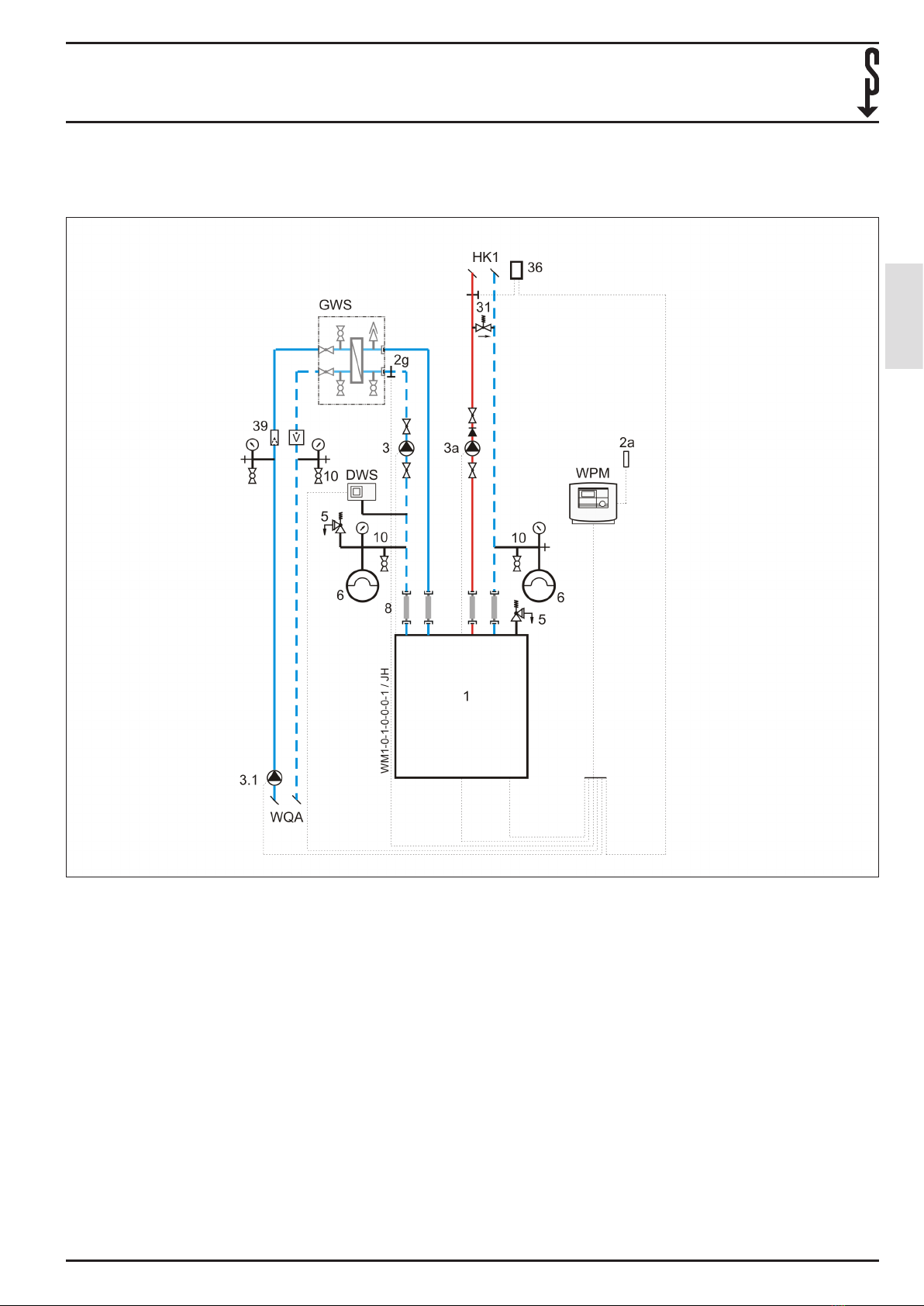

GWS |21

ENGLISH

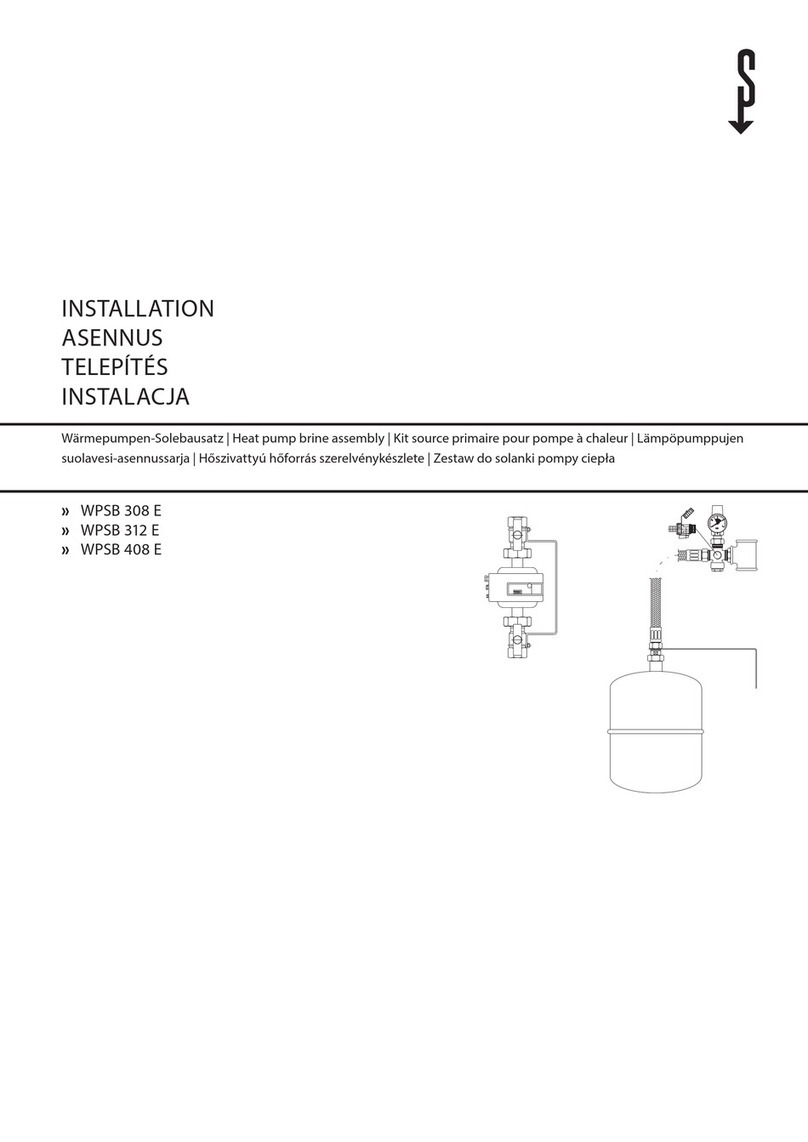

INSTALLATION

Commissioning

Required water quality

Common problems when using groundwater as a heat source

include:

- Erosion of heat exchanger and water supply lines.

- Heat exchanger corrosion.

- Sludge contamination or blockages in heat exchanger and

supply lines.

- Sedimentation (blocking) of the return well.

To prevent such problems, the quality of the groundwater used

as heat source must meet the following standards:

- The water must not contain any matter which might

settle.

- Never use surface water or saline water.

- The iron and manganese content must be less than 0.5

mg/l.

In pertinent individual cases, e.g. wells near salt mining areas

or regions with a great prevalence of livestock, the following

water content needs to be taken into consideration:

- Chloride < 300 mg/l

- Chlorine < 0.5 mg/l

If one of the specied limits is exceeded, operation of the

groundwater station is not permissible.

To prevent blockage of the heat exchanger caused by solid

particles transported with the groundwater (sand, ne sludge,

etc.), install a suitable dirt lter with a mesh size of 0.6mm on

site at the heat source ow. You can obtain a suitable dirt lter

via your contractor or from us as a spare part. Install appropri-

ate pre-lters and settlement basins if higher levels of solid

particles are transported with the groundwater.

After lling, vent the heat source system.

Adjust the heat source ow rate so that the brine ow rate at

the brine/water heat pump always corresponds to the required

values.

Note

Read and observe the operating and installation in-

structions for the brine/water heat pump and the di-

agrams in chapter “Specication”.

3.4 Insulation

To avoid condensate and therefore damage to the heat source

system and the brine circuit, insulate them with diusion-proof

material.

