4spray.com | 1.800.95.SPRAY | Intl. Tel: 1.630.665.5000

INTRODUCTION

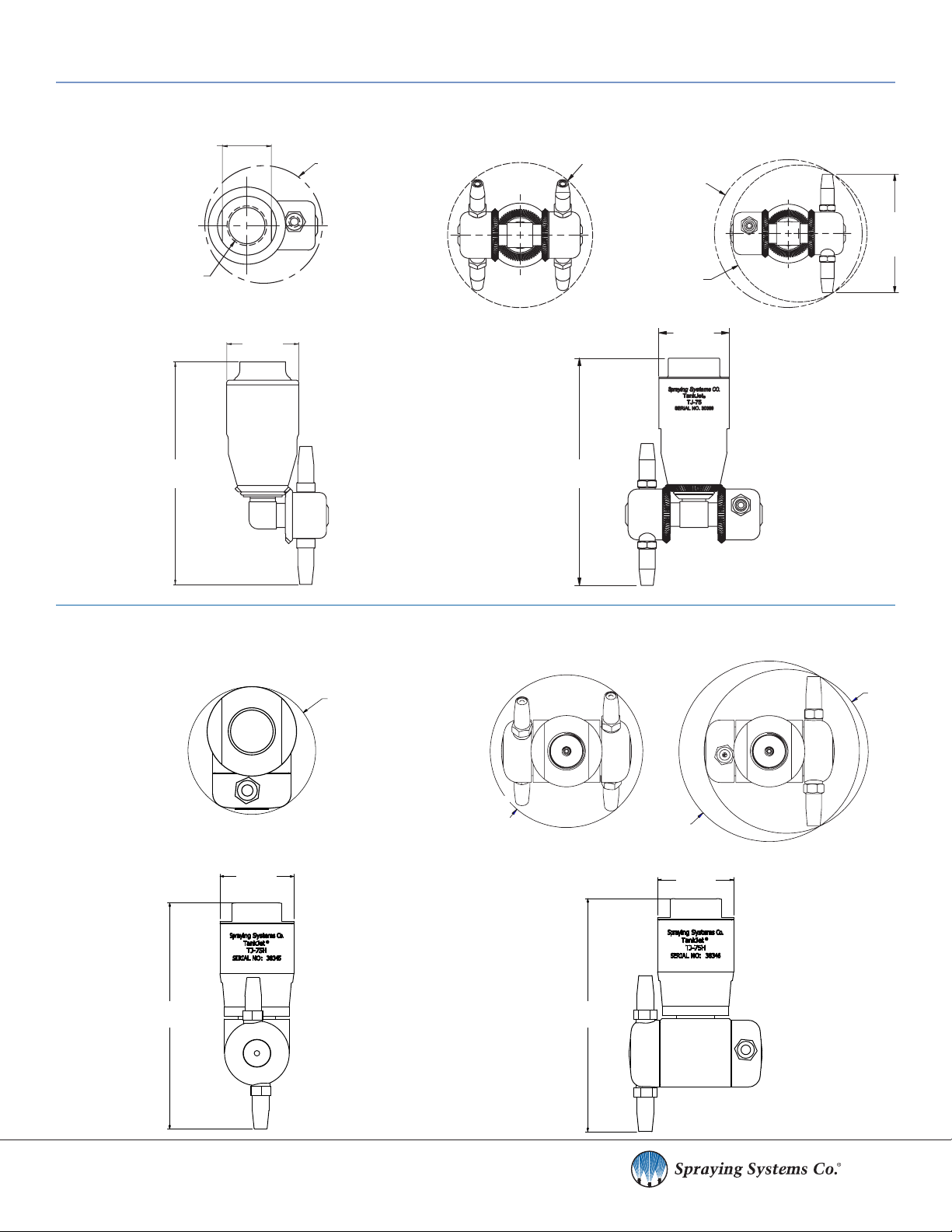

The TankJet®75 and 75H models are hydraulically driven rotating

heads with nozzles ejecting streams of liquid for spanning internal

tank surfaces to be cleaned, sanitized, treated, or rinsed. The

TankJet 75H-2 or 75H-4 models feature an enclosed gear housing

for hygienic option. Either model will provide a complete 360°

indexing path in both planes, the index pattern will repeat every

45 revolutions. The TankJet 75-2 and the 75H-2 are specifically

designed for 3" dia. openings, care must be exercised during

insertion and retraction of this unit because of the nozzle swing

span. The TankJet 75-4 and 75H-4 incorporates 2 nozzle hubs

thus 4 nozzles, and is designed for 4.2" dia. openings. The units

may be installed on a permanent basis (C.I.P.). Many types of

fluids, sanitizers, detergents and caustics may be used through

this unit to assist it’s cleaning effectiveness. (Please note caution

below.) The cleaning effectiveness of any unit is proportional to

all the applicable variables, such as volume, pressure, chemicals,

impingement, drainage, soils, etc. The unit will only operate

properly when mounted in the vertical position (suspended or

inverted) and can clean almost any type of contained area within

its range.

Caution: If chemicals, hazardous materials, operations, and

equipment are used in conjunction with this cleaning equipment,

it is the responsibility of the user to establish appropriate

associated safety and health practices. Prior to application, the

user must consult and determine the applicability of regulatory

(federal, state, local and facility) safety and environmental

agency limitations.

