UM0289 Overview

3/29

1 Overview

1.1 Getting started

eMotion is a motion control kit able to manage up to 3 motors (DC or BLDC) simultaneously,

it can be used as starting point for the evaluation of control algorithms, motors and drivers.

The complete kit is composed of:

●Windows GUI (XP-compatible): a Multi-Windows software for managing, through a

serial connection, the control of up three motors.

●MDK-ST10 board: control board based on microcontroller ST10F276 and three

connectors compatible with a powerSPIN board (eval 62xx)

●Interface board: a board with two shielded connectors, to be stacked into the sockets of

MDK-ST10 to allow motor feedback of encoder signals.

●powerSPIN boards: the eMotion kit can manage up to three motor driver boards based

on L6205 (DMOS dual full bridge motor driver) and L6235 (DMOS fully integrated

three-phase motor driver) chips, for DC and BLDC motors respectively.

●Firmware for open/closed loop operation: a complete source library is developed to

manage the control of DC and BLDC motors in open loop mode (PWM and driver

settings) and closed loop mode (speed regulation with encoder feedback) using 62xx

eval boards.

●Protocol communication: a complete frame-based protocol is developed to allow the

exchange of data with GUI via standard RS232 channel.

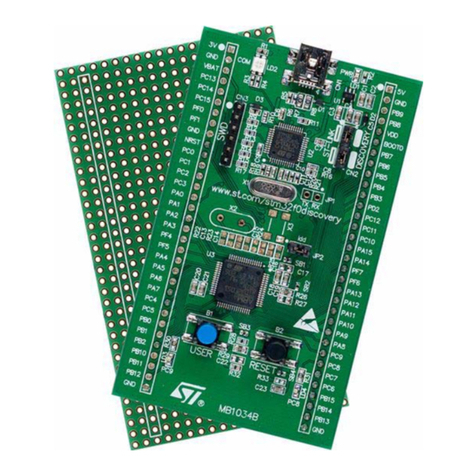

Figure 2. eMotion kit block diagram

It is possible via the GUI to interact with the ST10F276 control board (MDK-ST10) and

generate open loop signals for up three DC or BLDC motors. The PWM frequency (17-30

kHz) and duty cycle (0-100%) can be managed together with driver signals such as

enable/disable, brake/unbrake (BLDC) and forward/reverse (DC).

The closed loop operation can be performed in terms of motor speed with encoder

feedback.

A complete PID (Proportional, Integrative, And Derivative) control algorithm is implemented.

The user can configure:

●the value of PID terms (from 0.01 to 100)

●the speed (from 1 to 3000 rpm)

●the control loop time (from 1 to 52 ms)

●the number of encoder pulses per revolution (1 to 65536)

PC + GUI

Board

Power

Control

board MDK

ST10

Feedback

board

(shielded)

PowerSPIN

boards

Encoder

signals Encoder

signals

Power

signals

PWM/

Driver

BLDC or

DC

motors

Driver

Power

RS232

Serial

Protocol