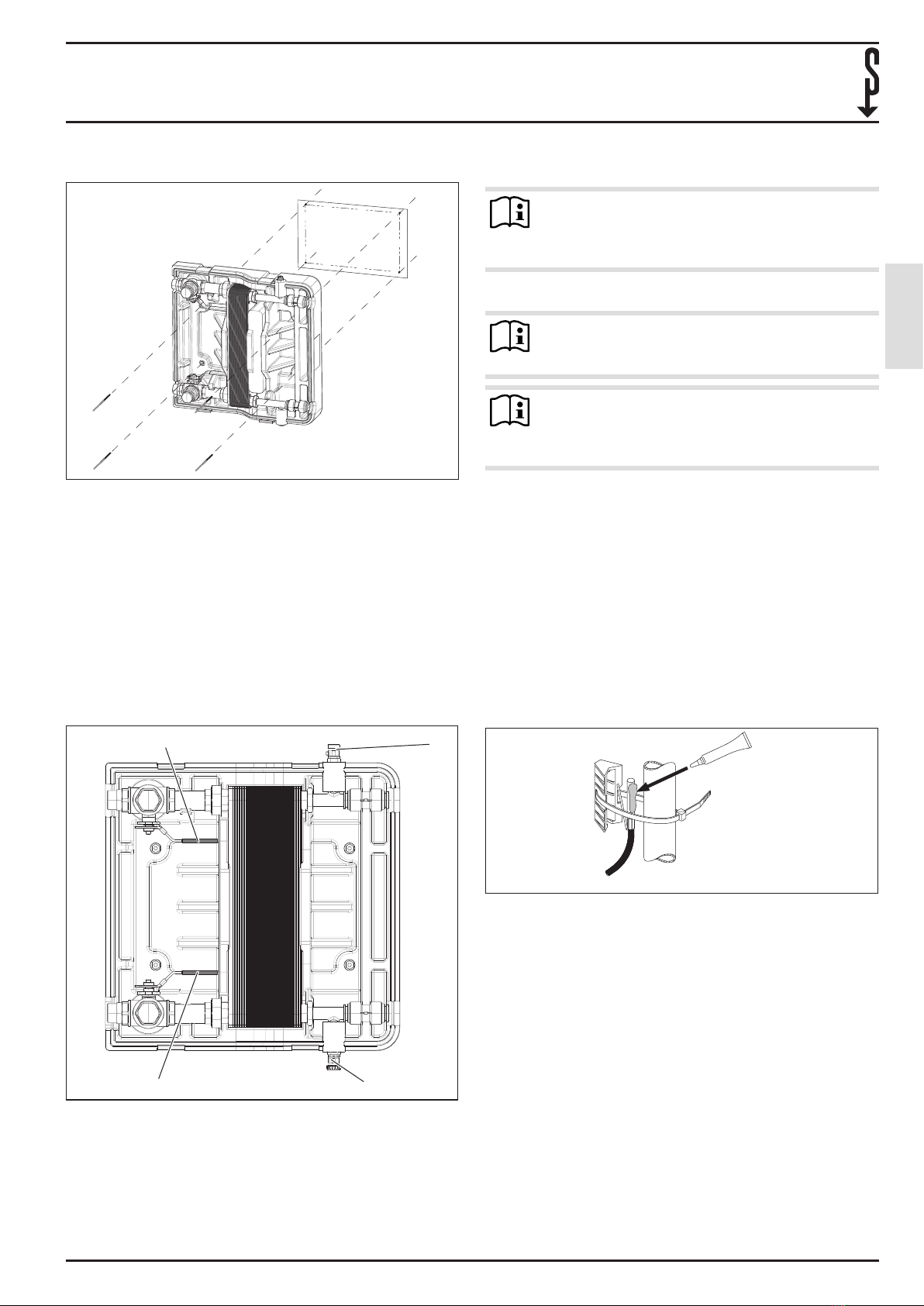

Also insulate the drain & ll valve, the air vent valve and

the brine pressure switch.

