Contents UM1672

2/22 UM1672 Rev 2

Contents

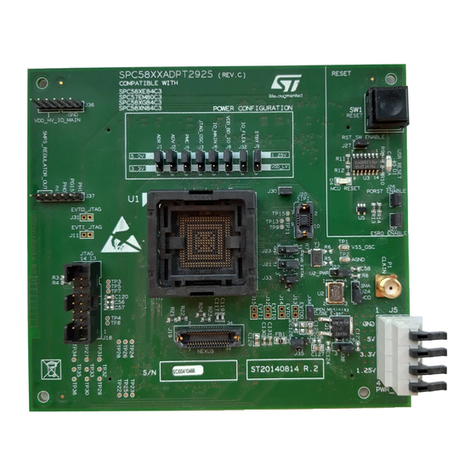

1 SPC56B-DIS discovery board with SPC560B54L5 . . . . . . . . . . . . . . . . . 5

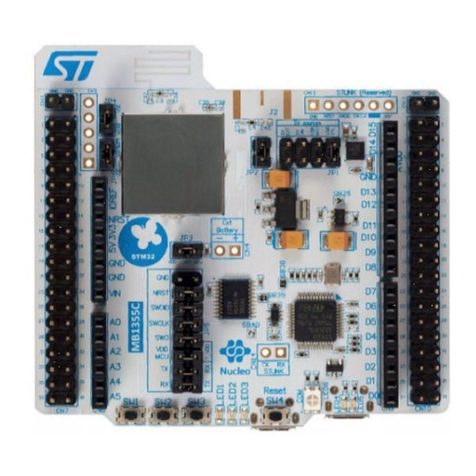

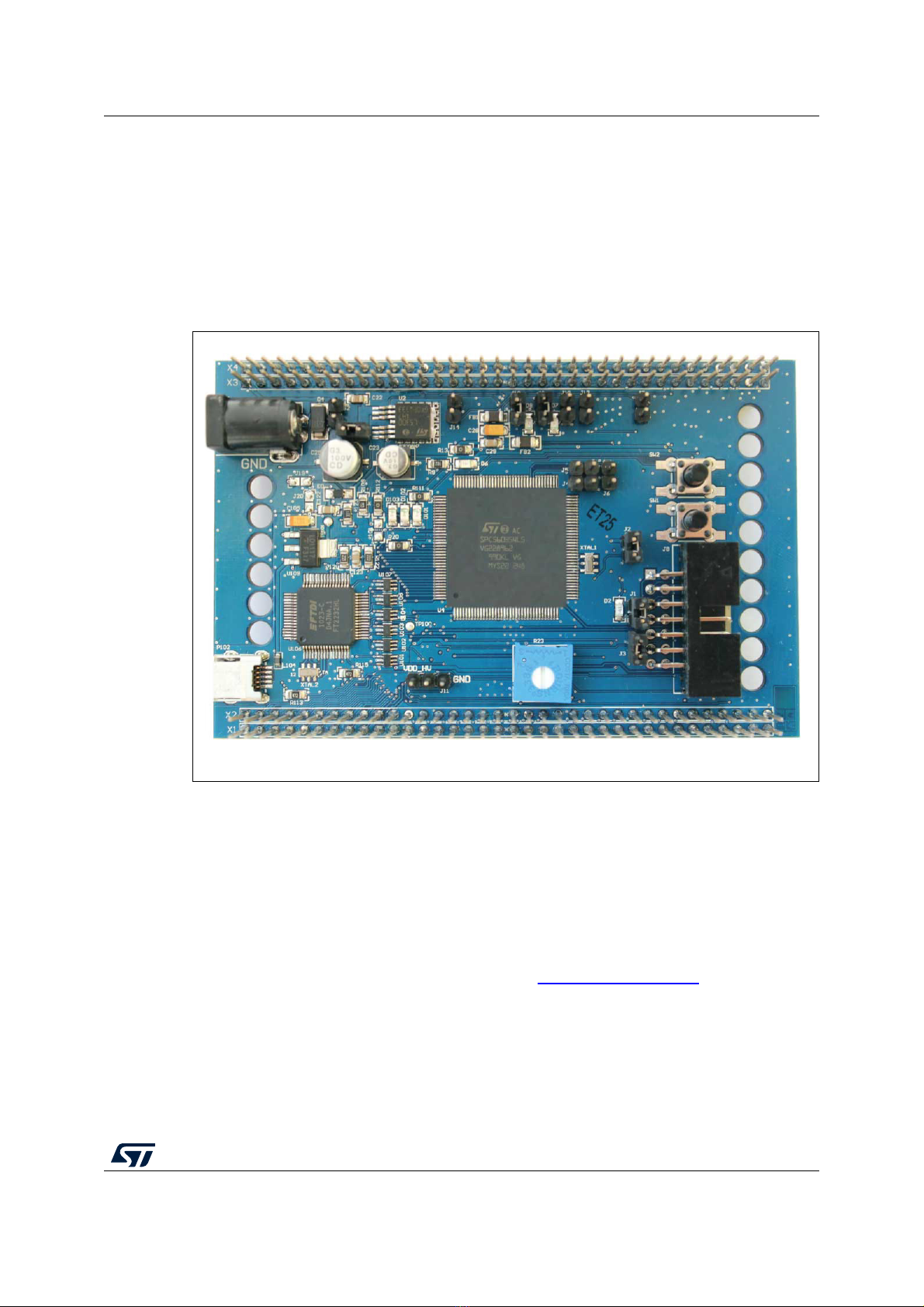

