Table of contents

g

3Overview

Safety equipment .................................................... 26

Truck description .................................................... 27

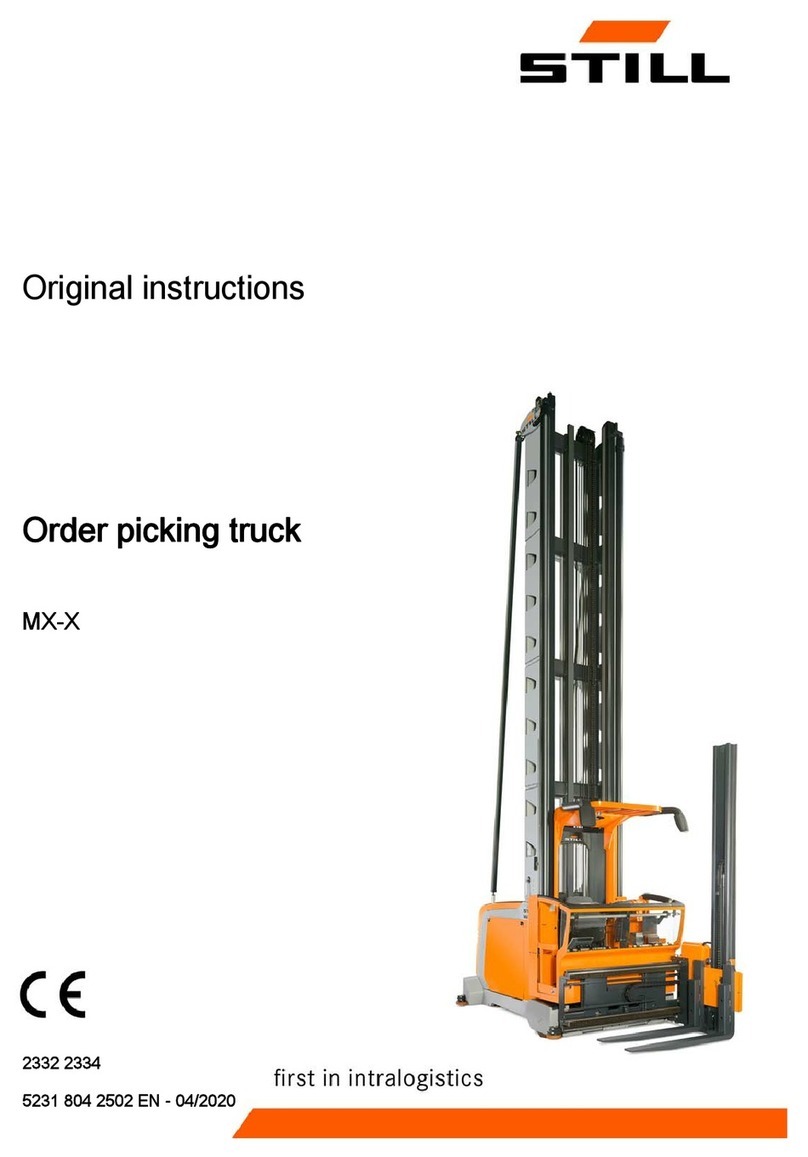

View of the truck with a low lift mast ....................................... 28

Viewofthetruckwithahighliftmast ...................................... 29

Labelling on standard trucks ............................................ 30

Labelling on special equipment .......................................... 32

Operator´s console .................................................. 33

Standard display unit ................................................. 34

Displays .......................................................... 35

LCD display unit with a keypad .......................................... 36

Displays, information ................................................. 3

7

View into the control compartment ....................................... 39

4 Operation

General commissioning ............................................... 42

Commissioning ..................................................... 42

Transporting and loading .............................................. 42

Drivebattery ....................................................... 45

Replacing the battery ................................................. 47

Daily commissioning ................................................. 49

Checklistbeforestartingwork ........................................... 49

Access to the driver's compartment ...................................... 51

Accesstothedriver'scompartment ....................................... 51

Operating devices ................................................... 52

Brakesystem ....................................................... 52

Steeringsystem ..................................................... 53

Switchingonthecontrolsystem ......................................... 55

Driving ............................................................ 56

Types of guidance ................................................... 56

Driving without automatic guidance ....................................... 58

Drivingwithguidance ................................................. 61

Pickingupaload .................................................... 64

Picking up and setting down loads ....................................... 64

Load capacity diagram ................................................ 65

Support screws ..................................................... 66

Load pick-up without automatic guidance .................................. 66

II 5212 804 3001 EN - 02/2017