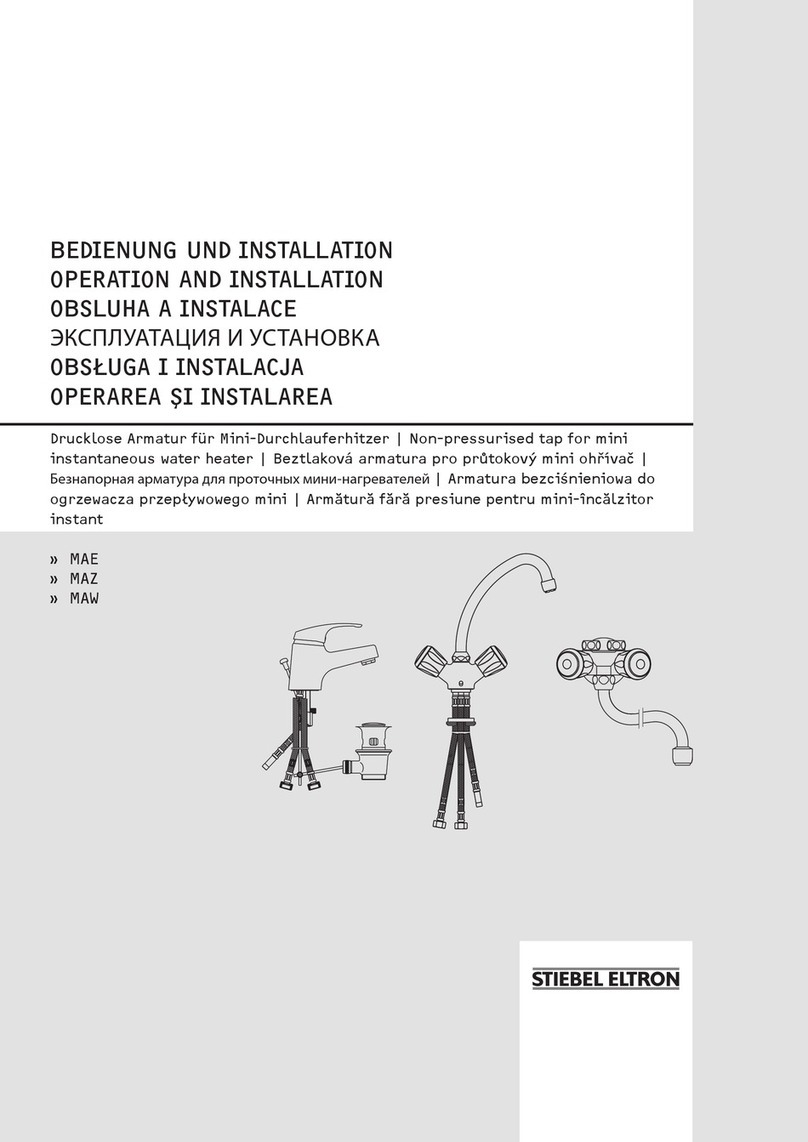

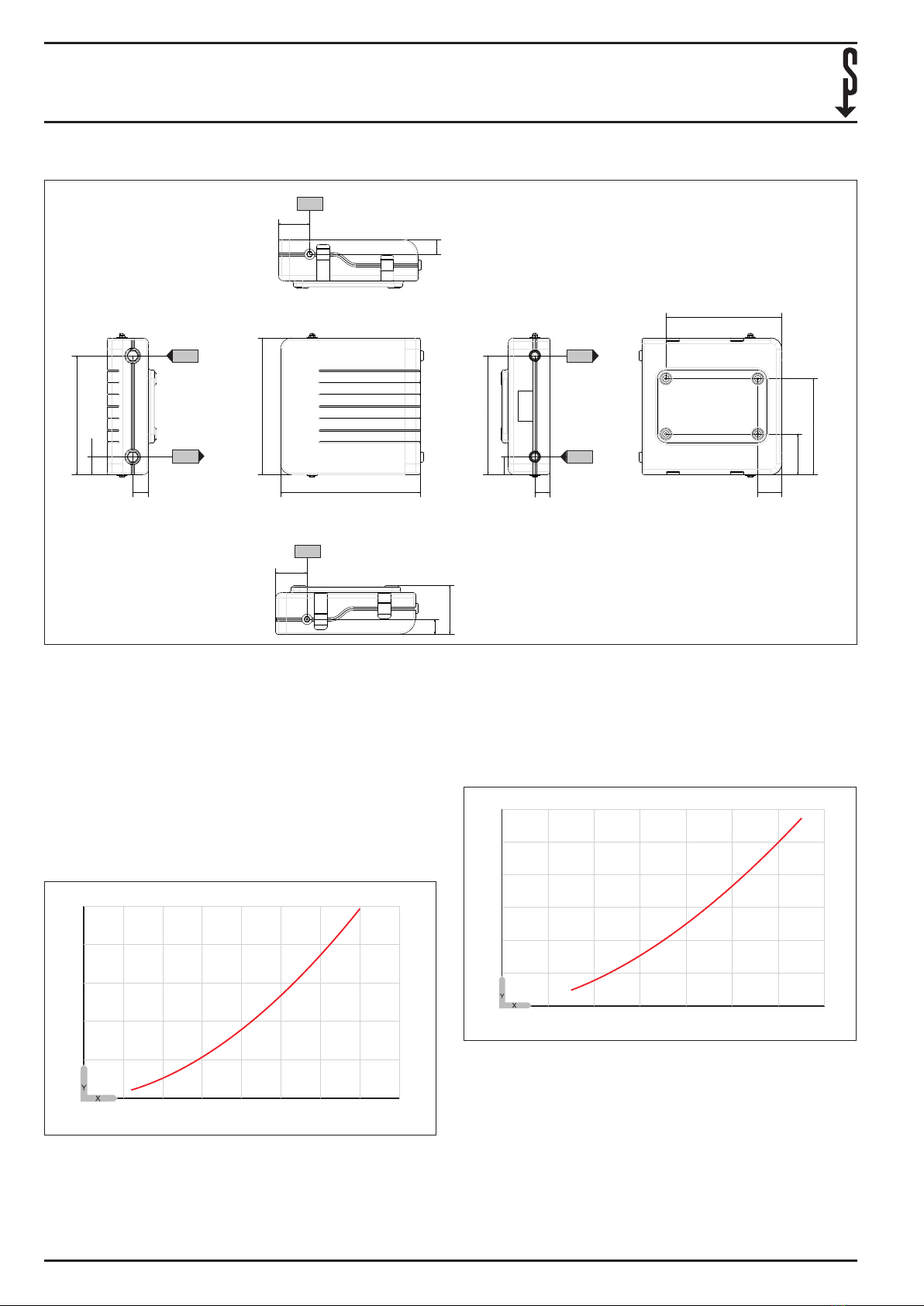

26�03�14�0101�

