5SP 81

English

Fuel your power tool in a well-ventilated

area, outdoors only. If you spill fuel, wipe

the machine immediately – if fuel gets on

your clothing, change immediately.

Your power tool comes standard with

either a screw-type or bayonet-type fuel

cap.

After fueling, tighten down

the screw-type fuel cap as

securely as possible.

Insert the fuel cap with

hinged grip (bayonet type

cap) correctly in the

opening, turn it clockwise

as far as stop and fold the

grip down.

This reduces the risk of unit vibrations

causing the fuel cap to loosen or come

off and spill quantities of fuel.

To reduce the risk of serious or fatal

burn injuries, check for fuel leakage. If

fuel leakage is found, do not start or run

the engine until leak is fixed.

Before Starting

Check that your power tool is properly

assembled and in good condition – refer

to appropriate chapters in the instruction

manual:

– Slide control / stop switch must

move easily to STOP or 0

– Smooth action of throttle trigger

interlock (if fitted) and throttle trigger

– throttle trigger must return

automatically to idle position.

– Rakes: Securely mounted and in

good condition (clean, move freely,

not warped or cracked).

– Check that spark plug boot is secure

– a loose boot may cause arcing

that could ignite combustible fumes

and cause a fire.

– Never attempt to modify the controls

or safety devices.

– Keep the handles dry and clean,

free from oil and dirt, for safe

control.

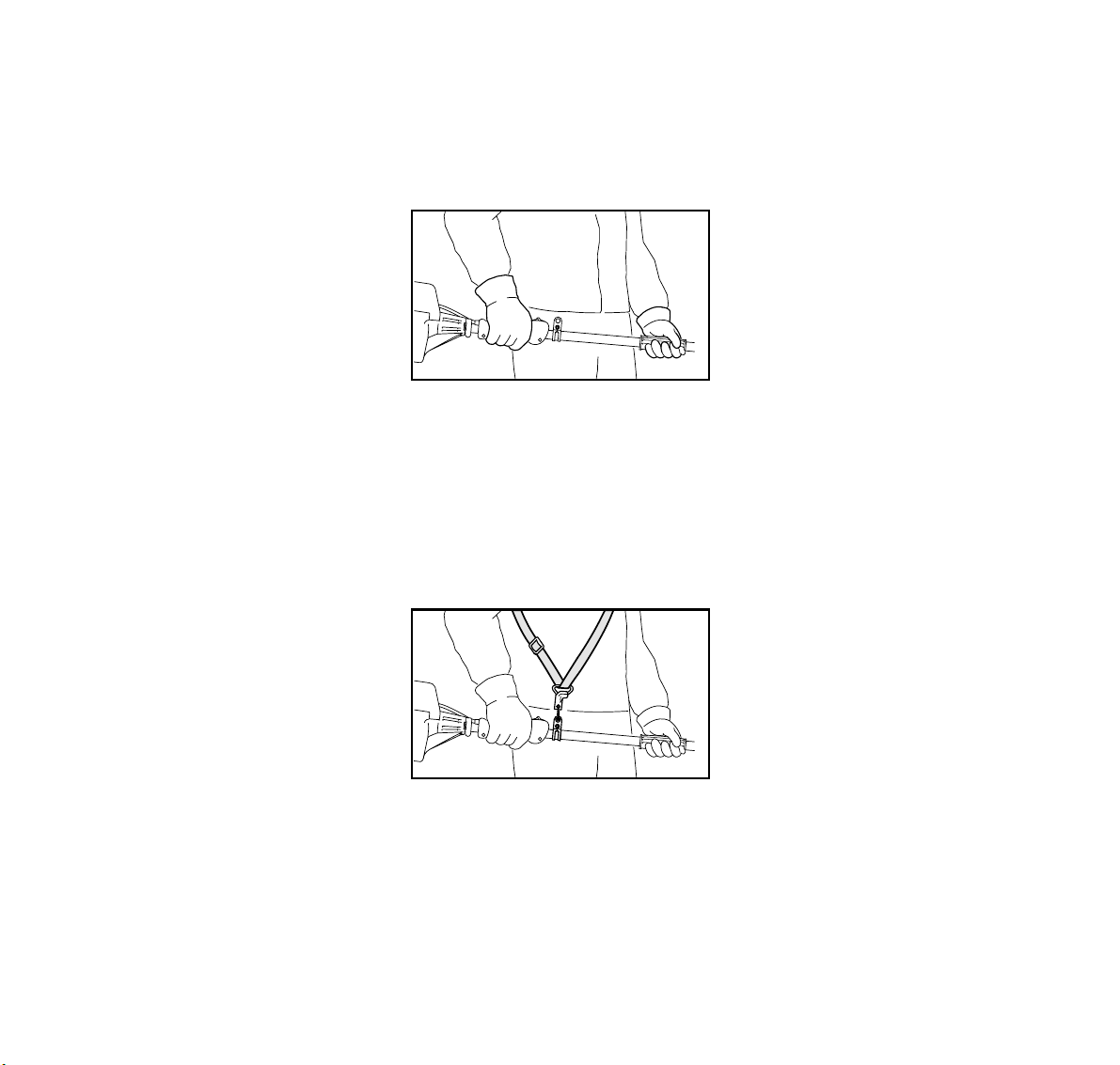

– Adjust harness to suit your height

and reach. See chapter on "Fitting

the Harness“.

To avoid the risk of accidents and

personal injury, do not operate your unit

if it is not in a safe operating condition.

Be prepared for an emergency when

wearing a harness: Practise quickly

setting down the unit. To avoid damage,

do not throw the machine to the ground

when practising.

Starting the Engine

Start the engine at least 3 meters from

the fueling spot, outdoors only.

Place the unit on firm ground in an open

area. Make sure you have good balance

and secure footing. Hold the unit

securely – be sure the rakes are clear of

the ground and all other obstructions

because they may begin to run when the

engine starts – also allow space for

movement of the rakes.