SPX 5012A User manual

© SPX Corporation

Form No. 106218

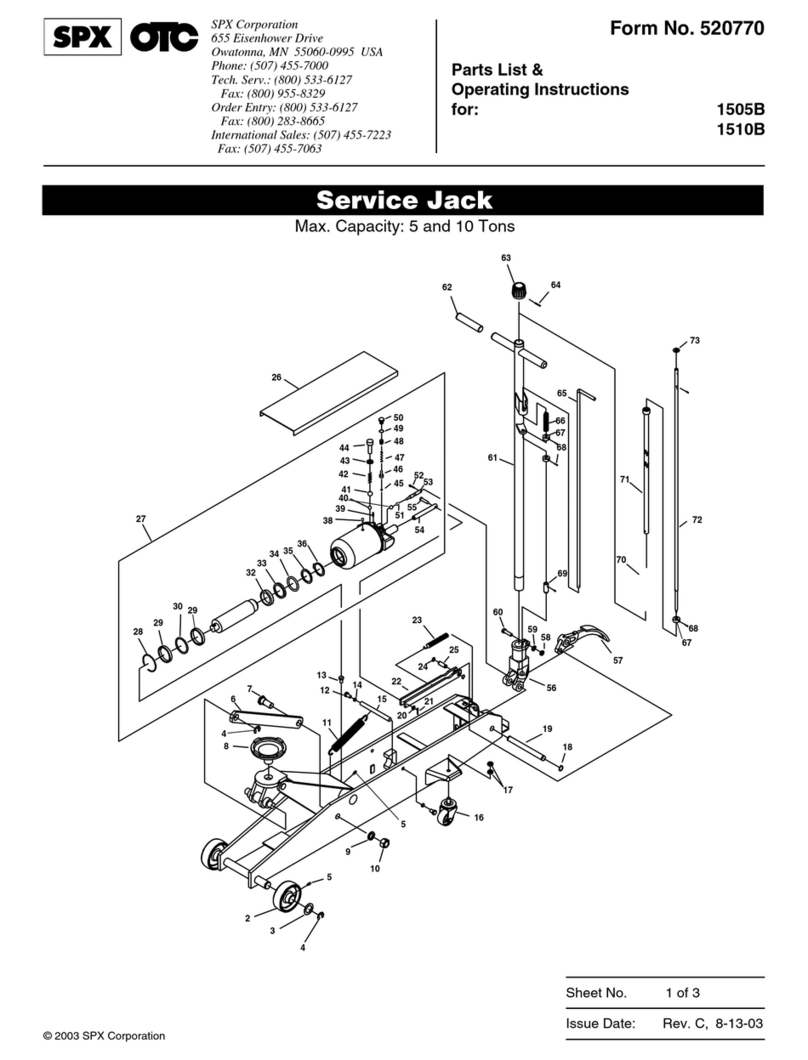

Under Axle Jack

Max. Capacity: 25 Tons

The Under Axle Jack is an air-operated lifting device designed for jacking loaded trailers and trucks using the

manufacturer's recommended lift points on the chassis.

SPX Corporation

655 Eisenhower Drive

Owatonna, MN 55060-0995 USA

Phone: (507) 455-7000

Tech. Serv.: (800) 533-6127

Fax: (800) 955-8329

Order Entry: (800) 533-6127

Fax: (800) 283-8665

International Sales: (507) 455-7223

Fax: (507) 455-7063

Parts List &

Operating Instructions

for: 5012A

Sheet No. 1 of 4

Issue Date: Rev. C, 8-16-02

Parts List & Operating Instructions Form No. 106218, Sheet 1 of 4, Back

Safety Precautions

CAUTION: To help prevent personal injury and damage to equipment,

•Read,understand,andfollowallinstructions,includingtheANSIB30.1safetycodefor

jacks. Before using the under axle jack to lift a vehicle, refer to the vehicle service

manual for recommended lifting surfaces on the vehicle chassis.

•Wear protective eyewear that meets the requirements of ANSI Z87.1 and OSHA.

•Inspectthejackbeforeeachuse;donotusethejackifit’sdamaged,altered,orinpoor

condition.

•Use the jack for lifting purposes only.

•A load must never exceed the rated lifting capacity of the jack.

•Only use the jack on a hard, level surface.

•Center the load on the jack saddle. Off-center loads can damage seals and cause jack

failure.

•Lift only dead weight.

•Stay clear of lifted loads. Place support stands under the axles before working on the

vehicle.

•Do not adjust the safety valve.

•Do not modify the jack or use adapters unless approved or supplied by OTC.

•Lower the jack slowly and carefully while watching the position of the jack saddle.

•Use only approved hydraulic fluid (Chevron AW Hydraulic Oil MV or equivalent). The use of alcohol,

hydraulic brake fluid, or transmission oil could damage seals and result in jack failure.

This guide cannot cover every situation, so always do the job with safety first.

Operating Instructions

1. Lubricate the air inlet on the jack with 1/2 oz. clean lubricating oil; lack of oil can cause pump malfunction.

2. Connect the air supply. (90 - 200 psi of clean, dry air is required for the capacity of this jack.)

3. Set the vehicle’s parking brakes and / or block the wheels.

4. Position the jack under the vehicle. Important: Use the vehicle manufacturer’s recommended lifting

points on the chassis.

