3 4

spirit. Then as the distillation is nearly over the smooth sweet spirit will slowly change into a bitter,

undesirable flavour which is described by some people as ‘wet cardboard’.

This changing flavour profile is what leads us to making what are called ‘cuts’ during the distillation.

The harsh tasting chemical flavours at the beginning are what are referred to as the ‘heads’, the

smooth, sweet spirit in the middle of the distillation is the ‘hearts’ and the final bitter, low alcohol

spirit is referred to as the ‘tails’. The change between these sections gradually occurs and so the real

art of distilling comes into what you let into your final spirit. This is completely influenced by when

you make your cuts which can be a difficult decision to make at the time of distilling.

Because of this difficulty it is recommended that users collect the heads and tails sections in multiple

small containers. Then, the transition to the hearts section from the heads can be made later than it

should be and the containers with the desirable flavours can be blended back into the hearts section

after distillation is complete. The same should be done for the tails section, except in this case the

hearts section should be finished early.

WHY DO MULTIPLE DISTILLATIONS?

For every distillation using a pot still the product becomes increasingly refined. The ethanol purity

increases, and more and more flavours are stripped from the product. For some types of spirit

such as vodka or gin, referred to as white spirit, this is desired, as a very pure and clean tasting

product is desired. For these spirits generally the more distillations the better and distillers find a

balance between quality and yield. Traditionally white spirits were made using pot stills and multiple

distillations, but as still technology has developed these spirits are now made using reflux stills that

can produce triple or even quadruple distilled quality spirit in one run.

For other spirits, such as whiskeys, rums and brandies, the flavours present in the wash contribute

significantly to the flavour of the final spirit. Because of this a balance needs to be achieved between

making a smooth-drinking spirit, and also one which has a nice flavour. Pot stills are a great way

of achieving this and two distillations provides the perfect balance between obtaining a smooth-

drinking final product and also one which contains the fantastic flavours present in the wash. The

first of these two distillations is referred to as the stripping run, and the second is called the spirit run.

You can still produce a brown spirit using a single distillation, the resulting product will be of a lower

percentage and less refined, but it will carry through more of the flavour of the wash. Brown spirits

can also be triple distilled, this will lead to a very refined product where a majority of the end-flavour

will come from the aging process, not from the flavour of the wash.

PREPARING A WASH TO DISTIL – BEFORE YOU BEGIN

Before distilling can take place it is paramount to ensure that fermentation has completely finished.

This can be done by using a hydrometer to check that the specific gravity remains constant for 3

days, or if you have achieved the desired final gravity of your recipe. If fermentation is not completely

finished, there will be unfermented sugars left in the wash and this can lead to excessive frothing of

the wash inside the boiler. If this gets out of hand the wash can froth up through the condenser and

undistilled wash can make its way into your distillate output.

When fermentation is finished, it is important to clear the wash to be ready for distilling. Yeasts

release off flavours when they are put under stress, and boiling the wash when there are still

significant amounts of yeast present leads to off flavours in the final spirit. To counteract this it is a

good idea to clear the wash, and then only transfer the cleared wash without the dead yeast into the

boiler. This can be done by syphoning the top of the cleared wash off and not disturbing the yeast

particles at the bottom of the fermenter.

There are multiple methods to clearing a wash, the fastest and most effective method is to use Still

Spirits Turbo Clear as per the instructions on the packet. A wash will naturally clear over time as well,

but if you wish to accelerate this process the wash can be chilled to 4°C (39°F) for 24 hours. This will

help the suspended yeast and proteins flocculate together and drop to the bottom of the fermenter.

Once cleared, transfer the wash to the boiler in preparation for distilling. Add the Still Spirits

Distilling Conditioner and the ceramic boil enhancers.

