0314 IH-2930PAGE 2 OF 3

TO OPERATE THE ECONODOT

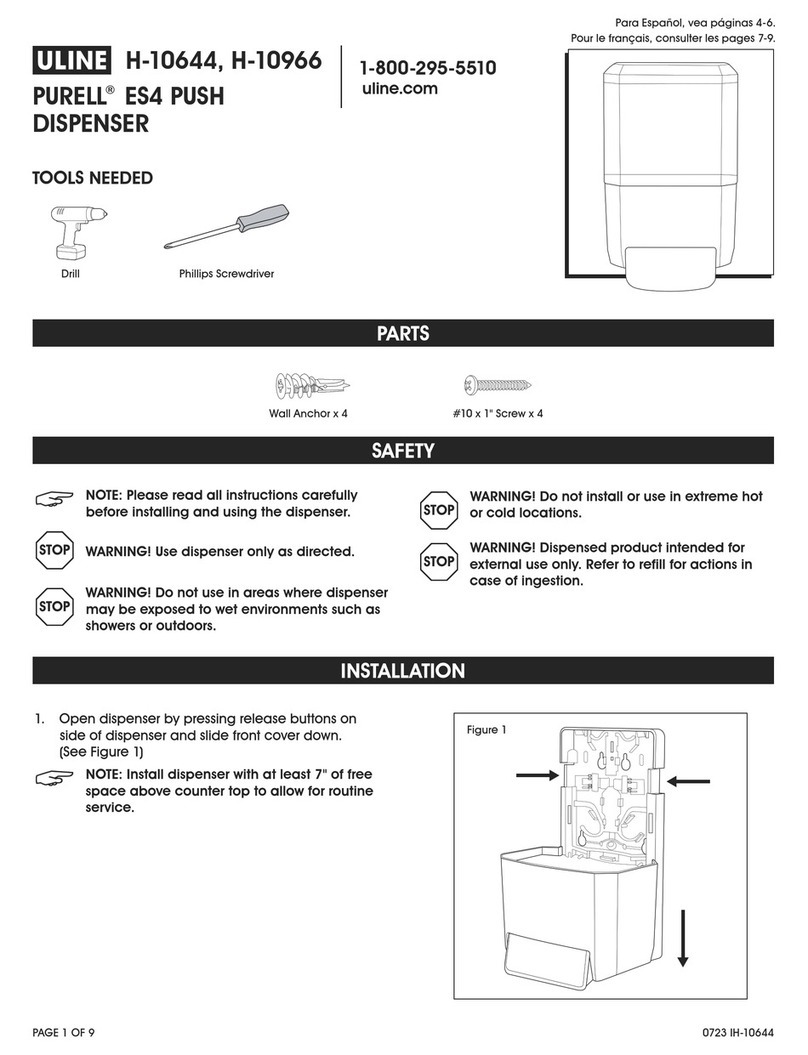

1. Plug the electrical cord into the back of the

machine and then into a wall outlet.