5. Close the release valve by turning the release knob clockwise (CW) as far as it will go.

6. Presstheairvalvelevertoraisethejacksaddleuntilittouchesthevehicle.Checktheplacementofthesaddle

lugs. Finish lifting the vehicle.

7. Place approved safety stands under the vehicle at points that will provide stable support. Before making

repairs, lower the vehicle onto the safety stands by SLOWLY and carefully turning the release knob

counterclockwise (CCW).

Bleeding Air from the Under Axle Jack

Aircanaccumulatewithinahydraulicsystemduringshipmentorafterprolongeduse.Thisentrappedaircauses

the jack to respond slowly or feel “spongy.” To remove the air:

1. Open the release valve by turning the knob all the way counterclockwise (CCW).

2. Connect the air supply to the jack.

3. Press the air valve control lever, and cycle the jack twenty or more times.

4. Close the release valve by turning the knob all the way clockwise (CW).

5. Press the air valve control lever until the ram is fully extended.

6. LowertherambyturningthereleaseknoballthewayCCW.Ifthejackdoesnotimmediatelyrespond,repeat

this procedure.

© SPX Corporation

Parts List & Operating Instructions Form No. 106218

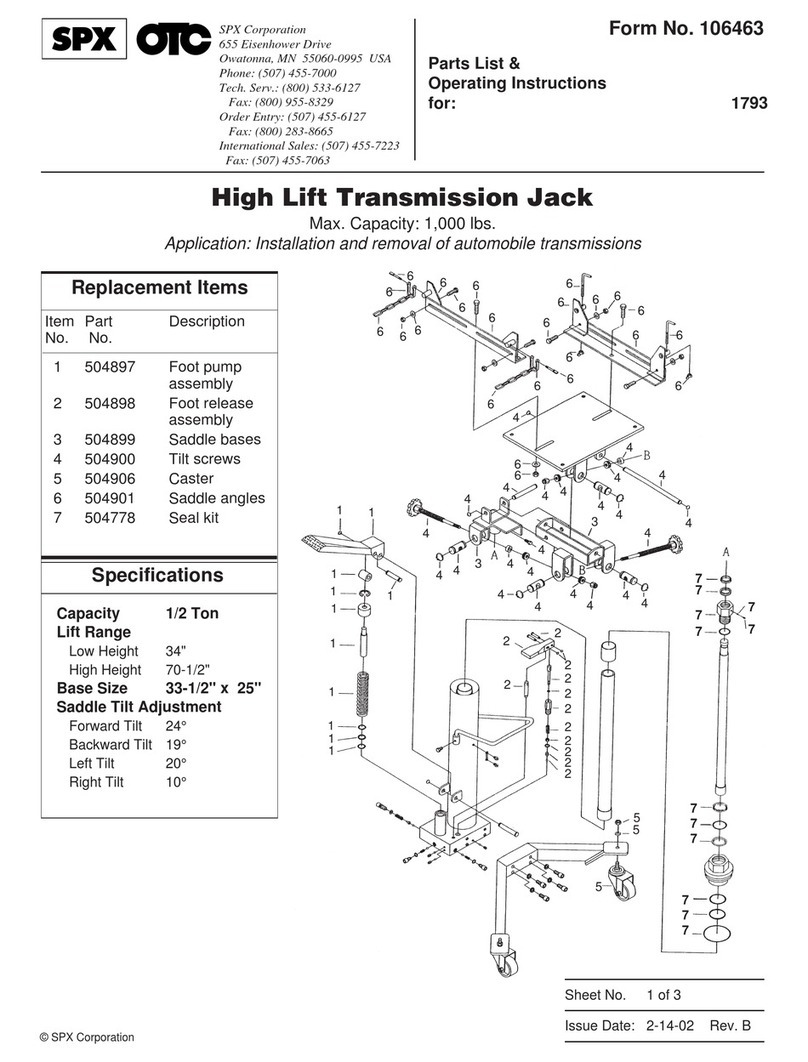

1

4

3

2

5

6

7

9

8

11

12

13

4

14 16 18 20 21 23 19 22 85 22 26

15

51

50 28 25 30

2427

29

34

38

36 31 32 33 52 35

37

39 36 41 42 43 45

48

48

47

Sheet No. 2 of 4

Issue Date: Rev. C, 8-16-02

Parts List & Operating Instructions Form No. 106218, Sheet 2 of 4, Back

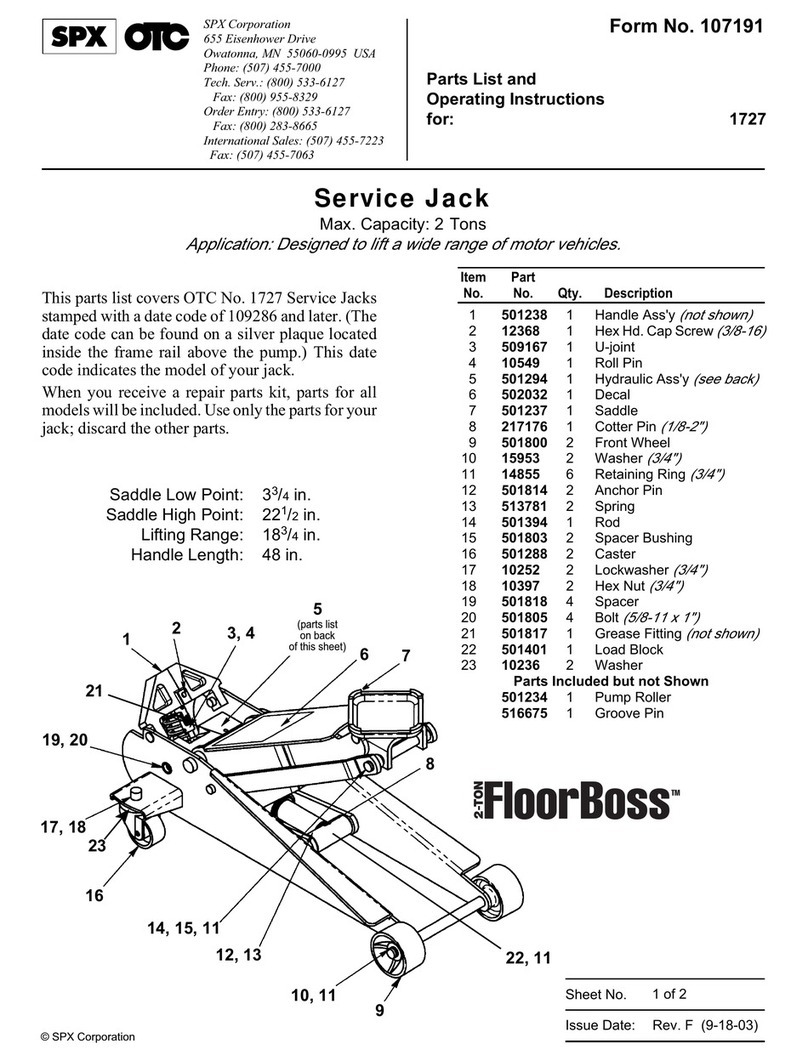

53 55 56 57 59 62 61 56 60

54 58

79

78

66

77

76

74, 75

73

72

71

60

62

68

70

69

68

67

66

65

64

63