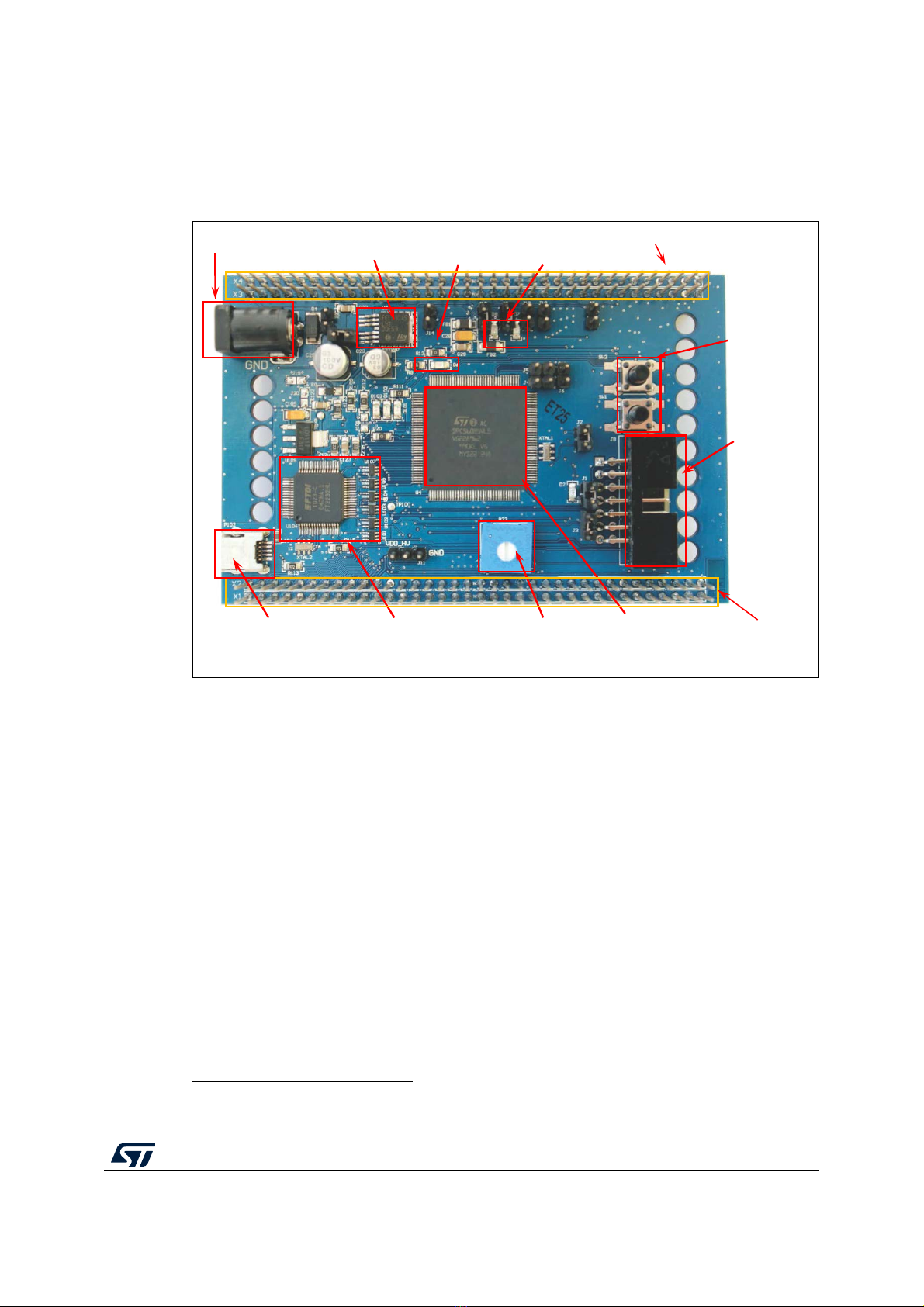

1.1 SPC56B-DIS discovery board . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

1.2 Debug interface . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

1.3 Microcontroller I/Os . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

2 Hardware overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

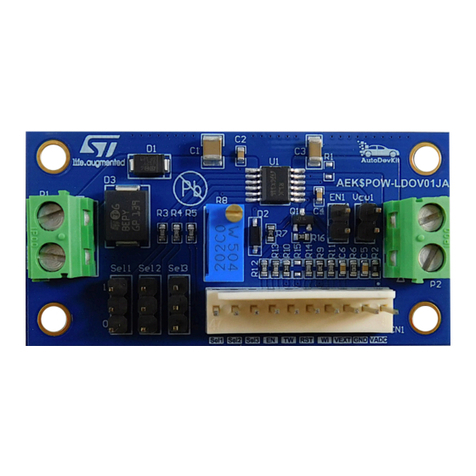

2.1 Power supply . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

2.1.1 12 V DC power supply . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

