SPX POWER TEAM C12-TON Use and care manual

C12-TON HAND HYDRAULIC

COMPRESSION TOOL

Form No. 1000026

C12-TON-B

Operating Instructions and

Parts List for:

Tech. Services: (800) 477-8326

Fax: (800) 765-8326

Order Entry: (800) 541-1418

Fax: (800) 288-7031

SPX Corporation

5885 11th Street

Rockford, IL 61109-3699 USA

Internet Address:

http://www.powerteam.com

®

INTRODUCTION

The C12-ton compression tool was designed for installing tubular

compression accessories on stranded electrical conductors. Twelve tons

thrust can be developed by this hand-operated compressor.

The compressor piston can be adjusted to a position that will require a

minimum of hand pumping to compress an accessory.

Twisting the pump handle clockwise will advance the piston until the

lower die-half contacts the accessory to be compressed. Compression is

completed by pumping the pump lever. When the die-halves touch the

compression is complete.

The piston is retracted by pulling the trigger on the pump lever and

making another pumping stroke. It will retract only to the positions

previously set, thus minimizing the amount of pumping needed to

complete the next compression.

Note that all operating controls are located such that the operator need

not remove his hands from the tool.

THE C12-TON TOOL IS NOT TO BE USED FOR "HOT LINE" WORK.

SPECIFICATIONS

PUMP SECTION:

SINGLE SPEED WITH MECHANICAL RAPID ADVANCE,

PUMP OUTPUT .042 CU.IN. (.00069 LITER) PER STROKE.

HIGH PRESSURE RELIEF VALVE SET TO OPEN AT 10,400/10,000 PSI (716/689 BAR).

RESERVOIR CAPACITY, 4 7/8 CU.IN. (.08 LITER).

USABLE OlL, 3 3/4 CU.IN. (.06 LITER)

OIL TYPE USED, AMOCO RYKON MV.

HANDLE EFFORT, 4 1/8 LBS. (1.87 KG) PER 1000 PSI (68.9 BAR)

TOOL SECTION:

1.813 (4.605 CM) DIA.RAM, .912 (2.31 CM) STROKE WITH DIES.

REQUIRES 2.35 CU.IN. (.038 LITER) OIL MINIMUM.

CRIMPING FORCE, 26,332 LBS. (11,944 KG)

AT 10,200 PSI (702 BAR)

(13.1 TONS U.S., 11.89 TONS METRIC)

TOTAL WEIGHT, 13.6 LBS. (6.16 KG).

CRIMPING CAPACITY:

NO.6 THRU 750MCM CU, 500MCM AL.

(3 THRU 379.5 SQ.MM.CU, 253 SQ.MM.AL)

Sheet No. 1 of 6

Rev Date: 09 Feb 2004

Litho in USA

WARNING

Operating Instructions and Parts List, Form No. 1000026, Back sheet 1 of 6

IMPORTANT SAFETY INFORMATION

It is the operators responsibility to read and

understand the following safety statements,

• Only qualified operators should install, operate,

adjust, maintain, clean, repair, or transport this

machinery.

• Inspect tool before use. Replace any worn or

damaged parts. Failure to observe these warnings

can result in severe injury or death.

Keep hands away from the crimping tool head

when crimping.

WARNING

To help prevent personal injury,

• Always wear eye protection whenever

operating hydraulic equipment.

• Always wear hearing protection as

required.

• Operation, repair, or maintenance of hydraulic

equipment should be performed by a qualified

person who understands the proper function of

hydraulic equipment per local directives and

standards.

• Hydraulic equipment must be assembled correctly

and then checked for proper function before use. Use

hydraulic components of the same hydraulic

pressure ratings. An appropriate hydraulic pressure

gauge is recommended to monitor pressure.

• Never place your hands or other body

parts near a hydraulic fluid leak.

Never use your hands or other body parts

to check for a possible leak.

High pressure fluid can be injected under your skin

causing serious injury and/or infection.

• Exercise caution to avoid the risk of fire.

An incomplete crimp can cause a fire. Use

proper die, connector and cable. Improper

combinations can result in an incomplete

crimp.

• This tool is not insulated. When using this

unit near energized electrical lines, use

proper personal protective equipment.

• This tool is intended for two-handed operation.

Maintain a firm grip on both handles during

operation. Using this tool in any other manner can

result in injury or equipment damage.

• Properly dispose of all fluids, components, and

assemblies at the end of their useful life.

• Hydraulic fluid should be compatible with all

hydraulic components.

WARNING

IMPORTANT

WARNING

WARNING

This is the safety alert symbol.

It is used to alert you to potential personal injury

hazards. Obey all safety messages that follow this

symbol to avoid possible injury or death

Denotes an imminently hazardous situation which, if

not avoided, will result in death or serious injury.

Denotes a potentially hazardous situation which, if not

avoided, could result in death or serious injury.

Denotes a potentially hazardous situation which, if not

avoided, may result in minor or moderate injury.

Caution used without the safety alert symbol indicates

a potentially hazardous situation which, if not avoided,

may result in property damage.

Denotes an operating or service procedure or condition

considered essential for expedient and efficient

operation and service.

IMPORTANT

CAUTION

CAUTION

WARNING

DANGER

Operating Instructions and Parts List, Form No. 1000026

OPERATING INSTRUCTIONS

DO NOT OPERATE THE COMPRESSOR WITHOUT DIES.

Select the proper dies for use on the accessory to be compressed. Push the die release button on the C-head and

slide one of the identical die-halves into position. The die retainer pin locks the die in place. Insert the other die- half

in the ram body by depressing the die release button located in a slight well in the ram.

Place the compressor in position over the accessory to be compressed. If the accessory is larger in diameter than the

throat opening of the C-head, put the compressor over the conductor and then slide it over the accessory in the

correct position for the first compression. Twist the reservoir handle clockwise until the lower die-half advances to

touch the accessory to be compressed. Back off a quarter turn - do not turn the reservoir handle again - ram will

retract to this preset position each time the hydraulic pressure is released. This partial retraction of the ram allows

enough clearance to move the compressor along the accessory for each successive compression and requires a

minimum of hand pumping for the next compression.