82

80 81

© SPX Corporation

Parts List & Operating Instructions Form No. 106218

Description

Item

No. Part

No. No.

Req'd

1j1Seal

(2-5/8 x 2-7/8 x 1/18; loaded lip)

25012-02 2Plug

(1/8 NPT)

35012-03 1Jack Cap

4 j2Backup Ring

(3-1/8 x 3/16 x 3-1/2)

55012-05 1Extension Screw

65012-86 1Hydraulic Ram

75012-07 1Hydraulic Cylinder

85012-08 1Outer Barrel Weldment

95012-09 1Bladder

11 j1Quad Ring

(2-3/4 x 1/8 x 3)

12 5012-87 1Socket Hd. Cap Screw

(6-32 UNC x 1/4" lg.)

13 j1Seal

(2-1/2 x 3 x 1/4)

14 5012-88 1Base Plate

15 j2Quad Ring

(7/16 x 1/4 x 3/32)

16 j1Backup Ring

(11/16 x 1/2)

18 5012-89 1 Pump Housing

19 5012-19 1Pump Plunger

20 j1Seal

(9/16 x 5/16 x 1/8)

21 5012-97 1Pump Housing Cap

22 j2 Quad Ring

(3 x 2-5/8 x 3/16)

23 5012-23 1Compression Spring

(1-3/4 OD)

24 5012-93 1Retaining Ring

25 j1O-ring

(2-1/4 x 1/16 x 2-1/8)

26 5012-91 1Motor Housing

27 j1 Shuttle Valve Seal

(31/32 dia.)

28 j1Seal

(1-1/4 x 1 x 1/8)

29 5012-94 1Air Shuttle Piston

30 5012-92 1Piston Cap

31 5012-31 1Compression Spring

(1/4 ID x 3/8" lg.)

32 5012-32 1Ball

(3/8 dia.)

33 5012-33 1Check Valve Spacer

34 5012-34 1Male Elbow

(90

°

x 1/8 NPTF)

35 5012-35 1Plug

36 5012-36 2Ball

(1/4 dia.)

37 5012-37 1Plastic Plug

38 5012-38 1Plug

(SAE #4)

39 5012-39 1Male Connector

(1/8 NPTF)

41 j1O-ring

(3/8 x 1/4 x 1/16)

42 5012-42 1Release Stem

43 5012-43 1Roll Pin

(3/16 dia. x 3/4" lg.)

45 5012-45 1Flex Shaft

jItems marked with an asterisk are

included in Seal Kit No. 222954.

Sheet No. 3 of 4

Issue Date: Rev. C, 8-16-02

Parts List & Operating Instructions Form No. 106218, Sheet 3 of 4, Back

Description

Item

No. Part

No. No.