2.1.2 Supply from USB port . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

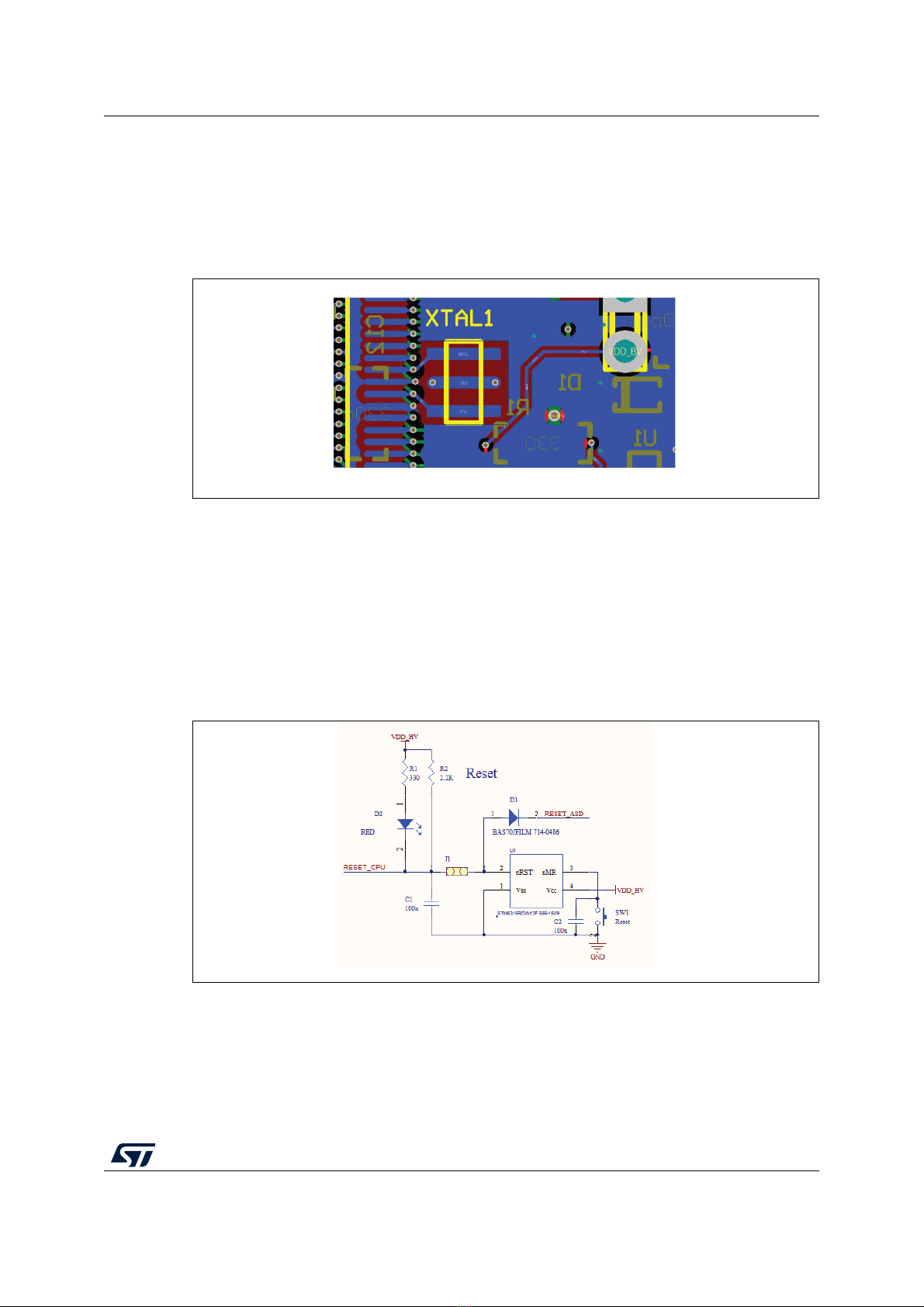

2.2 Crystal oscillator . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

2.3 Reset section . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

2.4 Programming and debug . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

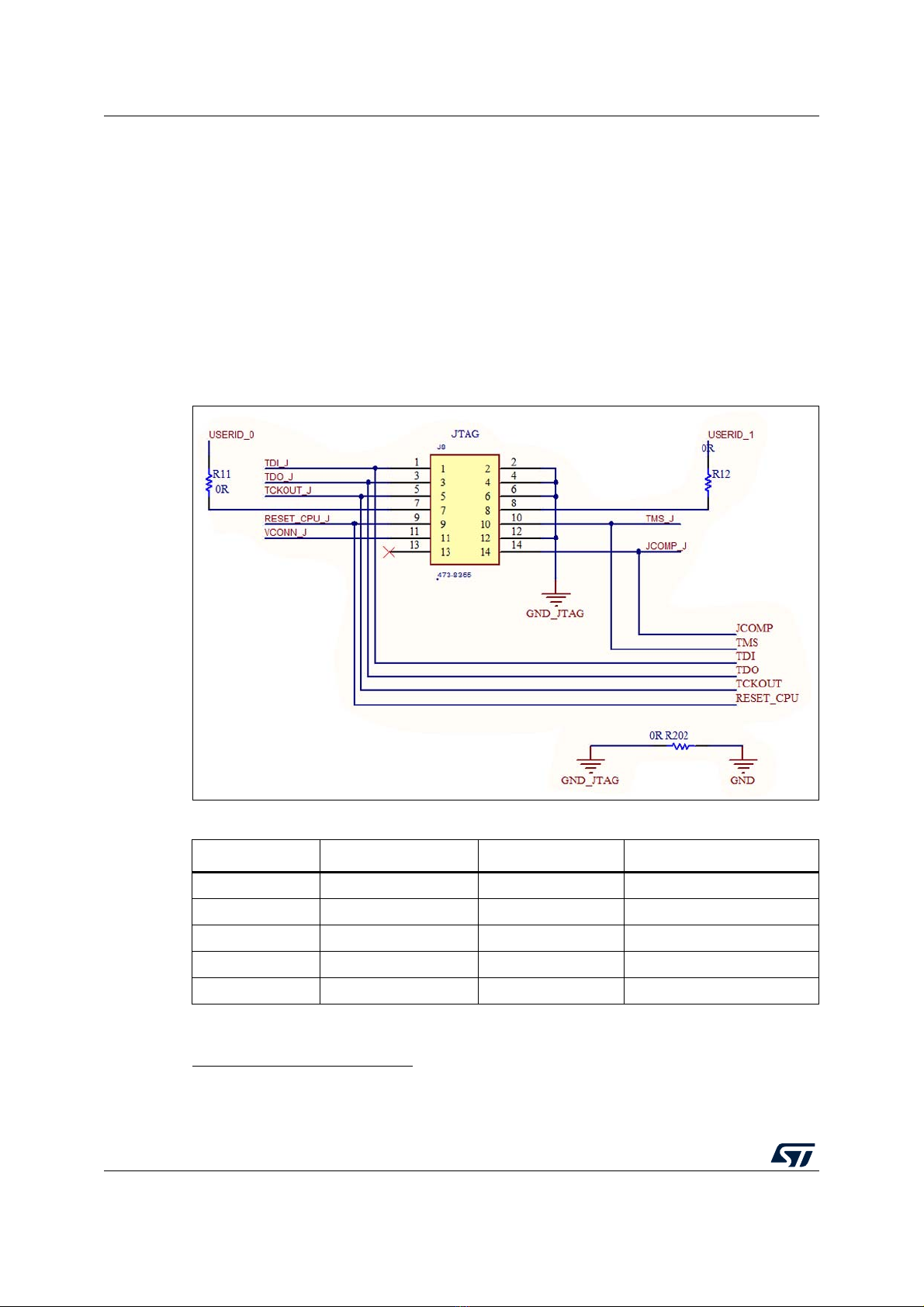

2.4.1 JTAG connector . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

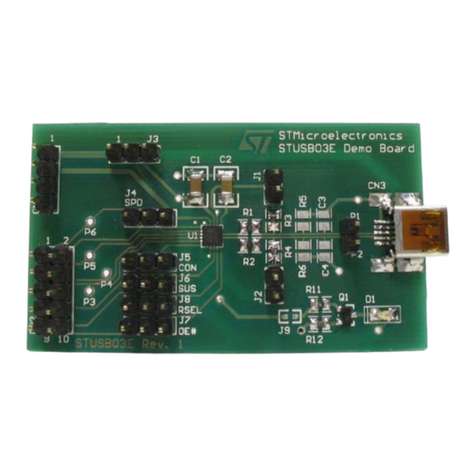

2.4.2 USB with integrated debugger from PLS (default configuration) . . . . . . 11

2.4.3 Board configured as PLS adapter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

2.4.4 HW configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

2.5 USB and Graphic User Interface (GUI) . . . . . . . . . . . . . . . . . . . . . . . . . . 12

2.6 User I/O pins . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

2.6.1 User LEDs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

2.6.2 Push button . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

2.6.3 User I/O pins . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

2.6.4 Boot configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

2.6.5 ADC input . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

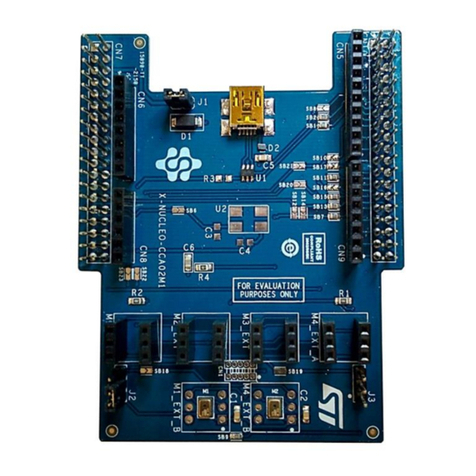

2.7 Daughter board connector and I/O headers . . . . . . . . . . . . . . . . . . . . . . . 15

2.8 PCB Layout . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Appendix A General handling precautions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

Appendix B Reference documents . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

Revision history . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21