Complete each compression by pumping until the dies touch at their flat surfaces nearest the throat of the C-head. If

it is not convenient to observe the dies, pump until the safety valve operates, although compression will have been

completed before the safety valve relieves the hydraulic pressure. The operation of the valve will cause an audible

click and a pronounced difference in the feel of the pumping.

To retract the ram, open the compressor handles, hold the pressure release trigger down, and close the handles

firmly to push in the pressure release plunger. The ram will retract to the pre-selected position. If the die opening must

be increased further, use same procedure as above and while the trigger is held down, turn the reservoir handle

counter clockwise.

It should be noted that the ram can be advanced rapidly by merely twisting the reservoir handle, but it is necessary to

both trip the release trigger and twist the reservoir handle to retract the ram from a pre-selected position.

Move the compressor into position for the next compression and repeat the procedure. Do not use the compressor for

any purpose other than that for which it was designed. This tool has been manufactured to precision tolerances. It

should be used with the same care and attention as any other fine piece of equipment.

The C-head of the compressor can be rotated through 180 degrees to place the throat opening perpendicular to the

conductor even though the operator may be working from an awkward position on a utility pole.

THE NEOPRENE COVER IS NOT INTENDED TO AFFORD PROTECTION TO THE

OPERATOR FOR “HOTLINE” WORK.

Compatible Hydraulic Fluids:

The use of Amoco Rykon MV oil is recommended. Compatible fluids include:

Mobil DTE 13

Mobil ATF 220

Shell Tellus 32

Arco Dexron III

Citgo AW32

Citgo Dexron III

Other fluids also may be used if they meet or exceed the following specifications:

Viscosity: 180 SSU at 100 degree F.

Flash Point: 350 degree F

Pour Point: -50 degree F

WARNING

WARNING

Sheet No. 2 of 6

Rev Date: 09 Feb 2004

Operating Instructions and Parts List, Form No. 1000026, Back sheet 2 of 6

SERVICING INSTRUCTIONS

PREVENTIVE MAINTENANCE

The majority of service troubles are caused by dirt collecting about the tool or in the oil system. Keep the tool clean

and prevent foreign matter from entering the compressor while filling the reservoir. Lubricate all moving parts and

keep the C-head stop screw, ram guide screw, and reservoir handle stop screw tightened.

FILLING RESERVOIR

To add or replace oil in the compressor, retract the ram completely. Loosen the reservoir handle stop screw and

remove the handle. Remove the reservoir plug and O-ring seal. Pull the stem of the reservoir piston out as far as

possible. Add oil until it fills the stem. See “Compatible Hydraulic Fluids” Section.

DO NOT USE BRAKE FLUID OF ANY KIND.

Before replacing the reservoir plug, advance the ram a short distance by stroking the pump lever. Retract the ram by

pulling the trigger on the pump lever and make a pumping stroke, first having taken precautions against splashing of

the oil. Repeat this procedure until air bubbles cease appearing. Add oil if necessary to fill the stem, first making

certain the C-head ram is fully retracted so that too much oil is not added. Replace the O-ring, reservoir magnetic

plug and handle; tighten the reservoir handle stop screw.

Pump until the die faces meet, and then retract the ram. If the ram does not retract completely, too much oil had been

added. Drain enough to permit complete retraction.

REPLACING HYDRAULIC SEALS

Maintenance and repair of this tool should be provided with the same reasonable care given other fine equipment.

Service should be performed by adequately trained personnel in repair shops under clean conditions. For those

owners having adequately staffed repair facilities, a hydraulic seal replacement kit No. 3-3554 containing O-rings,

gaskets, etc., needed for one complete replacement of hydraulic seals in the compressor. Include compressor serial

number when ordering all parts.

To replace the seals it is necessary to separate the C-head and piston assemblies from the cylinder. Remove both

die halves. Removing the quick coupler drains the oil and aids in dis-assembly. Remove screw and washer to unlock

cylinder.

Unscrew the C-head and the piston will also rotate. After nine complete turns the piston spring rod is unthreaded

from within the cylinder and the piston guide arrangement should be removed. Further rotation will separate the C-

head from the cylinder. Pull the piston from the cylinder. All seals and rings are now accessible.

Reassemble with clean parts lubricated with the same grade of oil used in the remote pump. The steel piston washer

and leather wiper are installed on the outside of the piston with the steel washer next to the shoulder on the piston.

Insert piston into cylinder, rotate assembly until hand tight. Backoff one-half turn to permit the piston wipers to center

themselves in the C-head bore. Thread the C-head onto the cylinder until the bottom of the die groove in piston is

flush at a corresponding point on the C-head. Continue rotation until the key slots align. At this attitude, top of piston

should not have entered C-head opening and a die-half can be inserted in piston groove.

Reassemble the piston guide arrangement with Loctite on screw threads.

Invert the tool and fill the cylinder with oil. Bleed air from cylinder by rocking tool back and forth. Assemble 3/8 inch

female quick coupler.

WARNING

Operating Instructions and Parts List Form No. 1000026

TROUBLE SHOOTING

Sheet No. 3 of 6

Rev Date: 09 Feb 2004

If the ram will not extend completely, it will generally be found that there is an insufficient amount of oil in the

compressor's hydraulic system. This trouble can also be caused by faulty pump plunger packing or release valve

packing by the pressure release valve being stuck open, or by foreign matter preventing the release valve balls from

seating properly. Faulty packing will usually be detected by excess oil leakage around the pump plunger. A stuck

valve ball can usually be freed by rapping the tool sharply.

Avoid damage to other parts in the process of rapping. Foreign matter can frequently

be flushed from a valve seat by pumping very rapidly with abrupt strokes.