Req'd

47 5012-47 1 Branch Tee (1/8 NPT)

48 5012-48 2Socket Hd. Cap Screw

(3/8-24 x 2-1/4" Ig.)

50 5012-50 1Washer

(1.750 x .320 x .064)

51 5012-51 1Backup Ring

(1-5/8 x 1/16 x 2)

52 5012-52 1Compression Spring

(.406 OD)

53 5012-53 1Lift Pad Casting

(5/8")

54 5012-54 1O-ring

(1-1/16 x 1-1/4 x 3/32)

55 5012-98 1Power Unit

56 5012-56 4Self-tapping Screw

(5/16-18)

57 5012-57 4 Cap Screw

(1/2-13 x 1"; Grade 5; plated)

58 5012-58 4Lockwasher

(1/2"; plated)

59 5012-59 1Base Frame Weldment

60 5012-60 1Tubing

(1 /4 x .035 x 45-1/2" lg.)

61 5012-61 1Top Cover

62 5012-62 1Tubing

(1/4 x .035 x 60" Ig.)

63 5012-63 2Handle Grip

(7/8" ID; black)

64 5012-64 1Handle Bar

65 5012-65 1Handle Wheel

66 5012-66 2Roll Pin

(3/16 dia. x 7/8" Ig.)

67 5012-67 1Handle Grip

68 5012-68 2Male Connector

(1/4 NPTF)

69 5012-69 1Nipple

70 5012-70 1Air Valve

71 5012-71 1Handle Weldment

72 5012-72 1Handle Release Rod Weldment

73 5012-73 2Jam Nut

(7/16-14; plated)

74 5012-74 2Washer Cap Palnut

(5/8 dia.; plated)

75 5012-96 1Bar Round

(5/8" x 14")

76 5012-95 2Wheel

77 5012-77 1Compression Spring

78 5012-78 1Release Control Rod

79 5012-79 2Cap Screw

80 216703 1Made in USA Decal

81 314486 1Decal

82 5012-82 1Decal

85 5012-90 1Motor Piston

Available Kits

222954 1Seal Kit (items marked with an (j) asterisk)

220972 1Lift Pad Extension Kit

(3")

© SPX Corporation

Parts List & Operating Instructions Form No. 106218

Preventive Maintenance

Important:Thegreatestsinglecauseoffailureinhydraulicunitsisdirt.Keeptheunderaxlejackcleanandwelllubricatedtoprevent

foreignmatterfromenteringthesystem.Ifthejackhasbeenexposedtorain,snow,sand,orgrit,itmustbecleanedbeforeitisused.

1. Storethejackinawell-protectedareawhereitwillnotbeexposedtocorrosivevapors,abrasivedust,oranyotherharmfulelements.

2. Regularly lubricate the moving parts.

3. Replace the oil in the reservoir at least once per year. To check the oil level, disconnect the air supply, place the under axle jack on

levelground, and completelyretracttheram.Removethe plastic coverandplugfromtheoil filler hole. Theoillevelshouldbe within

1/4"ofthefillerplughole.Ifnecessary,addapprovedanti-wearhydraulicjackoil,andinstallthefillerplugagain.Important: Theuse

of alcohol, hydraulic brake fluid, detergent motor oil, or transmission oil could damage the seals and result in jack failure.

4. Inspect the jack before each use. Take corrective action if any of the following problems are found:

a. Cracked or damaged housing d. Scored or damaged piston rod

b. Excessive wear, bending, or other damage e. Loose hardware

c. Leaking hydraulic fluid f. Modified or altered equipment

Troubleshooting Guide

Repair procedures must be performed in a dirt-free environment by qualified personnel who are familiar with this equipment.

Trouble Cause Solution

Erratic action 1. Air in system

1. To bleed air, place jack on its base with

ram retracted, open release valve knob,

and cycle ram 20 times.

2. Oil viscosity too high

2. Change to a lower viscosity oil

3. Internal leakage in cylinder

3. Replace worn packings. Look for

excessive contamination or wear.

4. Cylinder sticking or binding

4. Look for dirt, gummy deposits, or leaks.

Check for misalignment, worn parts,

or defective packings.

Jack does not lift 1. Release valve is open

1. Close release valve

2. Low/no oil in reservoir

2. Fill with oil and bleed system

3. Air-locked system

3. Bleed system

4. Load is above capacity of jack

4. Use correct equipment

5. Delivery valve and/or bypass

5. Clean to remove dirt or foreign matter.

valve not working correctly

Replace oil.

6. Packing worn out or defective

6. Replace power unit

Jack lifts only partially 1. Too much or not enough oil

1. Check oil level

Jack advances slowly 1. Pump not working correctly

1. Replace power unit

2. Leaking seals

2. Replace power unit or seals

3. Low air pressure

3. Adjust air pressure to 90 - 200 psi.

Jack lifts load, but doesn’t hold 1. Cylinder packing is leaking

1. Replace power unit or seals

2. Valve not working correctly (suction,

2. Inspect valves. Clean and repair

delivery, release, or bypass)

seat surfaces.

