The information contained in this document is confidential, and only for the information of the intended recipient and may not be published or redistributed without the prior written consent of Summa NV.

Summa

nv Tel +32 59 27 00 11 Fax +32 59 27 00 63 Email [email protected] Website www.summa.com Page 4 of 76 6.11 Vertical shift (X axis) ..........................................................................................49

6.12 Cutting stops after first panel.............................................................................50

6.13 Shift between panels ..........................................................................................50

6.14 Random lines......................................................................................................50

6.15 Jobs are too long or too short ............................................................................51

6.16 Jobs are too small or too wide ............................................................................51

7Print & Cut issues...........................................................................................52

7.1 Print & Cut shift .....................................................................................................52

7.2 OPOS registration marks not read .........................................................................55

7.3 Excessive bowing...................................................................................................56

7.4 Cutting stops after first panel................................................................................57

8Communication issues..................................................................................59

8.1 USB Interface ........................................................................................................60

8.2 Network interface ..................................................................................................62

8.2.1 Error messages.................................................................................................................. 63

9Menu Structure ..............................................................................................64

9.1 Service mode .........................................................................................................64

9.2 Settings .................................................................................................................64

9.3 Actions...................................................................................................................65

9.4 Service...................................................................................................................65

10 Diagnostics .....................................................................................................66

10.1 Procedure...........................................................................................................66

10.2 Sensors monitored .............................................................................................67

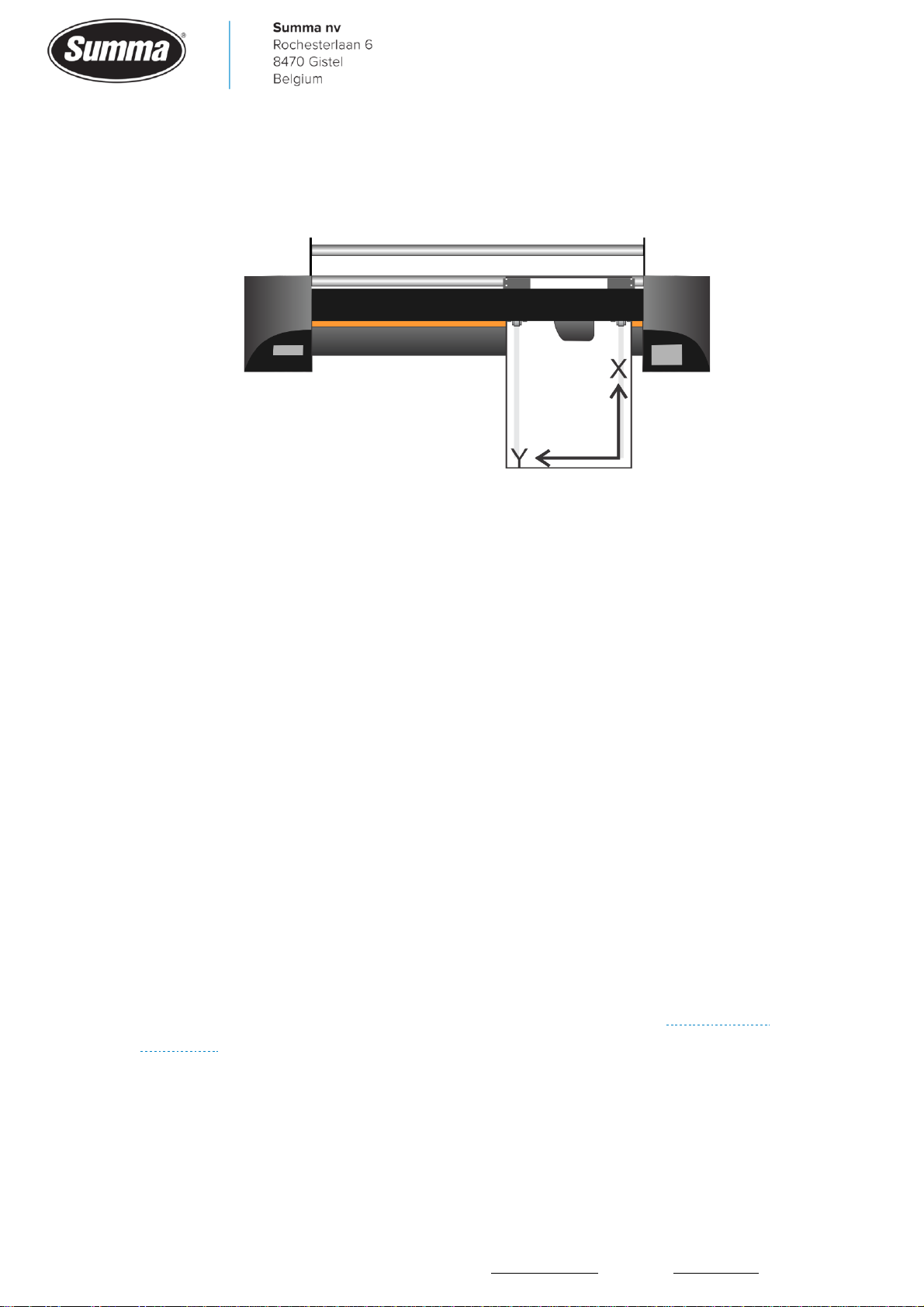

10.2.1 X-encoder ......................................................................................................................... 67

10.2.2 Y-encoder ......................................................................................................................... 67

10.2.3 Z-motor .......................................................................................................................... 67

10.2.4 UD-encoder .................................................................................................................... 68

10.2.5 Front sensor ................................................................................................................... 68

10.2.6 Back sensor.................................................................................................................... 68