If the dies will not close and pumping is difficult, check the die number to make certain the proper size die is being

used on the accessory. If the dies will not close and pumping becomes easier, usually additional oil is needed in the

compressor. There is also the possibility that the pressure release valve balls are not seating properly.

If the ram will not retract completely, it will generally be found that there is too much oil in the compressor. Drain

enough to permit complete retraction. If the ram will not retract and the oil reservoir is not full, the ram is likely being

held by a deformed washer.

A small amount of leakage is desirable around the ram; pump plunger, and pressure release valve plunger to

lubricate these parts. If enough leakage occurs to cause the oil to run, the packing should be replaced.

If rotating the reservoir handle will not advance the ram to within a half-inch of closing the dies, additional oil is

needed in the compressor. If rotating the handle will not move the ram, either the ram is being held by a deformed

washer or the reservoir piston has been deformed and is seizing on the reservoir walls. Such deformation occurs only

if the reservoir handle is screwed tight against a fully advanced ram and the pressure release or safety valve is

operated. The momentary pressure surge against the face of the reservoir piston may cause it to buckle and wedge

against the wall of the reservoir. No purpose is served in screwing the handle tight and doing so abuses the tool.

If the dies do not lock in position, the action of the retaining pins is probably restricted by dirt. Clean and oil these

parts.

If it is difficult to unlock the die-haves, the die release buttons should be lubricated. The die retaining pin set screw in

the C-head above the die release button is staked in position. To further tighten this screw will make it difficult or

impossible to release the die.