3. Air-locked system

3. Bleed system

Jack leaks oil 1. Worn or damaged seals

1. Replace power unit or seals

Jack will not retract 1. Release valve is closed

1. Open or clean release valve

Jack retracts slowly 1. Cylinder damaged internally

1. Send jack to OTC authorized service

center for repair

2. Link section is binding

2. Lubricate link section

Sheet No. 4 of 4

Issue Date: Rev. C, 8-16-02

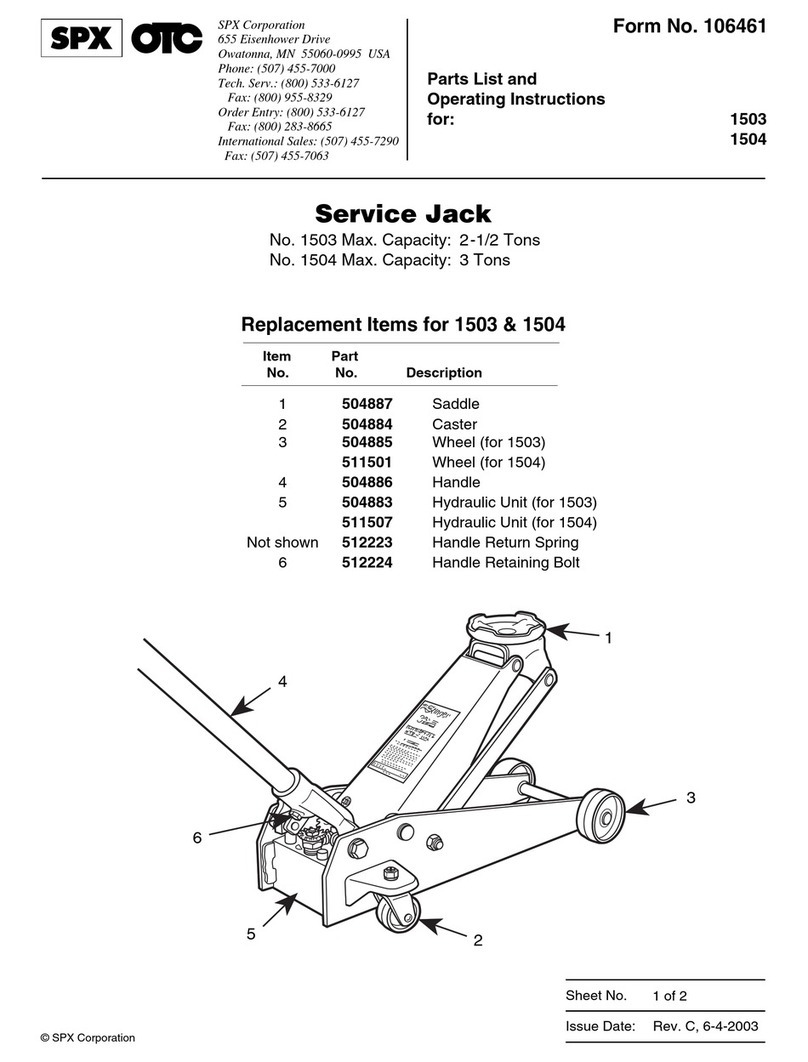

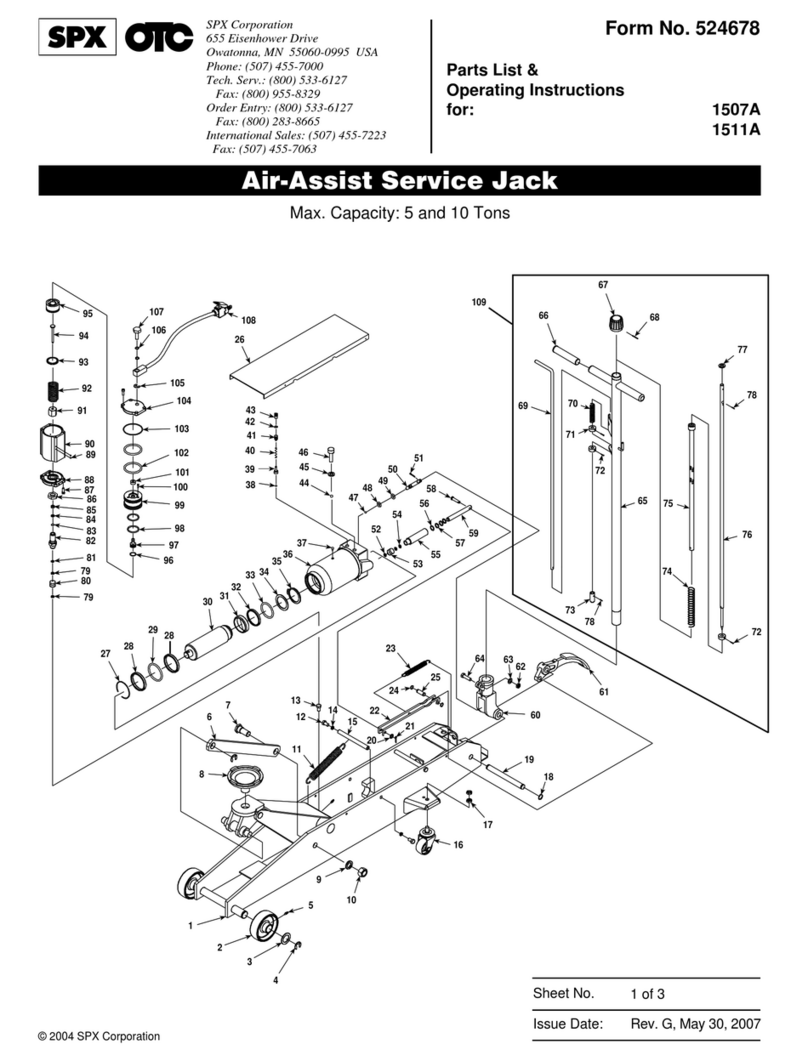

This manual suits for next models

1

Table of contents

Other SPX Tools manuals