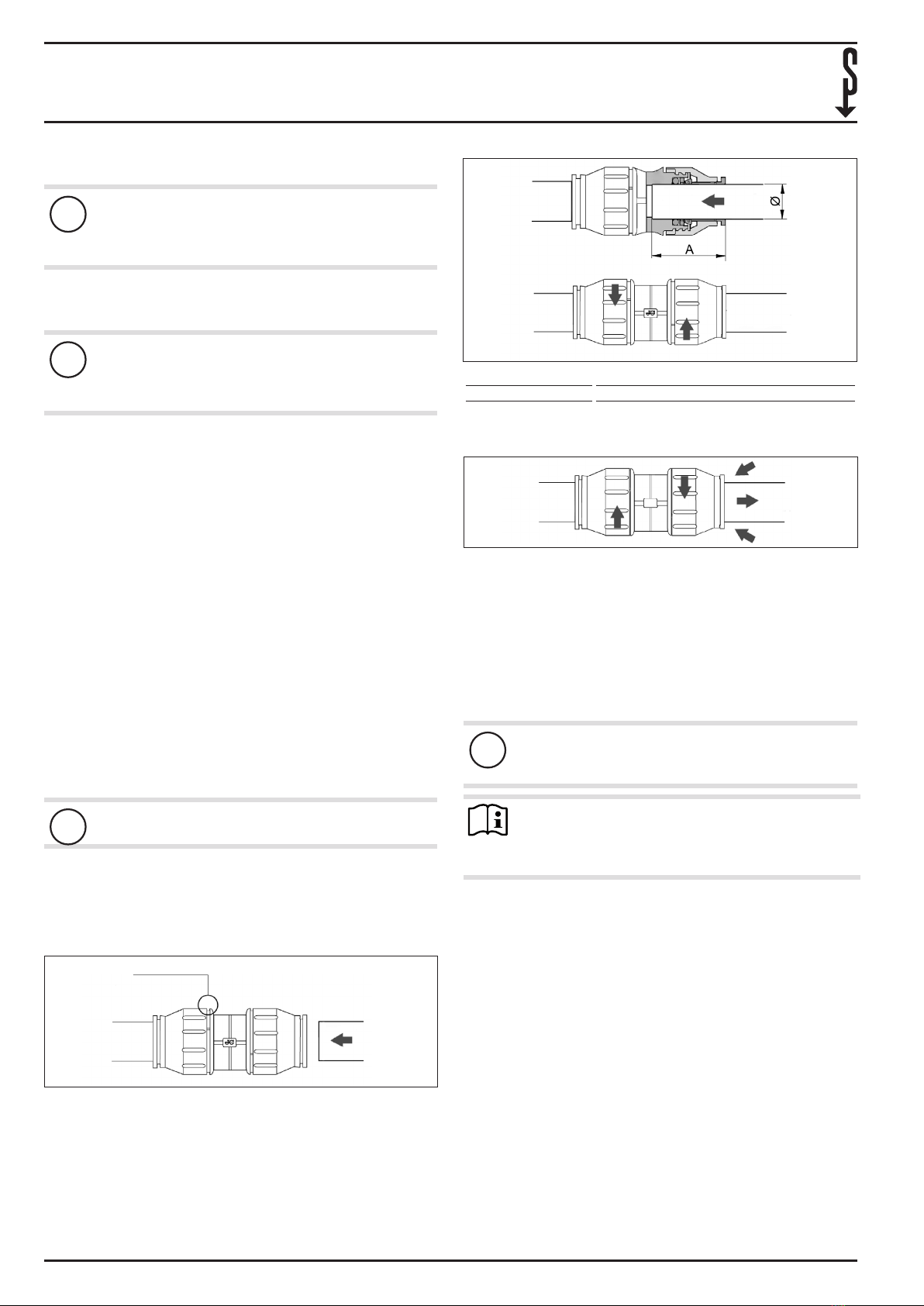

Fit the insulation hoses as shown in the diagram above.