CAUTION

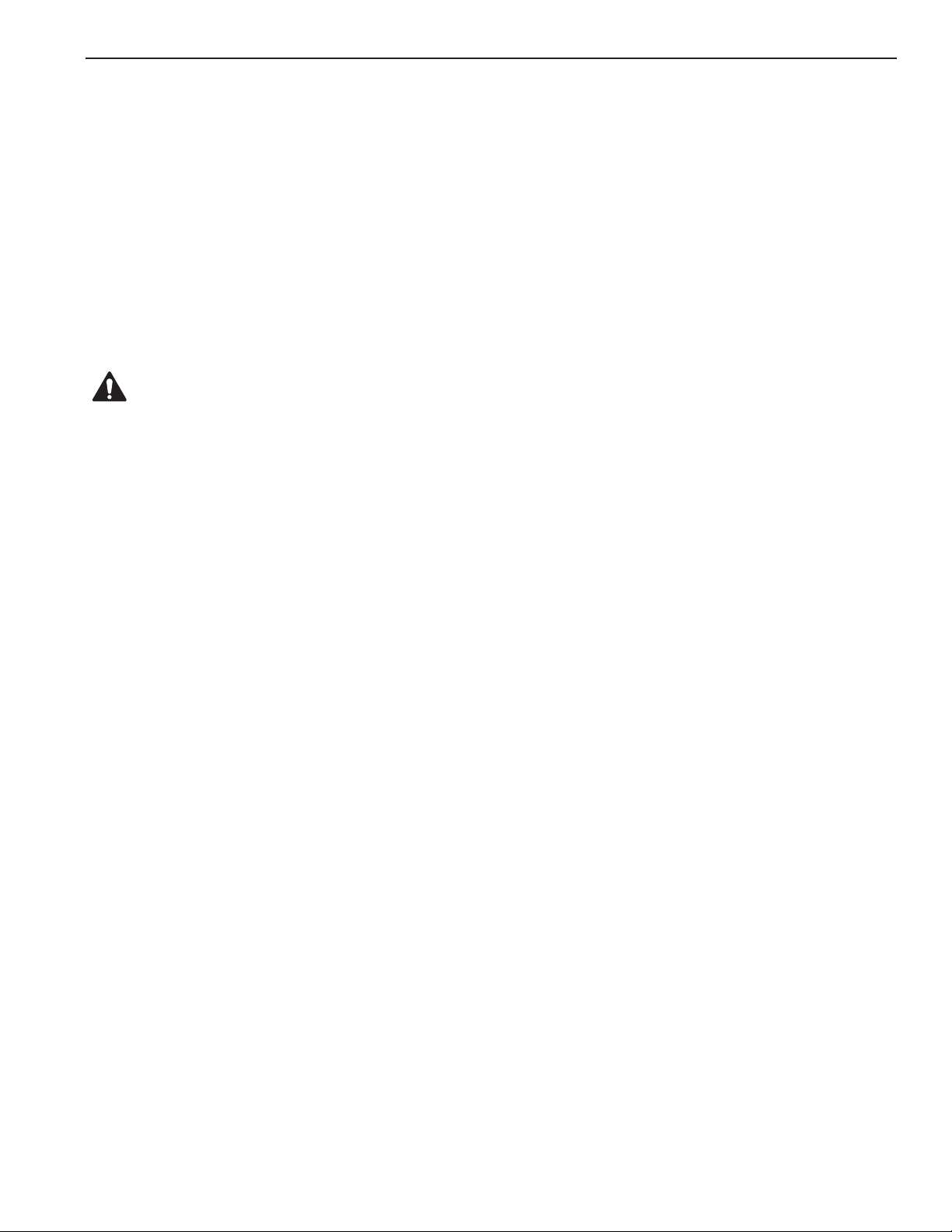

6

4

7

3

5

8

2

1

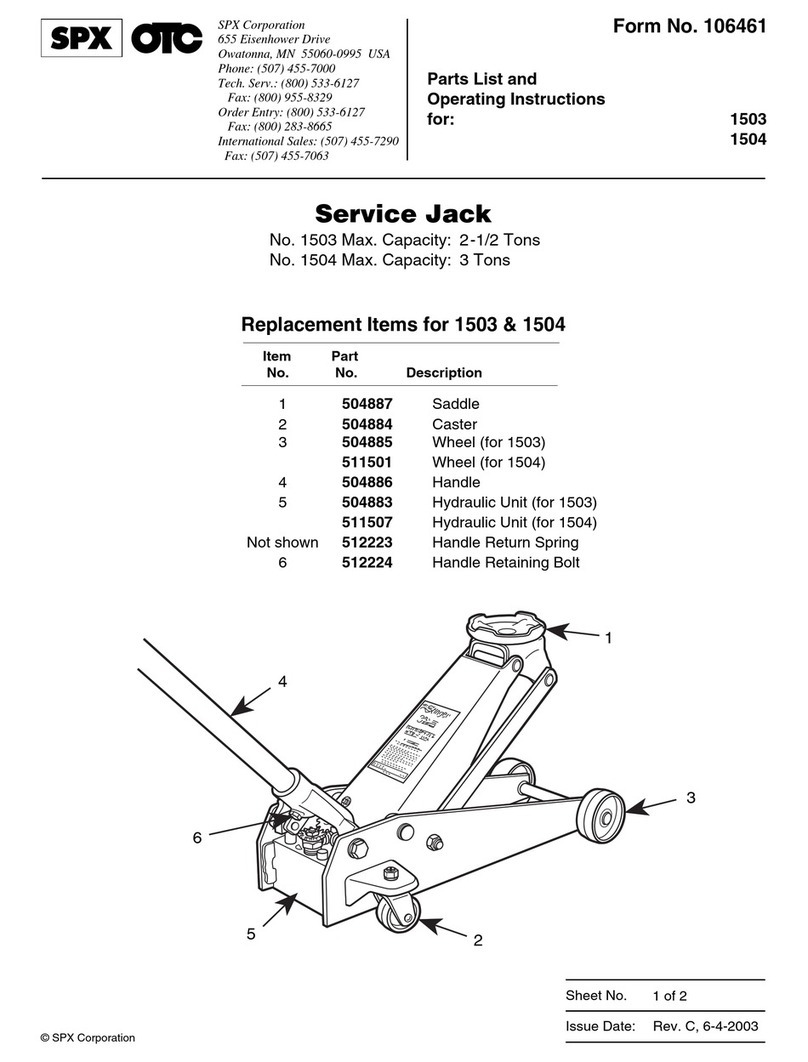

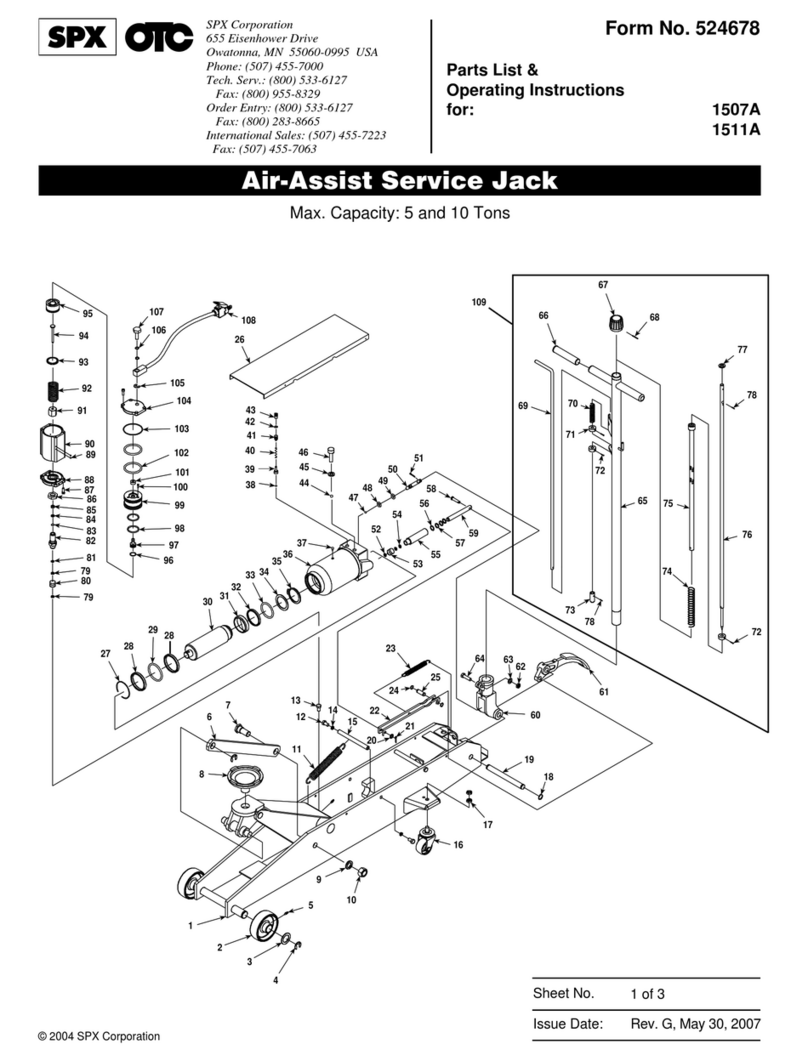

1. Top Die Release Button

2. Bottom Die Release Button

3. Piston Guide Screw

4. Piston

5. Reservoir

6. Reservoir Handle

7. Release Striker

8. Pump Lever

Illustration

Operating Instructions and Parts List, Form No. 1000026, Back sheet 3 of 6

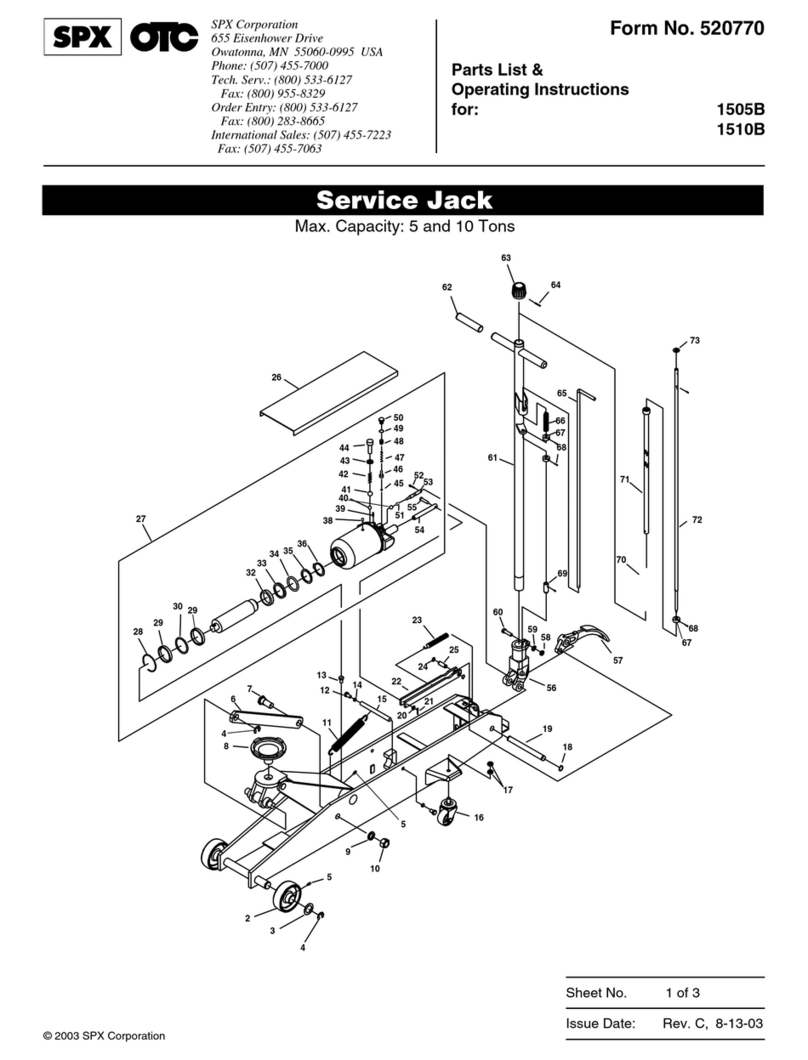

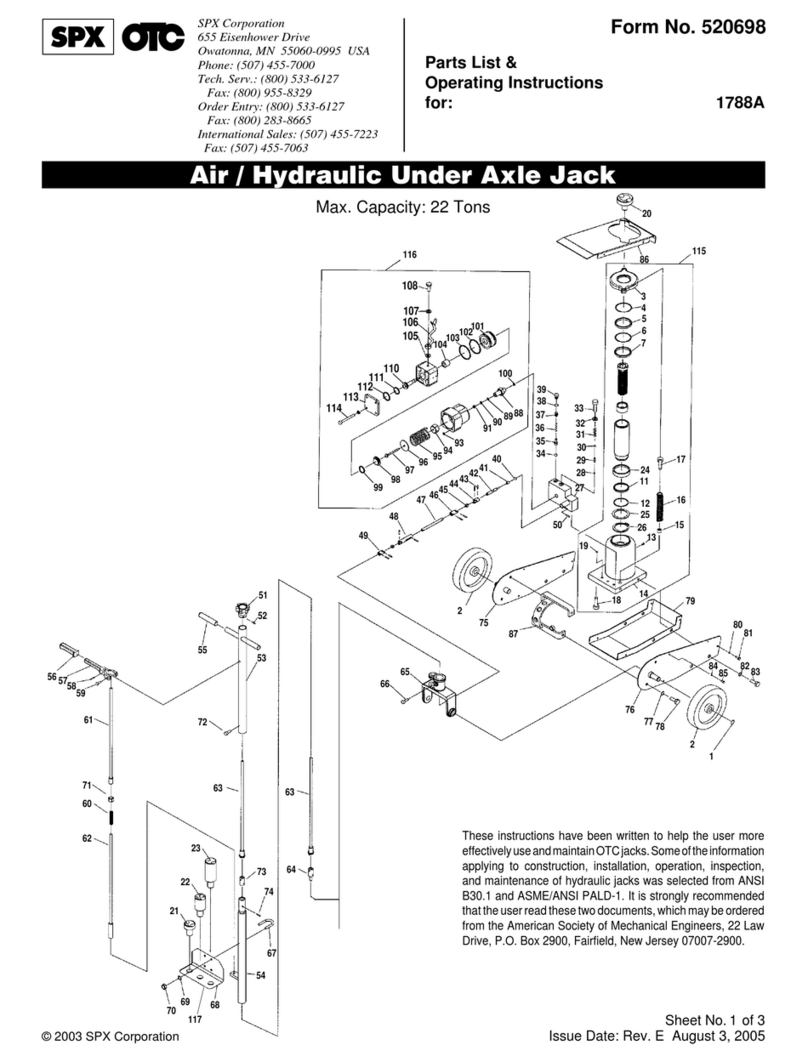

PARTS LIST