SPX

SPX 5106 User manual

SPX

SPX 5019 User manual

SPX

SPX 1505B User manual

SPX

SPX POWER TEAM C12-TON Use and care manual

SPX

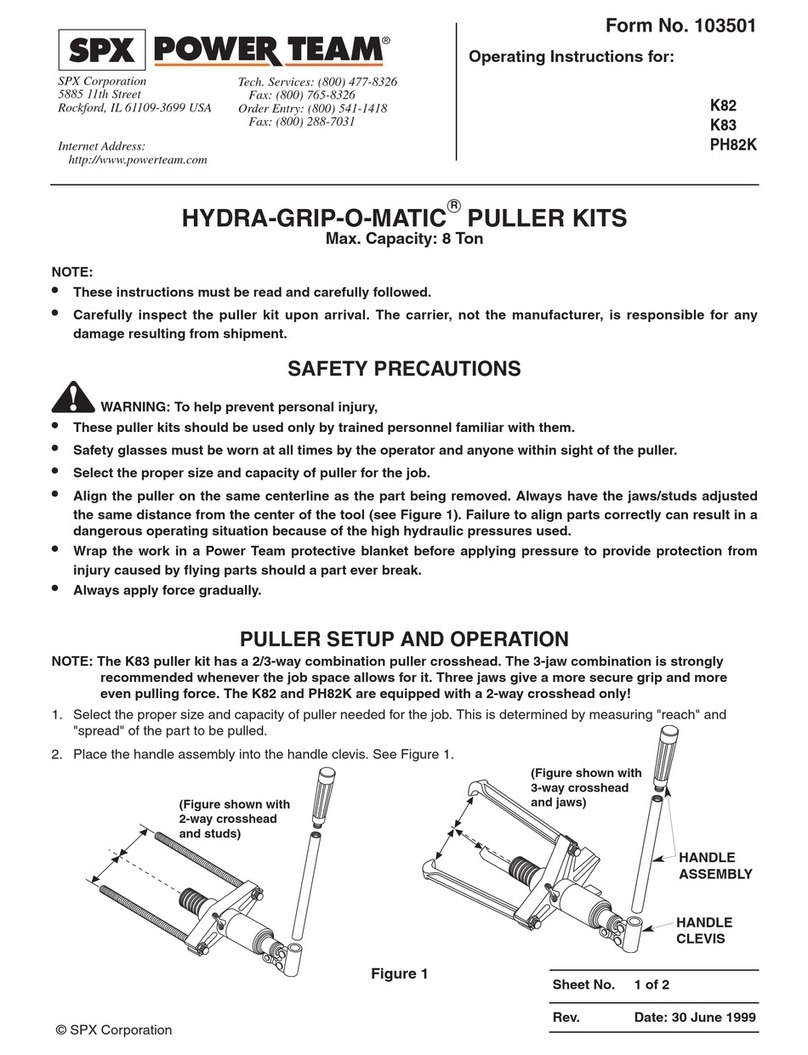

SPX HYDRA-GRIP-O-MATIC K82 User manual

SPX

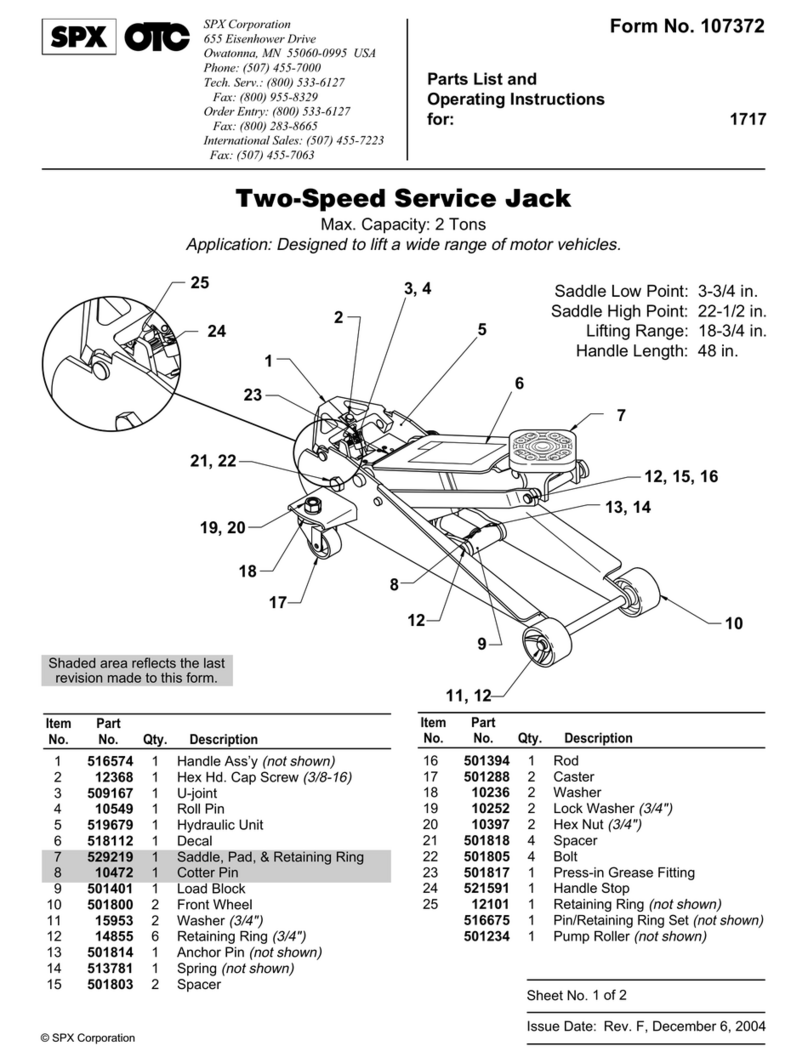

SPX 1717 User manual