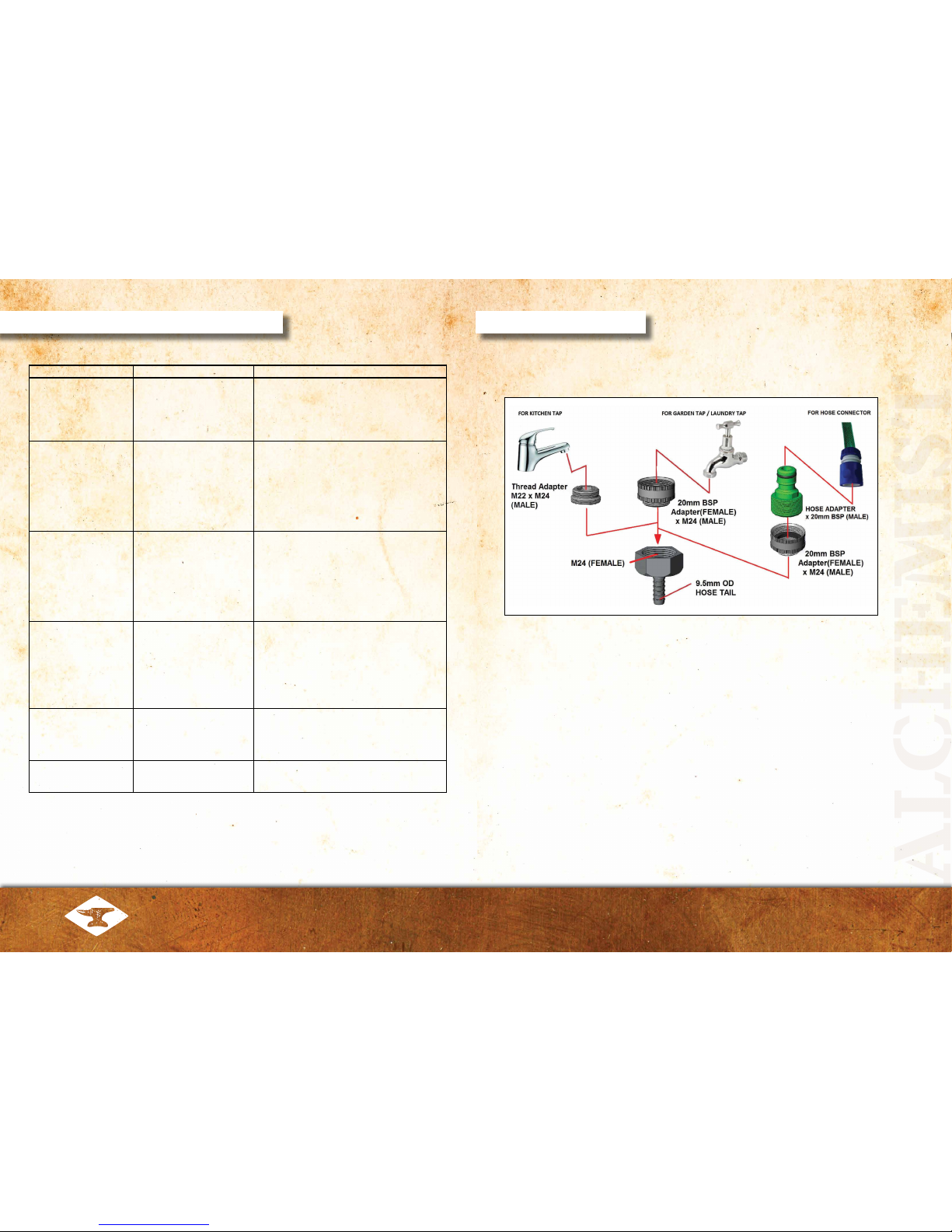

FOR USE WITH THE GRAINFATHER CONNECT ALL IN ONE

BREWING SYSTEM

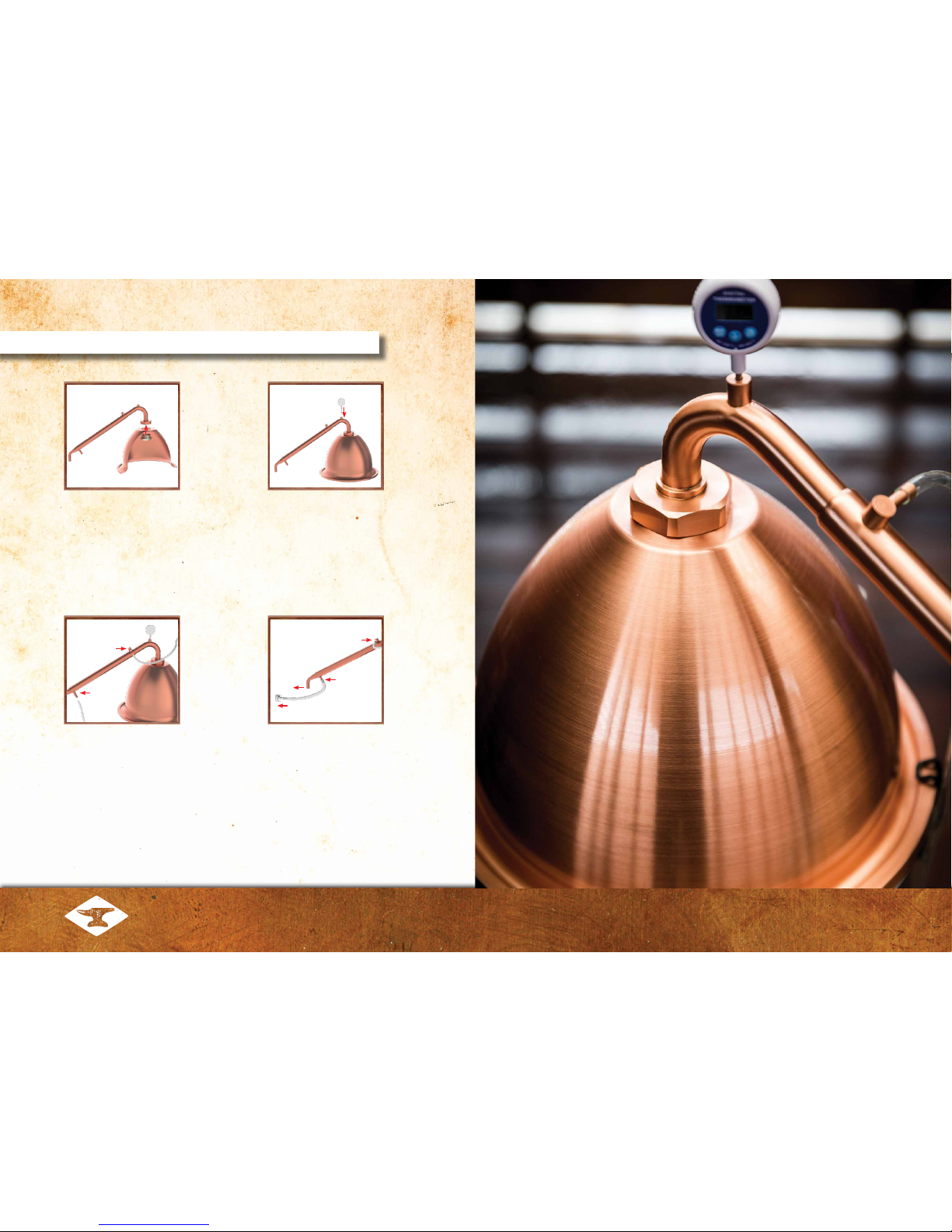

The Copper Dome and Alembic Condenser can be attached to the Grainfather to turn it from a

brewing unit to a distilling unit. The Grainfather Connect Control Box (included with the Grainfather)

has a ‘Power Control Mode’ where you can specify the power output rather than specifying the target

temperature. To enter (or exit) power control mode, hold the heat button for 6 seconds (there is also

an option to enter this mode from the mobile device app). Once power control mode is active, the

LCD screen will change to only display the current temperature and power output. You can use the

up/down buttons to change the power output in 5% increments.