11000056 1 Label, (Tradename Power Team)

21000055 1 Decal, (Warning & Caution)

3420691 1 Decal, (Product Blank)

45-0691 1 Ring, Tru-Arc #5103-31

53-1199 1 Pin, Fulcrum

63-1204 1Key

75-1258 1 Lockwasher 1/4 x .047 x .078 HI-C

83-1203 1 Screw, Key

93-1205 1 Washer, Piston

10 3-1211 1 Wiper

11 3-1192 1 Lever Assembly

12 5-0342 1 Screw. 8-32 x 1/8 Flat Pt. Skt. Se

13 3-1200 1 Screw, Stop

14 3-1196 1 Handle, Assembly

15 5-3667 1 Screw, 3/8-16 x 1/2 Fill. Hd. Mach.

16 10268 1 O-Ring, .50 x .37 Nitrile

17 3-1207 1 Rubber Covering, Cap

18 3-1197 1 Piston, Reservoir

19 3-5071 1 Rubber Covering, Cylinder

20 3-1201 1 Cap, Reservoir

21 5-1260 1 Quad-Ring, 1-5/8 x 1-7/8 x 1/8

22 3-1195 1 Cylinder Assembly

23 5-1263 1 O-Ring

24 5-1259 2 Screw, 10-24 x 1/4 SHCS

25 12356 2 Washer, Tooth Int. .37 x .20

26 3-1214 1 Ring, Back-up

27 3-1193 1 Ram Assembly

28 3000094 1 C-Head Assembly, ( Coated)

ITEM NOT SHOWN

2000147 1 Bag, Nylon Carrying

(2.5” x 6” x 22”)

Item Part No. Item Part No.