SPX

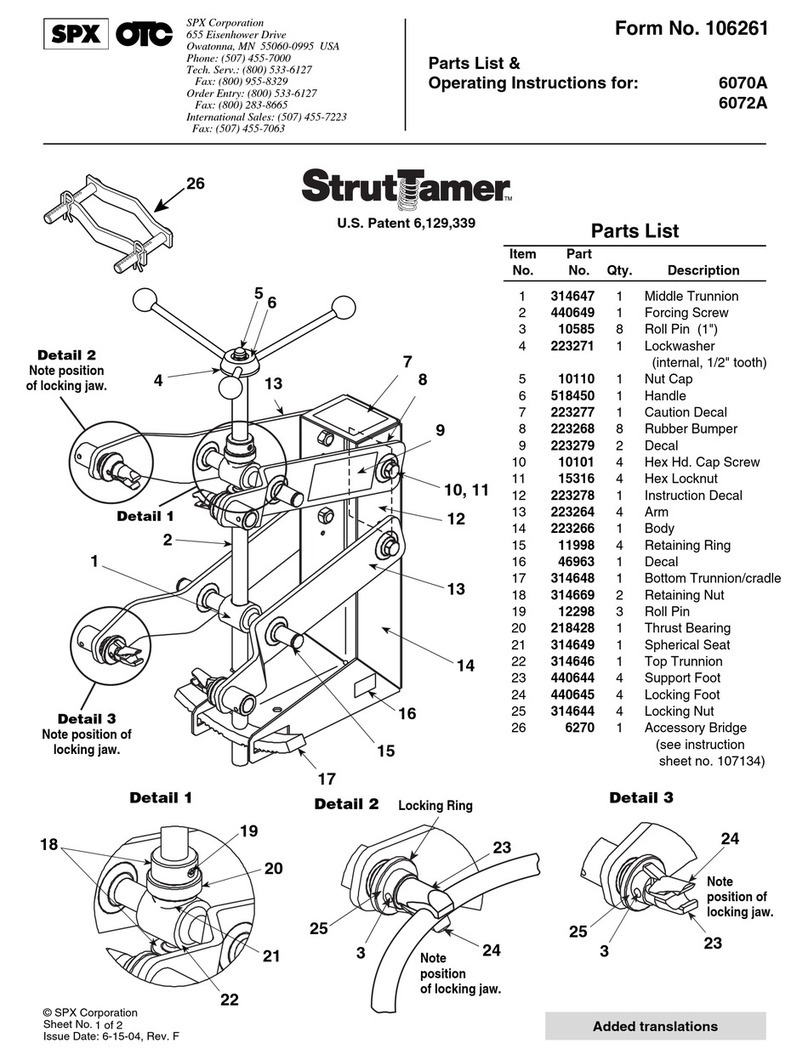

SPX StrutTamer 6070A User manual

SPX

SPX Power Team HYDRA-GRIP-O-MATIC PH6 User manual

SPX

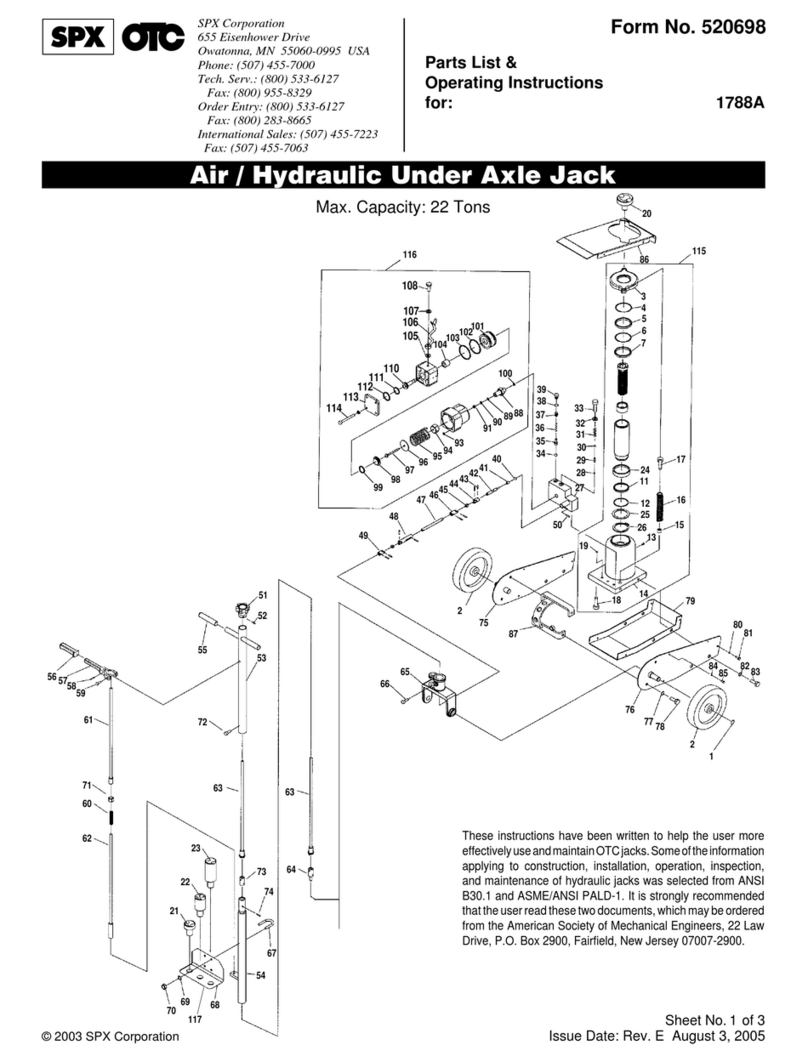

SPX 1788A User manual

SPX

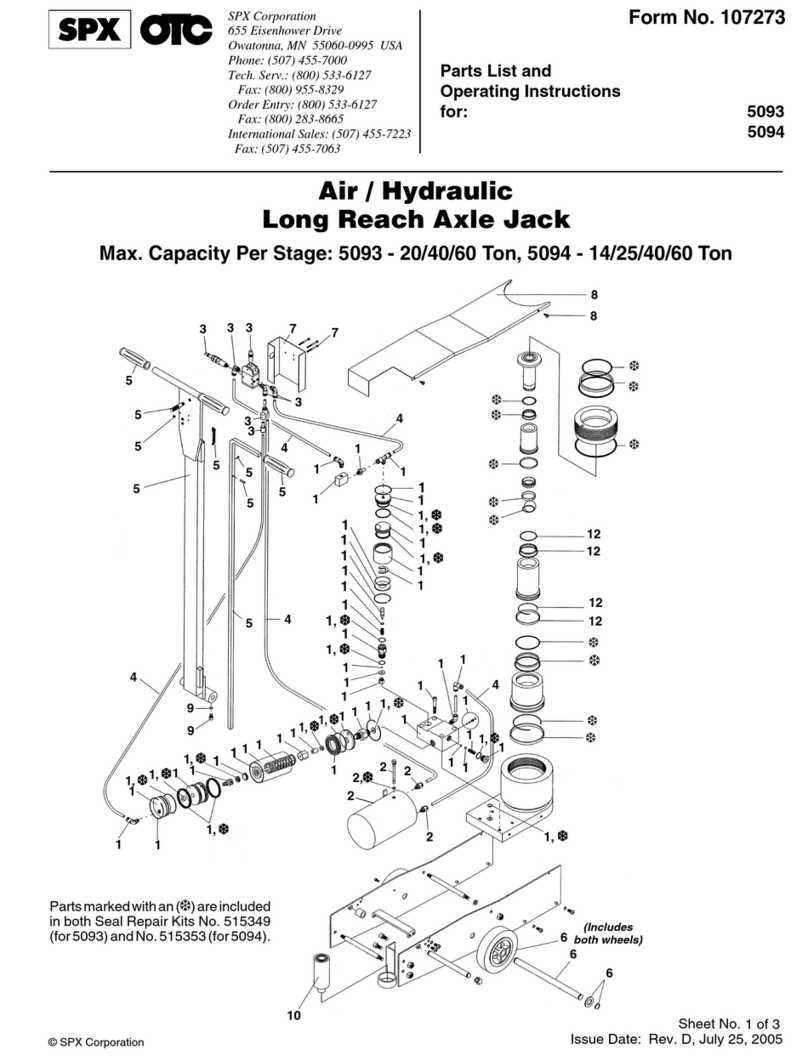

SPX 5093 User manual