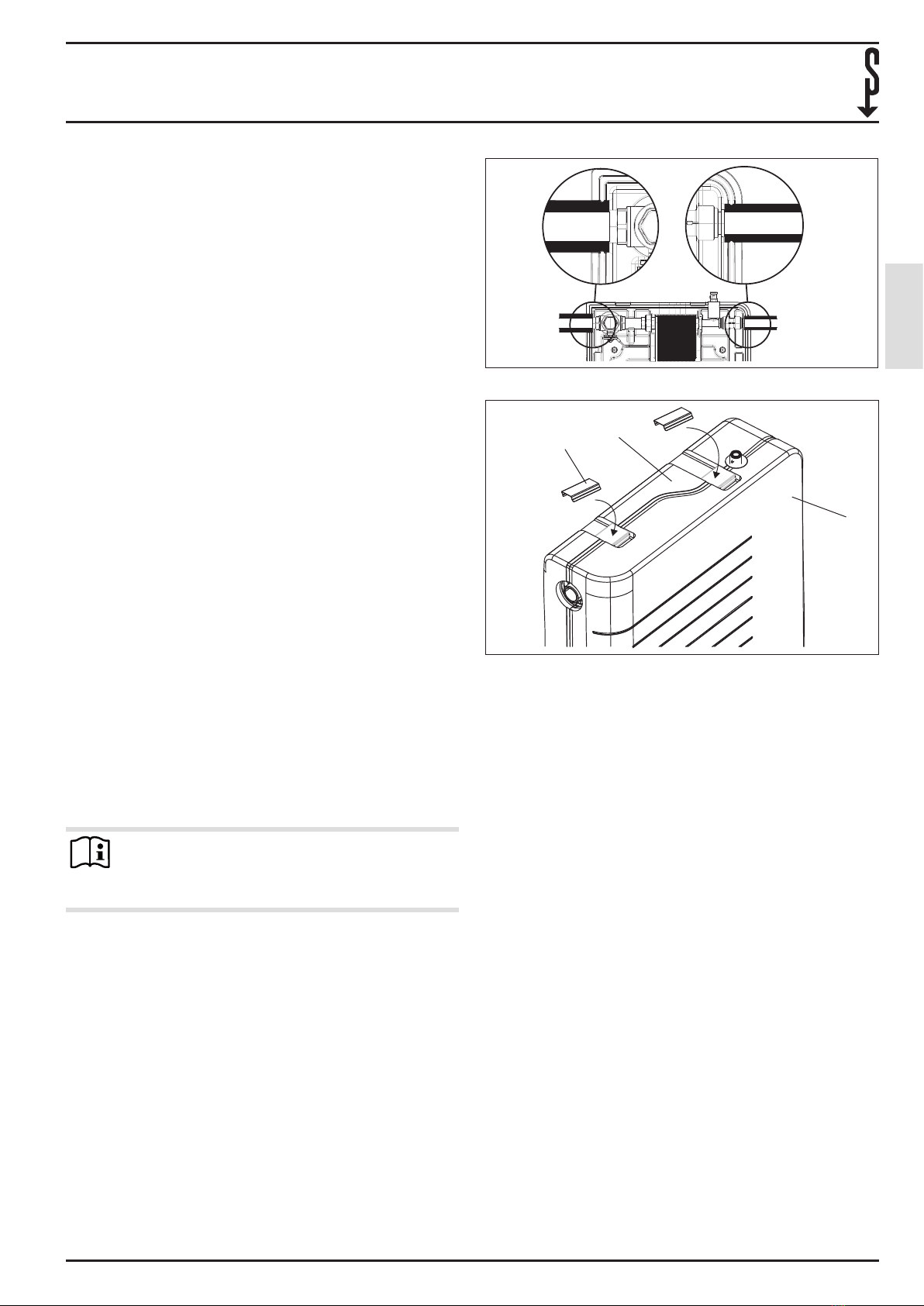

1

3

2

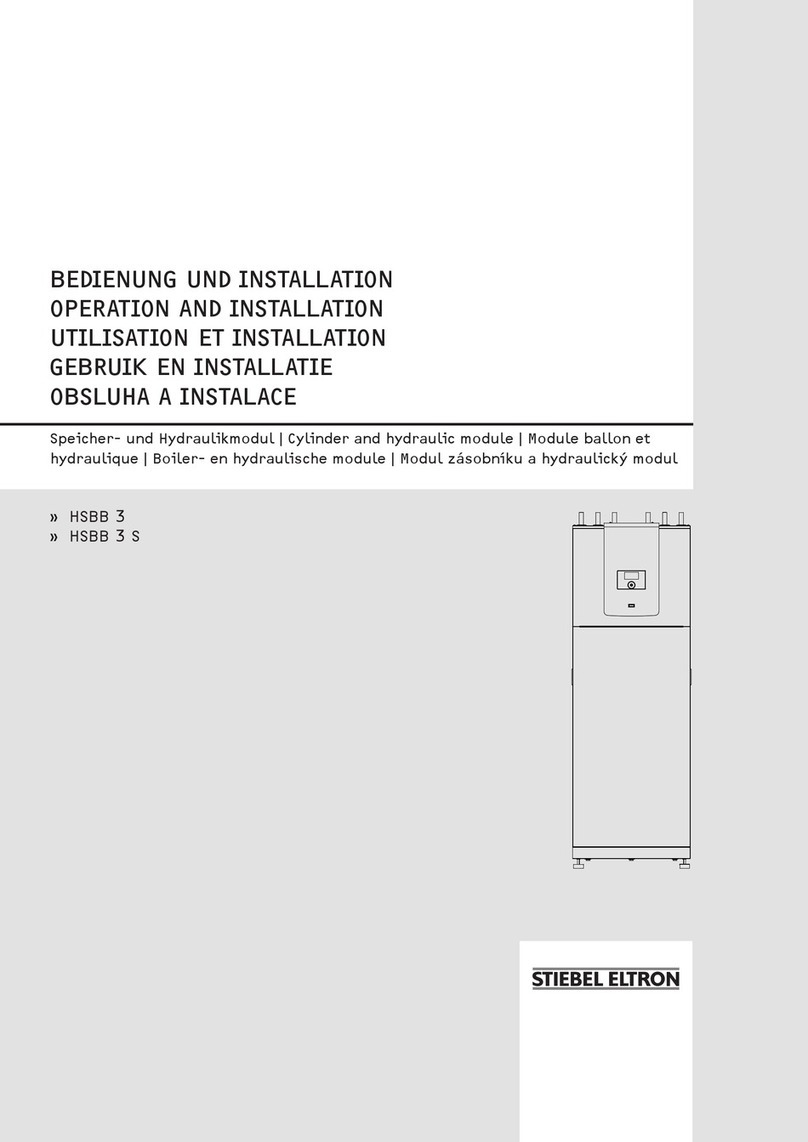

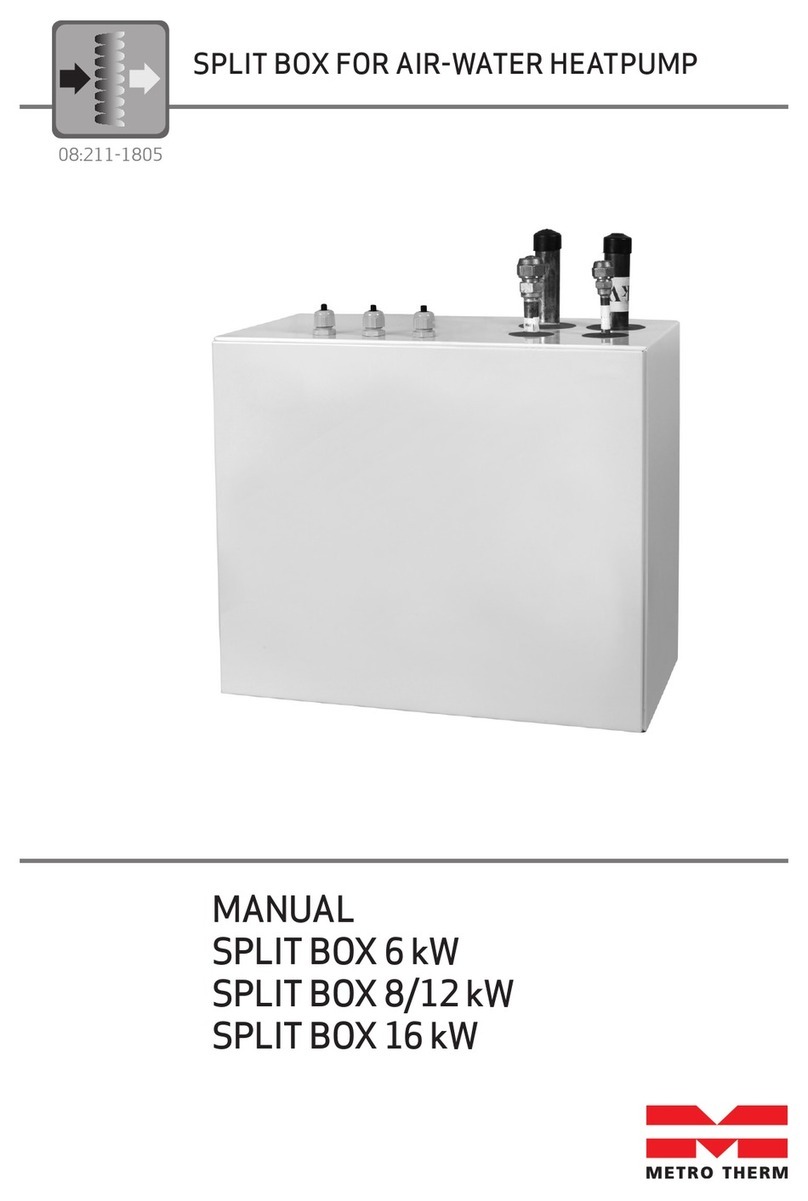

26�03�14�0098�

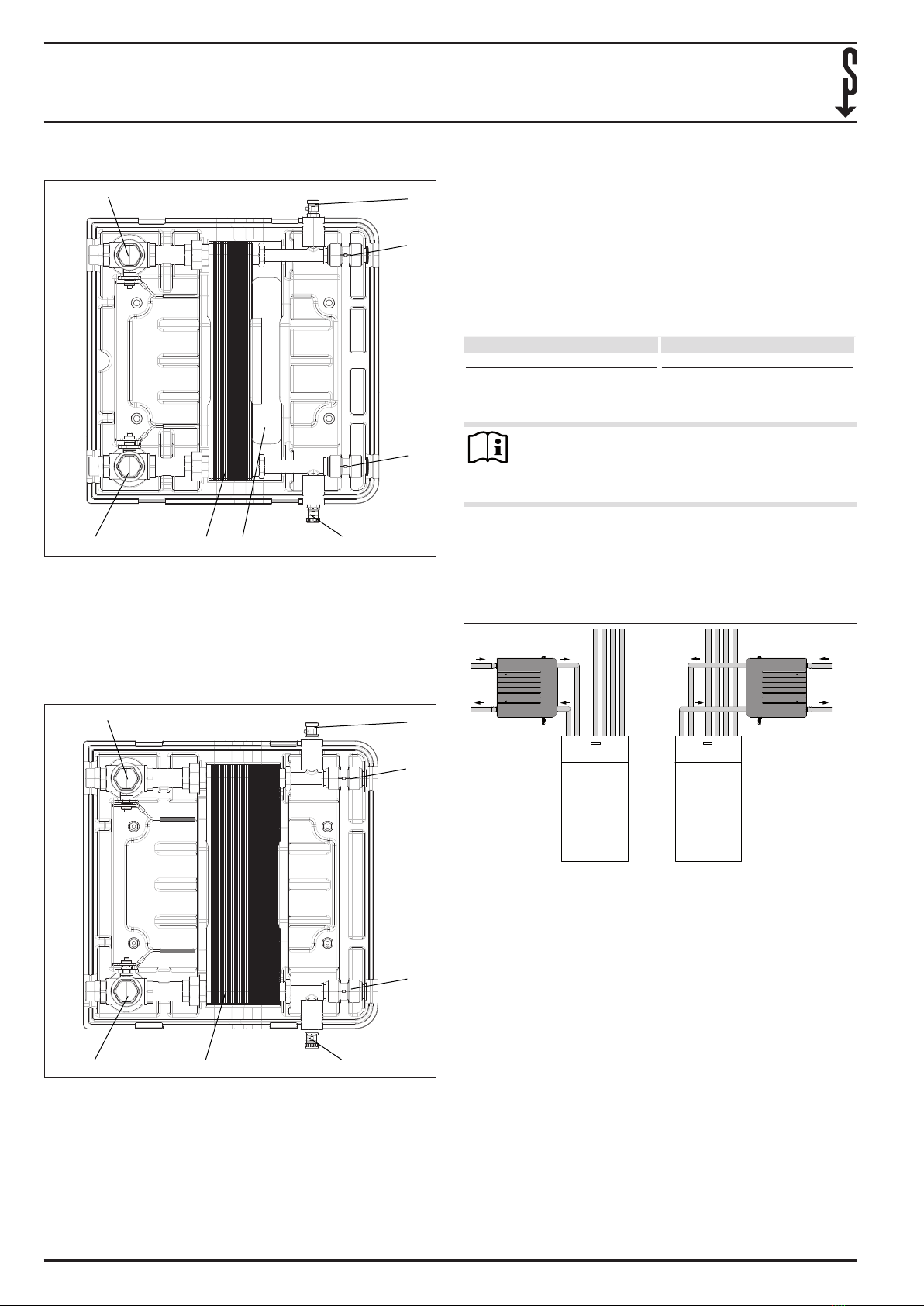

1 Lower shell

2 Upper shell

3 Clip

After insulation, t the upper shell on the groundwater

station.

Secure the upper shell to the lower shell using the clips

provided.

