Ĝƃ T.é ĪZ`.<é<`VHCĪHB

HC`C`ZHTV`.HC

&CV<.C%HVB`.HC

HC`C`Z

OPERATION ________________________________________________________ 10

1. General information _______________________________________ 10

1.1 Further applicable documents _______________________________ 10

1.2 Other symbols in this documentation ______________________ 10

1.3 Units of measurement _________________________________________ 10

2. Safety________________________________________________________ 11

2.1 Intended use_____________________________________________________ 11

2.2 General safety instructions ___________________________________ 11

2.3 Test symbols _____________________________________________________ 11

INSTALLATION _____________________________________________________ 11

3. Safety________________________________________________________ 11

3.1 General safety instructions ___________________________________11

3.2 Regulations, standards and instructions___________________ 11

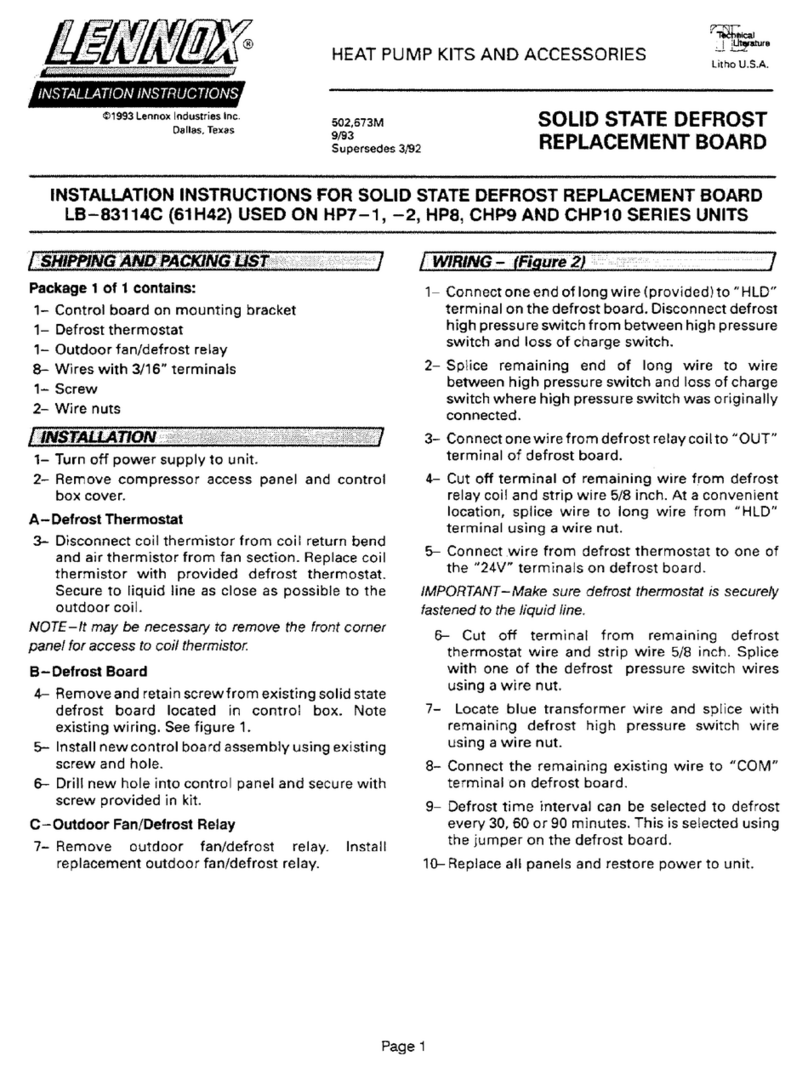

3.3 Standard delivery_______________________________________________ 11

4. Preparing for installation _________________________________ 11

4.1 General information____________________________________________ 11

4.2 Fitting the function module __________________________________ 12

4.3 Opening the function module ________________________________ 12

4.4 Hydraulic connection __________________________________________ 12

4.5 Safety valve ______________________________________________________ 13

4.6 Connecting electrical cables__________________________________ 13

4.7 Closing the function module _________________________________ 13

4.8 Connecting the air hoses______________________________________ 13

5. Specification ________________________________________________ 13

5.1 Data table ________________________________________________________ 13

5.2 Connections and dimensions_________________________________ 14

5.3 System example_________________________________________________ 15

WARRANTY

ENVIRONNEMENT AND RECYCLING

HTV`.HC

1. General information

The chapter “Operation” is intended for appliance users and hea-

ting contractors.

The chapter “Installation” is intended for heating contractors.

Note

Read these instructions carefully before using the ap-

pliance and retain them for future reference.

Pass on the instructions to a new user if required.

1.1 Further applicable documents

Operating and installation instructions of the heat pump

WPL E or WPL basic

Operating and installation instructions of the WPMII

heat pump manager

Operating and installation instructions of the hydraulic

module HSBB

Operating and installation instructions of all other com-

ponents in the system

1.2 Other symbols in this documentation

Note

General information is identified by the symbol shown

on the left.

f Read these texts carefully.

ZźăĒù

Material losses

Appliance disposal

f This symbol indicates that you have to do something. The ac-

tion you need to take is described step by step.

1.3 Units of measurement

Note

All measurements are given in mm unless stated othe-

rwise.