R. STAHL, INC.

13529 N. Promenade Blvd.

Stafford, TX 77477

Tel: 800-782-4357 FAX: 281-313-9302 E-mail: sales@rstahl.com

Website: www.rstahl.com

815060300190

1 July 16, 2013

INSTALLATION OPERATION

& MAINTENANCE SHEET

Series 8150/5

Explosion Protected Metallic Control Stations For

Hazardous and Corrosive Applications

Please read this entire document before beginning any work.

1. Safety Instructions

Installation and maintenance of these stainless

steel control stations should only be performed by

skilled and experienced personnel in accordance

with the National Electrical Code (NFPA 70) or the

Canadian Electrical Code (CEC) respectively and

any local regulations which relate to hazardous

(classified) locations.

CAUTION:

•Disconnect power supply before installing or

servicing these control stations.

•Cable or conduit entries may be field installed per

Section 3.4 & 3.5. of these instructions. All other

modifications can only be made after consulting

the manufacturer.

•Operate only undamaged and clean devices with

observations of the operating parameters in

Section 2.

•For a Class I Zone 1 conduit installation, conduit

seals are required, refer to NEC 505.16 (B) (1).

For any other cable or conduit installation NO

seals are required.

•Use only approved wiring methods for the loca-

tion, with the associate conduit/cable fittings.

Reference your local code.

•Supply wires shall be rated for 75˚C and internal

wires shall be rated 90˚C.

2. Technical Data

Please refer to the technical data on the enclosure

nameplate.

2.1 Certifications:

2.2 Environmental Protection:

IP 66 / Type 3, 4, 4X (depending on entry type)

2.3 Ambient Temperature:

(85˚C (185˚F) max.; -60˚C (-76˚F) min.

2.4

Component Data

2.4.1 Pilot Light, type 8010:

12V - 254V AC/DC, 0-60Hz

Terminal capacity 12-22 AWG. or 2.5 mm

2

tightened to 18 in-lbs. or 2 N-m

2.4.2 Contact Block, type 8082:

600V, 10A max.

Terminal capacity 12-22 AWG. or 2.5 mm

2

tightened to 18 in-lbs. or 2 N-m

2.4.3 Control Switch, type 8008/2-0...and 8008/2-1..:

600V, 10A max.

Terminal capacity 12-22 AWG. or 2.5 mm

2

tightened to 18 in-lbs. or 2 N-m.

2.4.4 Ammeter, type 8405:

600V. Ampere rating see data on device.

Terminal capacity 12-22 AWG. or 2.5 mm

2

tightened to 18 in-lbs. or 2 N-m.

3. Directions for Installation

3.1 Opening the enclosure

Fully loosen the cover screws using a screwdriver.

Do not remove these captive screws from the cover.

3.2 Enclosure Mounting

Mounting brackets are provided with the enclosure

which will accept up to 1/4" (6mm) screws.

3.3 Electrical Installation

There are two types of installation methods:

Conduit installation or cable installation. If the

enclosure is complete with factory installed entry

hardware, proceed to section 4.

If the enclosure does not include entry hardware,

select the appropriate hubs or cable connectors

from section 3.4 and install them as follows.

3.4 Installation of approved conduit hubs or cable

connectors

CAUTION: FIELD INSTALLED OPENINGS:

For field-installed openings, use a hand punch or

pneumatic type punch. Always wear safety glasses

and protective clothing when working.

