SRAM SRAM DUALDRIVE User manual

Other SRAM Bicycle Accessories manuals

SRAM

SRAM Stealth-a-majig User manual

SRAM

SRAM RockShox Super Deluxe User manual

SRAM

SRAM Zipp Wheels User manual

SRAM

SRAM RockShox Super Deluxe Flight Attendant User manual

SRAM

SRAM RockShox DebonAir Quick start guide

SRAM

SRAM eTap AXS User manual

SRAM

SRAM Zipp Wheels User manual

SRAM

SRAM Reverb Stealth User manual

SRAM

SRAM MTB Series User manual

SRAM

SRAM 1x MTB Series User manual

SRAM

SRAM Rock Shox TwistLoc User manual

SRAM

SRAM Quarq ShocWiz User manual

SRAM

SRAM RockShox RS-1 User manual

SRAM

SRAM Rockshox Judy Series User manual

SRAM

SRAM P5 8/2005 40 Seiten Guide

SRAM

SRAM X.0 User manual

SRAM

SRAM GUIDE RSC 2015 User manual

SRAM

SRAM SRAM SPECTRO T3 User manual

SRAM

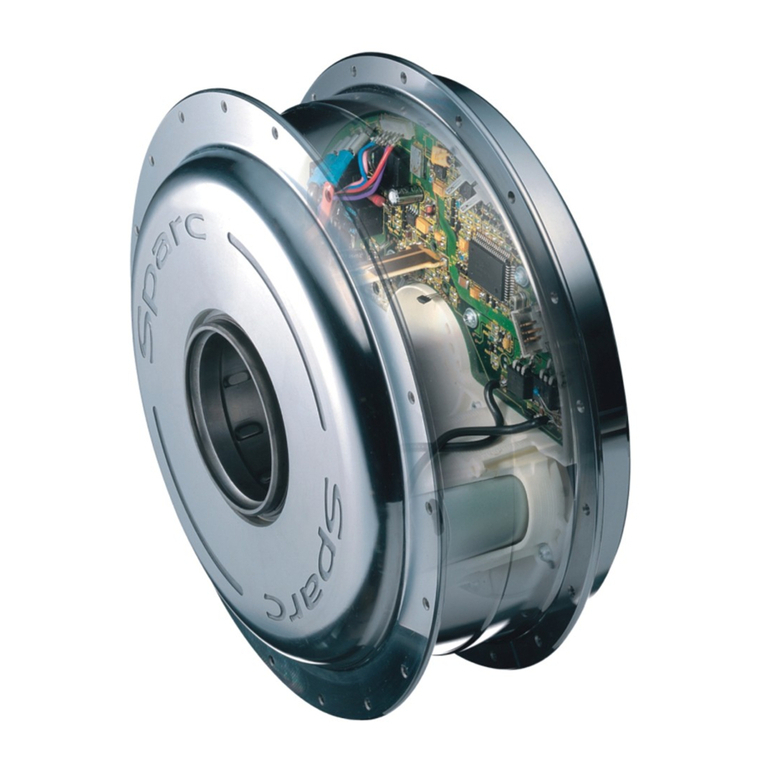

SRAM SRAM SPARC 16V User manual

SRAM

SRAM HydroR Series User manual