4. Commissioning

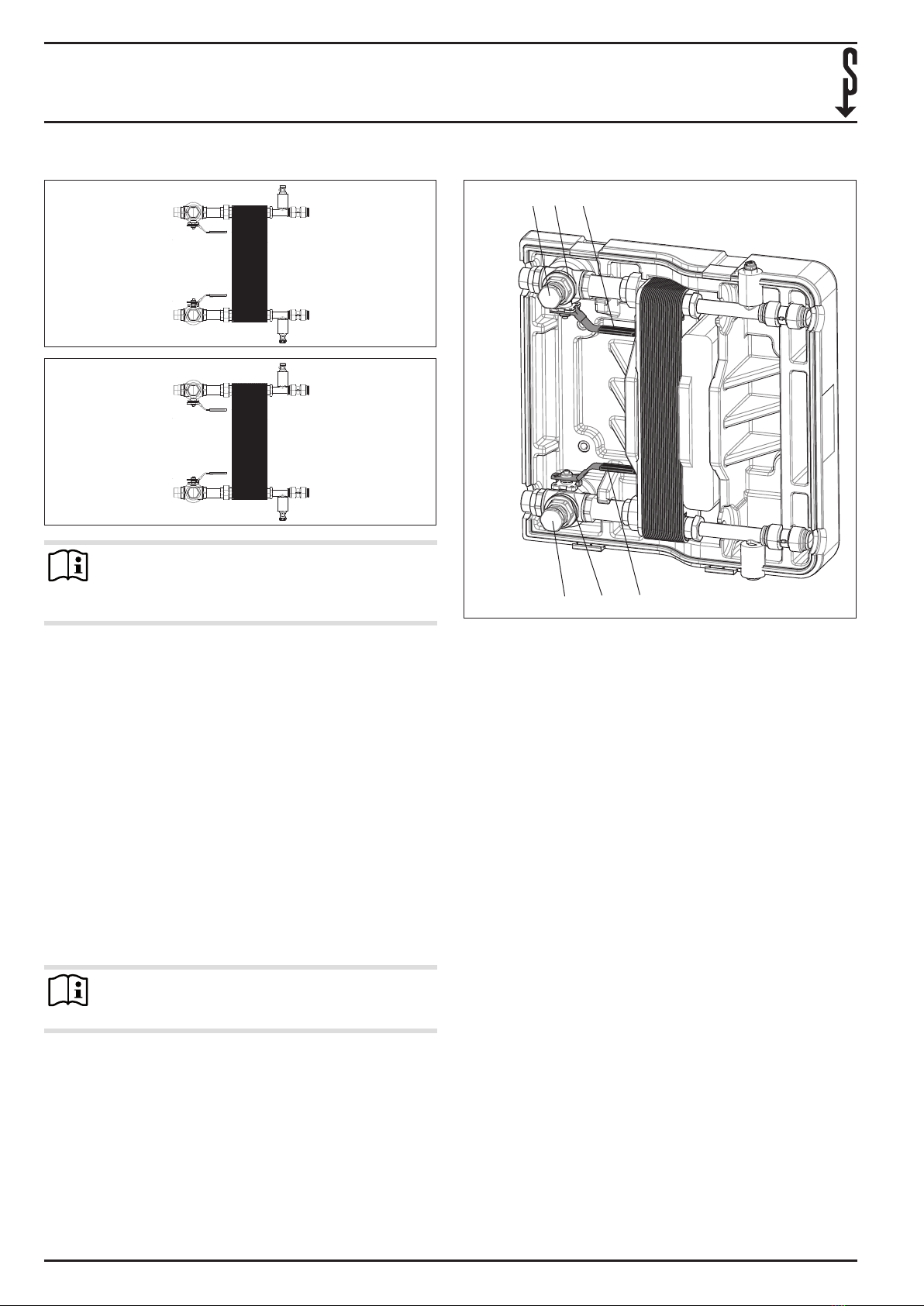

Move the levers of the 3-way ball valves to the throughput

position.

Check the system pressure in the brine circuit. The system

must have overpressure of at least 0.1 MPa.

With the “Relay test” parameter on the heat pump man-

ager, check the functioning of the well and brine circuit

pump.

Read the heat source temperature o the heat pump

manager under the “Info temperatures” parameter and

