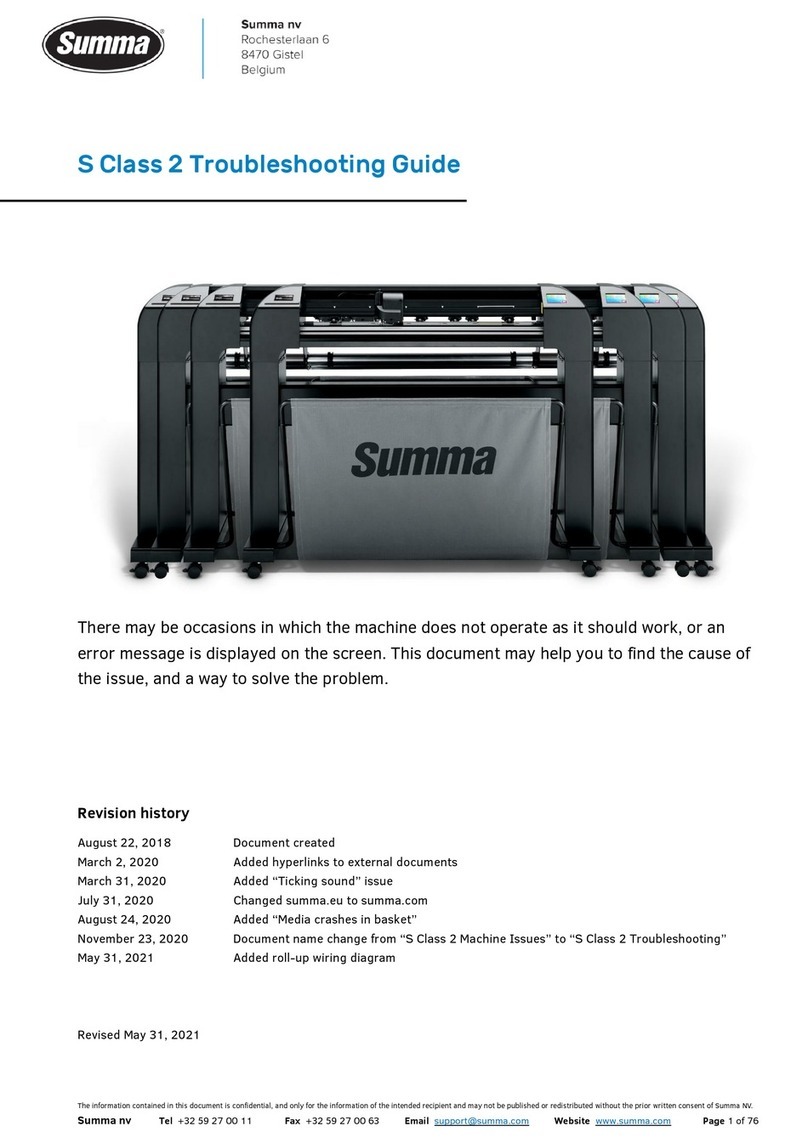

L1810 User’s Manual

Table of Contents

1Safety.............................................................................................8

1.1 Safety............................................................................................................. 8

1.1.1 General....................................................................................................................8

1.1.2 Symbols used in this manual ..................................................................................8

1.1.3 Safety symbols on the machine..............................................................................9

1.1.4 Safety precautions ............................................................................................... 10

Safety precautions related to movement...................................................... 10

1.1.5 Danger area during operation.............................................................................. 10

Safety precautions related to the built-in laser............................................. 10

Safety precautions related to the system components ................................ 11

Safety precautions related to the extraction system .................................... 11

Safety precautions related to the material.................................................... 11

Safety precautions related to fire.................................................................. 12

1.1.6 Safety features..................................................................................................... 12

Emergency stop buttons............................................................................... 12

Safety Covers............................................................................................... 12

1.1.7 Personal protective equipment ............................................................................ 12

1.2 Operating environment............................................................................... 12

2Laser cutting system components .............................................13

2.1 Laser Cutter................................................................................................. 13

2.1.1 Touch Screen....................................................................................................... 17

General Description...................................................................................... 17

Screens ........................................................................................................ 18

2.1.2 Head Transport Rails........................................................................................... 24

General Description...................................................................................... 24

Maintenance Procedure ............................................................................... 24

2.1.3 Cutting Head Drive Belt........................................................................................ 24

General Description...................................................................................... 24

Maintenance Procedure ............................................................................... 24

2.1.4 Optical Components............................................................................................. 24

General Description...................................................................................... 24

Maintenance Procedure ............................................................................... 24

2.1.5 Conveyor system ................................................................................................. 24

General Description...................................................................................... 24

Maintenance Procedure ............................................................................... 24

2.1.6 Extraction System ................................................................................................ 25

General Description...................................................................................... 25

Maintenance Procedure ............................................................................... 25

2.2 De-Reeler..................................................................................................... 26

2.2.1 General Description ............................................................................................. 26

2.2.2 Safety Information................................................................................................ 26

General......................................................................................................... 26

Residual Risks.............................................................................................. 26

Noise ............................................................................................................ 26

2.2.3 Positioning the De-Reeler.................................................................................... 27

2.2.4 De-Reeler Components ....................................................................................... 27