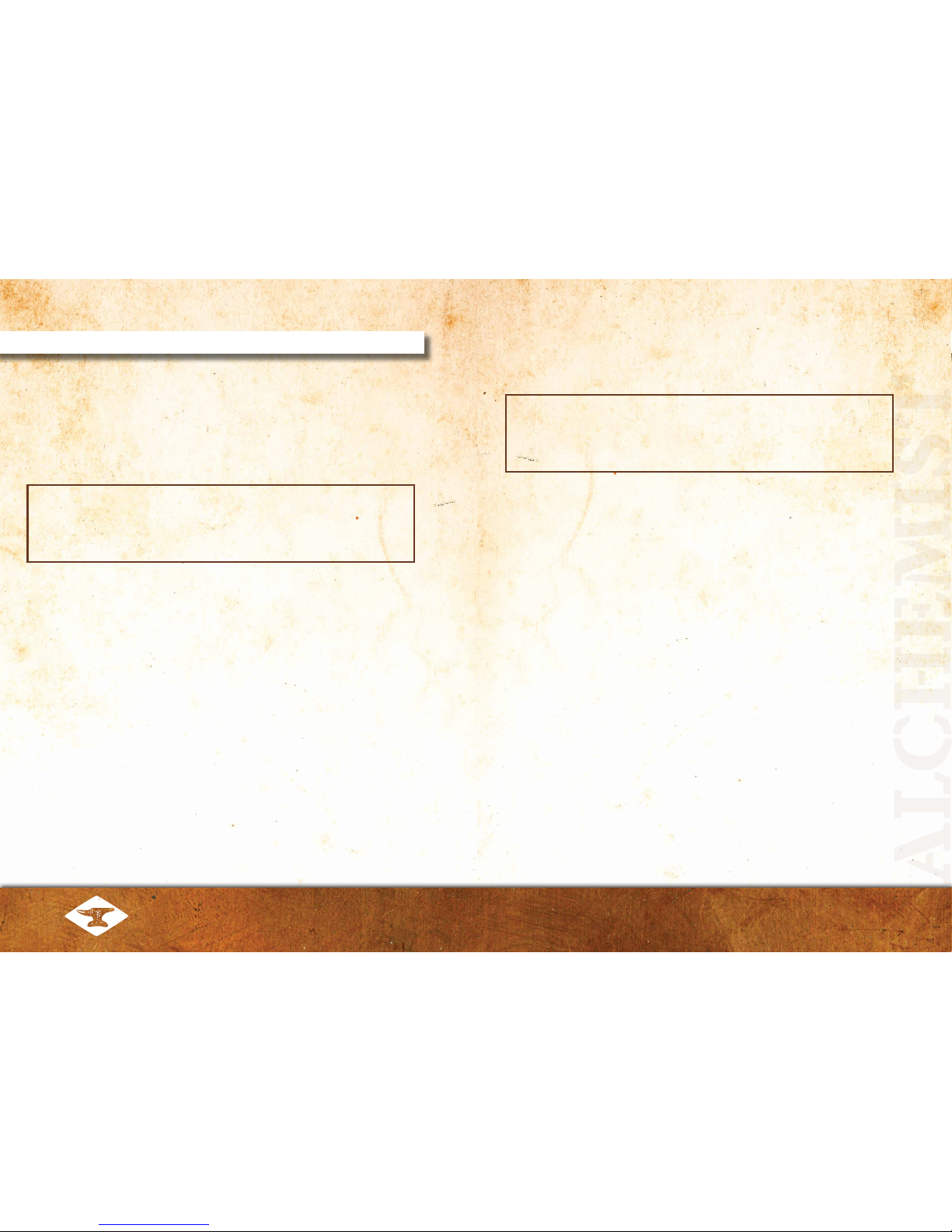

The benefit of this for distilling is that you can lower the power output to slow down the speed at

which the distilled spirits comes out. This is desirable during the spirit run when you are making

cuts to separate the heads and tails from the hearts. You should make your cuts at specific output

temperatures (or ABV) which changes constantly, but if you slow down how fast the spirit comes out

you have more time to take the measurements and make your cuts at the right time.

WHAT ARE CUTS AND WHY DO WE NEED THEM?

The fermentation process of the yeast converting sugars into ethanol also results in many other

compounds as by products. These other components are mostly made up of acetaldehyde, esters,

ethyl acetate, acetal, and a small amount of methanol to name a few. All of these occur in the same

quantities in the wash as are present in beer. However, these components, called congeners, increase

in concentration when they are distilled and can lead to levels which have undesirable tastes or are

even harmful. These congeners have different boiling points to that of ethanol so when the wash is

distilled some congeners come out before the majority of the ethanol, and others come out after the

ethanol. This causes the flavour profile coming out of the still to change markedly over the course of

the distillation. Some of these congeners contribute desirable flavours to the distilled spirit; these are

normally the congeners with the boiling point closest to ethanol. Other congeners taste and smell

very similar to paint thinners or nail polish remover.

At the beginning of a distillation any methanol present in the wash will be the first to be distilled off,

followed by other lower boiling point congeners. These lower boiling point compounds contribute

quite a chemical taste to the spirit, and are mostly responsible for causing ‘hangovers’. Over time

these undesirable and harsh flavours will slowly be replaced by much smoother, sweeter tasting

IMPORTANT POINTS TO NOTE BEFORE

GETTING STARTED