check the plausibility of this value.

Check the “SOURCE MIN” (minimum source temperature)

and “SOURCE” settings on the heat pump manager.

Commission the brine/water heat pump.

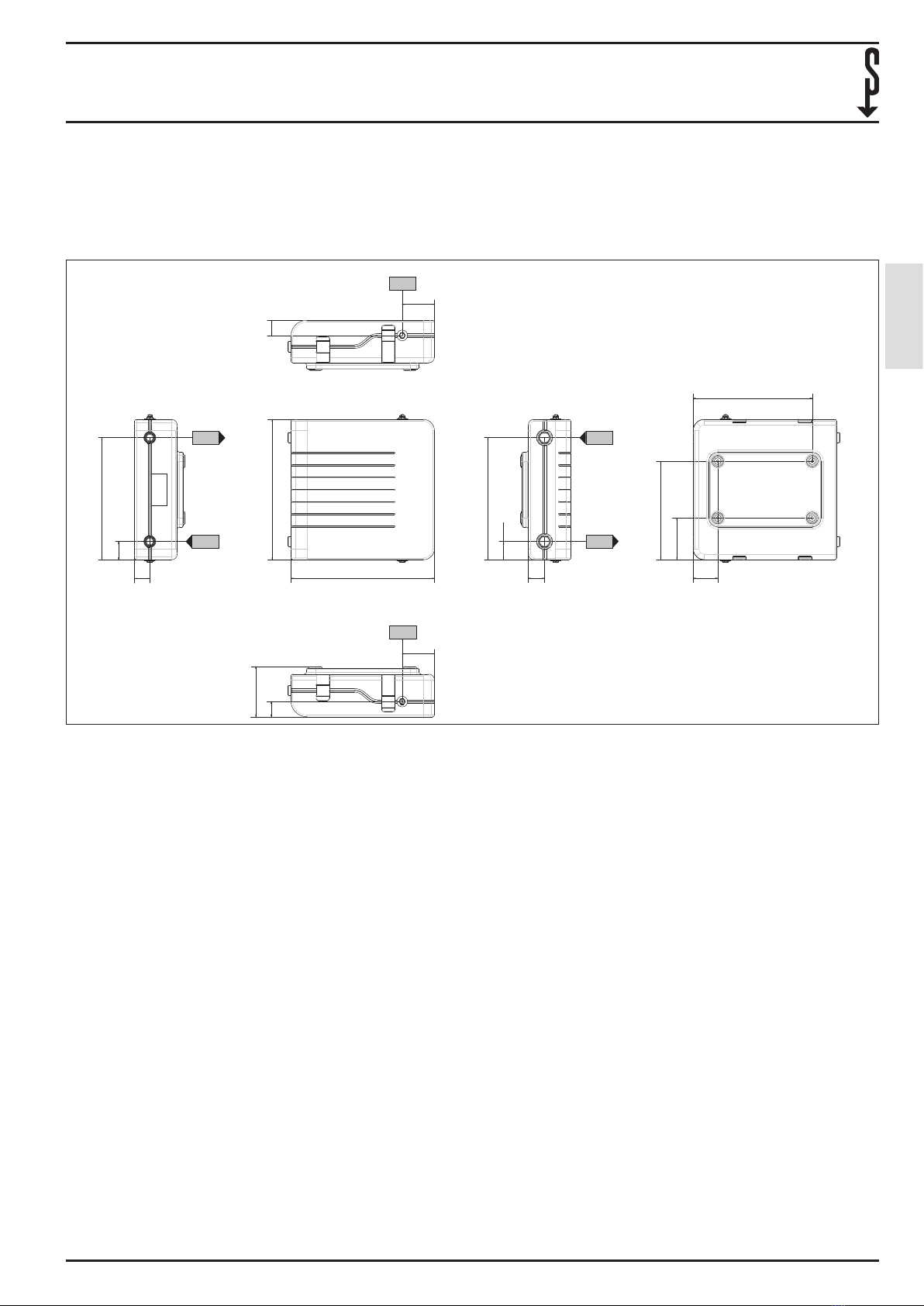

The groundwater station temperature dierential between

the heat source inlet and the heat source outlet should be no

higher than 3K.

The temperature dierential ∆ϕ1 in the heat source circuit

must be greater than the temperature dierential ∆ϕ2 in the

brine circuit.