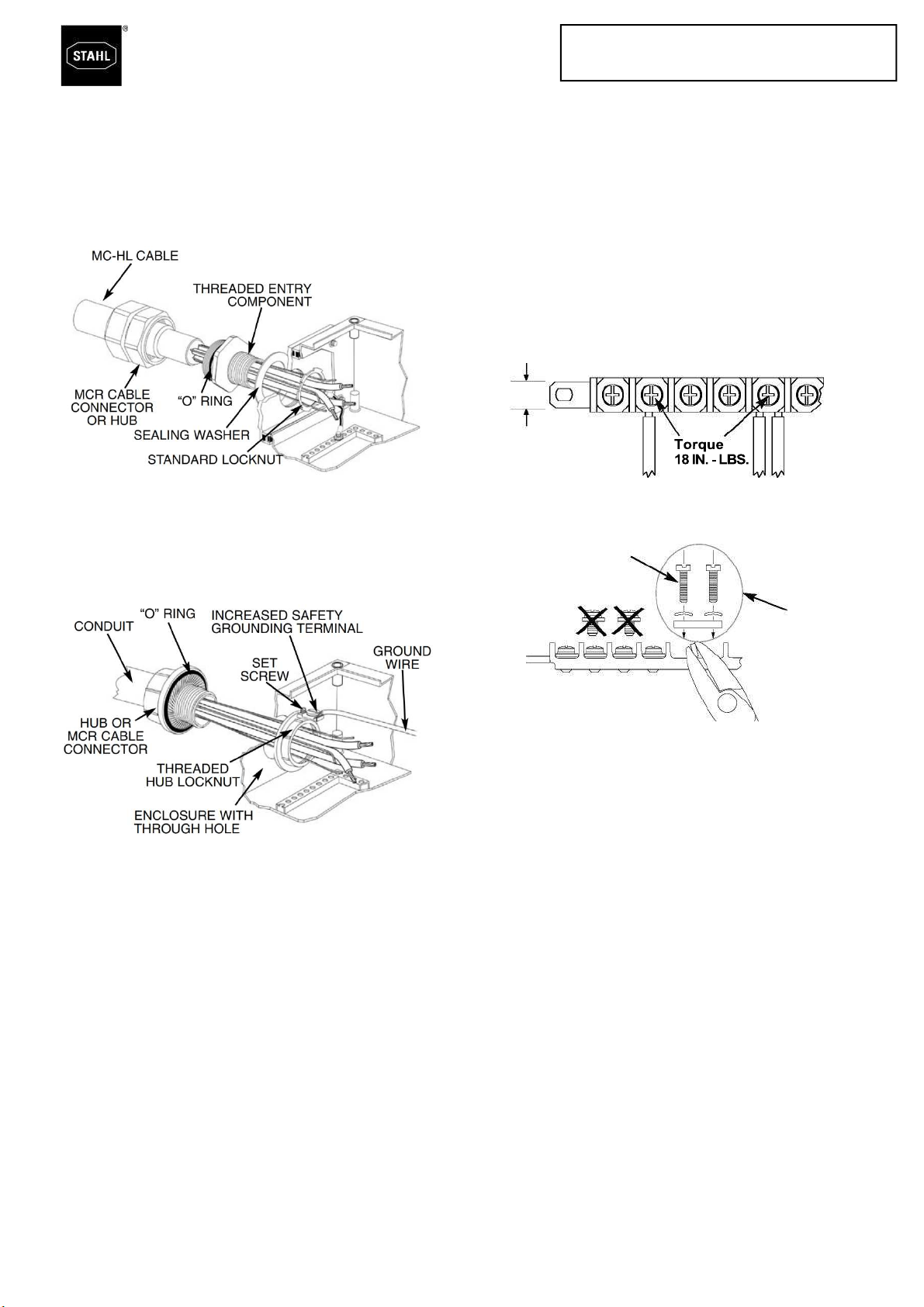

3.5 Conduit/Cable Installation

These enclosures make it necessary for the

metal cable connector and conduit hubs to be

bonded to the ground system. This can be accom-

plished by installing them either to method 1 or

method 2 as shown on next page.

Class I, Zone 1 & 2, AEx d e m [ia] IIC T6

Class I, Div. 2, Groups ABCD

Class I, Zone 1 & 2, Ex d e m [ia] IIC T6

Class I, Div. 2, per CEC J18-150

II 2 G Ex d e ia/ib [ia/ib] ma mb q IIA, IIB, IIC T6, T5, T4 Gb

2 D Ex tb IIIC IP66 T130°C, T95°C, T80°C Db

PTB 09 ATEX 1109

Ex d e ia/ib [ia/ib] ma mb q IIA, IIB, IIC T6, T5, T4 Gb

Ex tb IIIC IP66 T130°C, T95°C, T80°C Db

IECEx PTB 09.0049