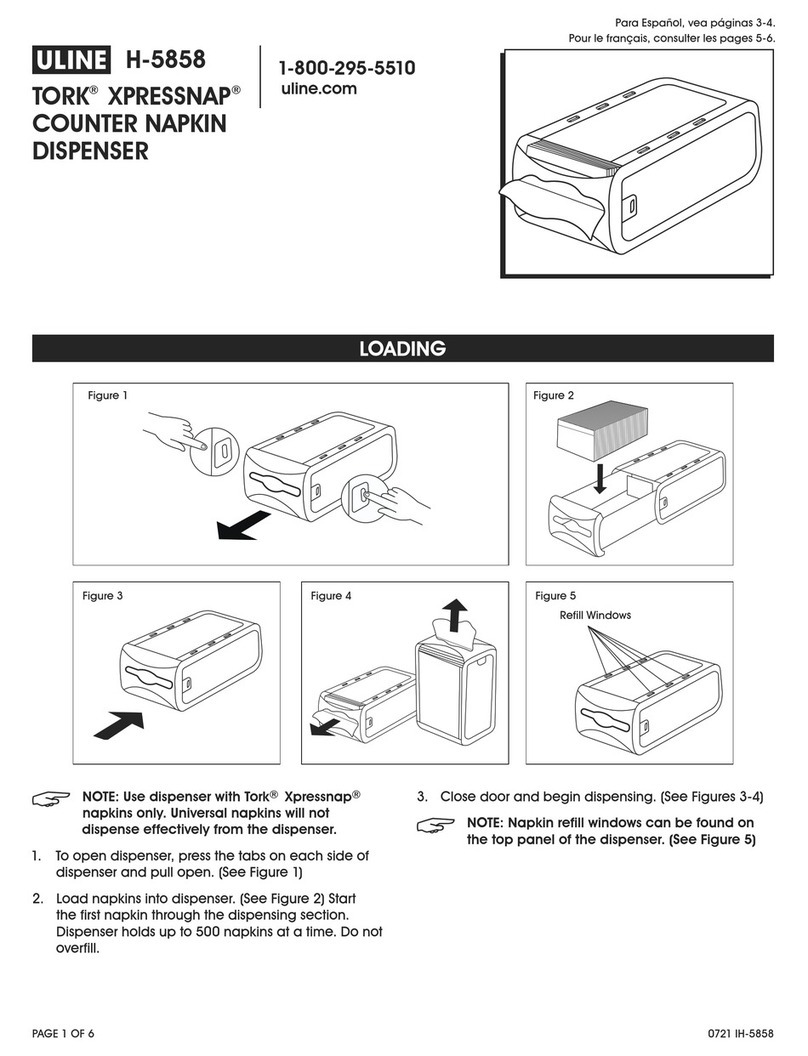

2. Load a roll of Glue Dots products and thread the

liner so a single adhesive pattern comes to rest on

the nose plate. (See Figure 2)

3. Turn on the power using the power button located

on the top of the control box.

4. Press the item to be adhered firmly against the

adhesive pattern resting on the nose plate, peeling

the item off the liner towards the supply reel. (See

Figure 1)

IMPORTANT: Lifting an adhesive pattern directly

up off the liner or in a direction away from the

supply reel may result in pulling excess liner

from the supply reel or tearing of the liner.

Avoid touching Glue Dots Adhesives as dust

and oils will compromise the bond.

5. When the item to be adhered is pressed to the

nose plate and covers the beam on the photo

sensing eye a signal is sent to the machine that the

adhesive pattern is being removed. Once the item

is removed from the nose plate, uncovering the

beam, the motor automatically advances the next

adhesive pattern.

IMPORTANT: The photo sensing eye's beam

must be covered then uncovered to ensure the

advancement of the Glue Dots Adhesives.

6. Repeat application instructions.

7. The EconoDot has a built-in

counter that displays the number

of adhesive patterns used. To reset

the counter push the reset button

located on top of the control box

and hold for 2 seconds.

TO LOAD THE ECONODOT

1. Loosen supply reel clamp knob located in front of

the supply reel plate. Remove the plate by turning it

clockwise and pulling it straight off the spindle. (See

Figure 2)

2. Load the Glue Dots roll onto the supply reel,

ensuring the liner runs in a clockwise direction. For

3/4" wide rolls, place the supply reel with pads

facing inward. For 1" wide rolls, place the supply reel

with pads facing outward.

3. Replace the supply reel plate. Tighten the supply

reel clamp knob.

4. Pull the liner over the first roller, under the second

roller, up through the U-channel sensor and over the

nose plate.

5. Press down on the peeler roller separation lever

located to the left and beneath the peeler rollers

in order to create space between the two rollers.

Thread the liner between the separated rollers.

6. Open the hinged door located on the side of the

shroud and continue to thread the liner downward

through the slit on the top of the shroud.

OPERATION AND LOADING INSTRUCTIONS

Nose

Plate

Figure 1

Reset

Control

Box

The EconoDot is designed to automatically dispense

Glue Dots or Glue Lines®, one at a time. The EconoDot

can dispense stock 1/4", 3/8" and 1/2" diameter Glue

Dots in all standard tack levels and profiles. It can also

dispense 1" Glue Lines and other custom products which

fall within the registration marks. No programming is

required with the EconoDot.

The EconoDot is not intended to apply other adhesive

types and should be operated indoors.

IMPORTANT: Altering the EconoDot and its

controls from its original manufactured state,

nullifies its CE standards compatibility.

IMPORTANT: Before starting any job, it is

important you test various Glue Dots to

determine the proper adhesive pattern, size,

tack level and profile. Product samples for

testing can be obtained by calling a ULINE

Parts Specialist at 1-800-295-5510.

OPERATION