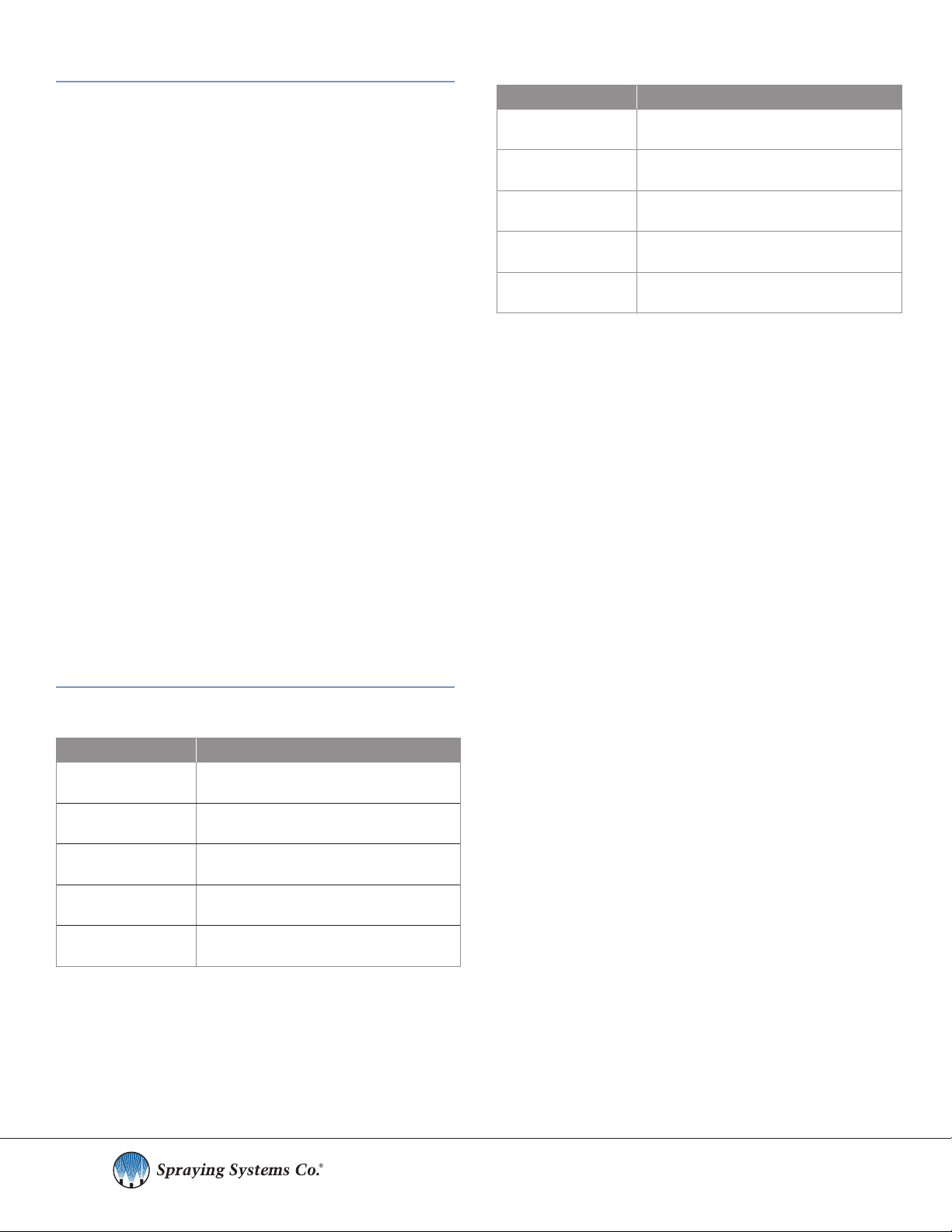

SPECIFICATIONS

TANKJET 75-2 OR -4 HUB MODELS:

SSCO. PART # DESCRIPTION

TJ75*-2-234 Standard Nozzle: 0.234

PSI: 150-300 | GPM: 17-24 | NPT

TJ75*-2-234LP Low Pressure Nozzle: 0.234

PSI: 75-150 | GPM: 12-17 | NPT

TJ75*-4-125 Standard Nozzle: 0.125

PSI: 150-300 | GPM: 15-21 | NPT

TJ75*-4-172 Standard Nozzle: 0.172

PSI: 150-300 | GPM: 23-33 | NPT

TJ75*-4-172LP Low Pressure Nozzle: 0.172

PSI: 75-150 | GPM: 15-23 | NPT

* Add B for BSPT connections after the model no.

Add SF for sanitary tri-clover flange after the model no.

See Tank Cleaning Catalog 75TJ for further flow and performance information.

TANKJET 75H-2 OR -4 HUB MODELS:

SSCO. PART # DESCRIPTION

TJ75H*-2-234 Standard Nozzle: 0.234

PSI: 150-300 | GPM: 17-24 | NPT

TJ75H*-2-234LP Low Pressure Nozzle: 0.234

PSI: 75-150 | GPM: 12-17 | NPT

TJ75H*-4-125 Standard Nozzle: 0.125

PSI: 150-300 | GPM: 15-21 | NPT

TJ75H*-4-172 Standard Nozzle: 0.172

PSI: 150-300 | GPM: 23-33 | NPT

TJ75H*-4-172LP Standard Nozzle: 0.172

PSI: 75 -150 | GPM: 15-23 | NPT

* Add B for BSPT connections after the model no.

Add SF for sanitary tri-clover flange after the model no.

See Tank Cleaning Catalog 75TJ for further flow and performance information.

MATERIALS

• 316 Stainless Steel (UNS S31600)

