle (0° parts pre-assembled in bag):

COMMON PARTS

1 x Upper Outer Wedge 1 x Alloy Preload Bolt

1 x Lower Outer Wedge 1 x Top Cap Rubber Plug

1 x Wedge Bolt 1 x Alloy Steerer Tube Plug

0° PARTS 2° PARTS 4° PARTS (Black)

1 x 0° Inner Wedge (Silver) 1 x 2° Inner Wedge (Coffee) 1 x 4° Inner Wedge (Black)

1 x 0° Shim (Silver) 1 x 2° Shim (Coffee) 1 x 4° Shim (Black)

1 x 0° Spacer 1 x 2° Spacer 1 x 4° Spacer

1 x 0° Centered Top Cap Washer 1 x 2-4° Angled Top Cap Washer 1 x 2-4° Angled Top Cap Washer

0° SETUP (Fig.1): 2° SETUP (Fig.2): 4° SETUP (Fig.3):

+3° stem angle (+) setting: +5° stem angle (+) setting: +7° stem angle

(-) setting: +1° stem angle (-) setting: -1° stem angle

Proper fit between the steerer tube and the stem is crucial to performance and safety. Incorrect sizing interface can result in

handlebar slippage or failure.

Please read the following instructions. If you have any doubt regarding your mechanical ability and/or installation of this product, visit your

local authorized dealer. Specialized recommends that the handlebar/stem be installed using a torque wrench, by a qualified mechanic.

Please read the following Warnings. Because the failure to follow any Warning may result in a catastrophic failure of the handlebar,

resulting in serious personal injury or death, this phrase may not be repeated in connection with each Warning.

Bicycle assembly is a complicated task which requires training and experience. Do not attempt installation of any component if you do not

have experience and training as a bicycle mechanic. Reference should also be made to Barnett’s or some other comprehensive bicycle manual.

The S-Works Rubymac Wedge requires that the fork’s steerer tube follows a tolerance range of 28.50mm to 28.65mm. If the steerer

tube tolerances are outside of this range, the fork is not compatible with the Rubymac Wedge.

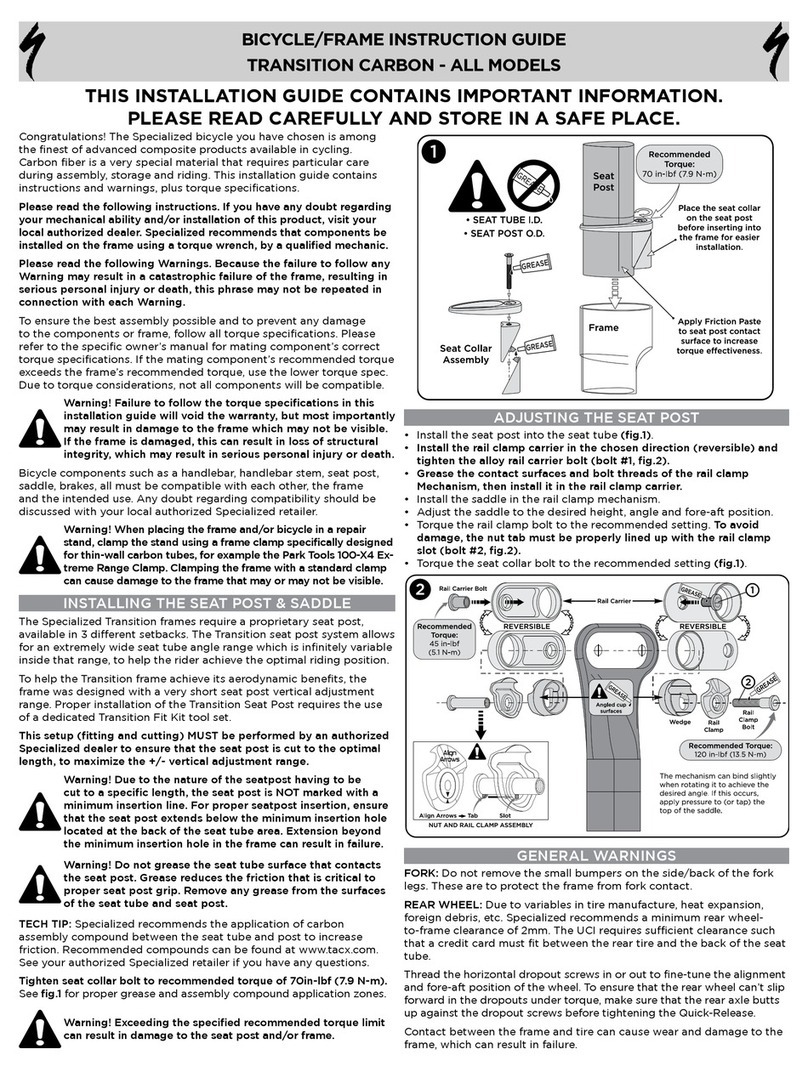

Before installing the handlebar/stem, ensure that the clamping interface surfaces between the stem and the fork are clean of any grease.

Apply grease to bolt threads and wedge contact surfaces only (see fig.4 & 6).

Do not apply grease to carbon surfaces! Applying grease reduces the friction that is critical to proper stem/handlebar grip.

NOTE: Do not cut fork steerer tube until final stem height is determined, after following assembly steps (fig.4-8).

Once stem height is determined, install the Specialized steerer tube expander plug (supplied with the handlebar) into the top of the

steerer tube. Only use the Specialized 48mm Long Expander Plug, it is designed specifically to maximize internal support for the

Rubymac wedge system when torqued. Do not torque expander plug above fork manufacturer’s recommended torque spec.

Do not use different angle parts together. Mismatched hardware can result in unevenly distributed loads on the stem and hea-

set parts, which can lead to failure, causing serious injury or death.

INTERFACE BETWEEN THE STEM AND THE STEERER TUBE

PREPARING THE STEM AND FORK

CHOOSING THE RIGHT STEM ANGLE