No. No. Req’d Description No. No. Req’d Description

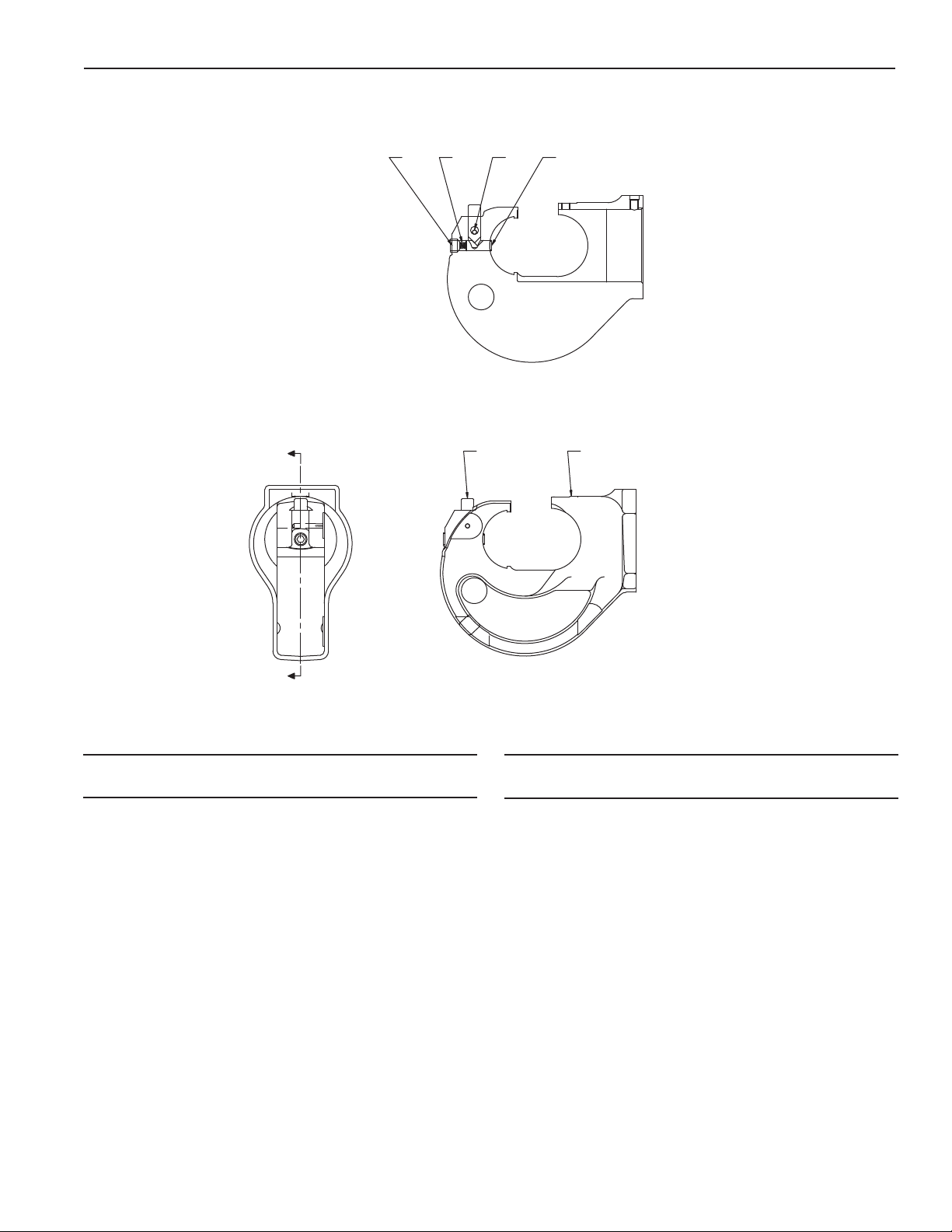

27

28

22

11

14

18

513

20

8

6

9

17

10

26

23 19

16

15

12

47

24

25 21

2

KEEP HANDS AWAYFROM

CRIMPING TOOL HEAD

WHEN CRIMPING

CAUTION

DO NOT OPERATE

WITHOUT DIES - DO NOT

ADVANCERAM WITHOUT

WORK INSERTED

®

SPX Corporation, Rockford,IL 61109 USA

http://www.powerteam.com

Made in USA

1

3

C12-TON

Operating Instructions and Parts List Form No. 1000026

PARTS LIST

Sheet No. 4 of 6

Rev Date: 09 Feb 2004

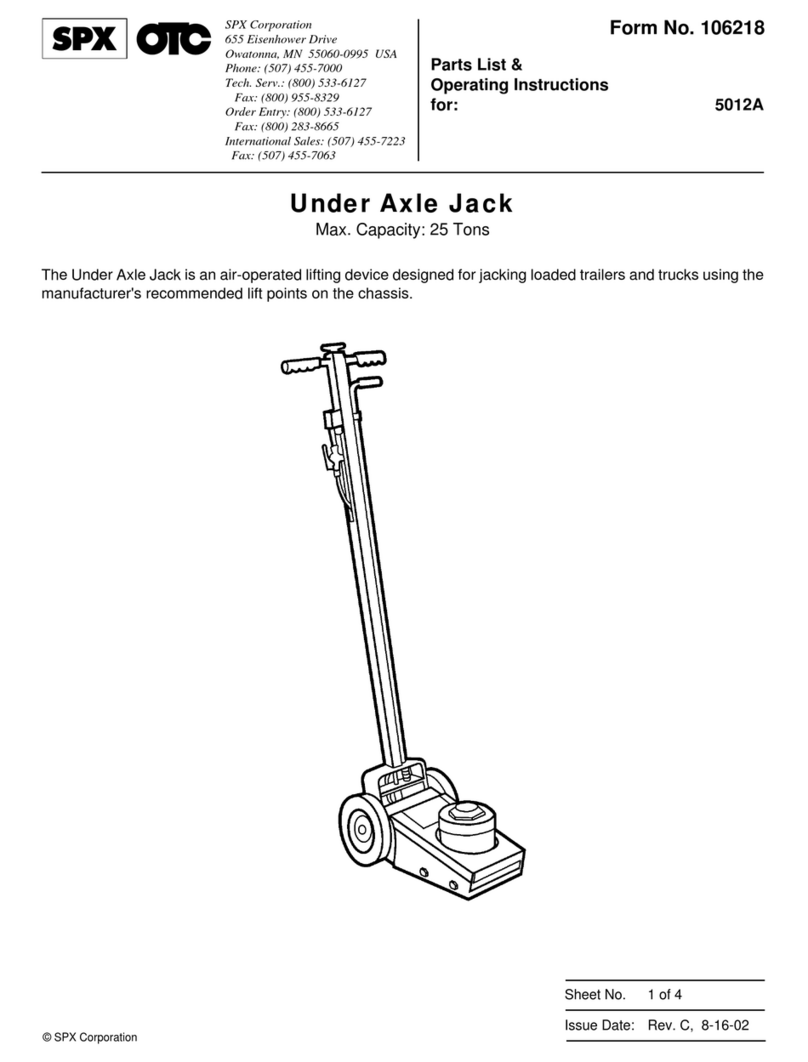

SECTION A-A SECTION B-B

SECTION C-C

12

9

738

1

26

11 10

5

4

AA

B

B

C

C

13-1246 1Lever

23-1248 1 Striker, Release

33-1249 1 Shaft

43-1250 2 Bushing, Lever

53-1251 1 Pin, Plugger

63-1252 1 Spring, Striker

73-1253 1 Trigger

83-1254 1 Covering, Rubber, Lever

95-1265 1 Pin

10 5-1269 1 Pin

11 5-1270 1 Pin

12 5-1271 1 Pin

Item Part No. Item Part No.

No. No. Req’d Description No. No. Req’d Description

LEVER ASSEMBLY 3-1192

A

A

12

3456

SECTION A-A

13-1237 1 Shaft, Die Release

22000152 1 C-Head, Crimped

35-0662 1 Screw, Set

43-1239 1 Spring

55-1265 1 Pin, Driv-lok

63-1238 1 Pin, Die Retaining

Item Part No. Item Part No.