• PTFE

• UHMW-PE

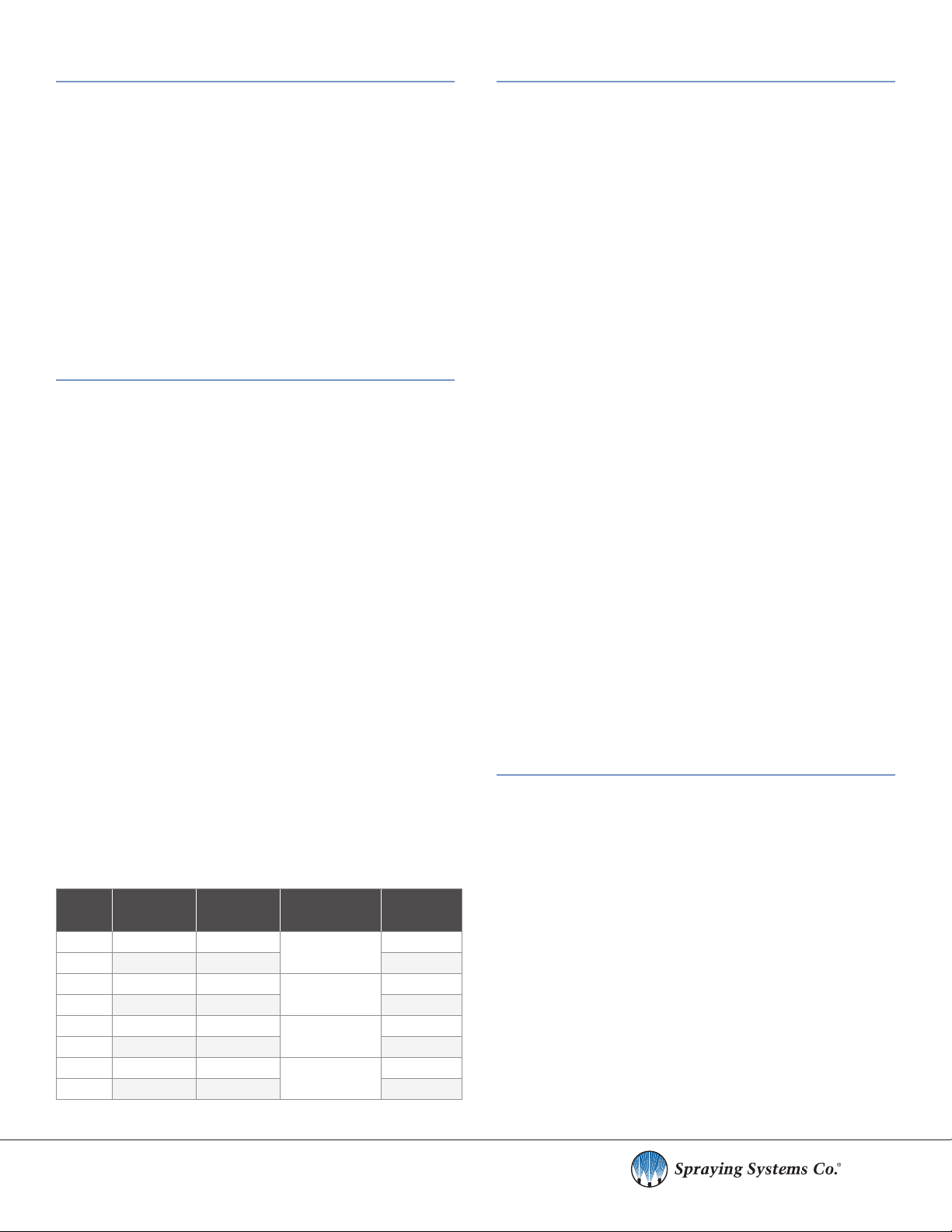

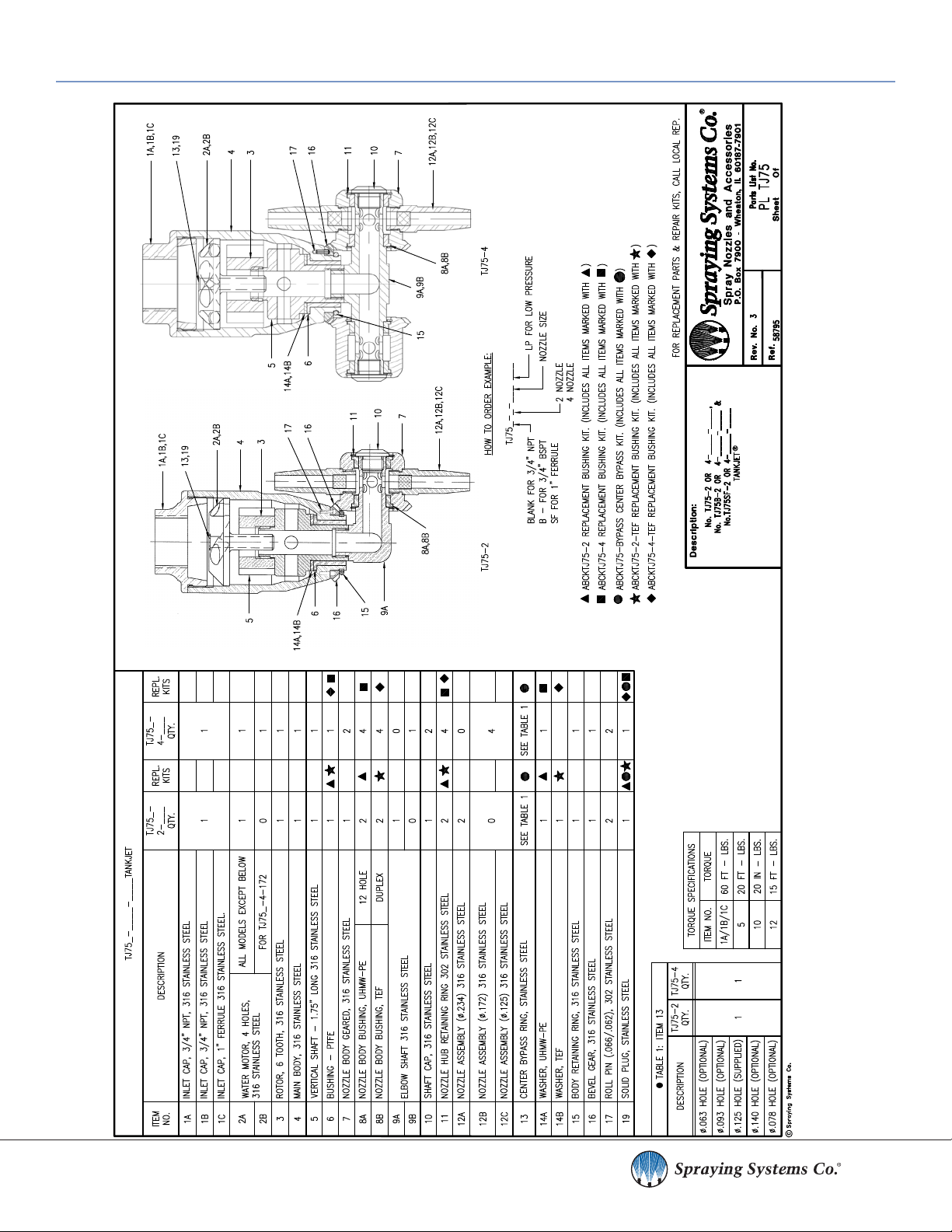

CONSTRUCTION

Referring to the Parts List on page 7 and 8, the unit comprises two

basic components; the drive, consisting of the body, motor, rotor,

and shaft; and the nozzle head, consisting of the nozzle body,

bushings, nozzles, and elbow shaft.

PRINCIPLE OF ROTATION

The liquid enters the inlet cap (1) and then flows through the

oblique and bypass holes in the motor (2) causing a swirling

motion in the liquid. This swirling liquid goes down the outside of

the vertical shaft (5) past the 6 tooth rotor (3) imparting rotation

to the rotor and thus the vertical shaft. The liquid flows through

the elbow shaft into the nozzle body (7), to be distributed out

each off-set nozzle (12). The rotational speed of these units can

be regulated through the use of various motor bypass plugs,

which influences the fluid diversion to provide additional speed.

Reference the Troubleshooting section and the Drawing Parts

List for additional information and location.

CLEANING DIAMETER

The cleaning and wetting distances are a function of rotational

speed and liquid pressure applied. The TankJet 75 has an

effective cleaning diameter of 30 ft. (9.1 m).