No. No. Req’d Description No. No. Req’d Description

Operating Instructions and Parts List, Form No. 1000026, Back sheet 4 of 6

PARTS LIST

C-HEAD ASSEMBLY 3000094

BB

CC

E

E

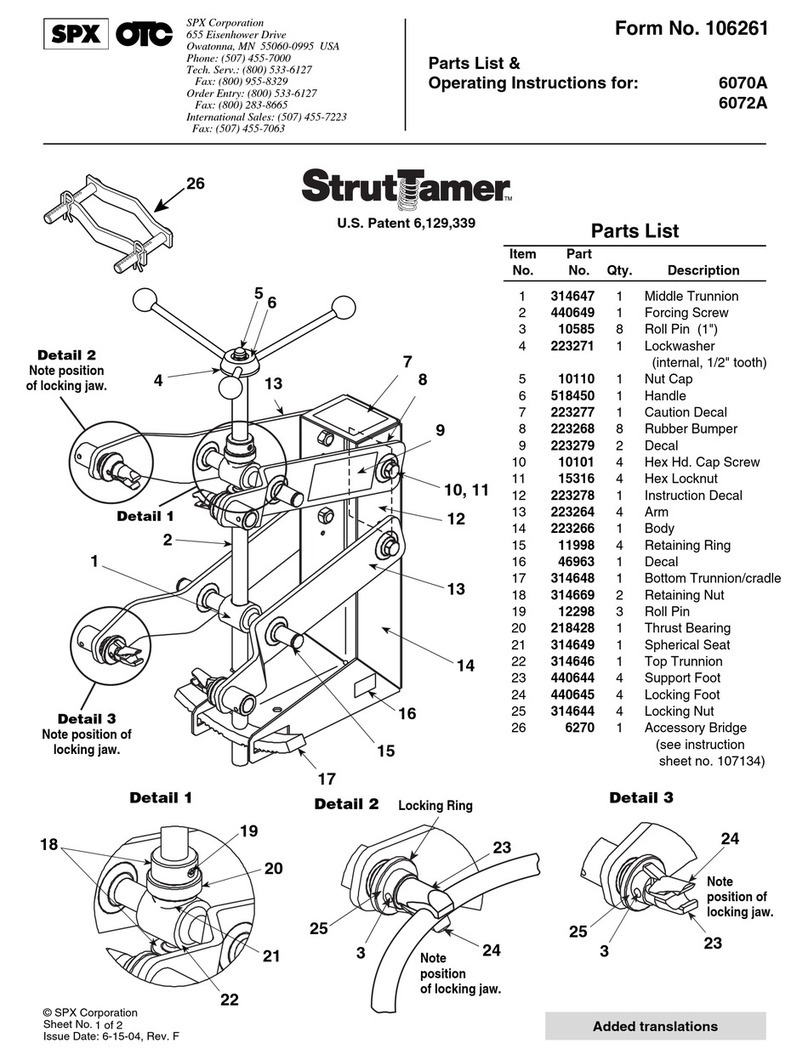

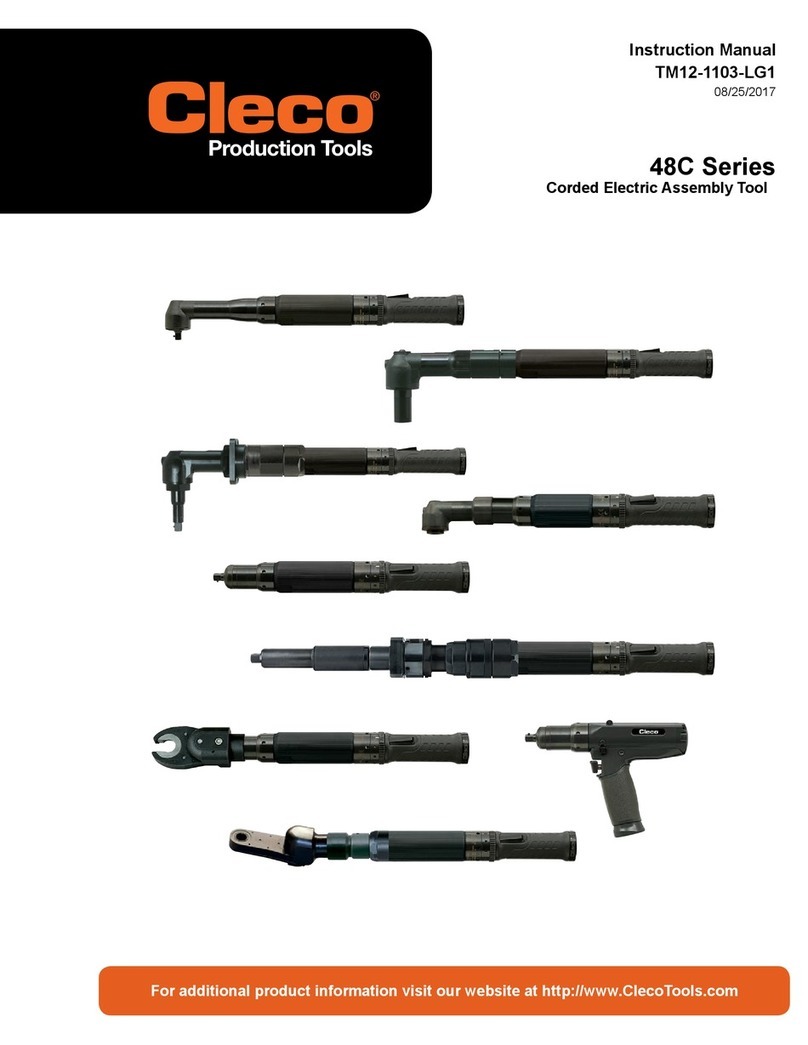

SECTION E-E

4

97

13

21

820

12

17

23

Apply 5-2538 adhesive to

threads of Item 10

SECTION A-A

6

10 14 19

14

SECTION B-B

SECTION C-C

16

2

Tighten Item 16 to 35 Ft.Lbs.

Stake Item 5 in place, Install

Item 3 flush to .030 above surface

and stake in place to prevent

Rotation

3

1

18

15

22

11

5

AA

13-0688 1 Spring, Compression

23-1215 1 Cylinder

33-1216 1 Screw, Valve Ball

43-1217 1 Screw, Release Stop

53-1218 1 Retainer, Screen

63-1219 1 Plunger, Pump

73-1220 1 Spacer, Packing

83-1221 1 Ring, Packing

93-1222 1 Plunger, Release

10 3-1223 1 Nut, Plunger

11 3-1225 1 Screen, Intake

12 3-1226 1 Spring, Compression

13 3-1227 1 Washer, Nylon

14 3-1228 2 Washer,

15 3-1229 1 Spring, Compression

16 3-2716 1 Valve Assembly, HP Relief

17 10377 1 Ball

18 10423 1 Ball

19 14763 1 O-Ring

20 10375 1 Ball

21 10268 1 O-Ring

22 10374 1 Ball

23 5-0658 1 Screw, Set

Item Part No. Item Part No.

No. No. Req’d Description No. No. Req’d Description

Operating Instructions and Parts List Form No. 1000026

PARTS LIST

Sheet No. 5 of 6

Rev Date: 09 Feb 2004

CYLINDER ASSEMBLY 3-1195

PTFE

263514

SECTION A-A A

A

13-0654 1 Plunger, Valve

23-1091 1 Screw, Adjusting

33-1232 1 Body, Valve

43-1233 1 Washer

53-1234 1 Spring

65-1264 1 Screw, Hollow Jam

Item Part No. Item Part No.

No. No. Req’d Description No. No. Req’d Description

98

5672

SECTION A-A

B

B

AA

SECTION B-B

3

4

1

10

Operating Instructions and Parts List, Form No. 1000026, Back sheet 5 of 6

PARTS LIST

H.P. RELIEF VALVE ASSEMBLY 3-2716

RAM ASSEMBLY 3-1193

13-1239 1 Spring

23-1240 1 Rod, Spring

33-1241 1 Pin, Retaining

43-1242 1 Shaft, Release

53-1243 1 Ram

63-1244 1 Spring

73-1245 1 Support, Spring

85-1266 1 Ring, Retaining

95-1267 1 Pin, Roll

10 5-1269 1 Pin, Roll

Item Part No. Item Part No.

No. No. Req’d Description No. No. Req’d Description

13-1255 1 Handle Sub-Assembly

(See below)

23-1256 1 Plug, Res. Handle

33-1257 1 Covering, Handle

Item Part No. Item Part No.

No. No. Req’d Description No. No. Req’d Description

13-4775 1 Handle, Reservoir 2 3-4776 1 Spacer, Stop

Item Part No. Item Part No.

No. No. Req’d Description No. No. Req’d Description

132

A

A

A

A

1

2Note: Use 5-2840 Adhesive to fasten spacer

in place. Spacer must not project above

O.D. Parts must be clean, dry, and free of

grease and oil prior to applying adhesive.

Operating Instructions and Parts List Form No. 1000026

PARTS LIST

Sheet No. 6 of 6

Rev Date: 09 Feb 2004

RESERVOIR HANDLE ASSEMBLY 3-1196

RESERVOIR SUB - ASSEMBLY 3-1255

Table of contents

Other SPX Tools manuals